Alice Luo (AL), CEO, Sicor India, shares insights with your author (SSP) on the company’s customer focus and continuously upgrading its product supply range.

SSP: What is the role of Sicor India within Sicor worldwide?

AL: Sicor, a global entity founded in 1981 in Rovereto, Italy, has been a beacon of Italian engineering excellence. Sicor India, a prominent name in the Indian elevator traction machine industry since 2014, provides the perfect blend of Italian precision and Indian innovation, making us a leader in the market.

SSP: What were the factors that influenced Sicor to enter the Indian elevator market?

AL: As the most recent vigorously growing elevator market, India was always the strategic marketplace in which Sicor was planning to have a physical presence. In 2014, Sicor India was invested in by Sicor Italy at Thandalam, Sriperumbudur, Tamil Nadu, which was connected with KONE for geared machine supply for the local market. Since then, Sicor started its journey in India with continuous geared and gearless machine development and supply for India market as a local manufacturer.

SSP: What is the importance of geared machines and gearless machines by Sicor India for the Indian vertical-transportation (VT) industry? What are its prospects? What advantages does it provide to the elevators installed in the Indian market?

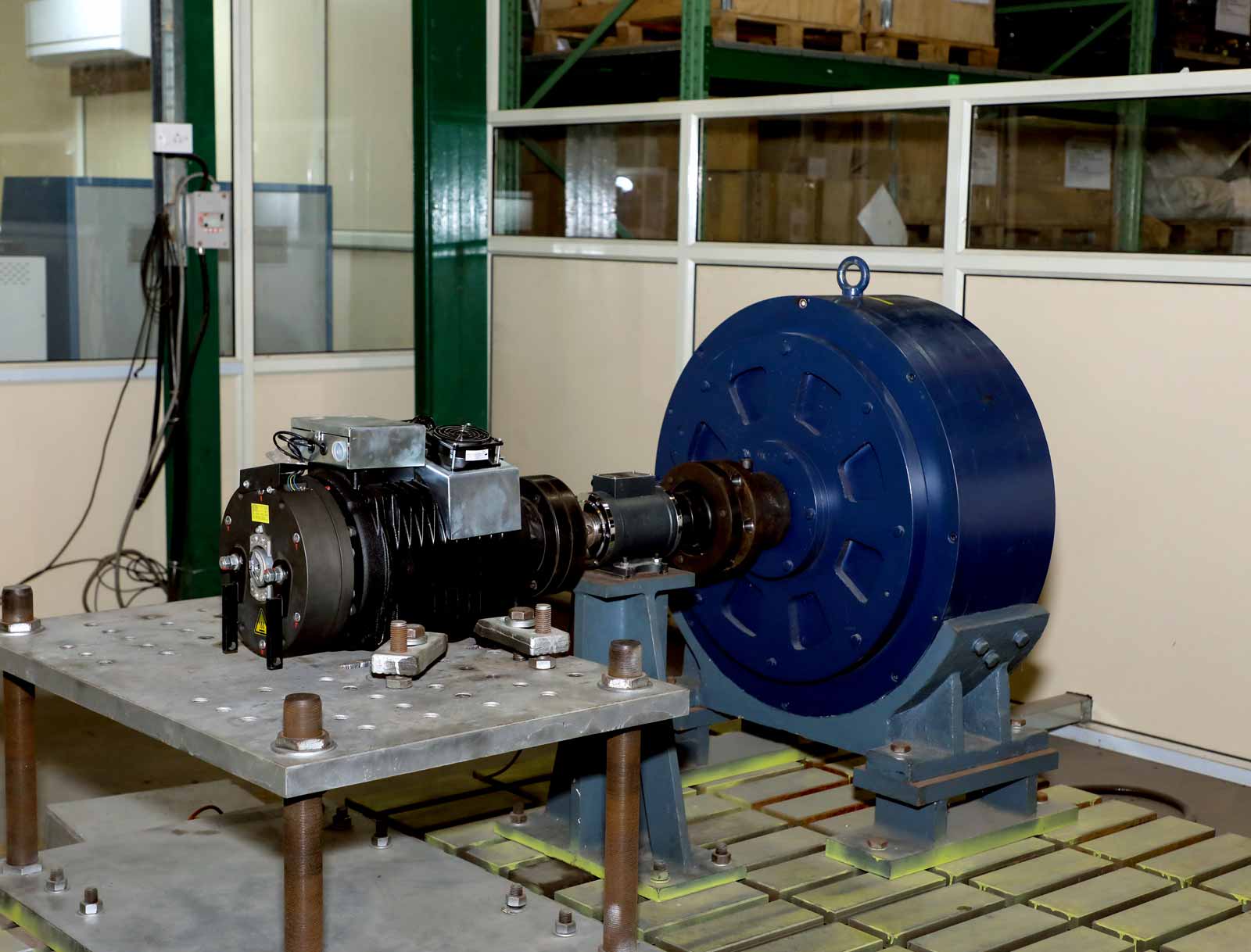

AL: Sicor group supplies a full range of geared products with high automation machining and assembly in Italy. And geared machine supply is maintaining as equal importance as gearless for our global presence. However, we strongly believe that gearless is the trend for Indian market transformation away from geared, with a proven record in the last five years. Therefore, Sicor India is continuously focusing on developing high quality gearless machines, covering a full range of pancake and sausage type machines, capacity up to 26 passengers and speed up to 2.5 m/s, localized and industrialized in India.

SSP: What is the operational setup of Sicor in India? How many manufacturing units are currently operational, and are there any plans for expansion?

AL: Our local manufacturing hub in Kancheepuram, Chennai, and R&D, project and sales management offices in China are the two key operational setups of Sicor India. The company has built a strong local operational team with the leadership of Aravinda Babu and the China management team. We are proud that all the machines supplied by Sicor India are completely made in our Chennai factory.

The maximum annual production capacity is 15,000 units of traction machines with the current manufacturing facility in Kancheepuram. Sicor India is looking for further expansion within the next few years to build larger capacity to address the continuous increasing demand of the Indian elevator market.

SSP: What are the major products by Sicor catering to the Indian VT market, and what are the specific sectors the company is targeting, for instance residential, commercial, retail, etc.?

AL: Sicor India is continuously focusing on the extension of gearless machines for both sausage type (SGI Series) and pancake type (SGP Series). We have products covering a wide range, from home lift applications (4 passengers with maximum speed of 0.6 m/s), residential applications (from 6 passengers to 16 passengers, with maximum 1.75 m/s), commercial mid- and high-rise buildings (speed up to 2.5 m/s, capacity up to 26 passengers), etc.

Meanwhile, our customers will see our new belt type of machine released during the International Sourcing Exposition for Elevators & Escalators (ISEE) show from December 5 to 7, while we are also expanding our gearless machine supply scope up to 3000 kg.

According to various market research reports, the elevator industry market in India is expected to grow at a compound annual growth rate of approximately 10%-12% in the next five years.

Alice Luo, CEO, Sicor India

SSP: How has the experience of operating in the Indian market been? Any specific challenges faced?

AL: Like any other market, India has its own market characteristics and remains a unique market due to its high potential and demand. However, I have been always fortunate to be able to find the best customers to support and help me to understand market needs. Sicor India has been continuously upgrading our product supply range, especially in gearless machines, to fit customers’ needs in the last five years, and is now becoming one of the leading domestic gearless machine manufacturers.

Talking about challenges, definitely, there are more than one, as everybody is aware. However, I want to mention one of the largest challenges that we faced and will continuously face: this is to localize and industrialize the larger gearless machines with completely “Made in India” and with the premium quality of the Sicor standard.

SSP: What are your future expectations for the VT industry in India? How will 2025 be for the VT sector? Any expectations from the Indian Government for smoother operations going ahead?

AL: As urbanization accelerates, particularly in metropolitan areas, the demand for VT is expected to rise significantly. The industry has been witnessing robust growth due to factors such as increasing population density, rapid urbanization and the construction of high-rise buildings. According to various market research reports, the elevator industry market in India is expected to grow at a compound annual growth rate of approximately 10%-12% in the next five years.

We saw that the Indian Government has been proactive in supporting the elevator industry in various ways, including the new elevator safety standard by the Bureau of Indian Standards (BIS) that will be implemented by the end of 2024, which is crucial for ensuring safe operations; more investments in infrastructure, metro rail systems in smart cities and other public transport facilities; and the “Made in India” initiative to encourage local manufacturing of elevator components to reduce cost and improve supply chain efficiencies.

If these measurements can execute consistently, we think it will bring VT sector growth in a healthy and fast direction.

SSP: What are current engineering requirements for high-rise and mid-rise buildings in India to enhance elevator performance, quality and safety, which will play a major role going forward? How are Sicor India products contributing to this aspect?

AL: As an emerging elevator market with great potential, India will continuously develop rapidly to cope with urbanization. We have seen that Mumbai and Chennai are good examples in this aspect. High-speed elevators are key factors in the urbanization with more high-rise buildings, which is creating significant demand for high-speed technology in both lift packages and components.

Product development and production capability for high-speed VT systems will be the key market differentiator, moving forward, for both elevator companies and elevator components companies. This happened in all the other mature elevator markets, such as the U.S., China, etc.

With our core R&D team within Elevantis Group in China and Italy, Sicor India is confident about providing the India market with the products to meet customer demands for high-speed units. As of today, we can supply gearless machines with a capacity of up to 26 passengers and speed of up to 2.5 m/s.

SSP: Sicor India is celebrating 10 years of business operations in India. How does it feel to mark such an important milestone, and what are your plans for the next decade?

AL: It’s been such a privilege to work for Sicor India and witness the growth of the company over the past five years. I would like to take this opportunity to send my sincere gratitude to all our esteemed customers who supported us during the last 10 years. We strongly believe that there are more successful decades to come for Sicor India as we continue our long story of “Made-in-India,” meetings the needs of the rapid development of the Indian elevator industry.

SSP: How has Sicor as a brand advanced and progressed in this country over the past decade?

AL: Sicor India started its geared machine manufacturing journey with a partnership with KONE India for the first few years, which allowed us to start at a high level. With premium quality supply, Sicor India was the best accepted geared machines supplier in India.

On the other hand, we have a team of professionals who have rich experience, sound background in this industry and a comprehensive understanding of elevator traction machines, and who have deep connections and cooperations with top players. People — the human resources — are the most powerful and valuable asset to the sustainable development and growth of the Sicor brand in the Indian market. I am proud of what we have brought into this market with our products and service, and I believe this is of unique value to our customers.

About Alice Luo

Alice Luo joined Sicor India and Fermator Group from 2019 as VP, Sales and Marketing of Asia. Currently she is holds the position of CEO of Sicor India from 2022 as well as director of Sales & Marketing for the U.S. platform of Elevantis Group from 2023. Alice has 20 years’ experience in the elevator industry, 15 years with Nidec (Kinetek) Elevator Group, and was holding VP, Sales & Marketing of Asia from 2015 in the previous company. Her experience is mainly related to elevator traction machines, elevator control systems, elevator door systems and complete high speed elevator packages, etc. She is able to drive the changes of management and operations and integrate teamwork between India, China and Italy within Elevantis Group. She is leading the company to keep developing the new products to meet India market demands and continuously driving company growth.

Get more of Elevator World. Sign up for our free e-newsletter.