This five-stop system provides accessibility to nearly 30 m of hillside in the city.

The Carmel district is a neighborhood area in Barcelona developed mainly in the 1960s and 1970s. During this time, many people built homes along the rural hillside, which has presented accessibility challenges over the years. ThyssenKrupp Elevator Southern Europe, Africa and Middle East received a contract to install an inclined elevator at Alguer Street as part of a global project for the integral rehabilitation of the Carmel district.

Many residents of the district regularly face mobility issues, because the area is mountainous, and the streets are narrow and steep. In addition, many of the district’s important public services, such as healthcare facilities and libraries, are located near the upper-level areas. The inclined elevator has improved accessibility in the area between Murtra and El Santuari streets, accessible only by stairs prior to its installation. The elevator saves a height difference of nearly 30 m, provides residents access to different streets and features five stops. It also provides access to the area’s other transportation networks, such as the underground system and buses.

Guide-Rail System

The guide-rail system consists of a compact “sandwich” structure. It was based on HEA commercial profiles that support and transmit the forces deriving from the unit’s weight.

Sling

The sling is robust in structure, and its design is based on previous models but modified for this installation. It consists of an inner space for inspection maneuvers, from where it is possible to access the safety systems (limiter, wedging, remote alarm device, etc.), as well as the operator control, load-weighing exchange and the well-occupation system. Access to this area is via a trapdoor integrated into the aesthetics of the installation. It remains open during inspection maneuvers and enables the maintenance operator to sit where the inspection controls are accessible and see the area while moving.

In addition, there is a rolling system with four trains with two wheels (for heavy loads and long duration) each, and an additional safety wheel on each train, serving as an anti-capsizing device. Another two trains (also with four wheels each) guide the vehicle using the wedging guide rail as a reference point.

Counterweight

The counterweight features a low-profile design, enabling it to be displaced within the inside of the HEA profiles, making the components in the well a compact system. Displacement is via four trains with two wheels each and an additional wheel to avoid possible lateral displacement of the counterweight. The space for the weights is thus used to avoid the necessity of this component being excessively long.

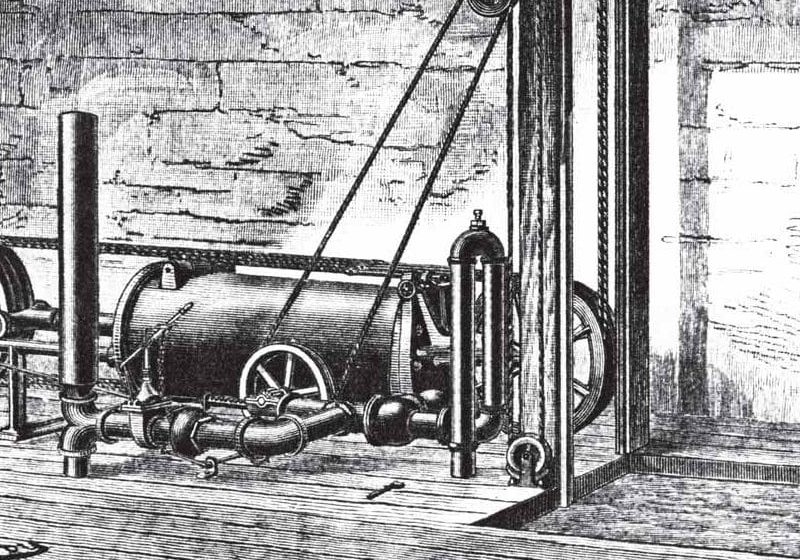

Traction Set

The traction set was designed for inclined traction in an engine room adjacent to the upper embarkation point. It consists of a robust structure of beams and a set of shock absorbers, installed in the three axes of the space, which permit the engine to be repaired, while softening the forces created by the engine and structure. The engine features a reducer and is controlled by a current-frequency drive and governed by ThyssenKrupp Elevator’s standard maneuver.

Door Operator

The door operator is a regulated speed operator with a bottom mechanism for lateral embarkation and was specifically designed for this installation. The design consists of a modification of an existing mechanism with a reliable cinematic function to which a new inclined retractable runner was installed, allowing the landing doors to open gently. It has a blocking system for when the elevator is between floors.

Safety Systems

The main safety elements of the inclined elevator consist of a speed limiter and wedging. A standard generation limiter was used and is mounted on a sliding tray within the sling, with two diversion pulleys. When the speed goes past a pre-established value, the limiter is blocked by a single pull on the cable, and the tray slides over the guide rails, while the vehicle continues to advance. This allows the limiter to act on a small lever and, in turn, operate on the progressive wedging of a single wedge.

Furthermore, the wedging slides over low-friction guide rails with respect to the sling, compressing a rubber shock absorber, which makes the slowing movement more gradual without jeopardizing the braking reliability. Upon unwedging, a recovery spring takes the tray to its standby position and the wedge to its place of origin.

Other noticeable elements of the safety system include a tensor, which keeps the cable of the limiter tense in the direction of the trajectory by means of a small vertical counterweight and plastic deviation pulleys for changing direction; a safety brake on the axis of the engine, integrated to avoid excess speed when going up; and a safety-stop rope along the entire length of the well for immediate electric stoppage in the event of danger.

Electric Cabling

The power, communications and video cables are flexible and guided between the maneuver cupboard and the car by means of a cable-carrying chain for an inclined sliding application, which is silently displaced over a stainless-steel channel. The cabling in the well was installed within tubes.

Car

The elevator cars are panoramic and were designed to withstand the area’s marine-like weather conditions. The glass panels and stainless-steel frames provide a security feature by allowing passengers to see in and out during travel. Embarkation takes place on the right side, and the outside features safety glass and stainless steel.

Rescue

The rescue of passengers trapped in the car would be carried out via an evacuation stairway, which runs parallel to the entire length of the well. Access to the stairway is via the car rescue door.

Conclusion

Overall, the inclined elevator provides Carmel district residents with comfortable transportation and features safety systems that improve the system’s reliability. In addition, the entire area around the elevator has been modernized.

Elevator Specifications

- Load: 1875 kg/25 passengers

- Nominal speed: 1 mps

- Travel: 56.061 m

- Height difference: 29.057 m

- Incline: 31.22º (constant and in a straight line)

- Number of stops: Five

- Embarkation points: Five (right side)

- Car type: Panoramic

- Traction control: Control by frequency and current- frequency drive for smooth starting and stopping

- Machine room: Located atop the elevator well, just below the upper-landing level

- Car doors: Central-opening automatic doors with two stainless-steel sheets; dimensions: 900 X 2,000 mm

- Landing doors: Central-opening automatic doors with two stainless-steel sheets; mechanism at bottom; dimensions: 900 X 2,000 mm; equipped with an LCD signaling system and landing-button panels integrated into the frames

Get more of Elevator World. Sign up for our free e-newsletter.