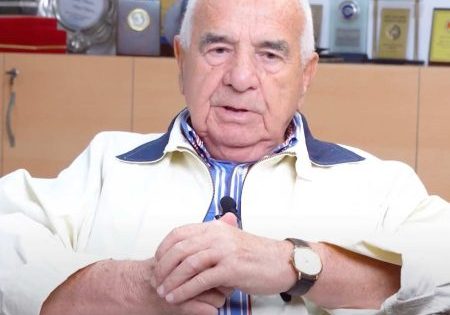

We interview Mustafa Uçar (MU), founding partner and general manager of Integra Asansör, as it looks back on its 11th year marked by success in the supply of lift electricity components.

BY: Let’s talk about the establishment of Integra Lift. How did the process start, and with which product groups did you launch in the market?

MU: In 2019, I started at Draka Istanbul Asansör. I worked as the sales manager of Türkiye and the Middle East for approximately five years. Within this period, I had the chance to get to know the market of the region closely. We have established a strong structure in technical terms and customer relations. In 2014, with the global merger of Draka and Prysmian groups, the operational structure of the company in Türkiye and neighboring countries changed. As part of this new strategy, it was decided to switch from direct sales to a distributorship system. In that transformation process, the group asked me to operate as a distributor in the region thanks to the success of our previous work. This important opportunity triggered my enthusiasm for becoming an entrepreneur. I started my own journey by establishing Integra Asansör on March 5, 2014. At first, our priority was to ensure the sustainability of Draka Prysmian group products in the market. However, we expanded our product range in a short time and created a portfolio that includes various technical components such as balance chain, lift cable, steel rope, full-length photocell, electronic overload and earthquake sensors.

BY: You have left 11 years behind this year. What has Integra Asansör done in this decade? Which products have you brought into Türkiye?

MU:Yes, as Integra Asansör, we feel the joy of leaving our 11th year in 2025. These 11 years were not simply a time passing by for us, but it was also a process of growth, learning and adding value to the industry in real terms.

Our focus during the first establishment years was on the supply of fundamental components such as lift cable, balance chain and steel rope. Over time, we quickly adapted to the changing needs of the sector. Starting in 2018, we started working to position Integra not only as a supplier but also as a “solution partner.” In this new period, we have focused on becoming a system supplier that integrates the panel, motor and button panel and adds a photocell, overload and emergency telephone as complementary features.

BY: You have provided new product designs that will facilitate the job of suppliers, especially. Can you mention these?

MU: Of course. We, as Integra Asansör, aimed to be more than a structure that only supplies products. We first started to make preliminary operations to facilitate work at the construction sites. We named these groups as products kits. When the rope/cable/balance chain cutting machine we designed for ourselves started to attract attention, we produced a model that can be used in small warehouses and on-site. The design attracted a lot of attention, and we have sold it to almost every European country by certifying it according to the machine directive.

BY: As far as I can see, you no longer fit into your new place. Do you think to move a bigger place? What are your future plans?

MU: Yes, you’ve observed right. Especially in the last few years, with the expansion of our product range, an increase in our stock volume and the growth of our technical support infrastructure, our current location has become insufficient for us.

Before planning to move to new premises, I should mention our expansion processes. For five years, all our Aegean Region operations have been in Izmir, where we have an office and warehouse. Since September 2024, we also have a work center in Konya together with Genemek. For almost one year, we have had an office in Bulgaria, which is the logistics hub of the Balkans. Rather than expanding our headquarters, our first expansion plan is to create locations that are close to the areas where our business is concentrated and that can contribute to us and our solution partners in terms of logistics.

Our future plans include making Integra a strong system supplier not only in the Turkish market but also in the international market. For this purpose, we continue to strengthen our team structure and infrastructure. We have a dream of making Integra not just a company, but a structure that provides an environment where our employees, business partners and new generations can gain opportunities and experience.

In summary, we implement our plans for strengthening our current logistics hubs at first as part of a new premises plan. I should also state that our preparations continue on a central logistics hub system with an area of 4,000 m2.

BY: Do you export? What is the place of exports in your total sales?

MU: At this point, exports constitute approximately 25% of our total sales. We have developed a serious vision to increase this rate and to become a stronger player in international markets. We have been in a renewal period in our export activities recently. Our business relationships, in which we initially took part as a component supplier, are now evolving into a system-supplier position. In other words, we are establishing a structure that not only sends products but also offers complete solutions and facilitates the process in the field with ready-to-assemble sets. There is also a change in the regions we export to. The situation where the Middle East and the Turkic Republics were more active in the early years has changed, and our exports to customers in Europe, the Balkans and Africa have increased.

BY: I see a new logo and brand face in the 11th year. What does the new design idea refer to?

MU: Yes, leaving a decade behind was an important turning point for us. We actually planned this logo for our 10th year, but we do not only care about a visual change; we give importance to transform our business understanding. For this reason, we chose to announce our new logo in the 11th year, not in the 10th year. It is a time when our corporate approach and way of doing business have matured. The handshake figure in our new logo symbolizes our trust-based relationships that extend from our suppliers to our customers, from our employees to our solution partners. This image is a reflection of our approach to long-term, sustainable and mutually beneficial collaboration. This transformation was not just a logo change, but also a visual expression of Integra’s transition to a system manufacturer and solution partner identity.

BY: You have several foreign component dealerships. Do you have any plans to manufacture together in Türkiye?

MU: We manage the distributorship of various reputable foreign brands in Türkiye. We have gained quality and innovative solutions from the industry thanks to these collaborations. However, we are no longer content with just being a distributor; we need to take further steps. Today, the world is evolving quite fast. In particular, the transformation in supply chains causes production centers to be relocated geographically. We clearly observe that some of the manufacturing weight centered in China and the Far East tends to shift to Europe and surrounding regions. Our region is still open to construction development and has serious potential. In this regard, we worked with the brands to develop solutions before manufacturing. We had projects such as a local assembly line and manufacturing of final products from semi-products. I would like to tell you a bitter but clear result: The company we first worked with asked us to take a break, stating that our country’s primary asset at the moment was consumption and that our advantageous position in manufacturing needed to be reviewed, which led to a result that caused us to put the project on hold.

BY: What are your plans for the second decade? Will there be any changes in the product ranges?

MU: Our first 10 years were shaped by understanding the industry, establishing solid relationships, building trust with quality products and establishing the Integra brand on the right ground. Now, we are on the verge of second decade. This will no longer be just a period of growth for us, but also a period of deepening, specializing and focusing more on production.

We will focus on innovative products that facilitate on-site assembly and reduce workmanship mistakes, especially in panels, motors, pushbuttons and ready-made kits. Moreover, we will work more on areas such as local manufacturing, technical documentation, digitalization and export-supported product strategy. If we divide the lift system into two groups, as mechanical design and electrical design in terms of production disciplines, Integra will specialize in the electrical design part of the system in this second decade, and its main goal will be to cooperate with mechanical design centers both in our country and in export markets.

Get more of Elevator World. Sign up for our free e-newsletter.