KEB Systems Show Promise of Remote Monitoring

Dec 1, 2017

Company’s remote monitoring, IoT solutions enter the vertical-transportation industry.

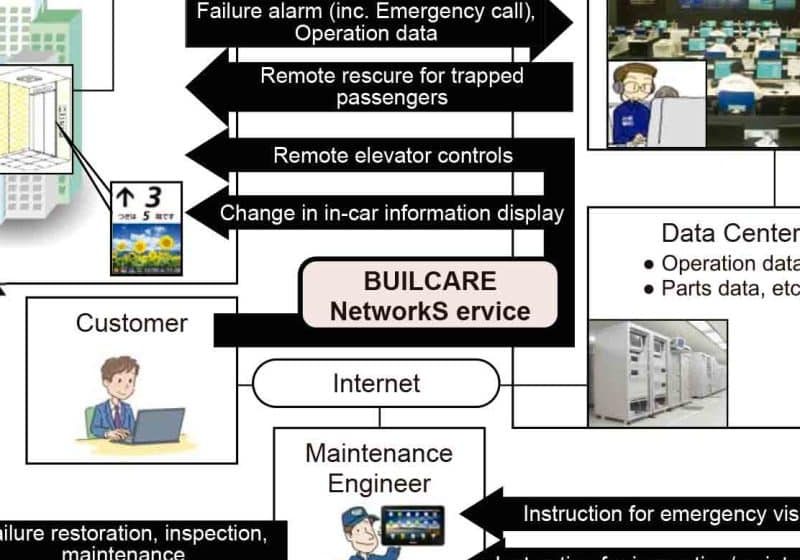

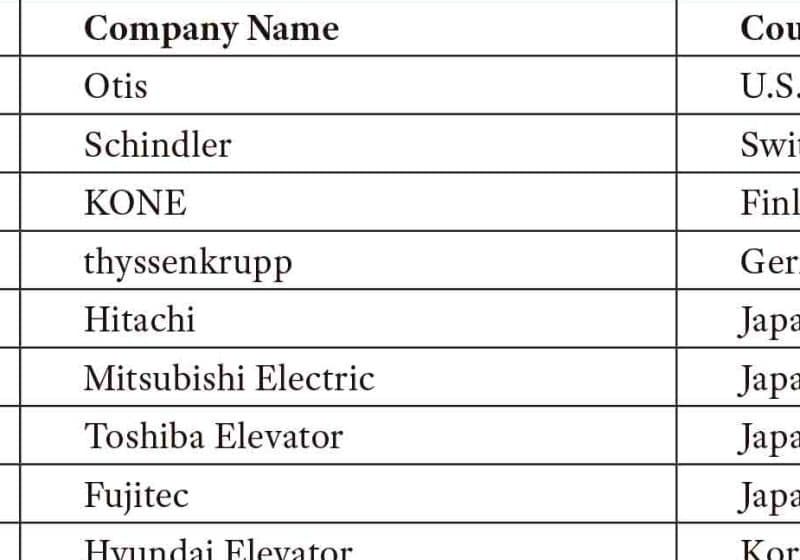

Many manufacturers offer a remote-monitoring option, which includes real-time system information such as car position, status, fault logs and more. This should come as no surprise, given the maturation of the internet, availability of cheap server space and an increasing number of networked devices. Slowly, elevators and escalators are intersecting with the Internet of Things (IoT). This article will not focus on the promise of IoT; instead, the objective here is to, one, briefly introduce the concept and possibilities of remote monitoring and IoT in relation to elevators and escalators and, two, discuss the key features and benefits of KEB’s remote-monitoring tools.

IoT Fundamentals

In the world of elevators, “things” are the controller, door sensors, load weighers and power drives, among others. Before achieving networking capability using the internet, these devices must be connected at a lower level. This means there must be a common hardware (RS485, Ethernet, wireless) and software used by the remote-monitoring system to communicate and collect system data. The next challenge is to connect the system to the internet for remote communication. Once this is complete, remote connections are possible, and system information can be sent instantaneously to elevator techs, design engineers and decisionmakers.

Uses for these connections are virtually endless, ranging from remote troubleshooting to faster shutdown response times. An example could be a high-profile job with intermittent elevator shutdowns. The only clue is a generic “NO Drive ON” fault from the controller, and, unfortunately, the drive has no faults in the log since the last shutdown. Thus begins the frustrating game of replacing components one by one, hoping to resolve the problem. On the other hand, let’s say the system has a modern-day remote-monitoring system connected to the drive input/output. When the system indicates a “NO Drive ON” fault, a detailed log is emailed to the responsible elevator technician. In our scenario, we may find the log proves the digital relay output (DRO) from the drive is picked during this fault, but, for some reason, the signal isn’t getting to the controller. The printouts show the DRO module is in series with a pilot relay. This allows the technician to eliminate incorrect controller signaling or a faulty drive, and look at the wiring and pilot relay between the DRO module and controller. The connected system, with its specific fault diagnostics relayed in real time, will reduce the time and money spent on troubleshooting and replacing other components.

The ability to connect, collect and analyze data from an elevator or escalator benefits all stakeholders. Unfortunately, in practice, this isn’t as easy as it sounds. Finding compatible hardware and software is difficult, and collecting a mass of data without knowledge of how to analyze it is not helpful. Most importantly, the system must be secure, and the information on it must be private. The implementation of a remote maintenance system requires careful planning and design. KEB offers help with secure remote connections to systems using virtual private network (VPN) technology and data collection with COMBIVIS ConnectTM and a line of industrial routers, human/machine interfaces (HMIs) and programmable logic controllers (PLCs).

KEB’s Remote Access Solution

KEB’s C6 router, HMI, and PLCs offer the possibility for remote connections as standard. Each is equipped with hardware to connect to systems with Ethernet and serial ports (RS232/422/485). KEB’s solution is the COMBIVIS Connect architecture and COMBIVIS Studio HMI software. The COMBIVIS Connect architecture is composed of three interconnected components: the control center (PC application), runtime (software on KEB hardware) and server infrastructure. Working together, a secure end-to-end connection between the control center and system network is generated through a VPN.

COMBIVIS Connect Architecture

The relationship between the control center and runtime is a client/server type, where the control center is the client, and the runtime is the server. The KEB server infrastructure acts as an intermediary point to discover, reach and authenticate connections. Using outbound connections to an access server, the control center sends user credentials and a list of devices registered to the customer’s account. At the same time, the runtime sends its availability with encrypted identification certificates with outbound connections. It is important to note that passwords are never stored in the control center or server databases. Instead, they are stored as an encrypted hash value, which must match the hash value stored on the access server. Additionally, all connections use secure sockets-layer/transport-layer security protocols for encrypted data transfer, ensuring data confidentiality. When a user connects to a device, all security credentials are exchanged, and the access server routes traffic to a relay server that acts as a bridge and common point for data transfer. KEB has relay servers located around the world to eliminate bottlenecks and ensure reliable connections. The relay server is always selected by the access server based on load and proximity.

Finally, when a VPN connection has been established, the runtime serves an internet-protocol (IP) address within the same physical machine network to a virtual Ethernet adapter installed by the control center. Therefore, the control center PC is a true member of the machine network and can access any devices on it as if it were physically connected with an Ethernet or serial cable. For example, if a C6 router is connected to a remote PLC, the user running the control center can perform a device scan with the associated PLC software and connect to the PLC.

Traditional VPN technology uses a central VPN server as an intermediary point between a VPN client and remote network. All data must pass through the central VPN server at all times. COMBIVIS Connect eliminates the need for a central VPN server and establishes a true virtual end-to-end connection, only using a relay server as an intermediary to route traffic. Not only is this more efficient, but data traffic will never be seen or managed by KEB, as even the traffic through the relay server is fully encrypted.

KEB developed the COMBIVIS Connect architecture based on industrial cyber security standards ISA 99 and IEC 62442. It passed an audit by independent third-party German security organization Protect GmBH.

Control Center Features

The control center is the PC application used by the remote user and belongs to a customer account called the “domain.” Each domain can be organized in a hierarchy of folders, devices, users, groups and firewall policies. Subfolders inherit users and firewalls of root folders but are completely private to other subfolders. This feature is very useful for managing a large number of devices. For example, a contractor can create folders for specific jobs or routes. They can then create users for the technicians responsible for each job or route in a specific folder. When each technician logs into the domain, they can only view devices within the folder they are permitted access. KEB devices can also be viewed, configured and accessed within the control center. Even before connecting to a remote network, the control center uses several features to control and prevent unintended device connections with user management, firewall policies, and activity audits.

User Management

First, the domain account is private and can only be accessed by users with a username and password. Each domain account has an administrator who can manage all users and groups by defining special permission profiles for all users. Permission profiles define the rights for domain administration, device installation, network security configuration (firewall policy creation) and device access. Device access rights can be further defined by limiting device actions such as remote network access, reading of remote files, writing of remote files, etc. The domain administrator also has an option to track the activity of all users and devices using an audit feature.

Audit

For complete visibility of all domain activity, the audit tool tracks all user and device interactions. This provides a complete record of who connected to what device, for how long and what they did (VPN connect, transfer file, etc.). Additionally, a log on each device is kept with similar information.

Firewall policies

In addition to end-to-end VPN connections, traffic to and from each remote device can be further limited by the creation of firewall policies. Firewall policies can restrict traffic by MAC address and Ethernet type. Depending on the Ethernet type, further restrictions can be applied, such as protocol, IP address and port. All policies can be defined as one- or two-way, which adds protection to the remote user’s network.

Data Collection

Remote monitoring systems become more powerful and useful with data collection. Data collection and visualization can be performed using KEB products with HMI runtime installed. COMBIVIS Studio HMI is the software tool utilized to develop HMI projects for data logging and visualizations. COMBIVIS Studio HMI includes more than 40 common software drivers to interface with a variety of systems, including Modbus, BacNet and OPC Unified Architecture. This data can be logged continuously with configured data loggers. Data can then be abstracted using the control center or through scheduled emails from the device.

It is also possible to push out data to cloud databases, such as Microsoft Azure or Amazon Web Services using the Message Queue Telemetry Transport protocol for advanced analytics. Instant notification to faults and shutdowns is possible with configurable alarms. Alarms can be associated with specific variables to send out a text message (SMS) or email to alert techs of faults. Lastly, real-time visualizations can be created and viewed. The control center offers remote viewing of HMI projects running on the desktop of the C6 router or C6 HMI.

Elevators and escalator systems can greatly benefit from remote-monitoring systems. With many different options on the market today, careful planning should be taken when deciding to undertake such a development. Trusted and well-tested tools should be utilized in such a system.

Get more of Elevator World. Sign up for our free e-newsletter.