“Is There Even More?”

May 5, 2023

3D printing in elevator manufacturing

Your author, Undine Stricker-Berghoff (USB), recently talked to Oliver Simmonds (OS), graduate engineer (University of Applied Science) in mechanical engineering and principal engineer at Schindler in Ebikon, Switzerland. In the interview, the main topic was 3D printing as a potential future production technology in elevator manufacturing. You will get an insight into the first applications at Schindler including their 3D printed car, tests, results and a rough prognosis for the future use of this technology.

USB: Mr. Simmonds, could you please tell us about your personal and professional background?

OS: I am a mechanical engineer, educated at the University of Applied Sciences Northwestern Switzerland. I started my career as a machinery draftsman. This is the third time I have worked with Schindler, in total more than 15 years. Immediately after graduating, I worked here on the development of safety gears for high-speed elevators. After that, I worked outside in start-ups on e-mobility and yacht architecture. I worked independently at one time to advance the technology of electromobility; at that time, I also had orders from Schindler.

Now, on my third go on the development side, I’m more involved with the research of new technologies. I follow up on technologies and look at them closely, considering how to incorporate them into new products. Of course, I follow trends, but I look more deeply into the technology itself. I have discussions with manufacturers on the state-of-the art to get to the core.

USB: Our general topic today is 3D print in the production of elevators, escalators and their components. What is your actual personal involvement in this technical topic?

OS: I have had a strong personal interest in 3D printing for a long time, which fortunately I have been able to transfer to my professional environment. I promoted the topic at Schindler and then delved deeper into the question: “What might originate out of it?” Doing this, I had my eye on more complex parts that could be manufactured in very small batches at an affordable price.

USB: Can you please explain what signifies the term “3D printing” as one form of additive manufacturing?

OS: The technology has improved greatly so it can be used for samples and small batches. There are X varieties of plastics and metals such as steel, copper and aluminum that need to be understood. The variety of materials and the correspondingly differing processes do not result in only one, single 3D technique. However, the common factor is always that material is built up in layers. Technically, these processes are referred to as “additive manufacturing.” However, the term 3D printing has become established in the popular language.

In the 1990s, the road began in the U.S. with the processing of powder on a type of inkjet printer. Resin was applied to a surface to bind the powder to the selected area. This is where the term 3D printing comes from.

Today, we mainly use the Fused Deposition Modeling (FDM) process, also called Fused Filament Fabrication (FFM). In this process, plastic is heated and pressed through a nozzle. The method is inexpensive, widely available and leads to good results. There is also the so-called powder bed process, which works with metal as well as plastic.

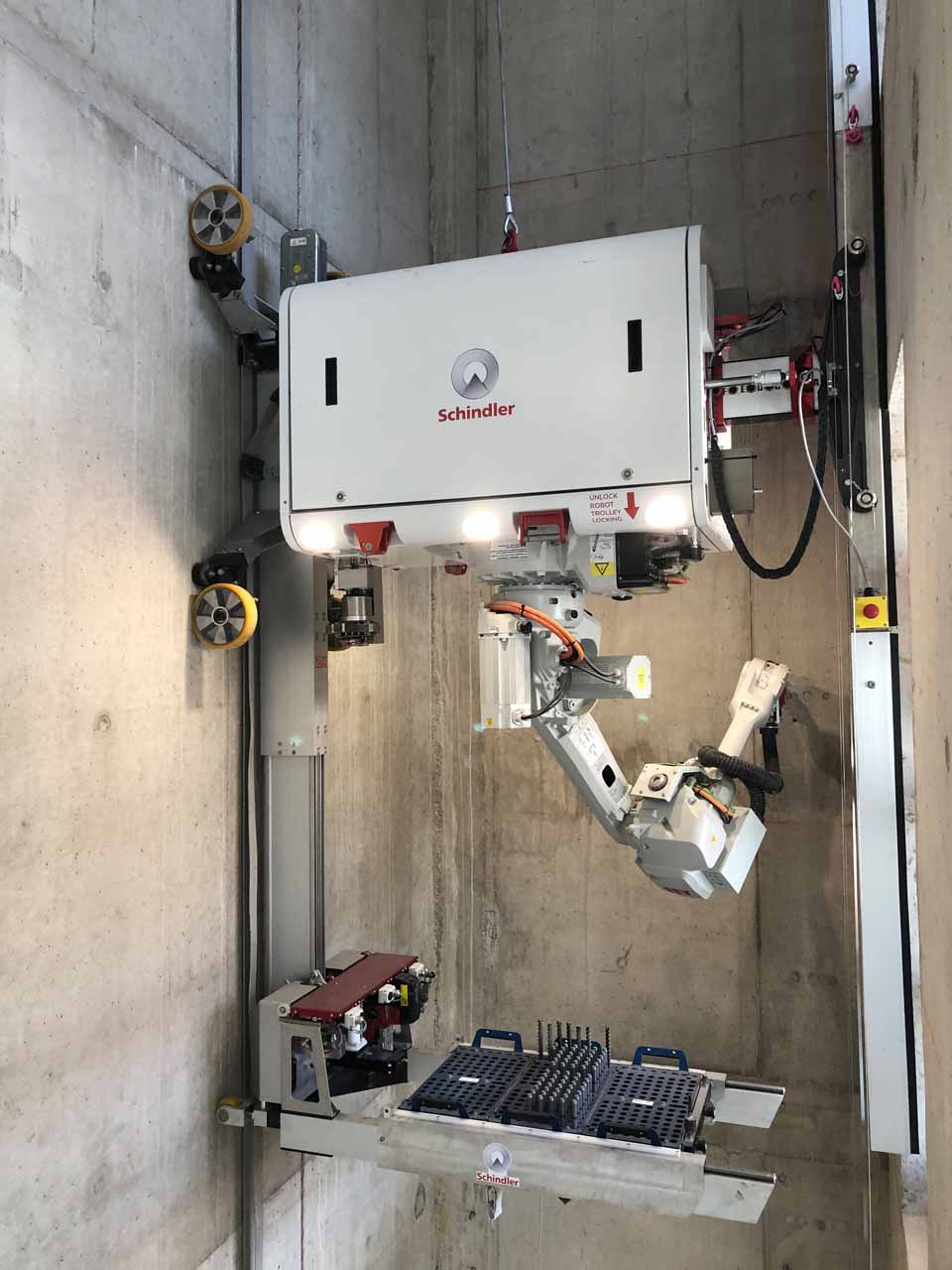

In our project, the car was built using the Wire Arc Additive Manufacturing (WAAM) process. A welding robot runs according to the design “drawing” and applies the material layer by layer.

USB: Behind these various calculation methods for optimization, I adumbrate a longer history.

OS: We’ve built up all this over the years, especially the design tool, always following the progress of digitization. We used to draw designs in ink. The enormous change has led to a largely paperless office. The entire work process has been digitized, which means that we no longer make drawings by hand for 3D prints, either.

USB: In your company, you start with 3D prints very early on in the careers of your staff. Already for apprentices, you offer metal and plastic 3D printers as tools. What is the next generation doing with these printers?

OS: We believe that it is time to bring the process into everyday life. 3D print technology has been available to everyone in the company’s R&D department for some time; small devices are placed in almost every office. The apprentices also need to know it. That is why we are already using the FDM process in our apprentice workshop. You can have a look at the printers and processes at Schindler website.

USB: Why do you involve the next generation in this technology?

OS: Young people can already integrate 3D into their everyday work. They find it easier than some older people. If 3D is already part of everyday life in R&D today, it will accompany the next generation in production throughout their whole lives. It is important to prepare them for this.

USB: Back to R&D. At what stage in production or for which products do you see opportunities for 3D printing, and why?

OS: We work conventionally in the production of elevator components by means of milling and lathing, also in plastic. For our Schindler R.I.S.E installation robot, for example, cover parts made of plastic would come into consideration. These would exactly meet the targeted niche: customized parts in small series. In larger quantities, 3D printing is still too expensive and too slow.

USB: What about spare parts?

OS: Generally, yes, but if plans are still available, they can also be produced quickly and inexpensively, computer-aided by conventional means. It has formerly been milled according to drawings, etc. Why should I change the process? The situation is different for old castings, for example, where molds are no longer available. These have usually more complex shapes that are difficult to produce by conventional means.

USB: And why is 3D printing not already used much more often then?

OS: The main difficulty in metal applications is the availability of reliable and reproducible material specifications. Many factors during the printing process must be controlled within narrow limits in order to achieve the desired quality. Often, only very specialized companies have these processes under control. Therefore, the obstacle to wider application is the lack of warranties and quality assurance measures. There are many approaches in this area, as well. The first printing system manufacturers are already issuing warranties. These materials are already being used in aircrafts and jet engines, for example, but still require bigger investments.

USB: As far as I know, you already tested printing elevator cars. Are there any other items on which you have already worked within Schindler?

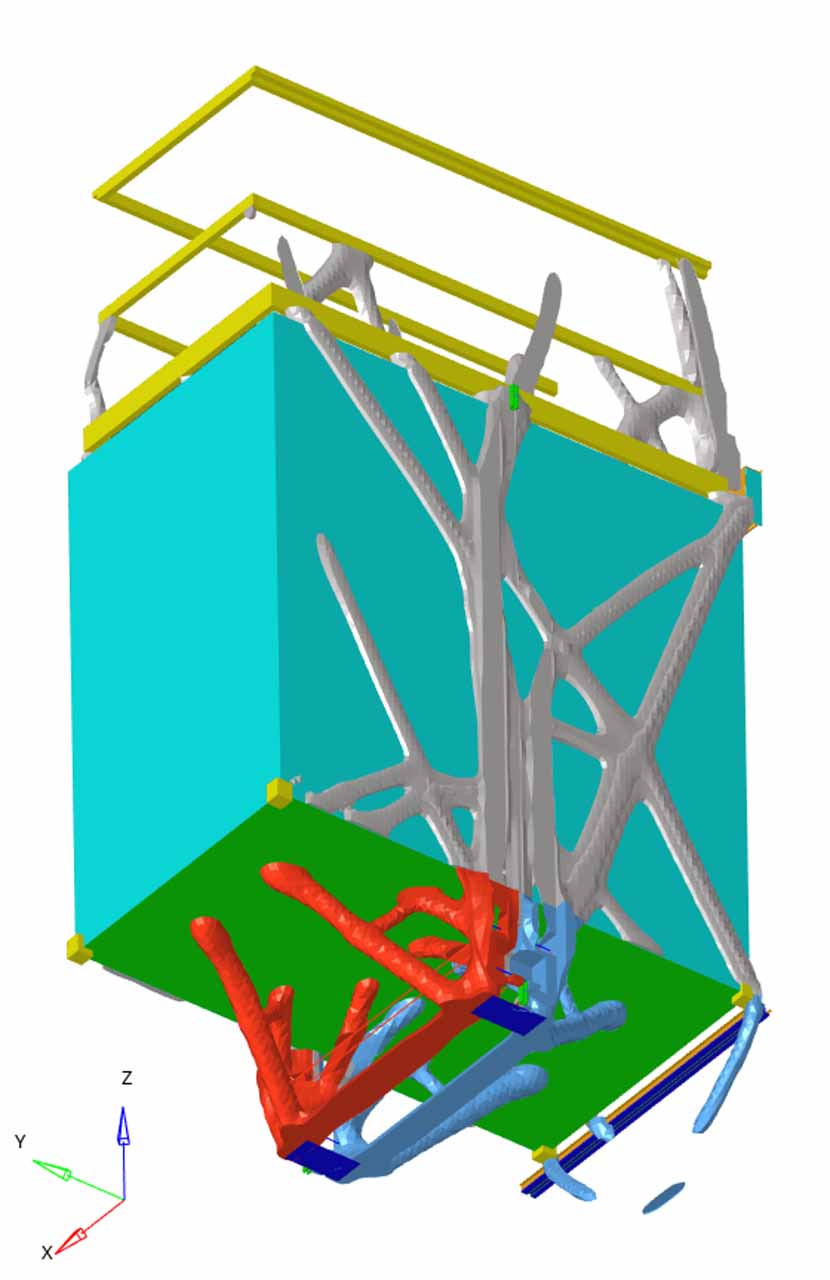

OS: Before we created the car, we had realized 3D-printed casting molds for a motor housing. We were looking for a part with a topology that could be optimized using mathematical methods. This applies to the car; its design has the forces in the frame as a determining boundary condition. With the help of software, the structure of the car can be optimized.

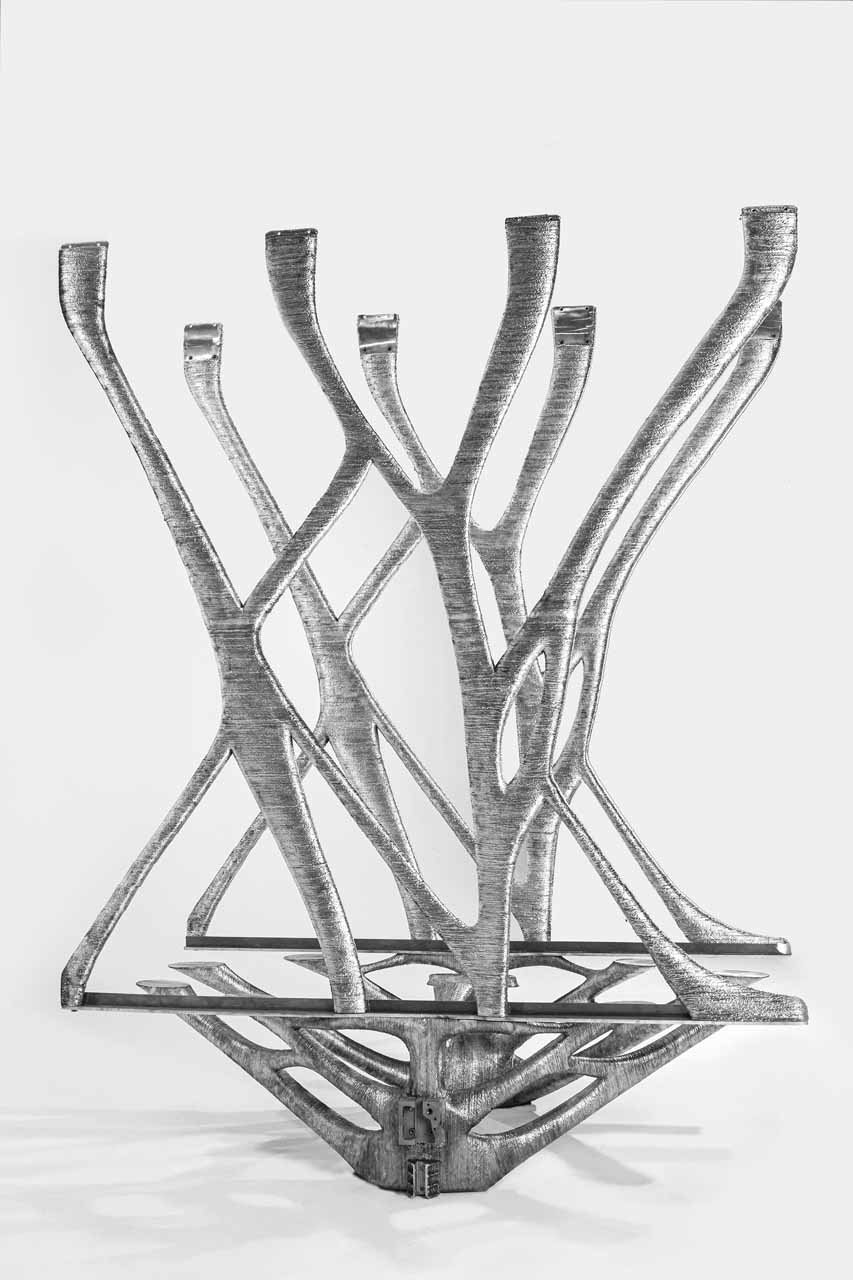

The whole thing started with a study of what is possible with 3D printing in terms of optimization. It’s like a tree: Where it needs nothing to strengthen, there is nothing — the branches are thinner than the trunk. We didn’t draw the design, but calculated it. The result was optimal in the first stages, for example, in terms of the use of materials, which is much lighter, but it could no longer be produced conventionally.

The whole thing only became feasible with 3D printing. So, our main concern with the car was to demonstrate that it was feasible. Can 3D printing achieve the calculated material reduction? Yes, 3D printing can! Consider this car like a concept car in the automobile industry.

USB: Let’s go then into this specific car project. When printing elevator cars, you call it art. Could you please tell our readers what is behind this unexpected label?

OS: I clearly detect the “art of engineering” in this, just as it always gave technology an aesthetic face in the early days. In retrospect, architects, too, used to be artists. Steam engines were decorated and painted. This aspect has been lost in industry. Everything became straight. Looks cost — and no one wants to pay for that.

3D printing brings together these two worlds. You can “slim down” and optimize, still keep the earnings high in the industry and the result is pretty to look at. There used to be beautiful mosaic floors. Today, with 3D printing, they’re feasible again. We will see many things once again.

What you develop as an engineer must also look good. This increases acceptance and sales figures in equal measure. For more information, have a look at When engineering meets art.

USB: Who was in charge of the actual execution of the printing itself?

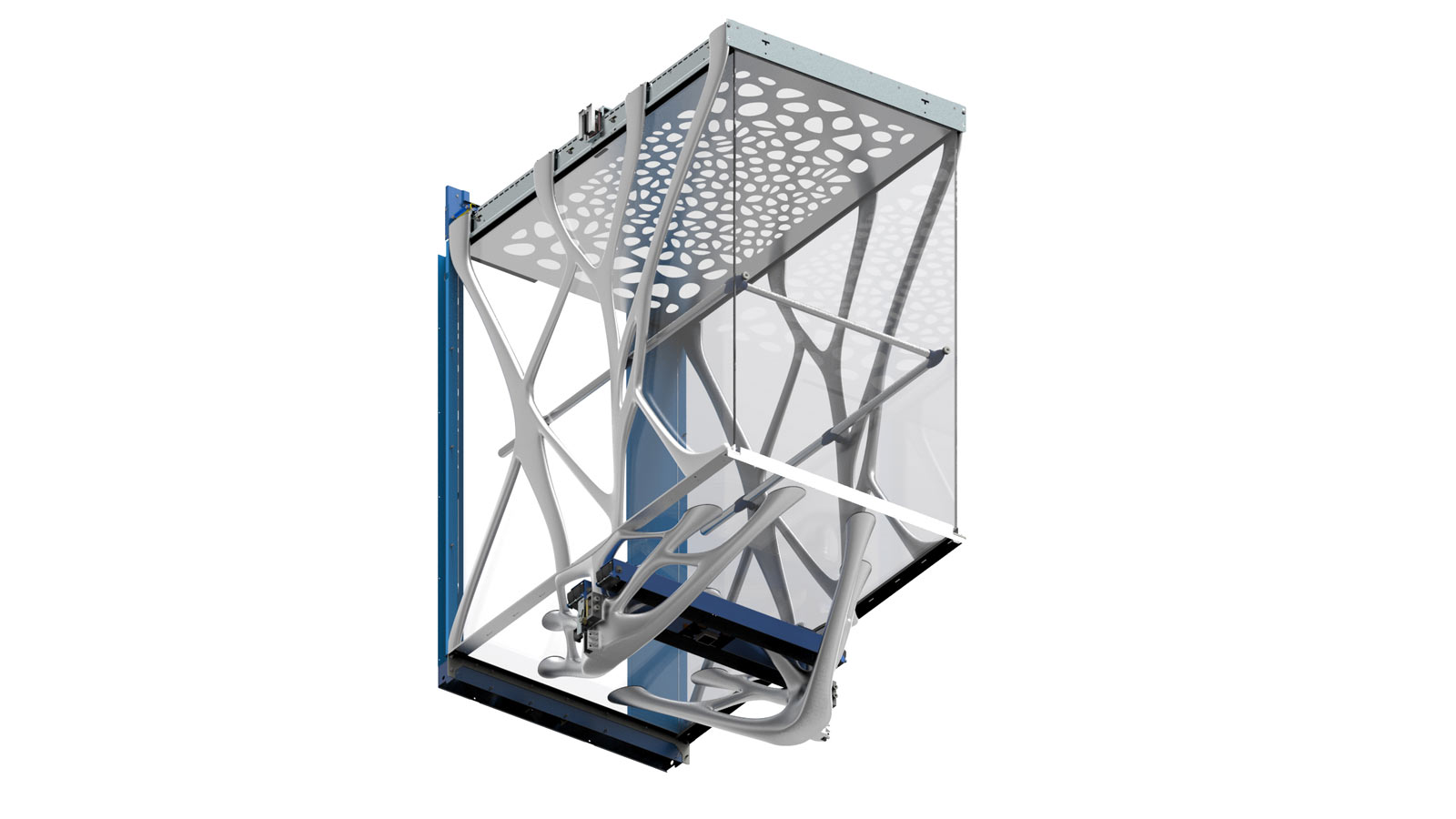

OS: The car is approximately 2.1 m deep X approximately 1.2 m wide X approximately 2.2 m high inside, with a superstructure even 3 m high in total. The printed parts were manufactured at MX3D in the Netherlands. There, innovative manufacturing processes based on industrial robots and wire welding processes are developed and tested. The company had also printed a steel bridge over a canal in Amsterdam before building our car. The steel was easier to process than the aluminum of our car. Printing large aluminum structures was new territory for everyone involved, which required a lot of input from everyone. Many tests were necessary in advance to achieve an acceptable result.

USB: Which metal did you use in this process?

OS: As previously mentioned, we used aluminum to realize a lightweight construction. Welding aluminum requires a lot of know-how. Plastic is much bulkier to achieve comparable strength. Steel also has minimum wall thicknesses, which makes it much heavier. However, we did not want to add unnecessary mass to the elevator system. Our exact goal was to build the optimized structure light. This would not have been reasonably feasible in plastic or steel. By using aluminum, we also wanted to inspire others.

USB: Which parts of the car were printed?

OS: We printed the structural elements of the car, that is, the floor and the sides. So, in total, three parts were produced: the floor, the left side and the right side. The floor, in turn, consists of four mirrored parts that were welded together afterwards. The two side parts were split horizontally and then welded together. It would also have been possible to make one large part each, but the assembly was easier than letting a 2-m robot arm handle the print. But we had some respect for the assembly. For example, the installation space for the floor structure was too small. The rest was put on afterwards, conventionally prefabricated. It consisted of a standard roof structure, glass walls and floor, as well as the door and its suspension.

This “printed” car did not run because the uncertainties are too high. Specifically regarding material safety, no verification is possible. It is walkable, but not drivable.

USB: What was the motivation behind this project?

OS: We aimed to learn the processes and the state of the art. Within the timespan of one year, we completed the calculations and the manufacturing. One and a half people in our house were actively involved in the project in this time, plus the colleagues from the Netherlands.

USB: What was the outcome of the project?

OS: We have shown: “It can be done!” We have learned a lot — also about the limits and weak points. And, of course, we are now asking ourselves: “Is there even more?”

USB: What are your future plans concerning 3D printing at Schindler?

OS: At the moment, we have yet to set up a follow-up project due to the lack of quality assurance for the material. There is a lot of interest in the group to use 3D printing and to run the results in highly visible places. But it is in the nature of our work in the New Technologies Department that sometimes the time is not yet ready. We will continue to monitor the technology, and, perhaps, in a few years, we will move forward with it in concrete terms.

USB: Is there even more potential for 3D printing?

OS: Probably. In our Schindler magazine, we gave some information about a whole building which was already printed in concrete. You can find the article with more details Schindler Magazine.

USB: Would you like to end our Q&A session with a personal statement?

OS: I love my job at Schindler in research. It’s exciting to observe new production processes, think about what we can do with them, try them out and, perhaps, change the future of the industry substantially as a result.

Technical Specifications of the “Printed” Car

Width: 1,200 mm

Depth: 2,100 mm

Height: 2,140 mm

Load: 1125 kg

Weight of empty car: 850 kg

Get more of Elevator World. Sign up for our free e-newsletter.