IoT Takes the Elevator World Into Industry 5.0

Jan 1, 2024

A new era of PLM and sustainability has arrived.

by Christian-Erik Thoeny

This paper was presented at Elevcon 2023 in Prague, Czech Republic.

KEY WORDS: IoT, Industry 5.0, condition monitoring, preventive maintenance, digital twin, elevator uptime, product life cycle management (PLM)

Abstract

The Internet of Things (IoT) has been enabled in recent years by powerful cloud systems. Near limitless bandwidths and data transfer rates now allow “real-time” condition monitoring and controlling. The health, safety and yield of, for example, a hotel vertical-transportation (VT) system or a simple single elevator application differ significantly from those of pre-IoT solutions. The permanently connected machinery generates “real-time” life data that continuously ensures the shortest door open-close cycles, promptly detects wrong trends of a sub-system, warns of potentially hazardous situations and helps optimize energy consumption. AI thereby distinguishes between problem-causing sub-systems and components. This represents a decisive contribution to a new era of PLM (product life cycle management) and, ultimately, sustainability – Industry 5.0. The origin of all such analyses and intelligent conclusions is sensor fusion; the micro (eco)system, the WSN (wireless sensor network), the macro (eco)system, and, finally, the total network of everything – the IoT COP (common operating picture) or the IoT common operating system.

“Ubiquitous development of IoT technologies is inevitably altering the world of elevators, a quantum leap for system utilization and yield.”

1. Introduction

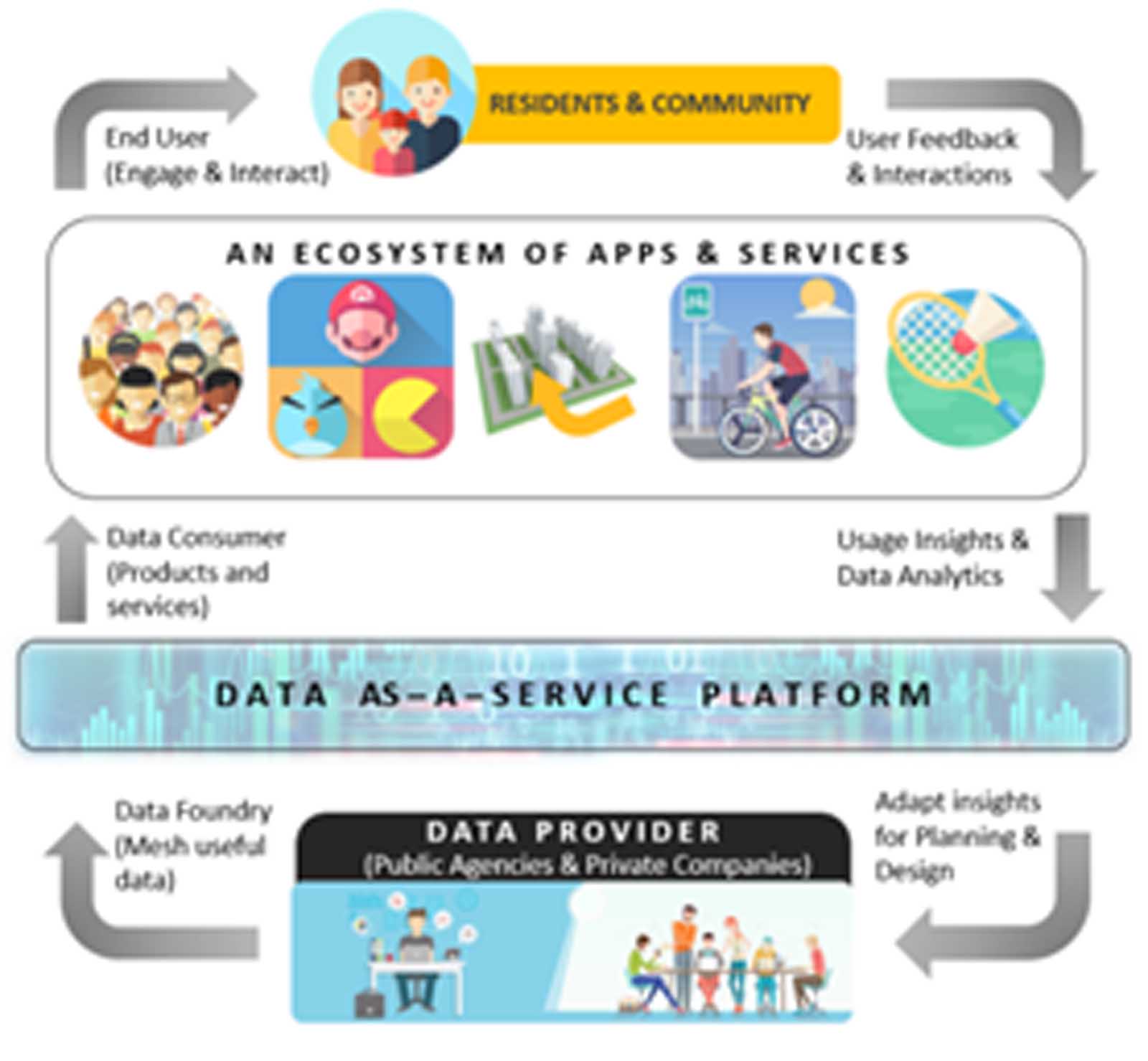

Stand-alone elevators are in the process of being replaced by networked VT systems, which are part of a bigger COP, reference example (CSIRO, 2023). At present, Singapore is the most advanced (*) city to have established an entire eco-system of connected systems: ranging from horizontal-transportation and VT systems to sports and health facilities, organizations and social activities, etc., pervading virtually every aspect of modern life. Everything is connected and every piece of data is collected in a data-as-a-service (DaaS) platform (Figure 1) and, most importantly, made accessible to all interested parties in the country. Elevators are an essential element of VT.

(*) Various publications support this perception (BCG Singapore, 2019; Singapore Government EDB, 2023).

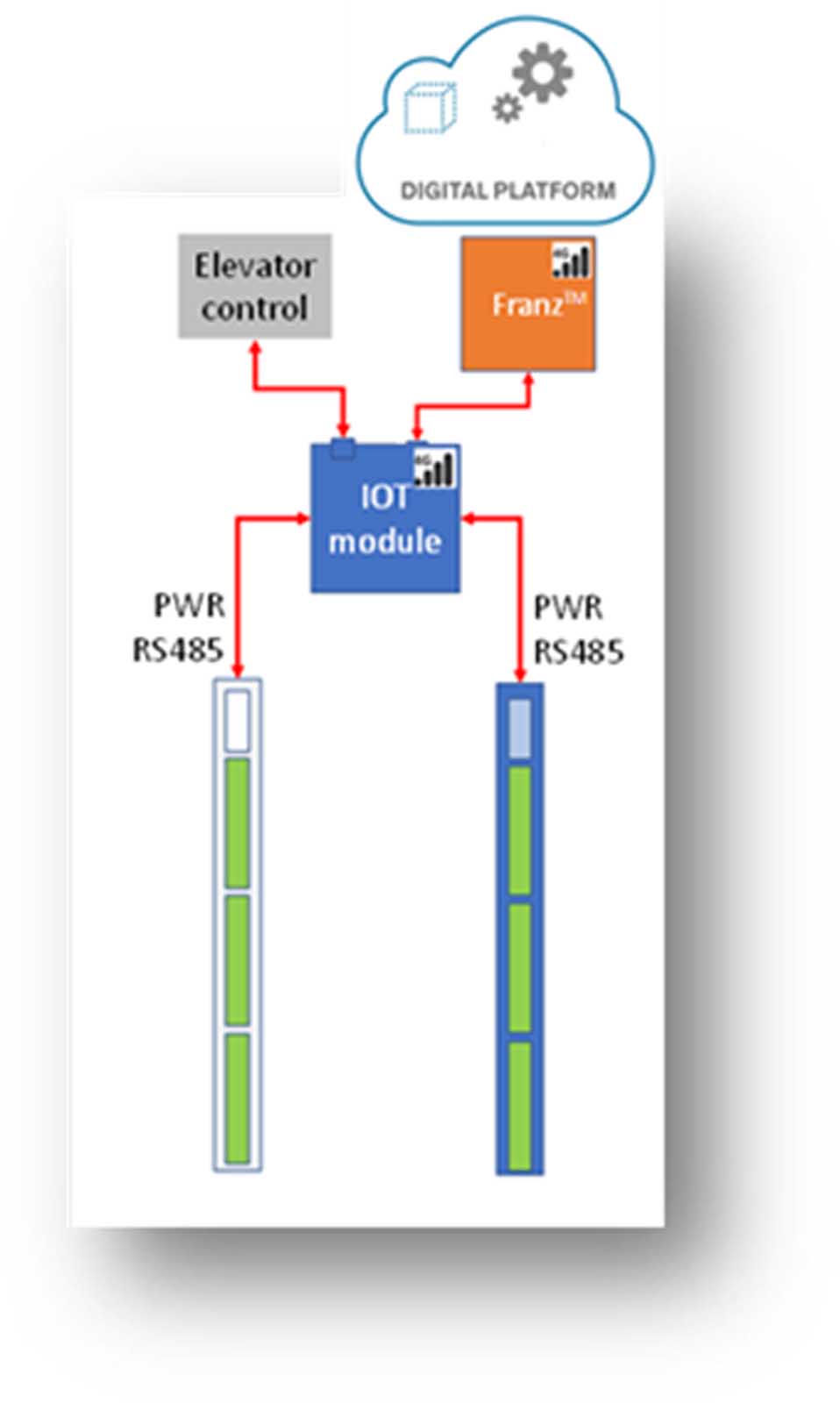

For example, elevators are monitored by separate government-maintained sensor systems. As such, elevator companies hesitate somewhat when it comes to allowing government access to their data, hence independent sensor systems are installed. In the future, it will not be possible to prevent operating data from being provided to surrounding IoT data platforms. But this is not the only reason for establishing a totally connected IoT sensor system. The first immediate benefit of an IoT-connected sensor farm, whether it is in one building or in several interconnected ones, is to increase the efficiency of an elevator (or also an escalator) and to reduce the overall cost of ownership through state-of-the-art preventive maintenance.

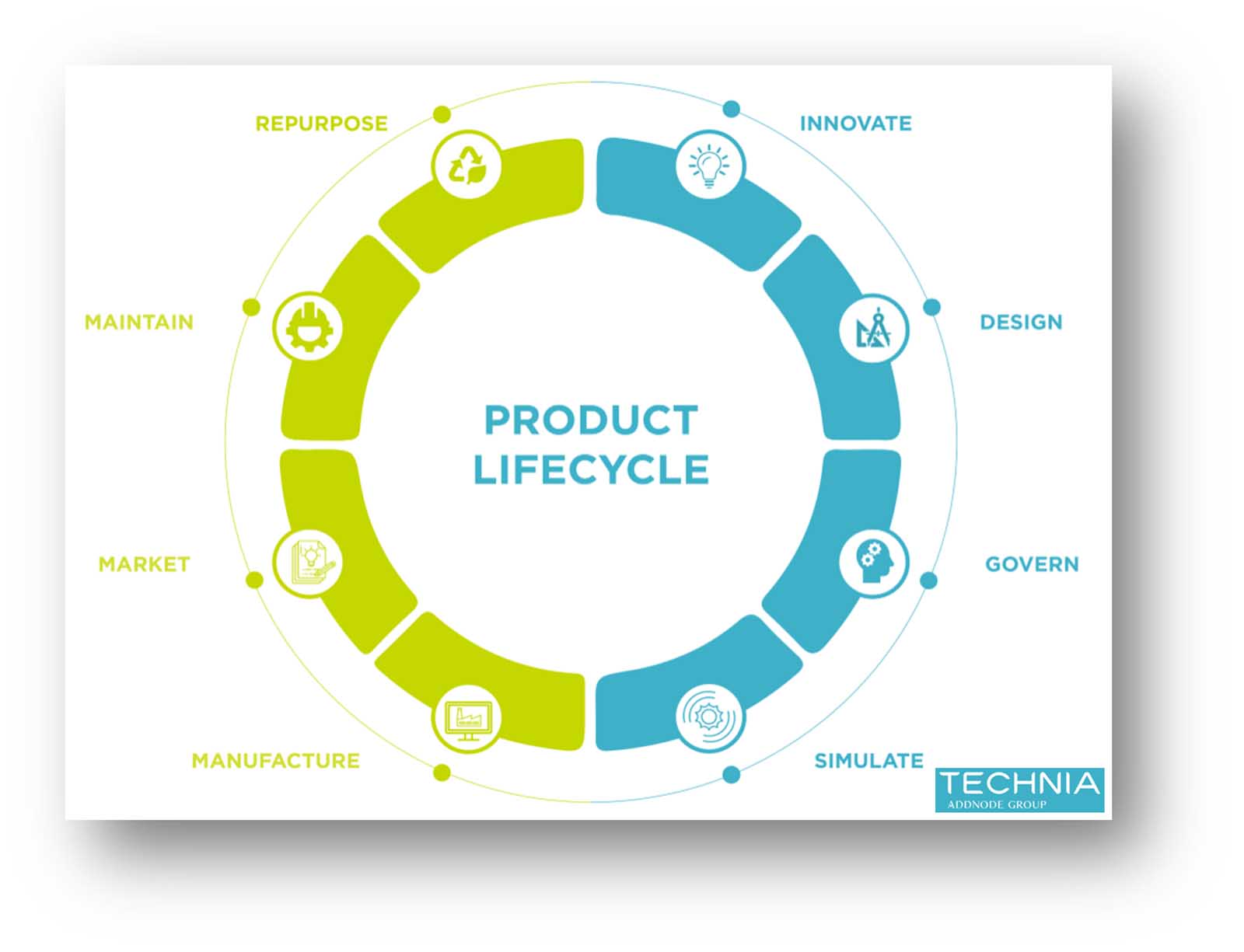

What other reason could there be for “IoT-ing” the elevator? The PLM (TECHNIA ADDNODE Group, 2023) of these machines is becoming more and more essential due to the sustainability requirements or simply due to the extremely high degree of standardization and relatively high number of sold units. The economy of scale allows for a drop-down in costs for all components, and only an advanced PLM (Figure 2) with a pragmatic cost optimization approach for every aspect of the lifecycle will keep the provider competitive.

It is easy to recognize that most of the stages in the PLM are directly affected by an IoT solution, thereby enhancing the availability of the elevator’s condition data.

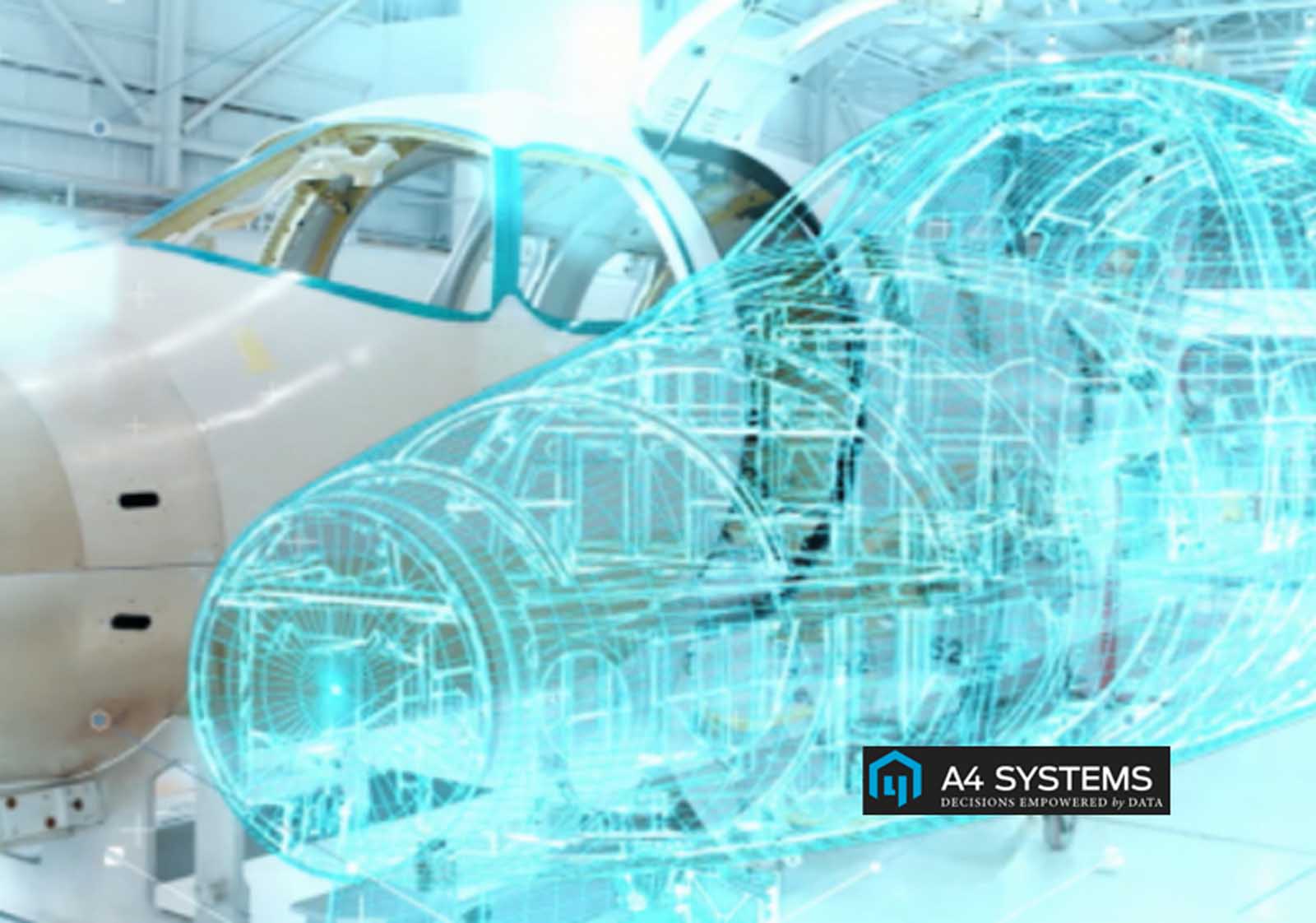

An astonishingly interesting aspect of the PLM is the digital twin (A4 SYSTEMS™, 2023), which is becoming more and more decisive for a leading design in terms of its functionality, safety and costs. Why? Again, it is quite simple, really. In the past, the digital twin was simply a design copy, but not anymore. Due to the “real-time” life data of an elevator (and not only data from the systems but equally from the real-life environment) the digital twin (Figure 3), or better the digital twins (the more the merrier), is provided with a real digital twin and not just a design digital twin, be it an aircraft or an elevator. Understood?

All real-life data are fed into the design twin, thereby upgrading it to a real-life digital twin. This serves as the ideal base to simulate all possible real-life situations and cost calculations and functional optimizations. Furthermore, hazardous situations can also be mapped out as soon as AI is involved.

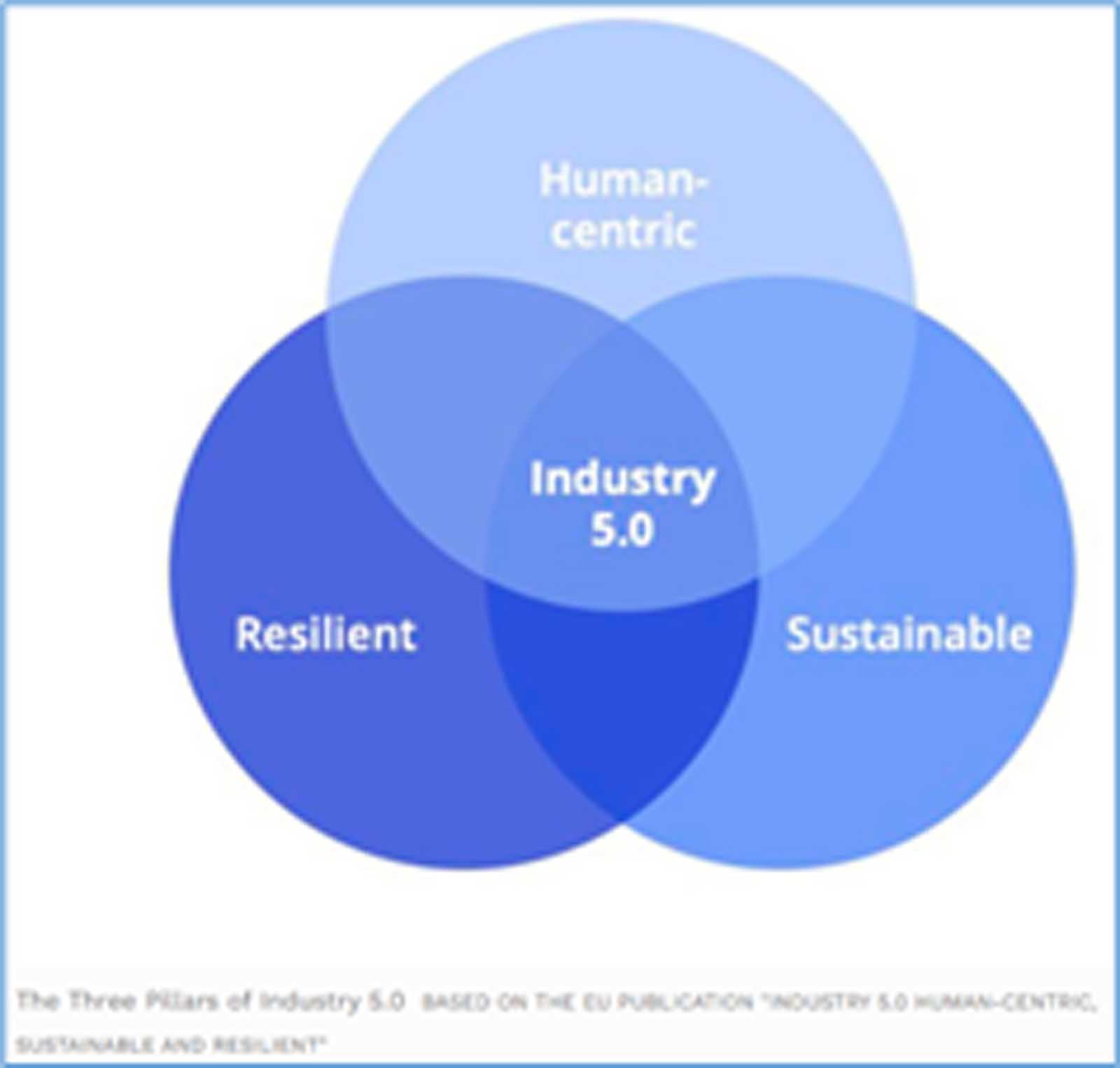

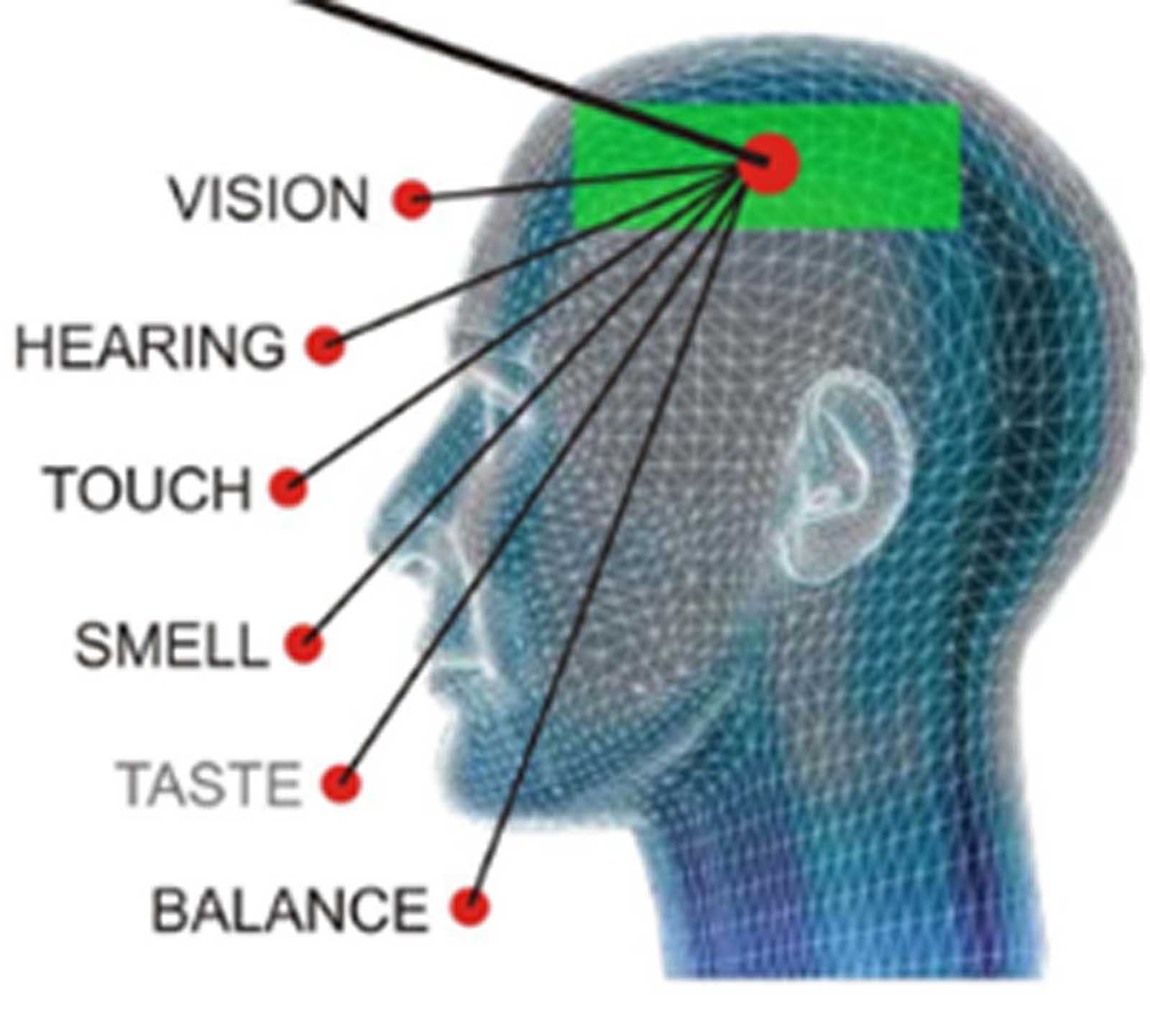

Ultimately, the quite recently proclaimed Industry 5.0 (Figure 4) is based extensively on IoT, i.e., offering the availability of a comprehensive database of all real-life machine and environmental conditions. All three pillars announced by the EU publication (European Commission, 2021) — human-centric, sustainable and resilient — are based on IoT data, scientifically analyzed by AI. Obviously, without sensors there would be no data, and sensor technology, therefore, plays a decisive role in all of this.

The following chapter shows how an elevator complies with and benefits from Industry 5.0.

2. Connection (of an Elevator) to an IoT Cloud System

Singapore is the avant-garde of connected life (Figure 5), with all its advantages and disadvantages. Today, interconnection with data platforms and data services is unstoppable, since it simply offers too many advantages to ignore: helping to save lives, boosting comfort, improving efficiency, saving costs, enhancing services and basically making life a whole lot easier for all of us (Singapore Government EDB IoT/DaaS hyperconnected smart platform, accessed 2023). Hence, more and more communities are set to follow this trend. New business models will be established to replace the old ones, allowing OEMs to perform better and adapt.

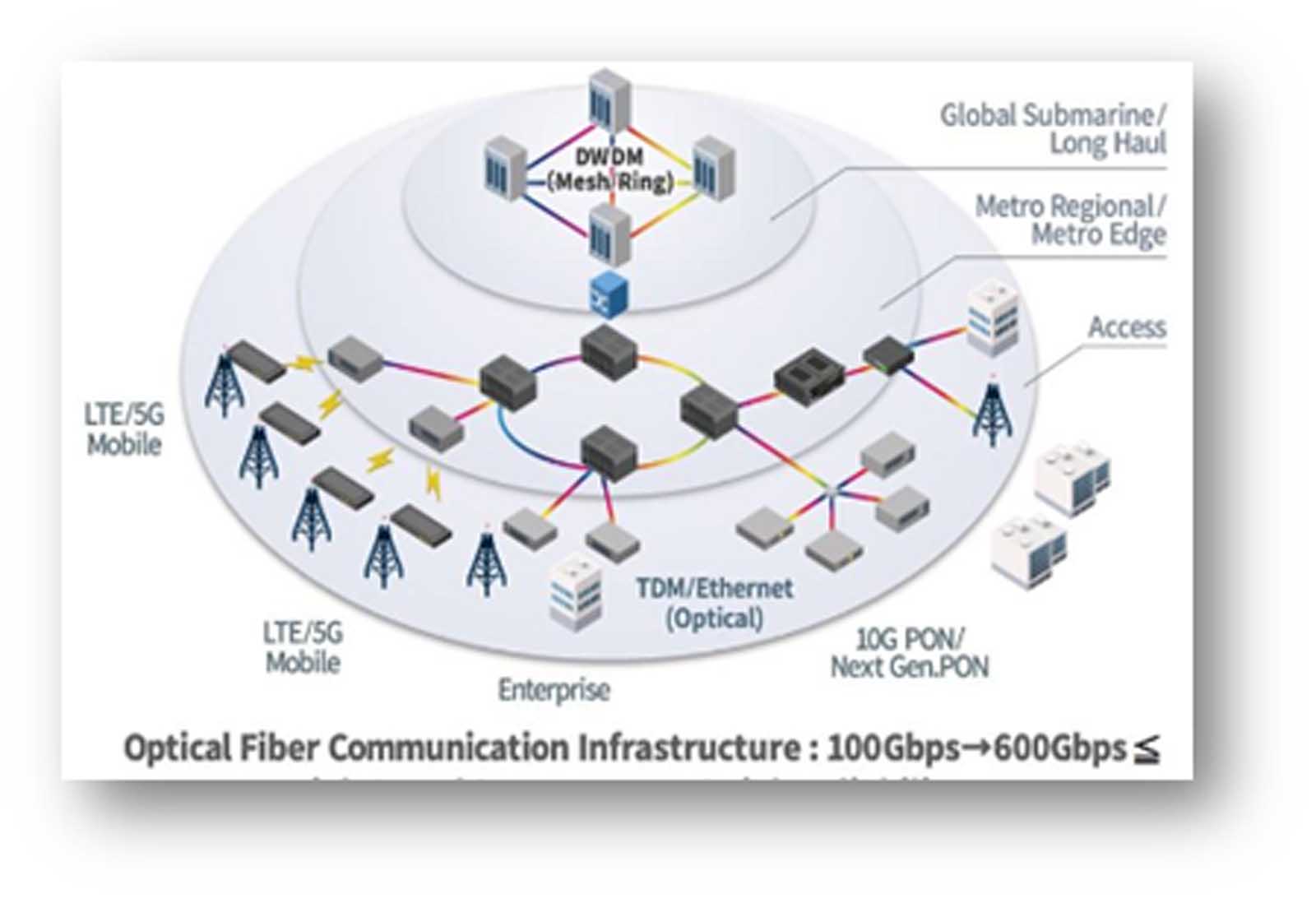

In the past, the only obstacle was the bandwidth or the data transfer rate to subordinate data platforms or clouds. But not anymore. The interconnection of glass fiber cable systems with 5G now provides 10 Gbit/s and higher rates, even in the weakest chain. The combination of optical glass fiber, for the backbones of subordinate systems, with Ethernet, PON, WLAN, LAN networks, etc., makes data collection — and ultimately computing — extremely powerful. Finally, the already extensively rolled-out 5G communication system ensures location-independent data collection and feedback at a sufficient rate.

You could say that the last mile has been unlocked and, as an example, a community is now able to connect all devices (Figure 6), regardless of whether it is located in a remote or difficult-to-access area, thus making its data available. The data are sent to the cloud and all necessary pre-processing, scientific (AI) analysis and the provision of features on the data platform can be done, if necessary, in real time.

2.1 Smart Light Curtain and Next-Generation Sensors for IoT

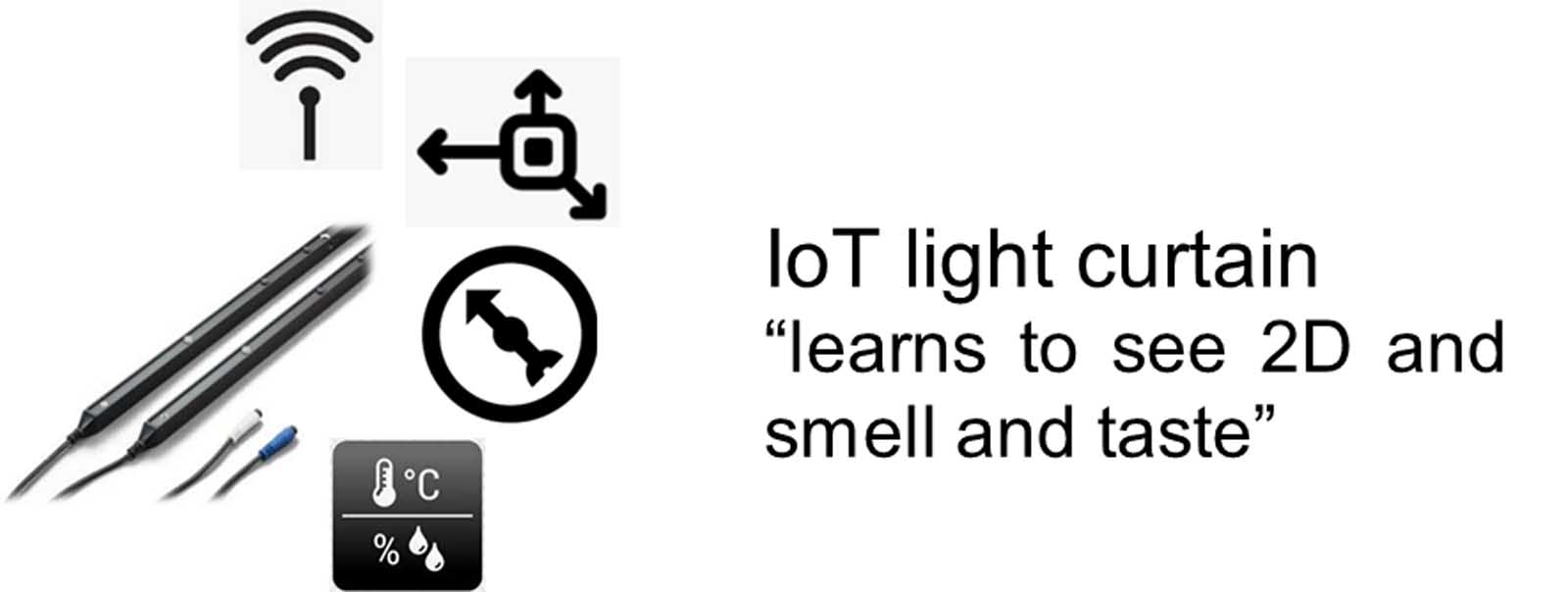

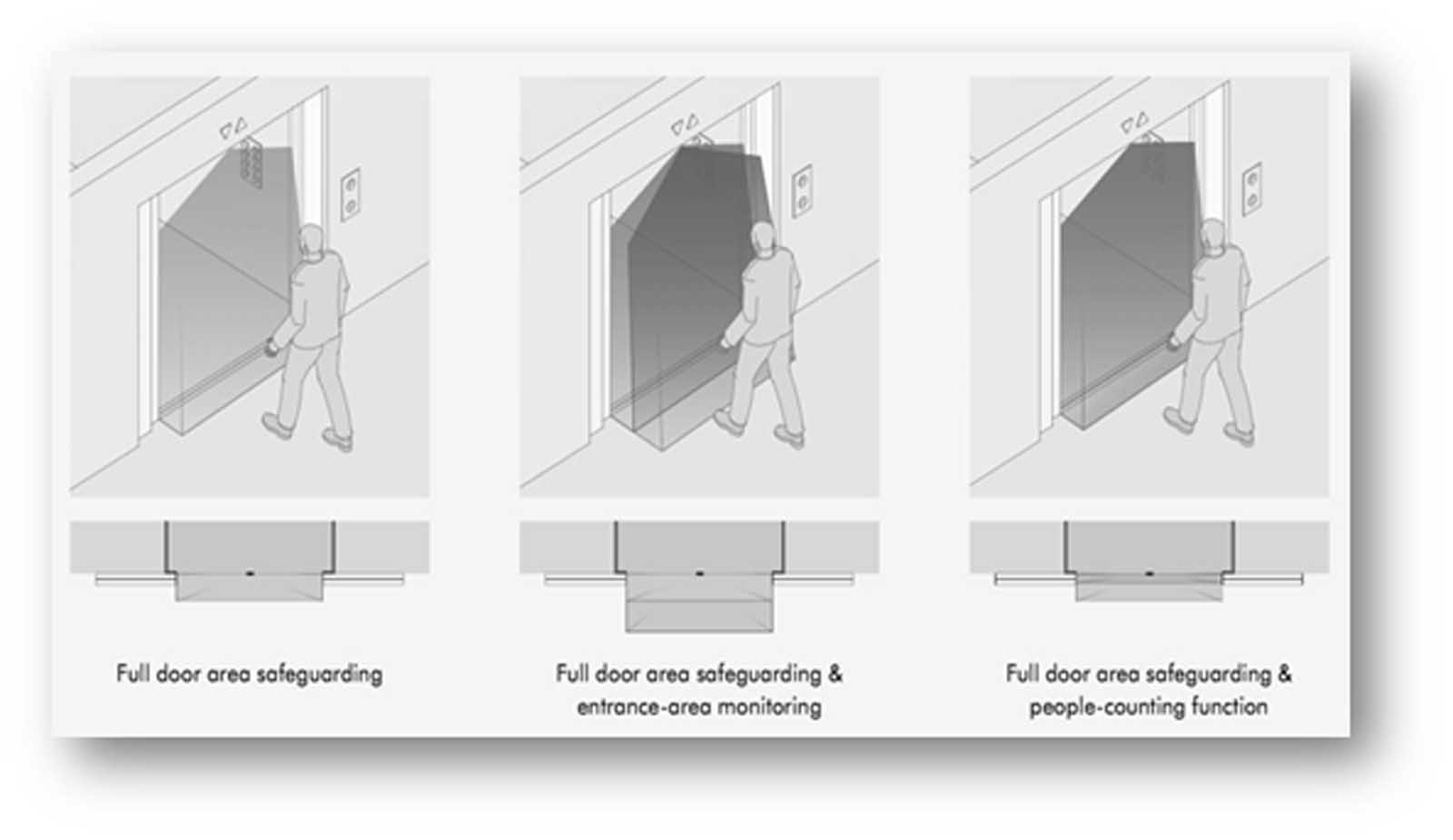

Is it possible to re-invent the decades-old concept of a light curtain? Yes, it is. The “combat value” of a light curtain (Figure 7) can be increased if the system’s condition, performance and anomaly are measured, monitored and made available in all situations:

- Door movement

- Object between the doors

- Car travel

- Car position in the shaft

- Environmental conditions

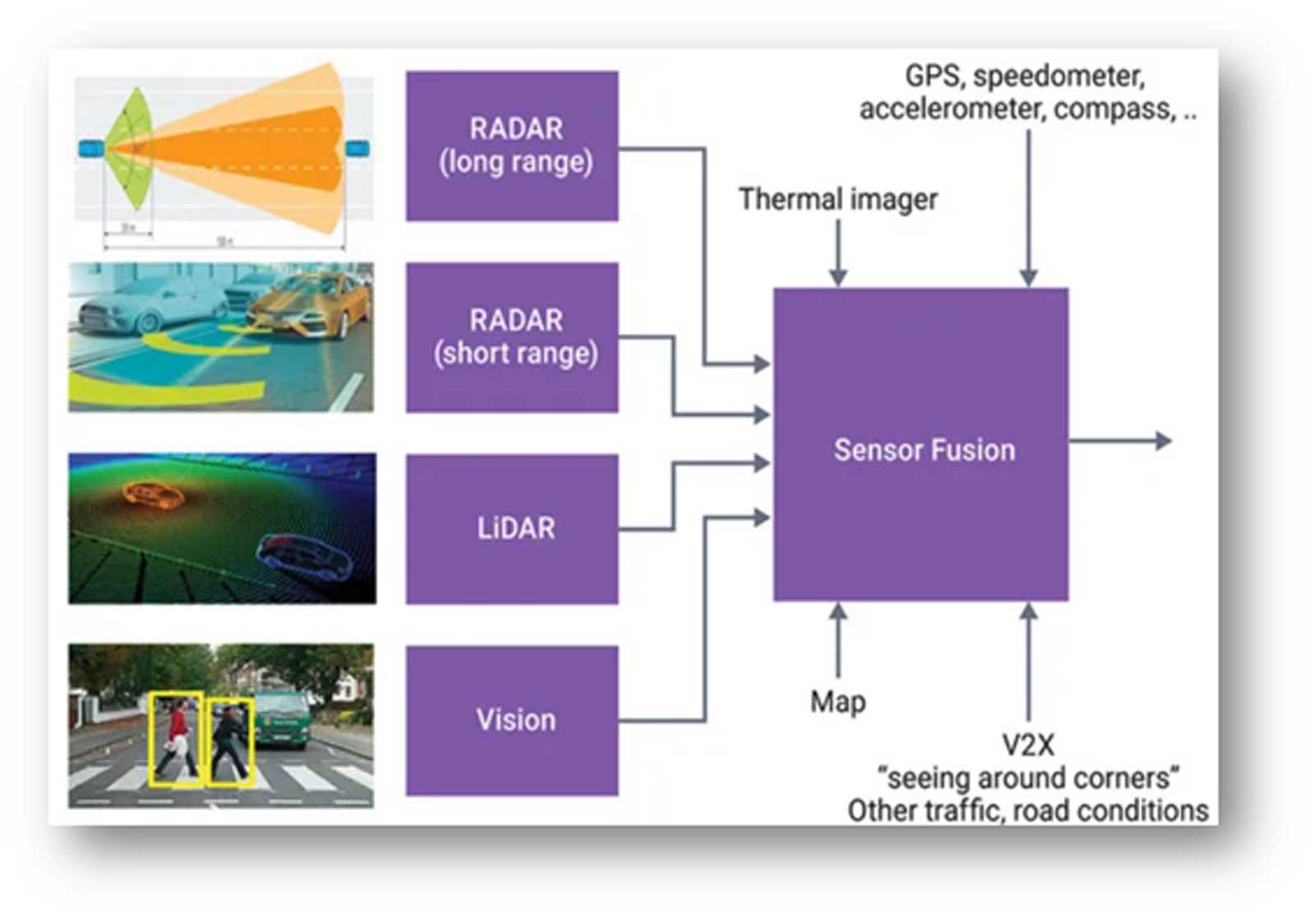

There is, therefore, no doubt that sensor fusion (Figure 8) is a prerequisite. A huge benefit is the ease of service, i.e., the system predicts which component is needed and what to do, meaning fewer skilled workers are required.

Multi-function sensors (CEDES Group, 2017-2022) are required to obtain all the necessary condition data; additional features can be provided by the same sensor fusion (several different sensor types in one).

Additional features are only of value if the acquired data are transmitted to subordinate clouds. Therefore, the sensors or sensor fusion need to be able to communicate at a sufficient data rate. The goal, of course, is to convey data in a frame rate considered adequate for the situation at hand and that is as close as possible to “real time.” Needless to say, transmitting all raw data is not realistic, and efficient pre-processing and suitable feature extraction in the sensor (fusion) is inevitable, even with AI-based computing.

3D sensors will eventually replace smart light curtains, which are already partially enhanced with 3D functionalities. U.S. safety code A17.1 for elevators and escalators stipulates various features, e.g., pre-area monitoring, which cannot be achieved without true 3D functionality (CEDES Group, 2017-2022).

But there are also full and true 3D sensors that can safeguard the entire door blades, ensuring all moving parts are covered/protected. The same sensors are also able to accurately count both boarding and disembarking passengers and, by means of entrance area monitoring, help disabled or elderly people to safely enter a waiting elevator. Additional features include helping to prevent unintended car movement (UCM) or detecting when moving parts of the cabin and floors (e.g., doors) start to slip-stick and thus requesting preventive maintenance whenever necessary. CEDES’ compact, disruptive ToF (time-of-flight) multi-axis sensor will be able to achieve and deliver this level of intelligence.

As sensor fusion and/or within a sensor network, such 3D sensors (Figure 9) are unbeatable IoT data collectors and feature providers (CEDES Group, 2017-2022).

2.2 Sensor Systems and Networks Up To a COP

It is not only about sensor fusion (Figure 10), as sensor systems are also connected in networks and subordinate systems to create a COP (reference example CSIRO cyber security research, accessed 2023), or common operating picture. Sensor fusion is already common in automotive settings.

- Enhanced sensors or evolving dynamic 3D point clouds; resulting in a quantum leap in higher intelligence

- Sensor fusion; the micro (eco)system

- Wireless sensor network (WSN); the macro (eco)system

- IoT; total network of “everything” – COP

3. Digital Twin, The Basis of PLM and Industry 5.0

A digital twin is a digital representation of an active unique product or unique product-service system that comprises its selected characteristics, properties, conditions and behaviors by means of models, information and data within a single or even across multiple life cycle phases (CIRP Encyclopedia of Production Engineering).

Professor Grieves from the Florida Institute of Technology was interviewed by the American Society of Mechanical Engineers. When asked: “Would it be fair to say that the engineer’s role in an advanced AI-driven digital twin is to be the decider of data sets?” Grieves answered:

“Remember, as humans, our focus is goal orientation, but we always don’t minimize resources. AI can help us to reduce resources by advising us on what won’t work or if it’s been tried before. It will serve as an augmentation to humans. Quite frankly, all the data being collected is overwhelming to humans. With that data, AI can organize and optimize our decision process by providing humans with the most reasonable engineering paths. Humans are too optimistic, and we tend to only look at data that confirms what we were thinking. I believe that AI can help us in that area.”

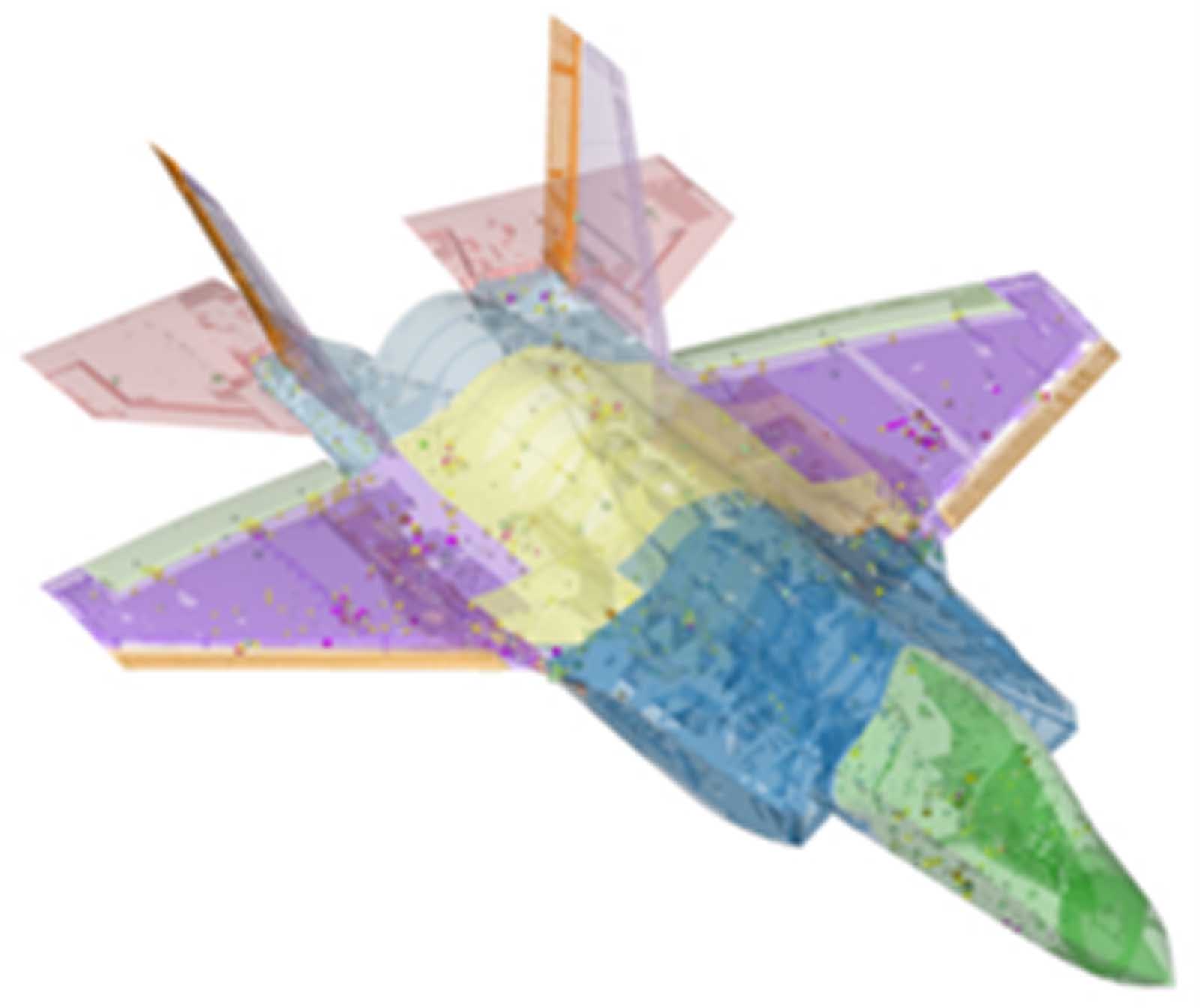

There are technical areas which are extremely advanced in digital twins; aircraft, e.g., are predestined for these applications (Grieves M., 2022).

The Lockheed Martin Aeronautics Common Analysis Toolset Data Manager (CATDM) is a tool that generates an aircraft’s structural digital twin (Figure 11). A structural digital twin is used to visualize all the known data of a physical asset into a digital one-stop shop. It is a digital replica that includes material information, test data, configuration and force management results based on operational environments.

The tool compiles F-35 aircraft configuration data, analysis and their results and historical documents from various sources for each tail number at the part number level. This includes things like type version effectivity, control point locations, stress analysis, photos of existing damage and repairs, inspection details and more. As a result, Lockheed Martin’s customers benefit from up to 75% cost savings in F-35 service.

A huge amount of data is collected during F-35 missions — not just from one aircraft but from principally all of the aircraft in service (Lockheed Martin CATDM, 2023). The fighter jet is equipped with a “countless” number of sensor systems that continuously send data back to the system and to the IoT cloud. This results in a perfect COP which represents the aircraft in all environmental conditions. As a conclusion, the digital twin is literally more augmented in information than each product that contributes to the digital twin.

3.1 PLM of a Product

It is not just the user who benefits from the augmented digital twin. The manufacturer is provided with an invaluable flow of information for its innovation and development activities. Subsequent versions and successors are entirely based on the huge amount of data scientifically analyzed by AI. Just imagine how many errors can be avoided and how many groundbreaking improvements will be considered. This information helps in every stage of PLM. It starts with innovation and development; development cycle times will be significantly cut, and engineering re-spins reduced to a minimum. Zero defect by design will, in all likelihood, be completely avoided. Extremely interesting is the information regarding sustainability, be it the reusability of elements, use of best-in-class materials for production or the lowest energy consumption in operation — all this has a positive environmental impact.

3.2 Role of the PLM in Elevators

The same methods that apply to aircraft can also be applied to elevators, but are obviously much less complex. Aside from all the positive aspects, such as cost savings, preventive maintenance and increased efficiency, there is one outstanding aspect: When feedback is provided from in-service elevators via IoT sensor systems (Figure 12), the safety of elevators can be increased significantly. AI-based analyses uncover all sources of hazards in the design and the applied materials.

ESG (Environment, Social, Governance) is at the top of our agenda. Therefore, environmental protection and, in general, sustainability plays a key role. Nowadays, there are millions of elevators in service and savings can add up to a big sum.

The life cycle interpretation shows that most of the environmental impacts of an elevator occur during its period of use, with electricity generation being one of the main environmental impacts during this period. The amount of CO2emissions generated during the lifetime of an elevator totals approximately 35 t. Roughly 80% of CO2 emissions are generated during elevator usage, as are about 71% of nitrogen oxide emissions and around 82% of sulfur oxide emissions. By comparison, CO2 emissions during material production are 15% and during component manufacturing 3% of the total.

The LCA values of end-of-life treatment are from the recycling process for multi-metal scrap. Some components have no need for a multi-metal separation process, as they can be smelted at a foundry without pre-processing. The assumed amount of material requiring multi-metal separation is 45% of the material weight of the elevator. When metals are recycled there is a clear reduction in environmental life cycle impacts, primarily because recycling of metals lowers the demand for primary metals as raw materials. On average, 70% scrap metal is used when producing cast iron and 20% when producing sheet steel (Swedish Environmental Management Council, 1999).

3.3 Industry 5.0

Key elements of the current Industry 4.0 include automation, robotization, big data analytics, smart sensor-based systems, virtualization, AI, machine learning and IoT.

Not every company has considered all aspects of Industry 4.0. Luckily, there is no need to worry as the concept of Industry 5.0 (Figure 13) is still quite new.

The European Union’s Industry 5.0 “provides a vision of industry that aims beyond efficiency and productivity as the sole goals and reinforces the role and the contribution of industry to society.” And “it places the well-being of the worker at the center of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.” It complements the Industry 4.0 approach by “specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient European industry” (European Commission, 2021).

Industry 5.0 shifts the focus from economic value to societal value and from welfare to well-being. This is remarkable, as it puts the workforce back at the heart of product development, manufacturing and usage (Forbes, 2022):

“The idea of Industry 5.0 is not limited to ‘industry.’ It applies to every sector and every organization one can think of. This means that its applicability is significantly wider than Industry 4.0. Therefore, when discussing the implications of Industry 5.0 for strategy, we need to take a broad and general perspective applying to all industries. As the European Commission spells out in this infographic, Industry 5.0 has three key pillars: human-centric, resilient and sustainable. All three have significant implications for business strategy.”

As the enabling chain (Figure 14), the entire range of sensor products and systems, IoT-connected devices, scientific AI-based analysis strategies in clouds, data platforms, SaaS (software-as-a-service) and DaaS that supply digital twin-based PLM all support the most recent industrial revolution (or better evolution) called Industry 5.0.

Figure 14: “Enabling chain”; intelligent sensor system, IoT, digital twin, PLM, lead to Industry 5.0

4. Summary and Confusion

Many elements that merge as one act as an enabling chain. The massively increased data transfer rates finally enable systems to react in “real time.” Intelligent sensor fusion based on inherent AI pre-computed feature extraction serves to monitor and control the entire product and enables a quantum leap to a higher level of performance. The features are made available in clouds, enhanced by further scientific analysis, either for the actual system or for supporting digital twins, which are an important source of PLM information. Ultimately, the entire chain helps to transform Industry 4.0 into Industry 5.0.

The “enabling chain” helps achieve huge savings in all aspects of the daily use of products, machines and systems in both communities and facilities. Direct cost savings are immediately apparent, increased efficiency and comfort are possible and, most importantly, significant energy savings can be realized, thus protecting the environment. Further, hazardous situations can be anticipated in all elements, distinguished by AI and, therefore, accidents avoided, enhancing safety remarkably.

Acknowledgements

Even after 10 years at CEDES, it is still a pleasure to team up every day with great colleagues from the management team within an exciting high-tech environment. This is an exceptional experience and one of the essentials of life. Many thanks to my wife, Luzia, and my children, Lola, Sina and Julie, whose patience supports my passion; to all CEDES’ employees and, in particular, to all the customers who have helped ensure we continually achieve outstanding results. Our esteemed suppliers have helped us get through some uncertain and difficult times recently. A big thank you also to all the stakeholders.

References

[1] A4 SYSTEMS (2023). Step Into the Future with a Digital Twin. Accessed 2023. a4.systems/fr/blog-step-into-the-future-with-a-digital-twin/

[2] BCG Singapore’ Market Report (2023). Accessed 2023. bcg.com/publications/2019

[3] CEDES Group (2017-2022), Various technical documents and brochures

[4] CSIRO (2023). Cyber Common Operating Picture (CCOP). Accessed 2023. research.csiro.au/cybersecurity-quantum-systems/cyber-common-operating-picture-ccop/

[5] European Commission (2021). Towards more sustainable, resilient, human-centric industry. European Commission R&I 7.1.21. Accessed 2023. research-and-innovation.ec.europa.eu/news/all-research-and-innovation-news/industry-50-towards-more-sustainable-resilient-and-human-centric-industry-2021-01-07_en

[6] Forbes (2022). What Is Industry 5.0 And How It Will Radically Change Your Business Strategy? Accessed 24.5.2022. forbes.com/sites/jeroenkraaijenbrink/2022/05/24/what-is-industry-50-and-how-it-will-radically-change-your-business-strategy/?sh=251e488320bd

[7] Grieves, M. (2022). Intelligent digital twins and the development and management of complex systems. Digital Twin 2022, 2(8).

[8] Lockheed Martin (2023). Common Analysis Toolset Data Manager (CATDM), Accessed 2023 lockheedmartin.com/f35/news-and-features/delivering-digitally-for-f35-force-management-solution.html

[9] Singapore Government EDB (2023). IoT / DaaS hyperconnected smart platform. Accessed 2023 edb.gov.sg/en/business-insights/insights/to-build-a-smart-nation-singapore-must-be-hyperconnected.html

[10] Swedish Environmental Management Council (1999).

[11] TECHNIA ADDNODE Group (2023). PLM example Picture, Accessed 2023 technia.com/finland/

Get more of Elevator World. Sign up for our free e-newsletter.