Precise measurement key to success for escalator modernization project in Türkiye.

submitted by Löher

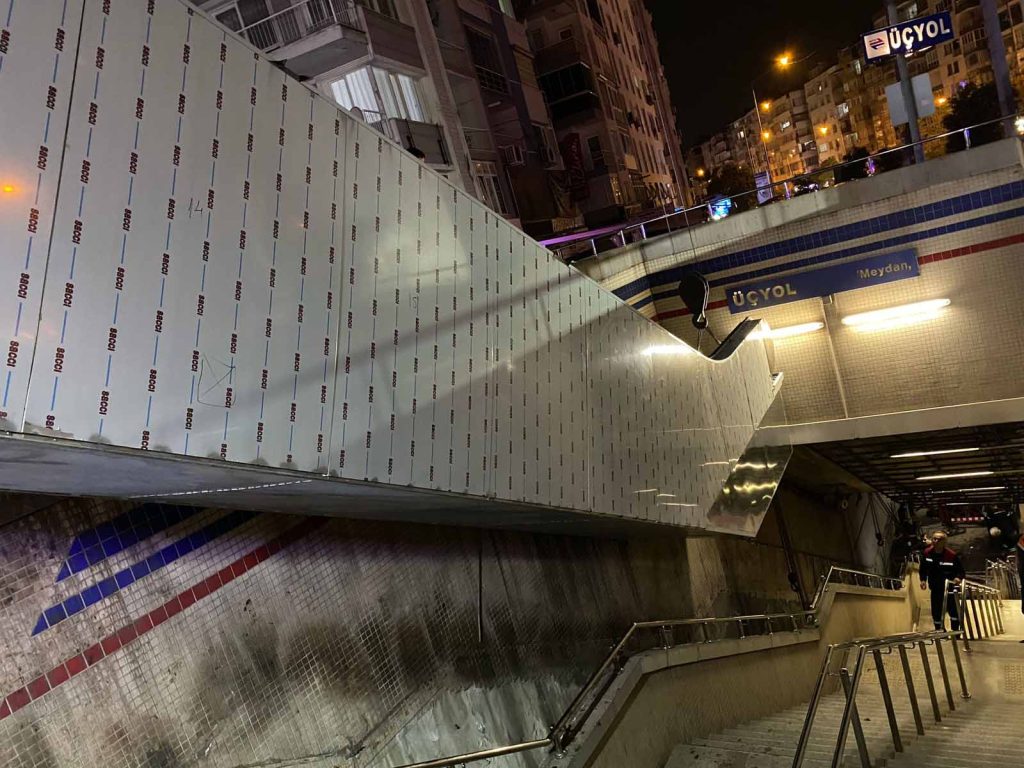

A crucial step in achieving outstanding project design is capturing precise and current measurements. When Löher modernized an escalator at İzmir Üçyol Subway Station in Türkiye, the height, top and bottom entry dimensions of the old escalator were not precisely known, so Löher had to determine the exact dimensions. For this process, the company’s expert installation team took numerous measurements to achieve accurate results. This was one of the most challenging tasks of the project. Given the location of the old escalator between the wall and the stairs, as well as the subway station’s location, incorrectly determining the exit height could have resulted in the escalator failing to fit into its original location. That could have doomed the entire project from the start.

Analyzing Processes To Solve Problems

While the Löher installation team took necessary measurements for the new escalator design, the escalator pitch was not visible since the old escalator was still in place. So the Löher installation team prepared a way into the pitch from the machine room section of the old escalator. Descending into the pitch using a folding ladder, the team discovered that the lower pit was filled with water and debris. This unwanted debris could not be completely removed while the old escalator was in place, making accurate measurements extremely difficult. Despite myriad challenges, the team took all the important measurements so the escalator design process could begin.

Prioritizing Passenger Safety

Due to its location, Üçyol Subway Station experiences high passenger traffic. Therefore, the escalator was designed for heavy-duty operation. All calculations (escalator motor power, motor chain and step chain) were made assuming the escalator would operate at full capacity. Passenger safety was paramount, and two motors were used to drive the main gear. These two motors operate in synchronization, ensuring that if either motor fails, the escalator will continue to operate safely.

All subsystems of the escalator were designed with safety as a priority. Each subsystem is monitored by dedicated safety sensors and safety devices/systems with real-time response, and the escalator goes into emergency-stop mode in the event of any threat.

Custom Solutions

In addition to the standard systems of all Löher escalators, the company offers customer-specific options. These include area scanning, error recording, automatic lubrication, skirting lighting, handrail lighting, a sprinkler, a heater and an oil-water separator. The error recorder and automatic lubrication system were used in the Üçyol Subway Station project. Furthermore, mechanical brakes were used to eliminate the risk of injury during the maintenance period. A drainage pit was created in the lower pitch of the escalator. As an additional feature, the escalator can be operated bi-directionally in the desired direction.

Löher cooperates with various brands for escalator components (step chain, motor chain, handrail, etc.). In this way, the company is able to make the sales price of the escalator affordable by offering different options.

Energy Savings

Löher escalators operate with a radar system, running only when they detect a user. The units switch to standby mode at all other times, increasing efficiency.

Old Escalator Dismantling

Due to safety precautions, the old escalator was not removed until the new Löher modernized escalator arrived at Üçyol Subway Station. Once the new unit arrived, the Löher team carefully removed the old escalator and delivered it to the Izmir Metro Co. Inc. warehouse. Löher, acting as the contractor, was responsible for all processes up to and including delivery of the old escalator to Izmir Metro Co. Inc.

Escalator Installation

The Löher expert transportation and installation team ensured the escalator arrived safely at its operating location. The cranes and hoists needed to carry the unit were selected based on the necessary calculations. After installation was complete, the team conducted final checks and tests, and the new escalator was deemed operational and ready for delivery to its owner.

Robust Solutions for Stronger Structures

The truss system of the designed outdoor escalator was to be hot-dip galvanized to increase its strength. This truss system was too large for both this process and single-piece transport, so the unit was designed to be split into two pieces.

Löher stays with customers throughout the lifespan of a project, with the goal of ensuring any piece of equipment — including this escalator — has a long lifespan. The company’s maintenance team also provides periodic inspections and maintenance services. As long as a maintenance contract is in place, Löher ensures any piece of vertical-transportation (VT) equipment continues to operate safely for many years.

Get more of Elevator World. Sign up for our free e-newsletter.