ISO 25745 Bypasses VDI 4707 as Standard for EPC Measurements

Apr 1, 2017

by Koos van Lindenberg

Since Liftinstituut carried out its first energy measurement on lifts in 2009, the standards based on how these measurements are performed have been developed further and further, with ISO 25745 increasingly taking over the role of VDI 4707-1. Clients increasingly impose demands on the energy consumption of lifts. They want the guarantee that the lift companies deliver on the agreed energy reductions, too. Liftinstituut contributes to this by making the energy performance of lifts demonstrable using advanced measurements toward producing a detailed report for an Energy Performance Certificate (EPC) and energy label to demonstrate a commitment to sustainability.

Measurement During Installation

The energy consumption of a lift depends on the structural circumstances, the manner of installation and the nature of use. Therefore, Liftinstituut measures the energy consumption of the lift after the supplier has installed it, both during operation and in “standby mode.” This measurement and certification is — wrongly — quite often referred to as type certification, a result that applies for each lift of that type. The standard does not leave any room for this, as a lift is a combination of components, and energy consumption is codependent on the manner of assembly and setting. This is quite different in the case of a refrigerator or washing machine, where an energy measurement of a type-characteristic sample will be representative of an entire series.

Standardization

When it began its energy measurements, Liftinstituut used the internationally accepted VDI 4707-1 guideline. In addition, the first part of EN ISO 25745 – Energy Performance of Lifts, Escalators and Moving Walks became available by mid 2012. This standard relates to measurements but was still rather general at the time. For example, this standard did not yet provide an energy label, something the market was specifically asking for, in its first iteration. As a result, the use of this standard remained limited. Only when parts two and three of EN ISO 25745 became available in 2015, the interest in the application of this standard started to grow. These standards were published as EN ISO 25745 Part 2 – Energy Calculation and Classification for Lifts (Elevators) and Part 3 – Energy Calculation and Classification of Escalators and Moving Walks.

Energy Consumption and Lifespan

Willem Kasteleijn, product manager for Lifts at Liftinstituut, is positive about the above developments in the standards, although he does believe they are particularly aimed at energy consumption, and that there is little reference to the relationship with lifespan. Of course, a traction lift is the most energy efficient, but, he says, energy savings must not be made at the detriment of the lifespan of a lift and its components. Therefore, it is important to take the envisaged application into account when selecting a lift. Lifts may have low usage and high nominal load, for example, where a hydraulic unit can offer a sustainable solution while still maintaining an acceptable energy consumption.

What Is Measured?

Lifts

In the case of lifts, energy consumption is measured after having been at a standstill for 5 min. and again after a ride upward, opening and closing of the doors and a ride downward. In EN ISO 25745-2, an additional measurement is taken of the standby power after a lift has been at a standstill for 30 min. The purpose of this additional measurement is to get better insight into the effect of long-term standstill on the energy consumption of the lift, where the installation is given 30 min. to switch to the most energy-efficient standby setting. Also, the EN ISO 25745-2 describes a 24-hr. measuring method, providing a realistic picture specific for lifts equipped with an energy storage system (battery).

Escalators and Moving Walks

In existing escalators and moving walks, measurements are based on the zero load (when “empty” and not in use). However, it is a prerequisite for the escalator/moving walk to have been “warming up” for at least half an hour before the measurement is taken. For new escalators, there is an additional requirement that they must have had at least 1,000 hr. in use before the measurement is taken. The measurements for escalators and moving walks are linked to the characteristics of these installations, such as the angle gradient, width of the pallets and the traveling height. Next, these reference values are compared with the consumption measured, determining the ultimate energy label. The location of the moving walk or escalator and the circumstances of use, therefore, do not play a role when determining the energy label, whereas this does have an impact upon measuring the energy consumption of lifts.

Experiences

Over the years, Liftinstituut has carried out many energy measurements and issued many EPC certificates accordingly. Kasteleijn has been involved in many of these measurements and noticed that measuring the energy consumption of escalators and moving walks is on the increase. He explains:

“Liftinstituut has acquired a lot of experience of measuring the energy consumption and determining the energy labels of all these installations in accordance with EN ISO 25745. Examples of measurements taken on escalators include the energy measurements taken on the escalators at the ‘North-South line’ metro in Amsterdam.”

Independent Measuring of Importance

Kasteleijn explains that clients believe it is important an independently operating body does all energy measurements. He continues:

“In many cases, the first measurement does not yet provide the desired outcome. This is often to do with specific installation settings that are not yet optimal. As we measure in real time, the installer can optimize the settings immediately in order to achieve an optimum energy consumption. This then often leads to a better energy label.”

EPC Certification in Relation to BREEAM

Liftinstituut also deals with EPC certification in relation to the Building Research Establishment Environmental Assessment Method (BREEAM) sustainability label for buildings. Kasteleijn explains:

“For new buildings, the two credit points that can be acquired within the BREEAM certificate for energy-efficient lifts are demonstrated by our EPC certificate. For the first point to be acquired, the minimum requirements are label C for a riding lift and label D for a lift at standby. The second credit point is acquired by label B for a riding lift and label C for a lift at standby as a minimum, based on VDI 4707-1. Liftinstituut has proposed to make the points to be acquired with BREEAM — in use, demonstrable with energy label C for the entire lift, as measured based on EN ISO 25745-2. This proposal has since been adopted. The expectation is that this will also be adopted for BREEAM NL — new construction.

“For escalators and moving walks, BREEAM’s use has since been brought in line with EN ISO 25745-3. An escalator earns the BREEAM credit points having an energy label C or better. Unfortunately, for BREEAM NL — new construction, the old criteria for energy-efficient escalators are still in place. In practice, these criteria have proven to be difficult to verify. We are expecting that BREEAM NL — new construction will be brought in line with this ISO standard soon, too.”

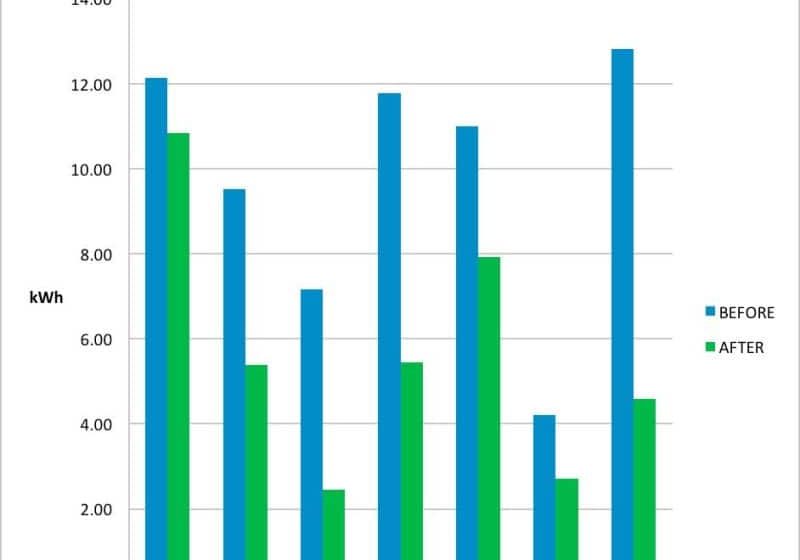

Modernization

When a lift is modernized, an energy measurement is not always considered, although it would be a great opportunity to do so. Kasteleijn elaborates:

“Manufacturers could pay more attention to this by including a calculation for an energy measurement prior to and after carrying out a modernization in their quotation or tender, obviously to be done by an independent body like Liftinstituut. This way, they can show that an investment into this can be cost effective and can be earned back relatively quickly with the energy saving achieved.”

Get more of Elevator World. Sign up for our free e-newsletter.