Inspection of Elevator Ropes, Part Two

Jun 1, 2022

Making informed decisions and taking remedial actions when ropes need to be replaced

by Kevin Heling and Joseph Thompson

Value: 1 contact hour (0.1 CEU)

This article is approved for Continuing Education by NAEC for CET® and CAT®.

EW Continuing Education is currently approved in the following states: AL, AR CO, FL, GA, IL, IN, KY, MD, MO, MS, MT, NJ, OK, PA, UT, VA, VT, WA, WI and WV | Canadian Province of BC & ON. Please check for specific course verification of approval at Elevator Books.

Learning Objectives

After reading this article, you should have learned:

- Which important factors to consider when ropes need to be replaced.

- That there are better, high-performance ropes for today’s demanding elevator systems.

- Equalization has always been important, but there is more to know.

- Many variables and interactions will impact suspension means’ performance.

- Tools are available that will help.

You’ve done required periodic inspections of the ropes on an elevator and find that the ropes must be replaced. Now what? If the last time the ropes were changed was approximately seven to 10 years ago — or more — nobody thinks much about it. The ropes are replaced and everybody carries on. Pretty routine. Standard.

If it has been fewer than five years, or fewer than two or three years — or worse — just around a year, thoughts emerge about why. Why?

In Part 1 of this series (ELEVATOR WORLD, December 2020), we covered what you need to know about inspecting ropes and, through that, how and why existing elevator safety codes define for us the times that elevator ropes need to be replaced, even when it is not completely obvious. The completely obvious situations are when one rope of a set is totally lost, fully separated or has lost one of its eight (or nine or sometimes six) strands. Another such situation is when one or more ropes are showing obvious fatigue and wear (including rouge or significant crown wear) that create performance issues (ride or sound).

When we think something isn’t quite right, we should consider why it is time to replace a set of ropes. We may feel that it is far too early, or maybe we have an idea that something is wrong with another part of the system that may need to be fixed. That is when we should think about and discuss why an irregularity happened and, more importantly, know that it is responsible and safety-minded to consider options and actions. From the perspective of total future cost and good maintenance for our clients (the owners of the elevator), we should consider what can be done to avoid an expensive re-roping occurring too soon, again.

We know elevators and their suspension means are systems, which makes them quite complex. Decades of experience — several decades, in fact — inform the education we share here. One of your authors co-wrote a first article on rope technology for EW in 2007. Here, we will cover three topics. At least one will come as a surprise, or may be unexpected, to some readers. The three topics are:

- Equalization of ropes (or belts) continues to be important, but there are times when qualifiers to this action are needed and times when other things need to be checked.

- Standard elevator ropes have always been 8X19 NFC (natural fiber core), right? In most elevators being installed these days, we should not use them. Instead, a better, more-resilient rope should be used. And, for most existing elevators, we should no longer use the old standard rope. Consider 8X19 sisal core ropes obsolete. Use a stronger, flexible and resilient rope with an improved bending-fatigue design. This type of rope is readily available from most elevator rope manufacturers. Think of these as high-performance ropes.

- Re-grooving sheaves should be carefully considered. In many situations, re-grooving them can amount to good money wasted, as they do not increase the life or performance of ropes installed after the re-grooving. In addition, they can cause further damage to the overall hoisting system.

In the EW September 2021 issue, one of your authors (Joseph Thompson) presented an excellent summary of the main factor, (in fact, “driving”) of the elevator system and its impacts on hoist ropes. “It’s in the Groove” is a thorough summary of technical impacts of the overall system on ropes. We have summarized that article as a sidebar to this presentation, since the technical range of factors and impacts is important, and worth revisiting.

Rope Equalization

The idea that rope equalization is good and necessary for elevator installations has long been understood by about everyone in the industry as an acceptable and practical need. General agreement with this does not mean it has been done consistently in most installations. While it has been an accepted “ideal,” whether it is standard practice or time is found to do equalization, or correctly do it, is often another thing. Like many other things in our world and in our personal lives, an ideal is one thing, and actual practice is another.

In practice, one of the overriding reasons for suspension means failure has been that, until relatively recently, good tools to set up and achieve optimum performance have not been available. That good tools are now available is an important message here. Specific tools to use is something for the practitioner to decide. If one is interested and motivated to consider them, he or she can find the right tools. We would like to lay out the fundamental principles of doing this. First, single devices (like individual rope-deflection clamps or torque wrenches) are ineffective equalization tools. When you clamp and deflect only one rope (or belt), the load on the others is affected and you are unable to know or measure that effect. Time spent looking at the “load” on one rope at a time is often time wasted; you are chasing a moving target. Add to this the principal fact that most single-rope deflecting devices are not very accurate (often something around plus or minus 25% deviation), and you are losing your time in a compounded manner. In choosing a system for measuring loads and equalizing rope (or belt loads), you must consider whether the measurement principle is sound and proven. You also must be sure that your use of that measurement principle is supported by a sound practice and process. The process of viewing and adjusting loads on ropes must be completed as a set. We could go into more detail about specific tools and systems, but again, this is not the intent of this educational message.

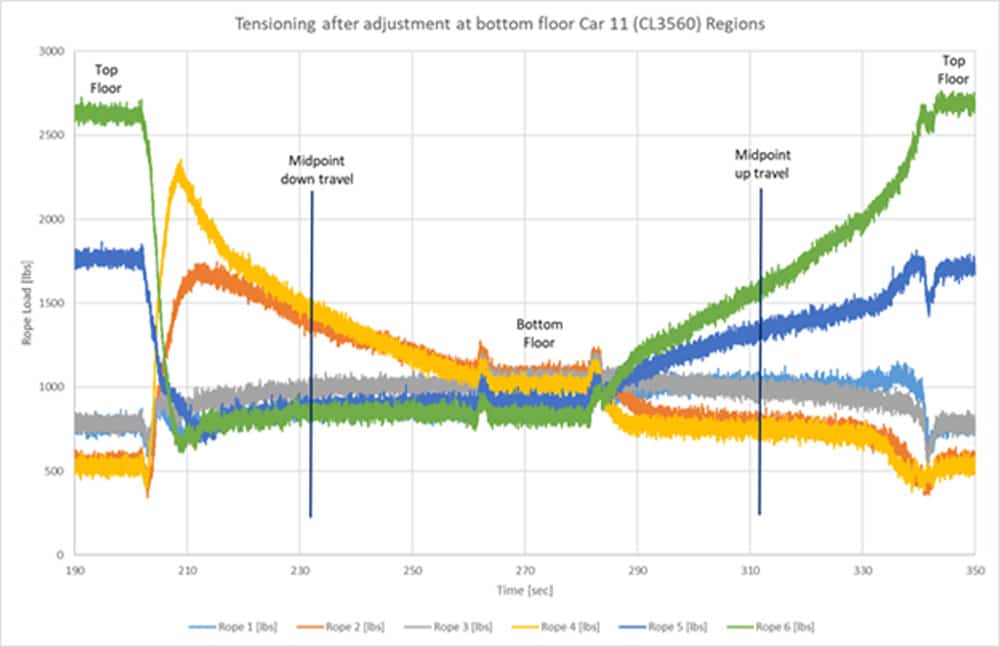

Using available tools on the market, we have reached some important understandings worth discussing in some detail. We can “equalize” suspension means in an elevator system at a specific point and position for that elevator car. Doing this in isolation shows only that the load is “equal” at that position and time. It does not tell us that either there is an induced or existing and inherent system inequality (i.e., worn or unequal sheave grooves or a challenging inequality related to system design). In either case, we benefit by having a tool system that can measure individual loads throughout the up-and-down travel of the elevator car. Relative loads are not and cannot be equal throughout travel. This condition is inherent to all elevator suspension means systems. There are angles between the hitch point of the ropes and where they contact the drive, and there are diverter and deflection sheaves that necessarily change the individual rope loads during elevator car travel.

We are now able to see (using specially designed rope load-monitoring tools) that, as elevators approach their limits (especially the top limit with overhead drive systems), that the individual rope loads will be the most different. It is when they are significantly different that we must become concerned whether this difference is having a big effect on the fatigue and lifecycle of individual ropes in the hoisting system. When one rope fails, the set must be replaced. To summarize and not belabor this point, more elevator systems today have this inherent challenge as a key factor. We know this is having a compound effect on rope wear and performance. Then there is the other effect: Sheave grooves (that were once equal) wear to some level of inequality where the life and performance of the ropes is dramatically affected. We have included here some graphical depictions of continuous measurements of rope loads during the full travel of elevators.

One example shows the typical condition of a representative elevator where we see that there is a difference in the load on each rope during travel. We have seen elevators where this difference can be minimized (but never adjusted to become completely equal). We also see a graphical example of a condition where one groove is differentially worn from the other grooves, and it is enough of a difference that the potential wear impact on that rope is clear.

Better Rope

Forever, the recognized standard for elevator ropes has been 8X19 NFC, which denotes natural fiber core or what many know as sisal core. Sisal core ropes made by several different manufacturers over the years necessarily have some range of variability based on how the core is built. Some makers use three fiber “legs” and some use four. Various sources for sisal are available globally. We have heard explanations that some sisal fibers are denser (depending on where it was grown and how it was processed). There is some logic to such explanations. For our purposes here, the bottom line is that elevator ropes made with a fiber core have more variation in their construction dimensions. Some will compress a little more (or less) under load. Thus, the construction stretch of ropes from one manufacturer to another can differ. Variability becomes one of several key factors that impact bending performance (fatigue) of these ropes.

Lots of variables in an elevator system will contribute to and affect the performance of its hoist ropes. Around 2009, there was a wise engineer from one of the major elevator OEMs who several of us had the chance to work with and learn from. He once sat down and made a list of all the intervening and impacting variables in the elevator hoisting system. His list included at least 24 items. All can combine and, at times, effectively contribute exponentially to negative impacts on rope performance. All of this has been covered in articles in this publication over the years. Those of us who are, or who have been, rope manufacturers could recount the many times we tried to explain the list of factors that combine to cause early 8X19 rope failures where a buyer at an elevator company (or a consultant) simply replied that they “knew” the ropes were the problem. From there, they would demand that the ropes be replaced free of charge. There were also demands for covering their labor costs. This was never fun, although it was a learning experience.

The learning experience was that their contention about the rope being the problem was correct: 8-X-19 fiber core ropes should not have been used. We made this point already. In installations where the rope failed, that design was not up to the demands of today’s elevators. Because we are dealing with a complex system with a bunch of variables and interactions, there are definitely several things that could be done to improve results (or, said another way, decrease combined negative impacts). We came to this understanding over some years and by paying attention and finding out — in many cases — that the next set of ropes put on that elevator, when they were also 8 X 19 from another manufacturer, often had similar unhappy results. Problem was, who remembers something that happened a few years ago in our fast-moving industry? We could explain more about these combined effects, although that has also been done in the industry over the years. That is not what we want to cover here. We have a basic recommendation that will make things easier and improve rope performance and results.

For today’s elevators (whether of new design or with worn systems), stopping the use of 8-X-19 ropes as the standard and using nine-strand ropes that are readily available from most rope suppliers is a good idea. There is a specific design and nomenclature for the kind of ropes we are talking about: 9+9+1 construction. This shorthand, looking at these elevator ropes from the outside and working toward the center, simply means there are nine outer strands on top of nine smaller strands, all built around a center strand. That center component can be steel strand (sometimes specially designed) or have a small polypropylene (plastic) center. Either will provide a foundation for a rope design that is more consistent in diameter and inherently rounder than 8 X 19. The results and performance of these ropes will be more consistent, and you will realize a major improvement in lifespan (time between installation and the need for re-roping).

A good argument can be made for recommending ropes with a poly center instead of a center steel strand. Drawings of these ropes (8-X-19 NFC, MCX9 and SCX9) are pictured. With the poly center, the interaction with the nine inner strands is beneficial, as there is lubrication between the plastic and those wires/strands. When it’s a steel strand (as in an SCX-9 rope) there can be added nicking and notching (steel on steel) where the strands cross each other. One thing we have seen that inhibits this choice is a simple hang-up of some engineers that relates to the published minimum breaking load (MBL) of full steel independent wire rope core (IWRC) ropes. When systems are specified using the higher MBL, it is sometimes a bit of an impediment to using a nine-strand composite steel core (CSC) in place of a nine-strand IWRC.

Whether the rope has a steel strand or a poly center, in ropemaker terms these ropes are referred to as IWRC with CSC offering some specificity. The wire rope “core” refers to the nine inner strands and the +1 inside them. Again, we are not here to revisit and debate the variables and any detailed design considerations. Experience has proven this rope type performs far better than alternatives. Ropes designed to be resilient cost a little more (now less in comparison to what they used to cost versus 8 X 19, as they are now produced in more standard quantities). However, the extra cost is more than offset by the total cost savings when a rope replacement is delayed, or avoided altogether. High-performance ropes, as we have explained, are also affected by the “24 factors,” but, because of their resilience, they can withstand abuse for much longer.

Re-Grooving Drive Sheaves

As we said in our lead and summary, the idea of re-grooving sheaves is something that, if considered at all, should be approached with careful consideration. An overriding reason for being careful is that the drive sheave and grooves are, by far, the biggest factor among all the endurance variables of an elevator hoisting system. An argument can be made that the drive sheave and grooves are more important than ropes (suspension means). This is why we decided to review here again (in the sidebar) the “It’s in the Groove” article.

Most drive sheaves installed in the U.S. and Canada are iron alloy castings. They are not hardened (term to be further, but nominally, addressed here). Logic tells us that V-grooves and large undercut U-grooves are sheaves that should be induction-(or flame-) hardened. If an iron alloy casting was done correctly, as explained by Hugh O’Donnell in “The Science (and Some Art) of Drive Sheave Alloy Gray Cast Iron” (EW, July 2010), we can have some confidence that the relative hardness (measured on the Brinell scale) is consistent throughout the entire sheave casting. We have found in industry literature that Brinell hardness sheaves for compatibility with elevator ropes need to be in the 210 to 290 range. Recent discussions with experts in this area suggest that Brinell hardness should be closer to 260. Thus, from this perspective, unless you know that the original sheave was a quality casting, with consistent hardness throughout that is something closer to 260 (as opposed to 210 or less), it’s not a good idea to re-groove a sheave.

On the topic of hardened sheaves (induction or flame-hardened surface and grooves), understanding a few basics is helpful. First, this hardness must be measured on the Rockwell hardness scale (50 Rockwell is the target). It is understood that these hardened sheaves will protect against the effects of wear for five to 10 times longer than gray alloy cast iron. This could mean that the effects, discussed earlier, of poor rope load equalization or even inherent high differences between grooves may not be expected to have a significant wear impact on the sheave. Further, you cannot re-groove hardened sheaves. The depth of hardness is something less than 1.5 mm. You cannot cut hardened steel with cutting tools, but must do it using only a complicated (and costly) grinding process. If you do this, you will pass the hardened area and into unknown, softer sections of the casting.

The above information is enough to cast doubt on considering re-grooving. A final related point here is that we are seeing that the tolerance for differences in depths of rope grooves may be exceedingly small in high-rise systems and also in MRLs where the ratio of the sheave diameter to the rope diameter (D:d) is just meeting elevator safety code minimum (40:1). Every full revolution of the drive sheave during a complete up or down run will impact the effect of maximum depth difference. Facts supporting this are currently limited, but we have seen elevator systems (based on continuous measurement of rope loads) where the difference of the rope load is significant and there does not appear to be a significant difference in groove depths. Anyone who has ever tried measuring groove depths on a working elevator knows it is another challenging task, impacted perhaps by too many uncontrolled variables.

As a last chance to mention rope-related tools, there are now hydraulic systems that can be successfully installed on some elevators that provide dynamic equalization of suspension means while the elevator is traveling. This could be an alternative remedy for a worn sheave that needs to be replaced, and doing so would be difficult or cost prohibitive. Potentially, a dynamic balancing system could be useful on new systems where the design necessarily needs better balancing between suspension means.

In summary, the above information should provide positive ideas for making informed decisions and taking remedial actions when ropes need to be replaced. We now can make better decisions when unexpected short rope life occurs. There should be a lower tendency to assume that the manufacturer or manufacturing process of your rope was the cause.

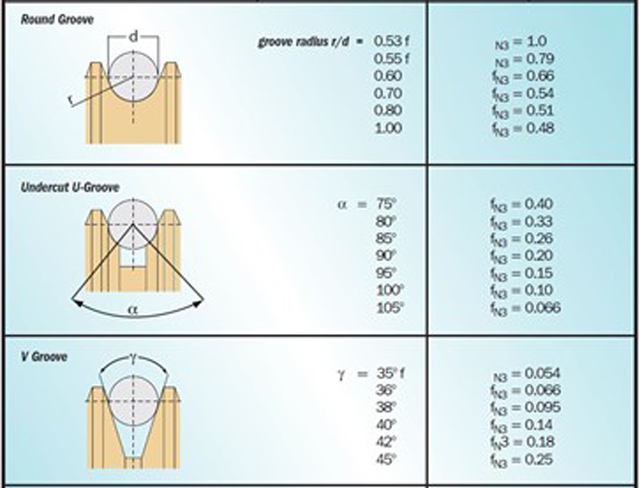

It’s in the Groove FN3

One must consider various factors when utilizing Feyrer equations to calculate the lifetime of a rope. If one were going to focus on one factor, or as called by Feyrer, the “Endurance Factor,” one should focus on what is known as fN3, the factor that is pertinent to the sheave groove. This, as well as the other endurance factors, are subjects that — when multiplied with the calculated number of bends obtained from Feyrer’s lifetime equation — produce a corrected number of expected bends. fN3 is the factor that describes the effect the groove design has on the lifetime of the rope. The basis for the fN3 factor is a round groove with a radius that is 6% larger than the nominal diameter of the hoist rope. This is seen when one looks at the factors for the various standard grooves.

The table below illustrates the factors for such grooves.

If one examines the fN3 factor for a groove that is 6% larger than nominal rope, Groove Radius/Nominal Rope Diameter = 0.53, one will see that the value for fN3 is 1.0. To look at it another way, if one has calculated the expected life in a given installation to be 1 million bends, to apply the fN3 factor, one would simply multiply the calculated number of bends times the fN3 factor to obtain the “corrected number of bends,” i.e., 1 million x 1.0 = 1 million. One can see that the basis for the groove factor is the 6% larger, full, round U-groove. If this same given installation were to have a groove that was 10% larger, for example, the lifetime would be diminished. Although still a full, round U-groove, the rope is not supported as it should be, and the corrected number of bends would be 1 million x 0.79 = 790,000 bends.

Staying with the same given installation with 1 million calculated bends, let us look at changing the groove type to an undercut. This can be necessary due to the traction requirement. The factors for this groove geometry were developed from 75 degrees up to 105˚ in increments of 5˚, and are shown above. Performing the same calculation as before, but with a 90˚ undercut U-groove, one will obtain the following results: 1 million x 0.20 = 200,000 or an 80% reduction in the life of the rope verses a round U-groove. In some cases, it is necessary — due to the traction requirements — to go all the way to a 105˚ undercut. In these cases, one would calculate 1 million x 0.066 = 66,000 trips or over a 93% reduction in rope life.

The final groove that we will look at is the V-groove. This groove type has the benefit of generating the maximum traction when new, or, if sufficiently hardened, as to prevent loss of its shape. It does, however, have the highest associated cost. If traction can be achieved with a 45˚ opening, then the cost is “only” 75% of the rope life, but if one was to go to the extreme of a 35˚ V, one would calculate (again with the same given install) 1 million x 0.054 = 54,000 bends or a 94.6% reduction in lifetime.

One final thing to understand when looking at the effect that the groove has on the ropes is that all ropes are not created equally. When one thinks back to the large D to d machines where the ropes were running in a full round U-groove, standard 8-x-19 rope performed well and lifetime was not an issue. With today’s 40:1 ratios of traction sheave to rope diameter, combined with the higher pressures generated from the aggressive groove, one’s only recourse is to use a High-Performance (HP) rope design. These would be an IWRC (Independent Wire Rope Core) or a PWRC (Parallel Wire Rope Core). Both HP designs are produced in full steel, as well as mixed core meaning the core is either a combination of steel and polypropylene or steel and sisal. When it comes to the selection of which HP rope to use, there are a few points to keep in mind. First, there is not a single design that is appropriate for all installations. Both IWRC and PWRC ropes have their unique advantages and disadvantages. Understanding these will aid in selecting the best rope for a particular installation. Secondly, no rope, even a high-performance rope, is going to reverse the effects of smaller sheaves and aggressive grooves have on the lifetime of a rope. What it can do is provide “better” results or “better” lifetime than that of a standard 8-x-19 rope if the proper HP rope is selected. When one looks at the slightly higher cost of an HP rope versus the cost of changing to the less expensive 8-x-19 rope, multiple times in some cases, it’s not hard to see the benefit of the higher-performance ropes.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at Elevator Books or on p. 118 of this issue.

- Can standard elevator hoist ropes still be used in all elevators?

- Are belts used as a suspension means the same as steel ropes?

- How is rope life calculated and estimated? What are the main factors?

- What is important with respect to the need for equalization of load on suspension means?

- When is re-grooving a drive sheave a good remedy?

Joseph Thompson

Joseph Thompson is the president and general manager (GM) of Brugg Lifting North America with responsibilities for the Americas. A mechanical engineer who obtained his degree from Southern Polytechnic, he began his professional career in 1990 in the heavy equipment industry. In his 20-plus years in this industry with Kobelco America, a subsidiary of Kobe Steel, and Case New Holland, a subsidiary of Fiat, he served as a staff engineer before assuming an engineering manager role. He transitioned into operations management before departing for management roles at Cobb Tool and Engineering and Precision Roll Grinders. He joined Brugg Lifting in 2014 where, in addition to his current role as GM, he serves on the global steering committee for the Elevator BU as well as a technical and engineering resource for suspension means.

Get more of Elevator World. Sign up for our free e-newsletter.