Dear readers,

The safety of lifts and escalators is a process; when it works properly, lifts and escalators are safe. Starting with the proper design, this process continues with the correct selection of materials and with the accurate installation and maintenance. Controls conducted at different times throughout the life of the product verify that the lift and escalator are safe.

If a lift, escalator or walkway is to be installed, the design must be correct to ensure that the product is safe. Nowadays, there are several safety standards for a proper design, including the main standards (type A and B) and type C, which we call the EN 81 family and EN 115 standards in our country, and the standards in practice in different parts of the world. If these standards are followed and applied properly, the design of lifts and escalators will then be safe.

If production is carried out with the correct and legal design and the production process complies with current scientific rules and discipline, the components for safe lifts and escalators will be produced accordingly.

In the next stage, correctly produced components must be assembled properly in the field. All necessary rules and conditions for this process have been determined by standards. The shafts to be installed and the safety conditions regarding the components have been determined so clearly and well that safe lifts and escalators will be installed if the installation is made following the standards. When the placing of lifts and escalators on the market is controlled completely and correctly by competent persons under the conditions determined by public authorities, there is no possibility that the lift or staircase will be unsafe when sold.

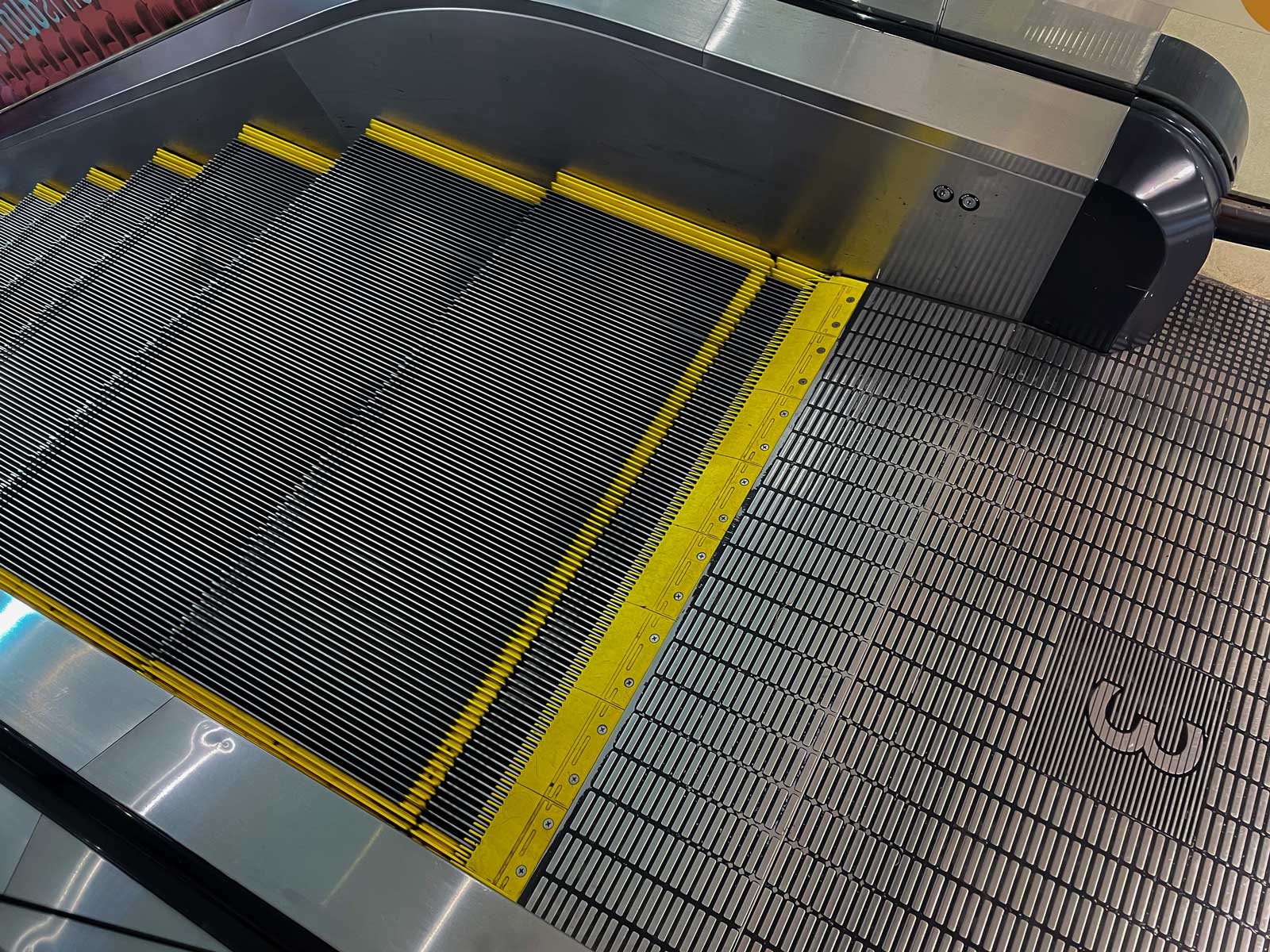

After the product is purchased, the lift and escalator usage service process begins. The service process is where accidents, unsafe situations and problems occur and the most attention and precaution needs to be taken. To ensure the safety of the public and users, the general public aims to ensure that lifts and escalators are safe by carrying out controls at regular intervals by law. Besides, lift companies take precautions for safe use by maintaining the products. I think this is where everything starts. The general public determines conditions for maintenance companies, and legislation determines how maintenance should be carried out and places the responsibility on the maintenance company and the building owner and management. Lift companies are developing various methods to increase maintenance performance and provide better maintenance service. So what happens in the end? Still, the accidents. Check out what we found during our field checks:

Do you think the lifts and escalators in the photos are safe? There is also evidence that the products are maintained every month. Also, the company that performs the maintenance has been identified by the general public, has met the service company requirements, and received authorization. Periodic inspection was carried out on the lift, which was blue-labeled. The general public aims to ensure that maintenance is carried out correctly, with the obligation of personnel training and certification to ensure that maintenance is carried out by competent personnel. It makes certain that the process is secured with quite detailed control forms that it requires to be completed every year. Service companies, on the other hand, develop methods and processes such as preventive maintenance, periodic maintenance, annual maintenance and remote maintenance. So, despite all these precautions and studies, why do we still see such lifts and escalators in the field? Why do accidents still happen? How can we prevent this?

Get more of Elevator World. Sign up for our free e-newsletter.