It’s a “Sensitive” Elevator

Mar 1, 2011

A look at how load weighing devices feature into modern elevators.

by Don Simons

Technology has been improving the safety and performance of almost everything in our world over the years, and the impact of sensors in the elevator trade is no exception. Everything from determining how heavy a car is, if someone is entering the cab, improving the installation and maintenance of wire rope, or determining if an earthquake has happened are just a few topics covered in this article.

Load-Weighing Sensors

Load-weighing devices are widely utilized in modern elevators. There are several different models to choose from, depending on where the device will be installed, potential loads on the device and the type of output required for the controller. There are also several benefits associated with having load-weighing devices installed. The most obvious is eliminating overload conditions. Most readers have been in an elevator when the maximum weight capacity was exceeded, when the elevator cab is typically quite crowded. While wire ropes and associated components are installed with a generous factor of safety, maintaining the overall load inside an elevator cab to a specified maximum weight is still necessary.

Elevators in high-traffic conditions greatly benefit from having a load-weighing device installed, as they are likely to reach load capacity on more than one occasion. An intelligent load-weighing device can temporarily stop the elevator from operating until someone gets off, thus reducing the load in the cab. Once an acceptable load is detected by the load-weighing device, normal operation is resumed.

Another feature of most load-weighing devices is “hall-call bypass.” If the load in an elevator cab is near capacity, the elevator can be programmed to ignore hall calls until the load has been reduced. Again, once an acceptable load is detected, normal operation is resumed.

Children playing in elevators add costs through wear and tear. A load-weighing device can curtail that activity using “presence detection.” If the load-weighing device detects a load below a minimum weight (65 pounds, for example), it can be programmed to ignore commands, assuming a child is playing in the elevator. It can also be programmed to ignore commands if no passengers are detected.

A load-weighing device can also combine with inverters and controllers to improve pre-torque adjustment, roll-back control and floor leveling. This real-time data flow informs the controller of loads and avoids excessive force when starting, avoids sudden stops when braking and perfects the floor-leveling process.

Light-Curtain Devices

Second, light curtains have had a wide variety of uses for many years. Manufacturing companies have made heavy use of light curtains over the years, primarily to ensure the safety of machine operators. Over time, designs have improved, making them much more dependable and affordable. As a result, cost and size of these devices have allowed them to enter the elevator trade.

History

As passenger elevators became automated, elevator doors were typically equipped with mechanical safety

shoes to ensure that people were not hit and possibly injured by closing doors. The shoes had to make direct contact with the obstruction (such as someone’s arm or leg) to operate.

Because elevator doors were fairly heavy, it took time to slow, stop and reverse the door direction. This often

resulted in personal injury or equipment damage. (A major reason for litigation in the elevator industry was – and still is – passenger injury when entering or exiting an elevator.)

Mechanical shoes were also prone to wear out or be damaged by day-to-day operation. Electrical contacts would corrode, and a significant amount of time and money would be spent on the replacement of this equipment. The cost of repair was aggravated by the inconvenience of downtime. Clearly, a way other than physical contact had to be found to prevent doors from closing on passengers.

Enter the light curtain. Light curtains offer a means of detecting a presence in the elevator door path without actually making physical contact. They also provide signal inputs to hold the doors fully open, while passengers enter or exit an elevator, reducing the potential for physical contact and possible injury. Light curtains allow passengers to move in and out of the elevator freely, holding the doors open as long as light beams are blocked in the door opening.

Operation

Here is a brief description of the operation of light curtains. Light Curtains (also called light grids, photoelectric sensors or door edges) are paired arrays of infrared transmitter elements facing one another in separate housings. The two housings create an array of light, in which each receiver recognizes light from one or more transmitters. When a target (such as an arm or leg) breaks one or more light beams, the receiver no longer sees light from its corresponding transmitter(s) and triggers the output state to change.

A well-designed light curtain incorporates methods of recognizing when its beams have been blocked for a considerable period. Some units incorporate a buzzer/ nudging interface to audibly and physically signal that an obstruction is present and should be moved before the elevator will continue operating. This interface can also provide reduced speed and torque instructions to the closing mechanism to shut the doors gentler and use reduced pressure that causes no personal injury or damage to equipment.

Wire-Rope Tensioning

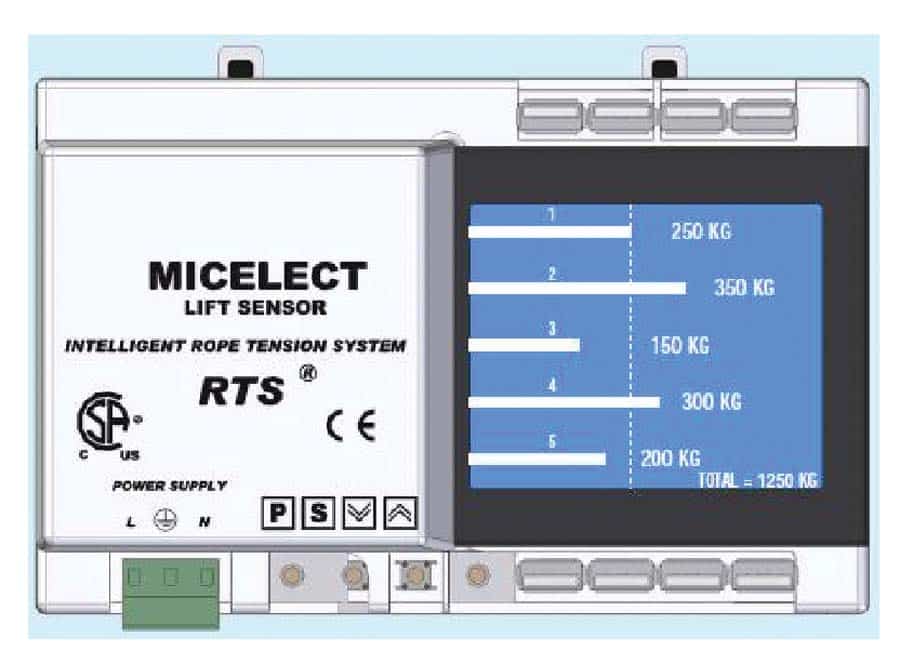

Establishing the proper tension in a set of hoist ropes is one of the most important aspects of elevator installation and maintenance, yet its importance is often overlooked. Proper tensioning of a set of ropes is one of the most critical factors in extending rope and sheave life, improving ride quality and maximizing cost savings. Proper tension adjustment ensures that each rope assumes an equal share of the total required load (Figure 1).

When ropes operate at different tensions, service life is not optimized simply because some ropes are performing more work than others. When the difference in tension among a group of ropes becomes appreciably large, all sorts of undesirable conditions may occur. The most common problem that occurs as the result of varying tension is uneven wear on the traction-sheave grooves. Ropes with high tension tend to reduce in diameter, placing excessive pressure on the sheave groove. They become deeply seated in the grooves and cause abrasion to the sheave (Figure 2).

Conversely, ropes with low tension tend to slide along the sheave grooves in a fashion not unlike that of a saw. The result is excessive abrasion to the sheave. The uneven groove wear produced by these differences in tension makes ropes operate at different speeds to compensate for the differences in groove depths. The net result is reduced rope and sheave life (leading to higher maintenance costs in the long run).

It is also important to note that ropes passing over uneven sheave grooves can never be properly tensioned. Replacement ropes will last only a fraction of their expected life, and each set of replacement ropes will have progressively shorter life due to differences in the sheave grooves.

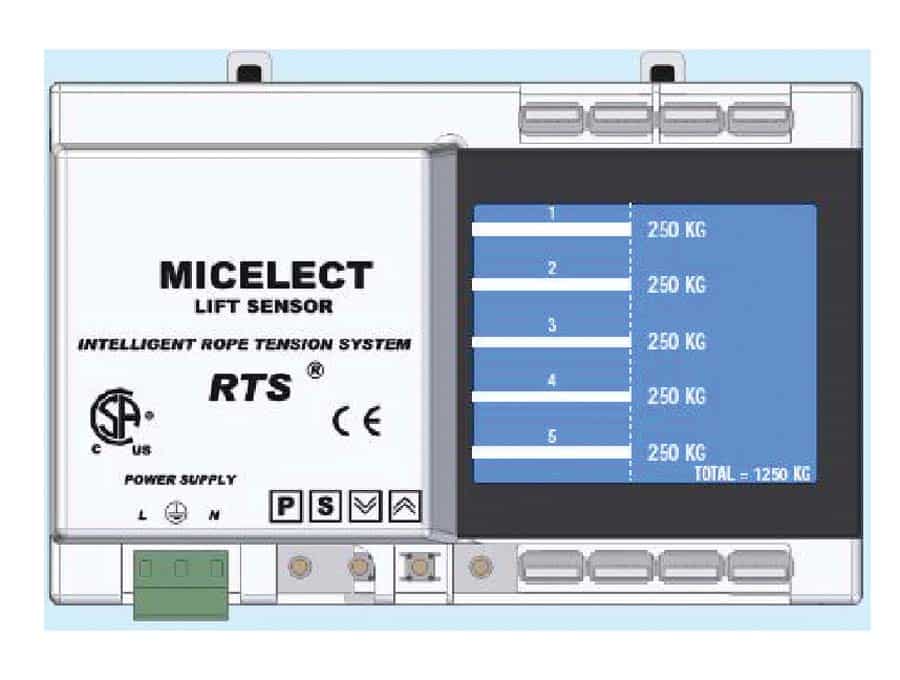

There are several ways to check the tension of the ropes, from “plucking”, to utilizing an analog rope-tension gauge, to a multiple sensor and control box with an LCD display for real time adjustments. For now, let’s explore the

latter. The system is comprised of two basic components. Individual sensors are attached to each rope to provide tension readings for individual ropes. The sensors are connected to the control box, which provides a graphical representation of the tension in each rope on a large LCD display (Figure 3). The user simply reads the tension in each rope and makes the necessary adjustments, eliminating test weights, calibration and guesswork (Figure 4).

In summary, maintaining hoist ropes in proper tension can greatly reduce unnecessary wear to sheaves and hoist ropes, and virtually eliminate the potential of early sheave and/or rope replacement.

Seismic Sensors

An earthquake, even a light one, can distort or break the precisely aligned components of an elevator system. Possible damage due to a seismic event includes derailed counterweights (which could collide with the cabs), damaged or unseated wire rope, and broken or damaged rails or guide rollers. Even a small tremor could bend a rail bracket and cause eventual failure of the rail months later. An intelligent seismic detection system can keep passengers safe by quickly getting the elevator to the nearest stop and prompting the passengers to exit the cab. Seismic countermeasures are fully addressed in ASME A17.1. Safety Code for Elevators and Escalators.

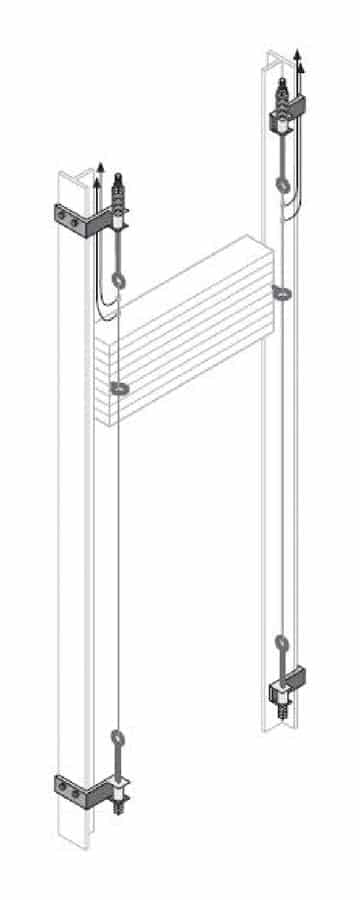

Modern elevator systems have a couple of ways to determine if they have sustained damage due to an earthquake. “Ring on a string” counterweight displacement hardware is a simple way to detect counterweight-derailment. Two steel cables run parallel to the counterweight guide rails and pass through a pair of eyebolts located on the counterweight (Figure 5). If an eyebolt contacts a cable (which indicates counterweight displacement), an electrical circuit is completed, which tells the controller to stop and redirect the car immediately.

A more exact way to determine if and when an elevator should be shut down is an electronic seismic detector that senses and measures acceleration on all three axes. If this motion, measured in G’s, exceeds a programmed limit, the detector signals the elevator controller to stop the cab at the nearest floor to permit a safe and speedy exit by the passengers.

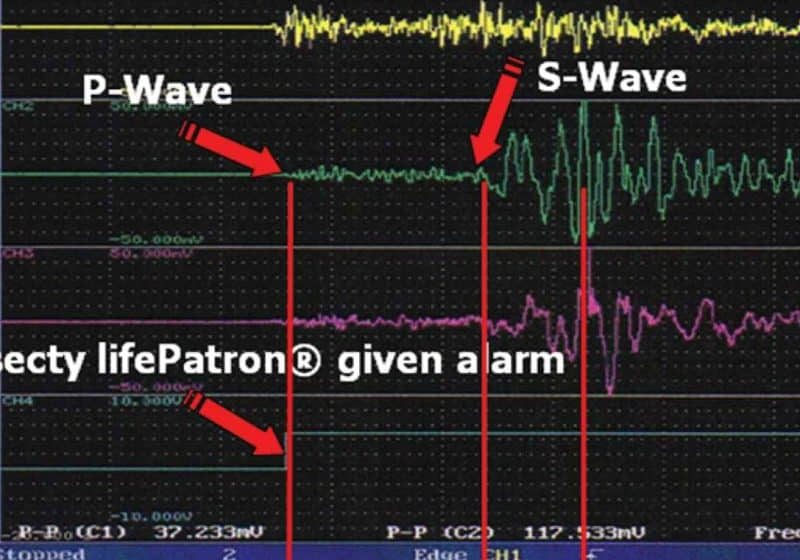

A fully featured seismic sensor (like the Draka P/N 010-4-0005 shown in Figure 6) detects both primary (P) and secondary (S) earthquake waves and will act accordingly. When the sensor detects a P wave of sufficient amplitude, it will send a signal to the elevator to stop at the nearest floor and allow the passengers to exit the cab before the more damaging S waves arrive. The elevator will remain out of commission until it is repaired and reset by a qualified technician. The product will also record the date, time, duration and peak acceleration in each axis for a seismic event that it detects. This can aid engineers in determining the extent of any damage.

Today’s Smarter Elevator

The use of sensors in elevators today has improved safety and efficiency. The elevator controllers are now able to receive much more precise data, making better use of power requirements and getting the public where it needs to be faster. These sensors are assisting other initiatives in our industry to become more “green.”

These are just a few of the sensors utilized in the elevator trade today. Their reliability, improved safety and durability are just a few points by which they help sensors make elevators more affordable for building owners and safer for the general public.

Get more of Elevator World. Sign up for our free e-newsletter.