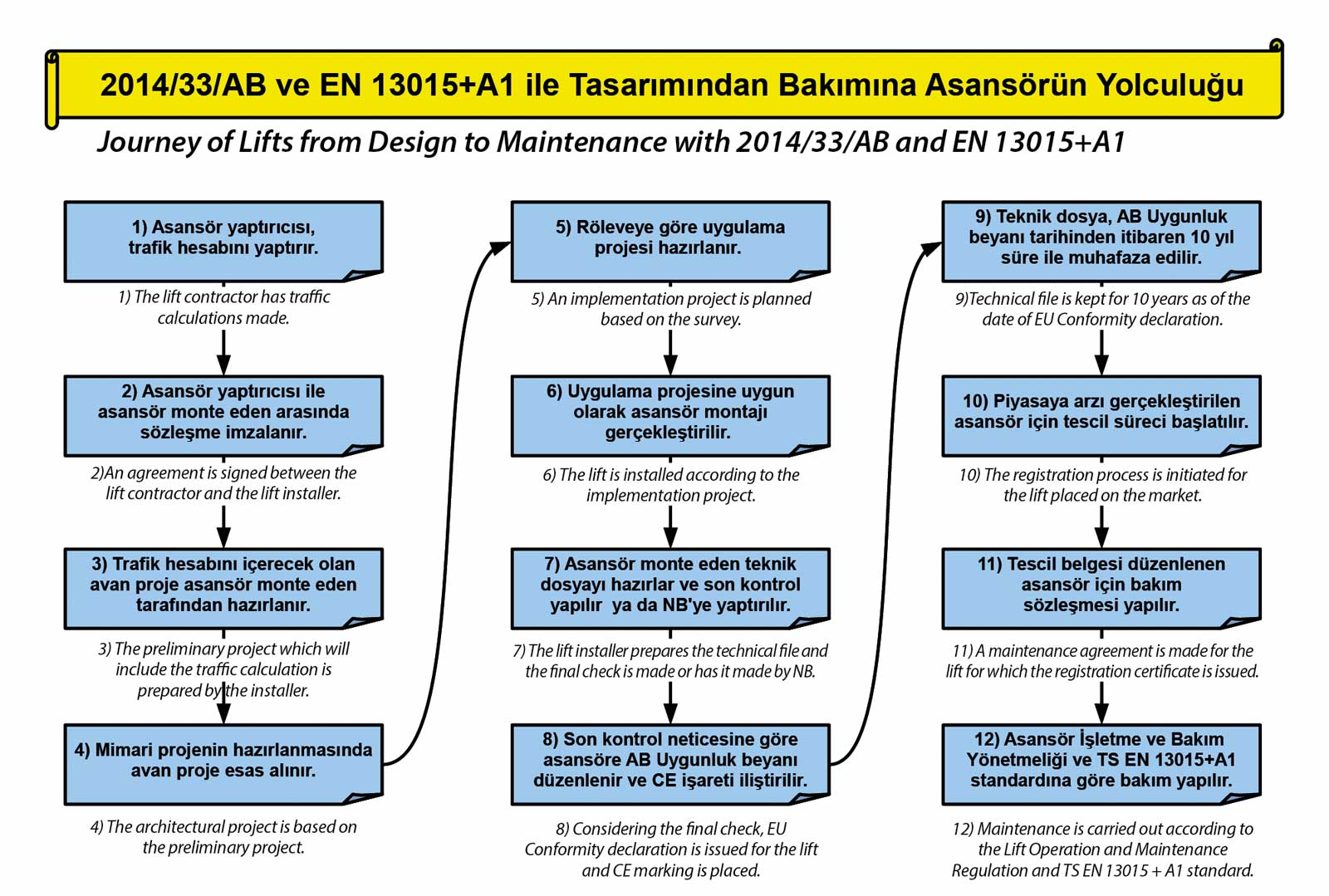

Journey of Lifts From Design to Maintenance

May 21, 2024

As our subject is lifts, it is necessary to begin the article with “Product Safety and Technical Regulations Law” No. 7223. The approach to the lift is properly communicated in the title of this law, isn’t that so?

Product safety and technical regulations …

The purpose of the law is “to ensure that products are safe and in accordance with the relevant technical regulations; to determine the duties of authorized bodies through market surveillance and the liabilities of conformity assessment bodies through economic operators.”

Although we have not yet succeeded in this matter, the law expresses its purpose quite clearly.

Besides, Article 5 of the Law sets forth everything clearly. Unfortunately, the rest is up to us humans to implement.

Product safety

“ARTICLE 5- (1) The product must be safe.

(2) The products that conform with the provisions of technical regulation regarding human health and safety are considered safe until proven otherwise.

(3) In cases that technical regulation is not available or does not contain provisions on human health and safety, the evaluation regarding the safety of a product is conducted according to general product safety legislation.”

It is mandatory that the lift and the components that make up a lift are safe. How can we understand this? The subparagraphs 2 and 3 explain it quite simply. Product safety is directly associated with whether the product conforms with technical regulations.

Given the industry in Türkiye, all lifts and the components that bring them together are tested, checked and inspected in certain ways to see if they comply with the relevant technical regulations. Then why do we still face numerous accidents in a market where all these tests and controls are conducted?

What lies behind this situation is hidden in the expression “10 years” included in various sections of the law. The law generally states that the documents and technical files regarding the conformity of a product placed on the market should be kept for 10 years and should be submitted to the authorized organization upon their request. It should not be understood that only a few pieces of paper should be kept for 10 years. It means that the law assumes that the relevant products will be used for at least 10 years. In this context, it should be understood that the product must meet the safety requirements for at least 10 years. I don’t want this sentence to be misunderstood. The product launched to the market following technical regulations must be in circulation under the definition of an absolutely safe product for at least 10 years. It should not be inferred that the product is not necessarily safe after 10 years from now.

Is this 10-year period taken into account when products are designed, manufactured, assembled, tested and controlled? If we are to speak about lifts when a technical file is requested for any lift in its seventh year, is it possible to respond immediately? Do the components in technical file match the components on lift? What is the reason for a change of a speed regulator that is replaced in the fourth year? What is the reason to change an engine that is replaced in the sixth year? Does a buffer that is 5-years-old still have the labels on it? Are we able to place our products on the market in a way that they will have at least 10 years of lifetime?

We should answer these questions sincerely. We should focus on the correct solutions to these questions. Otherwise, we cannot reap the fruits of this law.

How can we answer these questions correctly? Article 12 of the Law explains how we can answer such questions.

Traceability

“ARTICLE 12– (1) Economic operators regularly keep records of the name, trade name or brand and contact information of the previous and, if any, the next economic operator in the supply chain, as well as other information that will facilitate the tracking of the product, maintain the product at least ten years as of the date they place it on the market or make it available on the market, and they offer the product according to the demand of the authorized body.

(2) The obligations specified in the first paragraph are also valid for those who place or make available a product on the market in electronic form, intermediary service providers who provide the electronic commerce environment for the economic and commercial activities of others, and media service providers such as radio and television.”

Traceability, which is insufficient in practice in Türkiye, shows itself as another problem. The article is quite simple and clear, I suppose? For some reason, we lack of reading and understanding laws and the culture of living according to laws.

We expect the laws that we do not practice to protect our rights …

We should elaborate on Law No. 7223 first while placing a lift on the market. Then, we must understand the General Product Safety Regulation published in the official gazette dated 11.03.2021 and numbered 31420. However, we should read the “CE” Marking Regulation published in the official gazette dated 27.05.2021 and numbered 31493. Afterward, we will look at the Lift Regulation 2014/33/AB which will be deemed as a constitution for lifts under the light of these documents.

“ARTICLE 1 – (1) The purpose of this Regulation is to determine the basic health and safety requirements that lift and lift safety components must meet, the conditions for supplying these products to the market and the principles of market surveillance and control.”

The Lift Regulation is in full compliance with Law No. 7223 in terms of its purpose. I have no hesitation in stating this clearly: When a lift or lift safety components are placed on the market in full compliance with this regulation, the risk of an accident in that lift is almost zero. In other words, if an accident occurs in a lift, the provisions of the regulation were not fully implemented when the lift was placed on the market. Incomplete implementation of the regulation provisions does not mean that only the person who places it on the market is guilty. When we read the regulation carefully, all parties, especially the “Ministry” are responsible for the implementation of regulation provisions.

A problem catches my eye while implementing the regulation. Lift Regulation 2014/33/AB, which we will consider as our constitution, seems to have been pushed aside. Only the modules of the regulation are taken into consideration. Whether they are implemented in full or not is also another question mark …

When it comes to installation, TS EN 81-20 and zoning regulations are mentioned; when it comes to manufacturing, TS EN 81-50 is mentioned; and when it comes to application, only “Lift Operation and Maintenance Regulation” and “Lift Periodic Control Regulation” are mentioned now. Standards have begun to be put before the 2014/33/AB Lift Regulation. In fact, I have witnessed several times that expressions such as “it is like this or that in the regulation” are used when discussing a subject on standards or conveying the content of a standard. Of course, these documents are important and should be followed. However, if they are implemented without understanding 2014/33/EU, they will never give correct results. And that will cause different problems.

Let’s clarify all these statements a little more. The conditions that lifts must meet when placing them on the market are included in Annex I of the Lift Regulation under the title “Basic Health and Safety Requirements.” These conditions should be implemented through evidence with mathematical calculations by the organization/person placing the lift on the market. The purpose is always to implement the “Basic Health and Safety Requirements” under all circumstances. TS EN 81-20, TS EN 81-70, TS EN 81-72 and TS EN 81-73 standards are means that are used to fulfill “Basic Health and Safety Requirements.” Standards are documents that facilitate our work to prove that we follow such requirements. We do not use these standards randomly, nor do they become mandatory to apply just because TSE publishes them.

Presumption of conformity regarding lifts and lift safety components

“ARTICLE 17 – (1) Lifts and lift safety components that comply with the harmonized standards, the reference numbers of which have been published in the Official Journal of the European Union, or the corresponding harmonized Turkish standards or their relevant parts, are assumed to comply with the essential requirements specified in Annex-I as part of these standards or their relevant parts.”

The standards are used for proof of Annex I, thanks to Article 17 of the Lift Regulation. It would be legally wrong to attach more importance to the standards.

Let’s see how this connection is established. In the Annex-ZA section of the standards, it is stated which “Basic Health and Safety Requirements” the relevant standard and regulations meet. In this way, the regulation-standard connection is established and those who place the product on the market fulfill their legal responsibilities.

Going back to the beginning, product safety required by Law No. 7223 is fulfilled through this sequence.

On the other hand, implementation of zoning regulations is another legal obligation. However, it is not directly related to product safety. Since the issue of zoning regulations will be the subject of a different article, I will not cover it in this article.

Let’s see the regulations on the use of lifts.

“Lift Operation and Maintenance Regulation” and “Lift Periodic Control Regulation,” where will we position these two regulations? In fact, these documents embody the responsibilities given to the Ministry by the 2014/33/EU Lift Directive, so to speak. Even though they have some shortcomings, it is mandatory to implement them.

Why am I stating that they have some shortcomings? Because, while preparing these regulations, law no. 7223 and this law together with the General Product Safety Regulation, “CE” Mark Regulation, 2006/42/EC Machinery Safety Regulation, and 2014/33/EU Lift Regulation should be taken as the basis, respectively. However, these two regulations contradict these documents in certain places. Of course, such a contradiction also manifests itself in the form of wrong practices in the field.

I will give a simple example. Paragraph 7 of Article 10 of the Lift Operation and Maintenance Regulation contains the following statement: “The lift installer is obliged to provide spare accessories and spare parts for each type and feature of the lift that it places on the market for at least three years.” This statement contradicts the ten-year period I particularly focused on.

The main purpose of the Lift Operation and Maintenance Regulation is already clear from its name.

“ARTICLE 1 – (1)The purpose of this Regulation is to determine the rules to be followed regarding registration, operation, maintenance, warranty and after-sales services, service inspection, and improvement of existing lifts to ensure that the lifts used for the transportation of people, people and loads or only loads are used in a way that does not threaten the safety of human life and property and the environment is protected. ”

We must carry out regular maintenance activities to ensure product safety in lifts. Therefore, this regulation is greatly important for us. Articles 8, 9 and 10 of the Regulation specify maintenance, scope of maintenance and other issues related to maintenance. I want to discuss some of the subparagraphs of these articles.

In the 3rd Subparagraph of Article 8, it i stated that:

“Declared load of the lift placed on the market, declared speed, drive type, motor serial number and power, technical specifications of ropes and/or chains and parts and parts requiring type control certificate, facility plans, and electrical circuit diagrams, lift periodic control results and lift log book -where accidents will be recorded- are provided by the lift installer who places it on the market. In addition, the lift’s identification number, date of placement on the market, and registration date are indicated in the lift log book. In case the lift log book is completed fully, the new book is provided by the lift installer or their authorized service who signs a maintenance contract with the building responsible person. The completed log book is kept by the building responsible person so long as the lift’s lifetime. All requirements regarding the log book also apply to all lifts currently in use.”

In the 4th Subparagraph of Article 8 it is stated that:

“Disposal of waste generated after lift maintenance, repair, and service is carried out per Environmental Law No. 2872 dated 9/8/1983.”

. I think these paragraphs are ignored by our companies in practice.

In the 1st Subparagraph Article 9:

“The maintenance of the lift and all parts and components that make up the lift is carried out per the instructions in the maintenance manual prepared by the lift installer and the requirements specified in the current TS EN 13015: Maintenance of Lifts and Escalators, Rules for Maintenance Instructions standard.”

We refer from this subparagraph that maintenance activity in lifts is built on two basic issues: the maintenance manual to be prepared by the person who places the lift on the market and the TS EN 13015 standard.

TS EN 13105 includes rules for maintenance instructions.

Speaking of maintenance, it is necessary to focus a little on TS EN 13015. In the introduction part of the standard, it is stated that “The functioning of the facility in a safe and designed manner can only be guaranteed by correct and preventive maintenance carried out by expert maintenance personnel in accordance with the maintenance instructions.”

According to the explanation by the standard:

“3.6 Installation means fully installed passenger lift, freight lift, accessible goods-only lift, service lift, escalator or moving walk.”

From our perspective, installation in this statement refers to the lift. The sentence should be read word by word. For the lift to be operated safely, correct and preventive maintenance activities must be carried out by “expert maintenance personnel” under the maintenance instructions.

Correct and preventive maintenance is a MUST for safety of a lift!

Let’s get to the care instructions. TS EN 13015 obliges the supplier of lift safety components to prepare the maintenance instructions for these components and to provide them to the lift installer. Besides, the person installing the lift is responsible for preparing the maintenance instructions for the lift and providing them to the facility owner. Because the maintenance instructions will guide the maintenance organizations in carrying out the maintenance of the relevant lift. Correct and preventive maintenance can thusly be carried out.

While preparing the maintenance instructions for the lift, the following should be taken into consideration: the technical specifications and intended use of the lift, the environment in which the lift is located, restrictions on use, the risk assessment result to be prepared for the lift and the building in which it is located, the maintenance instructions for the safety components, and then maintenance instructions provided by the relevant manufacturers for components that are not safety components but require maintenance.

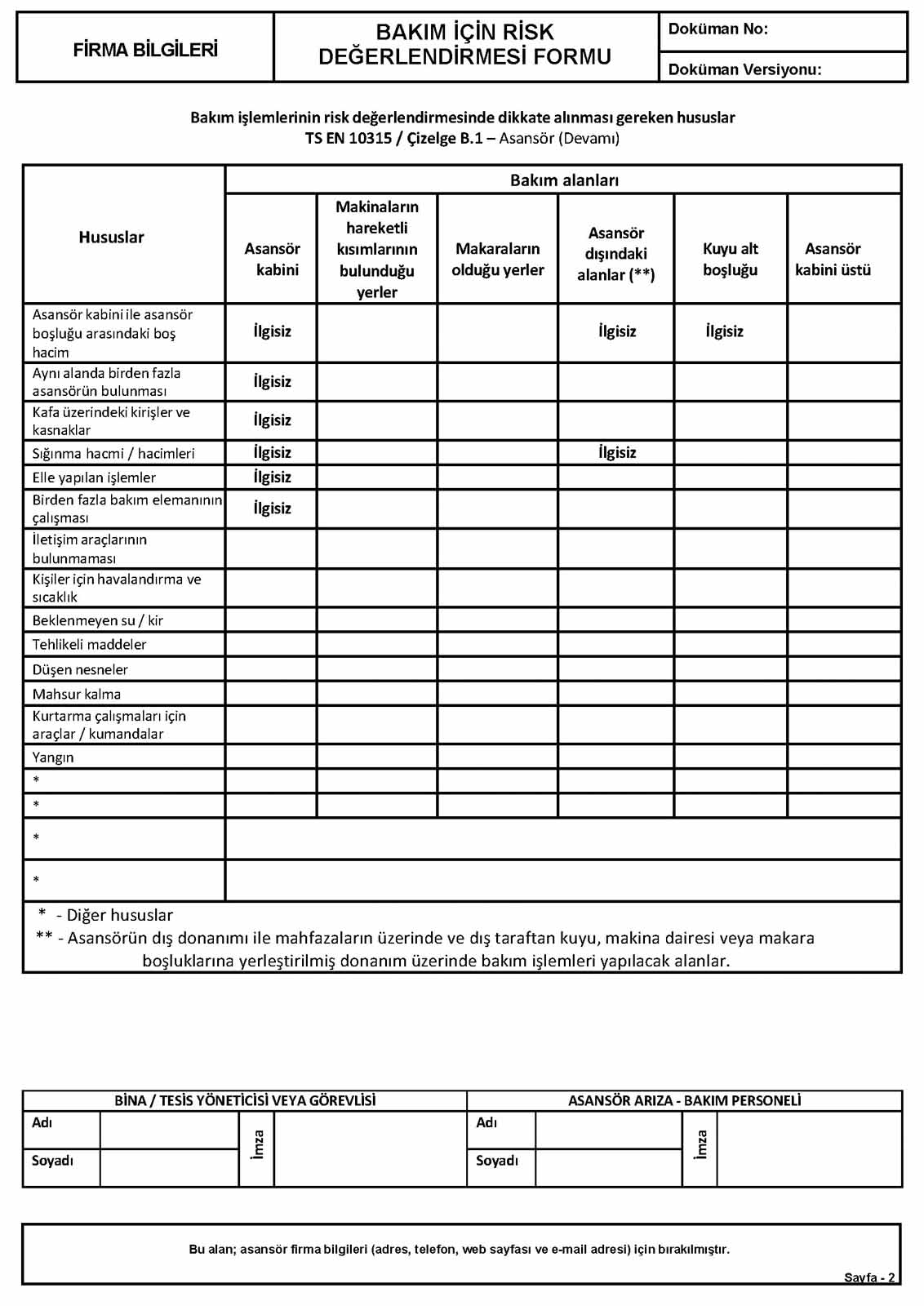

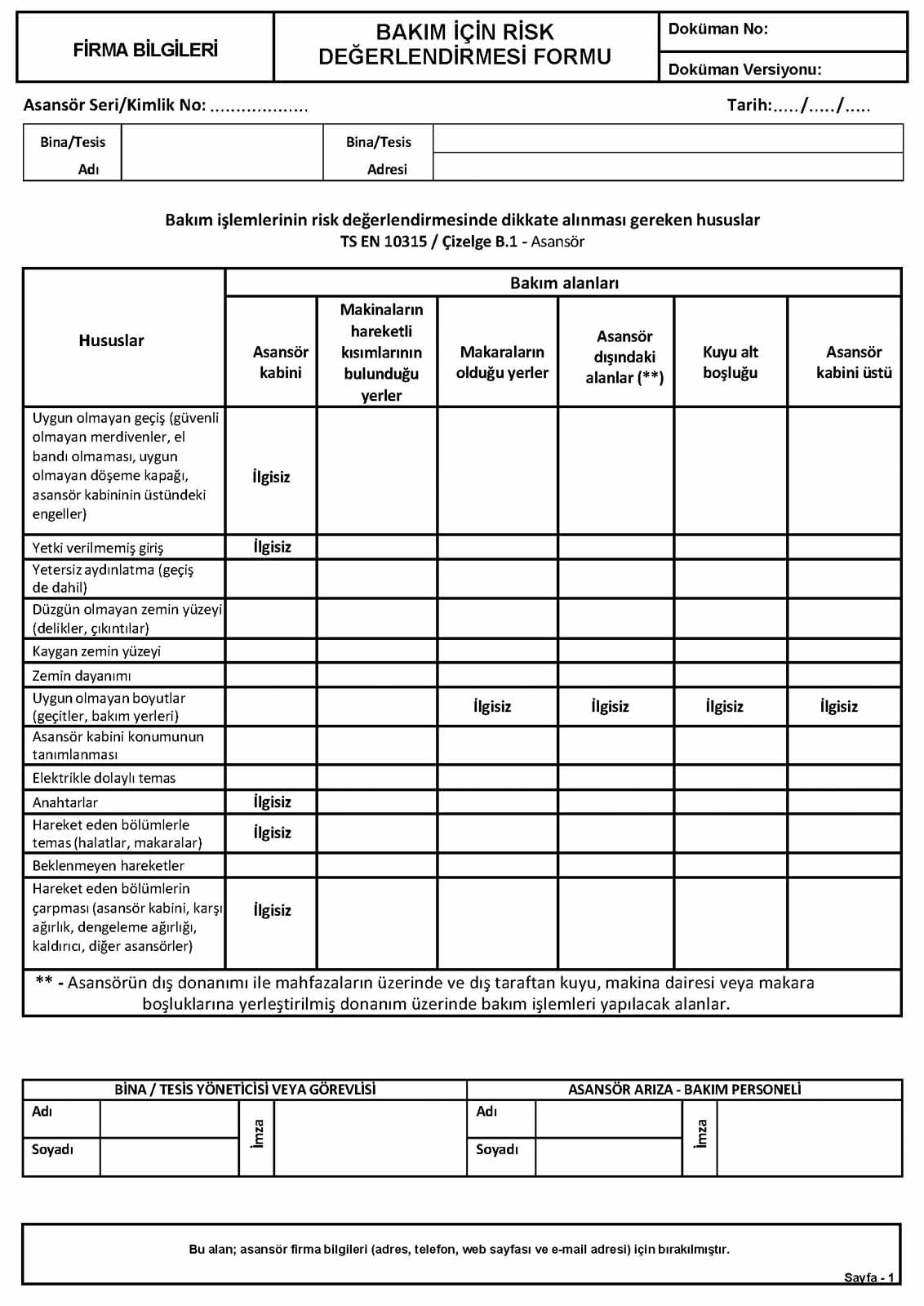

Regarding the mentioned risk assessment, a chart is given for informational purposes in Annex-B of TS EN 13015. On the other hand, security measures must be taken regarding these risks. Lift-related precautions must be ensured by the lift installer. Building-related precautions must be ensured by building responsible person.

The following statement is given in article 4.3.1 of TS EN 13015.

“Maintenance instructions must contain information regarding the duties of the facility owner and the maintenance organization respectively.”

At this point, I would like to touch upon the duties that the standard determines for the building responsible person one by one since, in our country, there is a common perception that all responsibility belongs to the person installing the lift. The responsibility is actually shared. The trick in this sharing is that the duties of the building responsible person must be reported to the building responsible person through the maintenance instructions prepared by the lift installer.

Let’s look at the duties of the building responsible person, which should be stated in the maintenance instructions:

“

- Building responsible person should operate the lift safely. To achieve this, it is necessary to work with a maintenance organization that complies with the rules of the standard.

- The building responsible person should work with an insurance company that provides full coverage.

- The building responsible person must follow and take into account national regulations and rules regarding maintenance.

- It should be ensured that the planned maintenance is carried out by the maintenance organization when the lift is first commissioned or before it is put into operation or when it is closed for a long time.

- If there is more than one lift sharing the same shaft or machine room, the building responsible person must have these lifts maintained by the same maintenance organization.

- A communication system complying with TS EN 81-28 standard for passenger/freight lifts must be provided by the building responsible person. This system should be active for 24 hours. In case the communication system is out of use, the lift must be kept from service by the building responsible person.

- The building responsible person must take the lift out of service in dangerous situations.

- The building responsible person should inform the maintenance organization:

- a. after any abnormal operation of the lift or abnormal change in its environment,

- b. after taking the lift out of service in case of a dangerous situation,

- c. after any rescue operation performed by authorized and instructed person(s),

- d. before any changes regarding the lift and/or its surroundings or the use of the lift, (the building responsible person must obtain maintenance instructions from the company that made the relevant changes and give them to the maintenance organization.)

- e. before performing any work on the lift other than inspection or maintenance work carried out by authorized organizations,

- f. before the lift is taken out of service for a long period of time,

- g. before the lift that has been closed for a long time is put into service again.

- The building responsible person must take into account the result of the risk assessment carried out by the maintenance organization.

- Building responsible person should ensure that risk assessment is made:

- a. when the maintenance organization is changed,

- b. when the building and/or lift usage is changed,

- c. after a major change in the lift or building,

- d. in case of an accident related to lift.

- The building responsible person must ensure, through risk assessment, the following.

- a. The outbuilding is safe and does not pose a health risk as long as it is used. This issue also includes access to outbuildings and lifts, and the tools or substances used in the workplace per the work equipment usage legislation.

- b. People using the outbuilding are informed about all the remaining risks.

- c. Any activity to be completed is carried out at the end of risk assessment.

- The building responsible manager must especially inform the facility owner’s maintenance organization of the following, depending on the access routes for maintenance personnel to restricted areas.

- a. Passage routes to be used and fire evacuation procedures from the building,

- b. A place where keys to areas restricted to maintenance personnel can be found,

- c. If necessary, individuals who will accompany the maintenance organization to the facility,

- d. If necessary, personal protective equipment to be used on passageways and the probable location of this equipment.

- Building responsible person must ensure that the name and telephone number of the maintenance organization are available to those who will use the lift at all times, are permanently attached and are clearly legible.

- The building responsible person must ensure that the keys to the machine and pulley room doors (floor covers), inspection and emergency doors (floor covers) are permanently available in the building, and that these keys are used only by authorized persons for passage purposes.

- The building responsible person must, in all cases, ensure safe passage into the building and the lift for the maintenance organization involved in the rescue of persons.

- The building responsible person must keep the passage to workplaces and work rooms safe and clear for maintenance personnel and must inform the maintenance organization of any danger or changes in the workplace and/or passageways (lighting, obstacles, ground conditions, etc.).

- In addition to these inspections and tests that the building building responsible leaves to the maintenance organization, he must carry out the following at periods of his own choosing:

- 18- For the lifts:

One full take-off between the top and bottom floors to assess any changes in cruising quality or equipment damage.

Know-how is checked to ensure that the following are present, undamaged and functioning correctly:

- Stop doors and bottom doors rails,

- Precision to stop on the floor,

- Indicators that are not located in areas restricted to maintenance personnel,

- Stop movement controls,

- Lift car movement controls,

- Door opening controls,

- Two-way communication tools located in the lift car, which provide continuous communication with the rescue service,

- Normal lighting of lift car,

- Route-changing mechanism for the doors,

- Safety signs/pictorial warning signs.”

Such maintenance instructions, which will be prepared by the standard lift installer, also include instructions on the following topics.

- Information to be given about the duties of the maintenance organization that will perform the maintenance activity,

- Risk assessment,

- Information to be provided regarding rescue operations,

- Markings, signs, pictorial warning signs, and written warnings,

- Format of maintenance instruction manual,

As we approach the end of the article about safe lifts…

In fact, I would like to touch upon an issue that we do not often come across in practice, but which I think will be significantly beneficial when implemented. The risk assessment section of the standard includes the following statement: “The use of fault detection systems (for example, a remote monitoring system based on EN 627) can support the detection of faults, improve the availability of the facility, and reduce the likelihood of maintenance personnel being exposed to hazards.” Accordingly, companies that install lifts must develop an application (software) or incorporate an existing application to monitor and manage maintenance processes. Naturally, with this application, preventive maintenance processes will be operational. In this way, many possible maintenance-related hazards will be prevented.

Concerning the maintenance of the lift, all parties must learn and fulfill their responsibilities by ensuring the TS EN 13015 standard. This will ensure safe operation of the lift throughout its lifetime.

Another issue that is important during the life of the lift is modernization. For the modernization process to be carried out in lifts, the 2014/33/EU Lift Directive should first be taken as a guide. The technical file must be checked and the operations to be performed must be added to the technical file in an accurate and up-to-date manner.

Modernization

Of course, the modernization process must be implemented in a way that meets current security requirements. For this, the provisions of the TS EN 81-80 “Lift – Safety rules for construction and installation – Existing lift – Part: 80 rules for improving the safety of existing passenger and freight lift” standard must be met. The current version of this standard was published by TSI in 2019 in our country. The fundamental difference between the earlier versions is the cited standards. While the earlier version included references to TS EN 81-1 and TS EN 81-2, the current TS EN 81-80 standard refers to TS EN 81-20.

Modernization can be the topic of another article. Thank you for the valuable time you spent on the article.

Regards

Get more of Elevator World. Sign up for our free e-newsletter.