IoT Safety Predictive Monitoring of Lift Operations, Shafts and Buildings

Nov 23, 2022

by Andrew Gorin, Paolo Riva

This paper was first presented at the 13th Lift & Escalator Technologies Symposium in September 2022 and printed at the symposium website at liftsymposium.org.

Keywords: Safety, Predictive Maintenance, Continuous Monitoring, Lifts, Buildings

Abstract. The current market is lacking single reliable and cost-effective solutions for lift and building health monitoring systems that are suitable for both of them. A purposely designed safety device would turn any lift into a building structural monitoring system that enables continuous remote monitoring and real-time diagnostics of both the operational status of lifts and health of building structures. A cloud-connected sensor package would continuously track variables like vibrations, accelerations, displacements and other physical phenomena. The data gathered from specifically positioned sensors would be wirelessly transmitted to the cloud and screened via bespoke analytical software using reliable specific algorithms based on machine learning and cognitive computing. As a result, many lift or building anomalies can be detected in real-time. Users can receive alerts, notifications and reports through a dashboard, on smartphones, tablets and PCs for further engineering analysis. This solution would allow lift companies and building owners to plan and act prior to breakdowns, damage or accidents, subsequently reducing their financial costs in the medium/long terms (predictive maintenance).

There are no potential disadvantages in combining lift monitoring with building monitoring, and there is no risk of conflicts between building and lift maintenance contractors as the root cause of a threshold breach is differentiated by the two separate signals for lifts and buildings. The data analysis focuses on one or the other given the different frequencies responses. However, both collected data can easily be combined and provide additional information that would otherwise not be available. The reading combination of data would increase people’s overall safety, optimise maintenance, improve performance and protect the long-term value of assets.

Buildings and lifts are also prone to a gradual ageing process. In accordance with European Union (EU) Commission data, about 80% of the EU building stock is more than 25 years old, and people spend approximately 86.9% of their lives inside buildings, including lifts. Additionally, all buildings are subject to hazards due to fast-growing urbanisation and adverse natural occurrences, including earthquakes, landslides, floods, etc.

Progressive deterioration or defects of building structures and lifts are, in most cases, hidden and evolve unnoticed until a failure occurs. Currently, lift and building maintenance is based on several periodic inspections, resulting in high costs and low efficiency causing CO2 dispersion. A purposely designed safety device can provide a solution to monitor lifts and buildings 24/7/365 remotely by using the lift shaft as a vector. A user-friendly solution which enables accurate maintenance planning, therefore reducing the number of site visits to the ones needed, and therefore minimising traffic and personnel on the road from making unnecessary site visits, helps to generate a more efficient ecosystem.

1. Introduction

Buildings and lifts are prone to a natural and gradual aging process. About 80% of EU building stock is more than 25 years old. All buildings, including new ones, are subject to hazards caused by human actions, fast-growing urbanisation and the natural environment including earthquakes, landslides and floods. Progressive deterioration/wearing and even damages or defects of building structures and lifts are, in most cases, hidden and evolve unnoticed until a failure occurs. Accidents, resulting from faults and critical events or disasters, occur. People spend around 86.9% of their lives inside buildings and lifts. Homes, offices, schools, hospitals, shops and hotels are places to be kept safe! To date, stakeholders cannot have access to 24/7/365 information about the state of their assets and cannot monitor factors that can affect buildings and lifts, making them unsafe until uninhabitable or inoperable. Statistics of human and economic losses are quite impressive. It is not a deferrable need.

This paper will take a brief look at how IoT remote continuous monitoring is the key to a worldwide digital transformation and modernisation of buildings and lifts, improving the resilience of cities by means of assessing and providing a diagnosis of buildings and lifts, aiming at decreasing critical events, protecting people’s life and real estate investments. Analysis of the data obtained enables predictive maintenance resulting in improved performance, greater reliability with less downtime, and a consequent increase in overall safety while reducing costs in the medium and long terms. An extended application in urban environments of an economically and socially sustainable solution can contribute to risk mitigation on a large scale, making the world’s buildings/cities safer, more resilient, and more efficient.

Approximately 20 million lifts are installed worldwide, most of which before 1999, the date when Directive 95/16/EC came into force. Now, they are in a state of technological obsolescence regarding energy and safety efficiency; additionally, buildings are at risk due to ageing and natural and human threats. Prevention and safety requirements often struggle to climb the priority list of administrators in a world that constantly finds difficult economic balances. Market data indicates a strong trend in urbanisation on a worldwide basis, leading to the construction of approximately 13,000 new buildings a day between now and 2050; most will be built in urban areas requiring constant monitoring of potential risks affecting structural health.

Why Now?

Today, structural health monitoring is a complex and expensive service. In the absence of specific legislative rules that favor its adoption, it is planned to use lift predictive maintenance, which brings tangible economic benefits, as the strong driving force behind the introduction of a capillary system for monitoring the health status also of buildings for a safer, resilient and efficient society. At present, on the market there is no cost-effective solution to bring old installations to a new life with the described features and peculiar characteristics.

The technological advancement of sensors, cloud computing, AI, machine learning and the achieved quality of applicable scientific knowledge are such as to facilitate fast vision-design-prototyping-go-to-market processes. Even more, the issues addressed are current and in line with Europe’s objectives for resilient cities (safety), circular economy (reuse of existing installations), accessibility (greater availability of installations) and energy-saving (fewer empty travels, general efficiency). All together, the new trends of home or remote working are factors and prerequisites for the surfacing of latent and hitherto unmet needs. Statistics on damage related to accidents in lifts or due to the partial or total collapse of buildings are increasing. The latest reported events in Bordeaux, France, and Miami, Florida, confirm that buildings are extremely vulnerable structures that must be monitored in an effective way. There is a definitive need for a solution that can raise risk awareness and improve assessment with new diagnostic capabilities for lifts and buildings.

2. Continuous Remote Monitoring and Real-Time Diagnostics of Both Building Structure Health and Lift Operational Status

2.1 IoT Monitoring Solutions: Basics

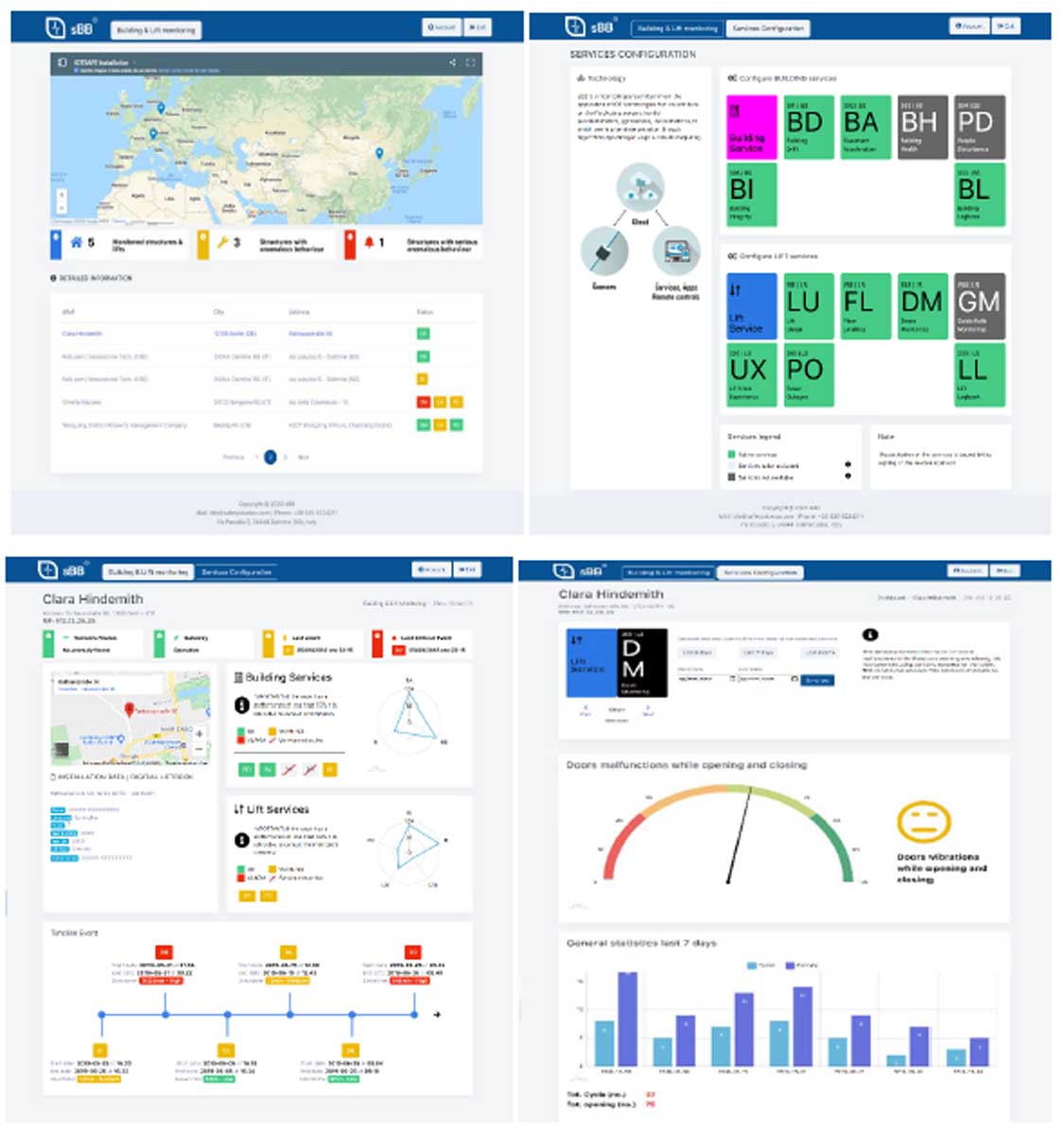

A cloud-connected sensor package continuously tracks variables like vibrations, accelerations, displacements and other physical phenomena. The data from the sensors are wirelessly transmitted to the cloud and screened via bespoke analytical software using reliable specific algorithms based on machine learning and cognitive computing. In this way, anomalies can be detected in real-time. Users can receive alerts, clear notifications and reports on smartphones, tablets and PCs and gather building and lift data remotely, ready to be aggregated for further analysis, all through a customisable and user-friendly dashboard.

2.2 What are the Existing Solutions and What Are Their Limits?

The maintenance of lifts is often limited to periodic codified checks, a preventive maintenance logic that, while raising the standards of safety and reliability, is not very efficient, especially as it does not consider the real use of the lift. It is time-frequency that cannot guarantee maximum safety and efficiency. Interventions are often carried out only when failures and accidents occur. Solutions currently on the market are all aimed at implementing, at different levels, lift monitoring systems only where suppliers of electronic boards interface with the lift controller, allowing remote viewing of only some data of the operating status and others that, thanks to the installation of sensors, can measure in more depth the state of wearing of specific components.

2.3 Why Is the Proposed Solution New Compared to the Existing Solutions?

The proposed solution makes use of the latest technological standards provided by the up-to-date generation of “MEMS” sensors, a cloud platform with proprietary machine learning algorithms. “MEMS” are considerably less expensive than other types of sensors (e.g., “FE” piezoelectric sensor) and provide sufficient response for a first level analysis (alarm threshold) for a more in-depth follow-up (especially for buildings). Unlike others, the proposed solution works on any lift, being in fact an independent chain that does not invalidate the warranty or safety of a lift. It is easily installed by the lift maintenance people and is activated through a convenient subscription. The main innovative feature is that, to date, there are no other remote lift monitoring solutions incorporating, in a single installation, also the remote monitoring of changes in the structural state of a building. It is important to measure the impact of different threats in all phases of the building’s life to determine its structural health, which becomes a fundamental requirement to consider for raising the level of safety of the “lift-building-people” ecosystem. The use of the lift shaft as a means of collecting lift and building data provides strong advantages: economic, technical and practical implications resulting in lowering costs, less invasive and safer installations compared to other solutions on the market while providing a richer amount of data available for further analysis.

2.4 Why Is a Significant Improvement of Something Existent?

The proposed remote continuous monitoring solution represents a significant improvement in the maintenance service process for buildings and lifts in a new and existing applications environment. Analysis of the data obtained enables predictive maintenance resulting in improved performance, greater reliability with less downtime and a consequent increase in overall safety, while reducing costs in the medium and long terms. The rich data obtained with the proposed application is extremely useful, as it can improve the overall diagnostic capabilities of the entire ecosystem over time. This is the core value of this innovation: to transform any lift into a tool for monitoring the structural health of a building with overall benefits for energy efficiency, accessibility and safety.

A building and lift “combined” monitoring system can help correlate the effects of the building to the lift and of the lift to the building. In this way, it is possible to identify the cause/effect generating a malfunction by attributing objective responsibilities either to the lift system/maintenance or the building structural behaviour.

To date, a study or research on the correlation between buildings and lifts’ mutual interactions has not been produced. Therefore, the combined monitoring of buildings and lifts can be of help in identifying the root causes of problems generated.

A study done by Hitachi has shown that an earthquake caused the shutdown of approximately 15,000 lift installations, highlighting the need for strong maintenance/replacements while indicating the necessity for capillary monitoring, as it took a long time for surveying and repairing. A punctual monitoring of the building before and after an event allows a timely survey of the state of the building itself and, consequently, of the lifts by identifying any post-event structural deformations that may have affected the lift systems.

Thanks to continuous and punctual monitoring, it is possible to understand the behaviour of the building and the problems that this can cause to the lifts, and also identify, on a statistical basis, the most frequent anomalies that can be generated over the years.

Official reports from independent bodies (ELA) and companies have shown that, in recent years, the majority of the lifts’ accidents are due to:

Are these problematics caused by poor maintenance, errors during installations or building movement effects? Proper, easy monitoring is aimed at intercepting, in advance, the root causes.

2.5 The Benefits

Since rapid urbanisation and population growth will drive, to a large extent, the impact of human and natural hazards on buildings, stakeholders will need to better understand building and lift behaviour and their health status. A platform is needed that helps stakeholders make decisions and plan adequate intervention before serious damages and occur, avoiding both accidents and money losses (predictive maintenance), or after critical events like an earthquake. This ultimately allows for smarter decision-making, thanks to improved awareness. The aim is to impact the market with high-quality, efficient and cost-effective digital technology that improves the safety of buildings and lifts, reducing overheads in a challenging economy, providing notification of potential problems before they result in damage or failure or worse in accidents, minimising downtime costs, improving the overall performance, maximising product life and utilisation and preserving asset value over time while helping to manage emergencies after a critical event. Insurance companies may introduce “building black box” solutions enabling the monitoring of critical elements to offer the market a parametric insurance model.

3. Monitoring Platform: The Project Components

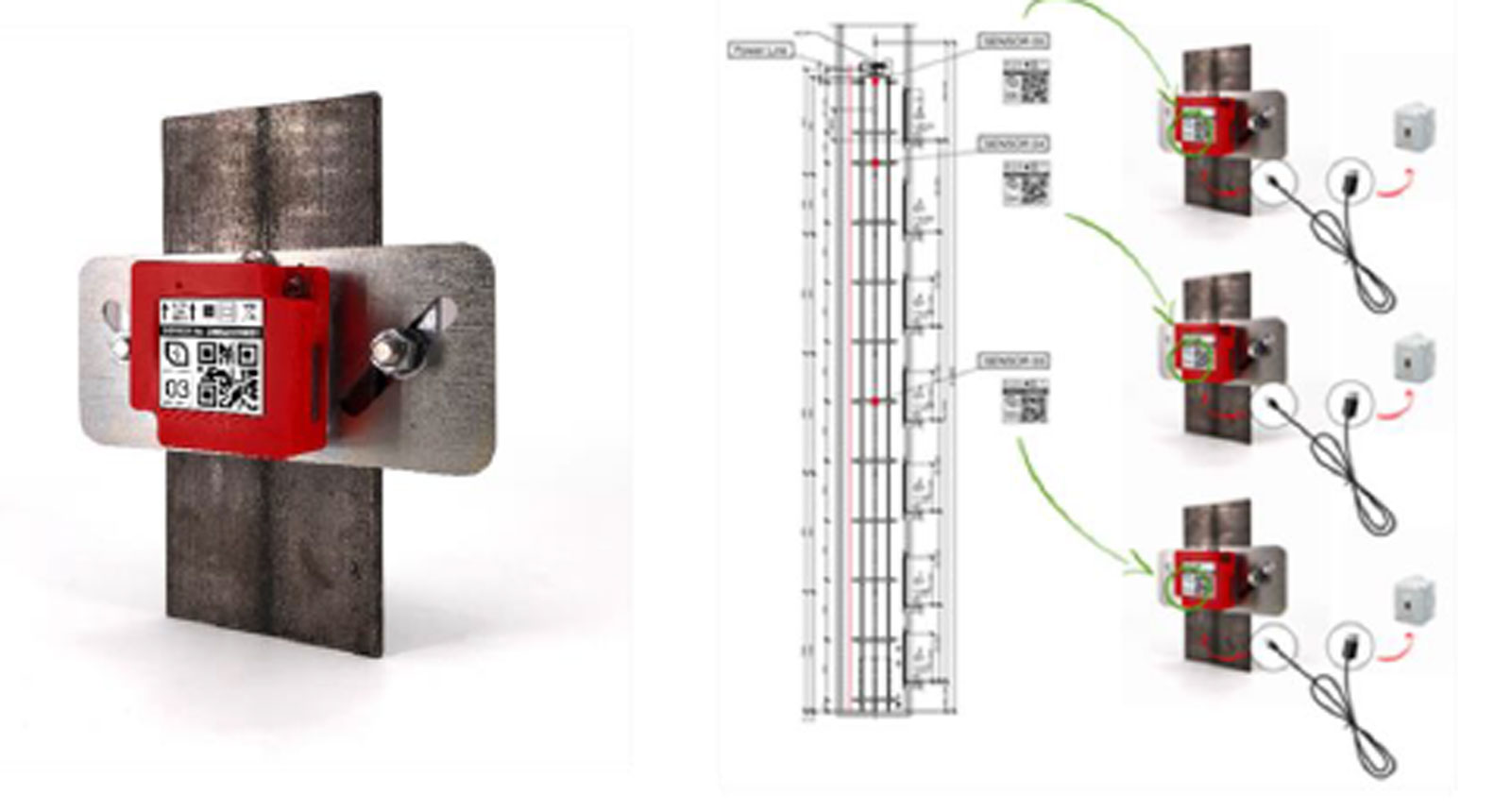

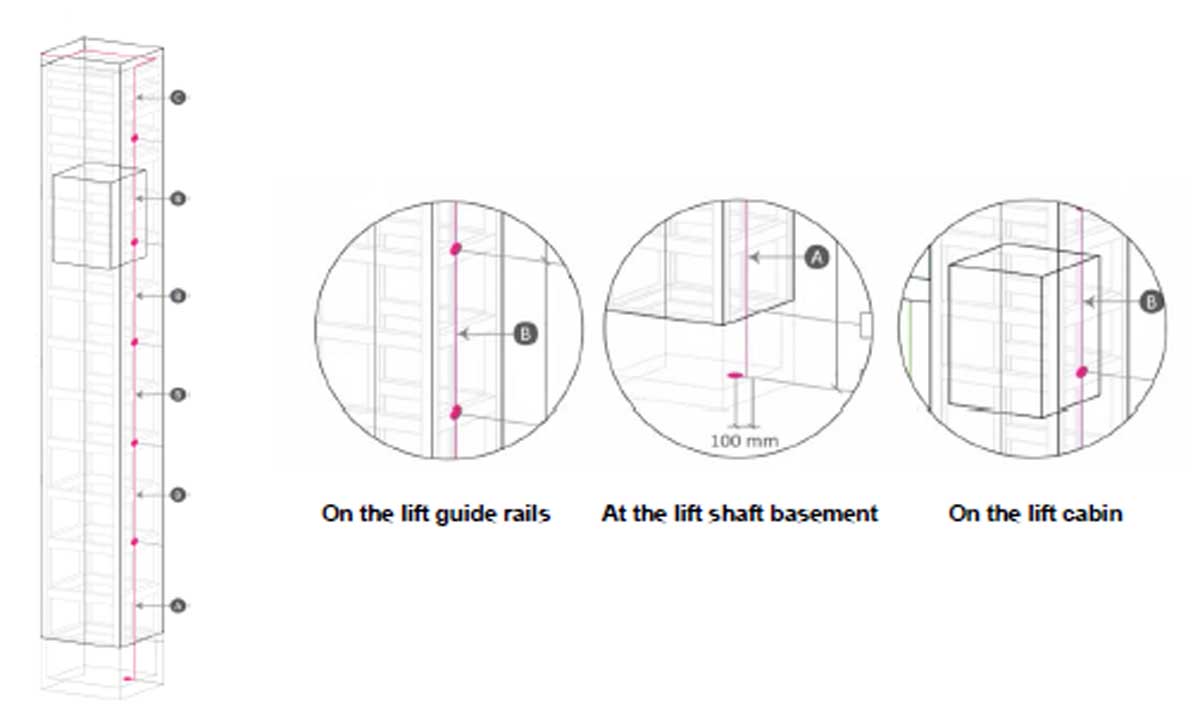

- Sensors: The hardware is designed with state-of-the-art sensors, based on “MEMS” technology, including triaxial accelerometers and inclinometers. Additional sensors are used to measure physical quantities such as noise, temperature, humidity, etc. “MEMS” sensors have reduced dimensions, continuous monitoring (24/7/365) and are connected between each other forming a chain. They are located strategically along the lift shaft: on the lift guide rail, on top of the lift cabin and in the pit.

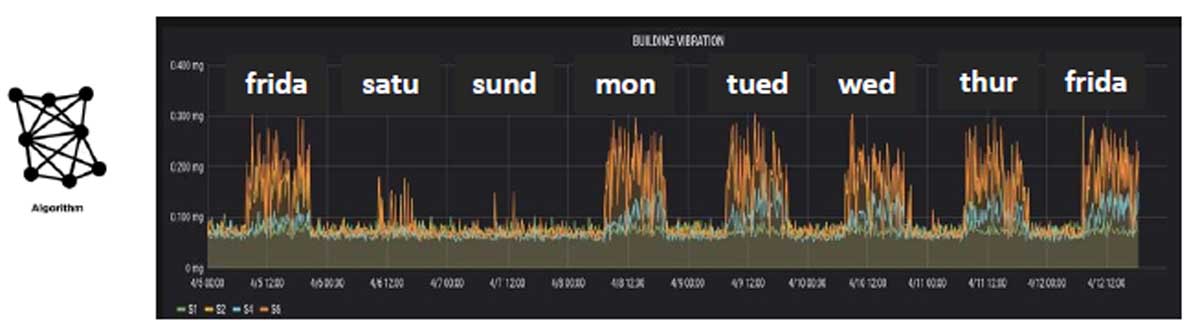

- Algorithms: Algorithms perform different functions in building safety applications. The large quantity of data coming from sensors are hedge computed among those to be sent to the cloud. In-house developed algorithms represent the most crucial part of the project since they generate valuable information out of big data. Algorithms analyse vibrations, accelerations and displacements and carry out diagnostics in order to assess the health of the system and send alarm signals in a preventive manner. These algorithms, being specifically embedded, translate the data received into useful indicators and provide a visual representation on a dashboard.

- Gateway: Data collected by the sensors are transmitted to a gateway for analysis and filtering and then transferred to the cloud. A gateway is connected to the chain of sensors through dedicated cables and filters. A huge amount of data flows from the sensors, which is analysed locally by suitable algorithms, thus extracting synthetic indicators. In this way, only much smaller amounts of information are sent to the cloud than the amount of raw data collected by the sensors. The gateway includes a specific in-house-developed firmware for the electronic devices, communication protocols among different modules optical fibre/2G/3G/4G/5G and custom algorithms.

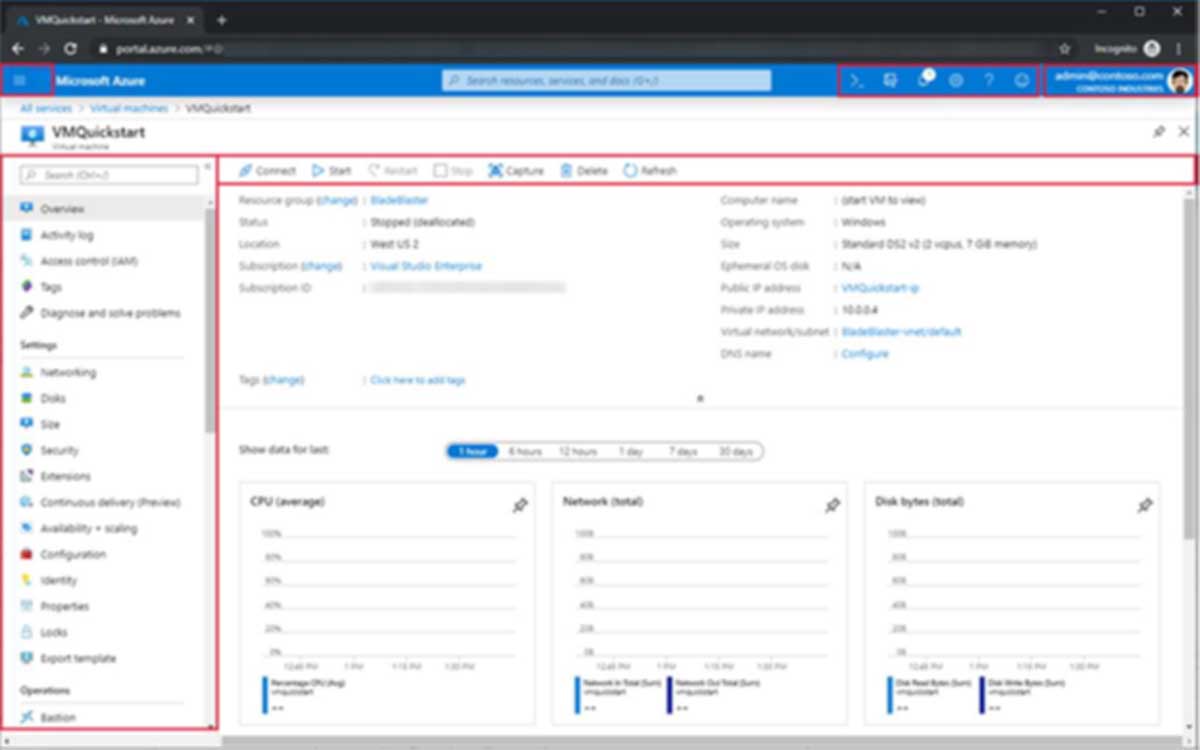

- Cloud platform: The constant and continuous transmission of data is possible through a different kind of connectivity. Data is treated in an advanced cloud platform, on which in-house powerful algorithms for analysis have been implemented, making use of cognitive computing. More specifically, the cloud receives data from the gateway, runs deeper analysis using cognitive computing and sends outputs to the front-end dashboard.

- Dashboard: The most relevant information is presented visually through a user-friendly dashboard, accessible through any modern electronic device. This can be customisable according to the contracted services and on customer preferences.

4. Installation

A proprietary technology design is installed in the lift shaft of a building. With the lift shaft rigidly connected to the building, any building movement (displacement, rotations, accelerations) is kinematically related to the shaft’s movements; hence, the same sensors installed to assess lift performance can provide the data needed to assess the structural stability of a building. Sensors are in key locations of the lift shaft, as illustrated in Figure 6.

5. Features/Use Cases

LIFT AND BUILDING LOGBOOK: Can provide periodic reports or real-time notifications available on PCs and/or smartphones. The data supplied provide objective evidence of the presence of elements of disturbance or risk, together with valuable information which can be used to perform extraordinary maintenance works. It tracks the history of the lift and building performance response when subject to environment-induced deformations and vibrations. A real black box can also facilitate and accelerate the verification of post-event usability.

- LIFT USER EXPERIENCE: By merging data resulting from different sensor measurements, it is possible to evaluate the exceeding of a set threshold, in accordance with a defined set quality of service.

- LIFT USAGE: Provides a first-level statistical analysis of Lift Travel Data, measures the number of trips made, provides the count of major destinations, the mean travelling time, measures the capacity utilisation over time and measures the total trip’s distance on a monthly basis. Provides an estimation of the usage of the lift system for re-planning of basic maintenance services (e.g., lubrication). The lift usage analysis can be of support to a people traffic management analysis and for checking when the lift goes in “out of order” mode.

- PEOPLE DISTURBANCE: Measures vibrations in the three axial dimensions, even those produced by human activity (operation of industrial machines, road and traffic in general, building site activity), and is used as an “indicator for potential disturbance to people.”

- BASEMENT ACCELERATION: Monitors the effects of earthquakes and nearby natural or human-induced vibrations (e.g., by subways) to the building basement. Such motions that typically propagate in the ground.

- BUILDING DRIFT: Computes the maximum and residual inclination of a building generated by external agents inducing oscillations. By analysing the data received from sensors, it is possible to assess the risks associated with a potential structural failure.

- BUILDING HEALTH: Checks the structural response of a building to internal or external events. Detects the anomalies of the typical behaviour of a single building in its own environment of reference in case of explosions, seismic swarms or building works in the vicinity, constantly monitoring the stability conditions thereof. A specifically designed algorithm can perform a dynamical identification of the building characteristic response, in terms of proper frequencies of vibration and damping properties.

- BUILDING INTEGRITY: The triaxial accelerometers of the sensors detect vibrations that can induce cosmetic damage to the building such as cracks, fissures and plaster detachments. In this way, the non-structural damage threshold is monitored.

6. Key Characteristics and Capabilities

Key characteristics of the solution include:

- Suitable for all lifts, both new and old. It is a system that guarantees maximum compatibility with the lift technology used (electric, hydraulic, legacy or newer).

- Key performance parameters of the lift (e.g., vibration, loading, speed/acceleration, friction, usage and working hours) are accurately measured via a kit of sensors strategically positioned.

- Valuable information on the structural behavior of the building can be obtained from the sensors installed in the lift shaft and used to detect structural behaviors.

- Real-time monitoring is continuously available to technicians and operators through a cloud-based platform and dedicated app (PC, laptop, mobile phone); alarms can be sent to notify of risks or failure.

- With a bespoke predictive algorithm, it is possible to:

- Avoid unexpected breakdowns by sending an alarm when anomalies are detected

- Reduce lift downtime by enabling quick, remote diagnosis of failures

- Reduce on-site maintenance visits: provide increased efficiency and effectiveness, reduced costs

- Assess the wearing of components, manage preventive maintenance and spare parts stock optimisation

- Increase safety overall of both lift and building

- Increase quality of service

7. Summary

This paper has shown how it is possible to turn every lift into a monitoring tool for the structural health of buildings without impacting the privacy rights of individuals — aiming to ensure a high level of human health protection. The innovation brought is intended to impact our society, especially in a highly human-dense environment like communities, companies and institutions. Typical users are the lift local and multinational companies as, through them, over 2 billion people use lifts every day on a worldwide scale. The innovation also benefits flat owners and tenants, building managers, lift maintenance companies, large owners (multinationals, hotel and commercial chains, banks, insurance companies, public administration owning building stock), facility managers and civil protection institutions. The innovation will impact the entire AEC (Architecture, Engineering and Construction) sector, insurance companies, lift manufacturers and system integrators.

Lift manufacturers could adopt a new system to increase the safety of users in areas prone to risks of natural events or strong urbanisation and differentiate their offer in the market. Owners with better awareness of the state of health of their assets will be able to protect their investments, reducing expenses. Public institutions will access data on the effects of natural events useful to coordinate rescue interventions and assess building and lift “fit for use” status. Lift maintenance companies will monitor their lift fleets, optimising their work by offering better service, avoiding non-productive or decisive exits and interventions or providing useless too early replacements of components. Facility managers get simplified management of heterogeneous real estate assets, optimising performance and costs, raising the overall level of safety. All users of lifts and buildings equipped with such systems will enjoy greater safety and better comfort.

Continuous remote monitoring of lifts is a rapidly emerging technology and certainly a requirement of the predictive maintenance market. A lift monitoring solution with built-in “building features” improves processes, increases efficiency, improves profitability, but most importantly, increases people’s safety and accessibility. The statistics of human losses and economic damages are overall alarming, and global awareness of this factor is currently growing. Turn every lift into a tool for monitoring the structural health of buildings is a unique solution in the current market landscape.

References

[1] UNI 9614: 2017 Misura delle vibrazioni negli edifici e criteri di valutazione del disturbo

[2] ISO 2631/1:1997 Mechanical vibration and shock — Evaluation of human exposure to whole-body vibration — Part 1: General requirements

[3] UNI 9916:2014 Criteri di misura e valutazione degli effetti delle vibrazioni sugli edifici

[4] ISO 4866:2010 Mechanical vibration and shock — Vibration of fixed structures — Guidelines for the measurement of vibrations and evaluation of their effects on structures

[5] “MEMS” also written as micro-electro-mechanical systems (or microelectronic and microelectromechanical systems. en.wikipedia.org/wiki/Microelectromechanical_systems and www.cnr.it/en/focus/029-4/mems-micro-electro-mechanical-systems-for-wireless-architectures

[6] “FE” Finite element.

Get more of Elevator World. Sign up for our free e-newsletter.