Remote monitoring revisited: new developments in an old concept

by Rob Wurth and Rich Madarasz

To those of us who have been in the elevator industry more than a few years, the words “remote monitoring” likely conjure up any number of things, including questions, concerns, intrigue and, perhaps, skepticism. While the concept of remote monitoring has been around for decades, enough has changed in the technology available today, along with the elevator industry as a whole, that the idea of remote monitoring is worth thoroughly revisiting.

The Business of Remote Monitoring

New Developments

Gone are the days of dot-matrix printouts full of fault codes, or rudimentary devices offering little value, or systems so complex and costly that only the highest-profile jobs justify remote monitoring. Instead, remote monitoring available today, through companies like LiftAI, is nonproprietary, installs in less than 2 hr. with no hardwiring to the controller and offers a user interface designed for anyone from the lifelong “elevator man” to office administrators who have never been in a pit or turned a wrench in their lives.

In addition, systems today can be built with an open platform design and, therefore, be applicable to any equipment. This allows easier adoption across maintenance portfolios made up of a wide variety of equipment, yet offers the user a standardized interface for the simplest possible view into the data.

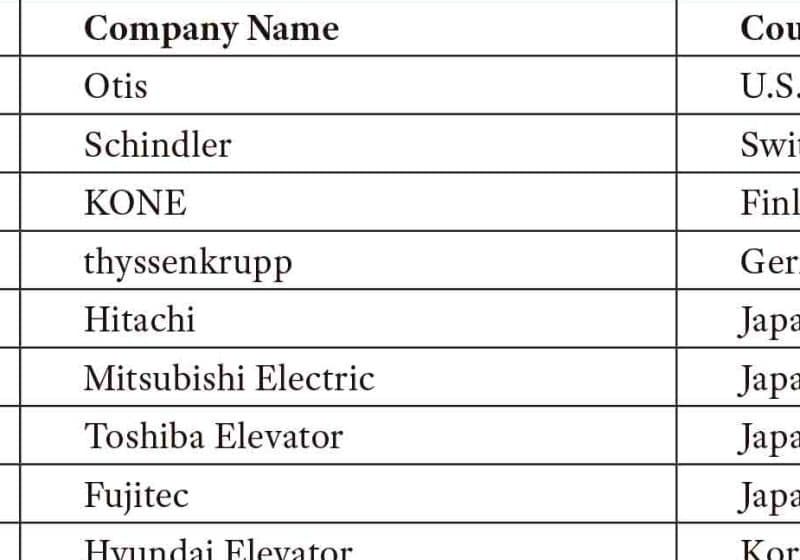

Systems like LiftAI are also open to a variety of companies — manufacturers, service providers, contractors, consultants and more. Anyone interested in utilizing remote monitoring has immediate access to a robust and flexible platform on which to build their solutions, either for themselves or for their customers. For example, in an elevator portfolio of 1,000 units made up of equipment built over five decades from 10 different manufacturers, users can now view data on the performance of their elevators through a single, simple-to-use interface.

New Approaches to Service Using Remote Monitoring

Despite the significant changes in technology, it is actually the business models enabled by remote monitoring that offer the greatest potential for impact to our industry in the future.

While applications of remote monitoring were limited by the complexity and cost of available solutions in the past, today, the ease of use and dramatic cost reduction of systems have opened up new opportunities to those who choose to use remote monitoring. A few of the most attractive opportunities are outlined below:

- Bid on new projects and contracts: with remote monitoring specified more frequently than ever in bids of all sizes and complexity, elevator contractors no longer have to be wary of, or intimidated by, meeting those specs to win the bid. Remote monitoring is now offered as a monthly service that requires little to no technical expertise, offers easy-to-read dashboards built for business users and is available at a cost per month of less than a tank of gas. The contracts specifying remote monitoring are now open to anyone and everyone.

- Grow a maintenance portfolio faster: a classic problem in growing a maintenance portfolio is the question of whether to add a mechanic or win a contract for a full route first. With remote monitoring that operates 24/7 and alerts users to potential shutdowns, faults and other issues, contractors now have new options in how they grow their contract portfolio. Visits can be structured to be less frequent for low-use elevators, units that run consistently well or extremely price-sensitive customers, while still providing the peace of mind and safety of continuous, real-time monitoring. The end result is more units under contract more profitably than what was possible in the past.

- Reduce risk, while maximizing profit: with remote monitoring that collects measurements such as door position and open/close times, acceleration/g-forces, up/down speeds, vibration, motor temperature, voltage and more, never before has so much data been available to use for elevator maintenance. By analyzing this data with our artificial intelligence (AI) engine, LiftAI can help companies with full-maintenance contracts reduce call-backs and the risk of component failure and, therefore, the cost of replacement. It also provides data that can protect contractors from frivolous lawsuits. In an industry with liability levels like ours, reduced risk with greater profitability is a welcome proposition — one that could only be delivered recently with remote-monitoring technology.

- Deliver better customer service: all the best elevator maintenance companies know the secret to winning and keeping contracts: providing the best customer service and highest-quality maintenance. Remote monitoring provides a data-driven element that greatly enhances the customer experience. Service companies can now be alerted to problems and have them fixed before their customer ever knows something is amiss. Additionally, data can be used to identify trends and potential problems to prevent shutdowns and increase uptime. Elevator-maintenance companies of all sizes have a new tool to separate themselves from the pack further, in terms of customer service.

The Technology of Remote Monitoring

Design Philosophy

As noted earlier, remote monitoring has faced its share of challenges. With LiftAI, we crafted a design philosophy around addressing as many of these issues as possible: data collection, data analysis, data processing and communication.

Data Collection

Starting with the objective of ensuring LiftAI could be applied to any elevator, regardless of manufacturer or age, we used a common hardware module that allows configurations for different types of elevators: traction, hydraulic, rack-and-pinion and residential. This hardware module utilizes a sensor-based measurement approach to monitoring, thereby eliminating the need for an electrical connection to the elevator or controller, which allows us to monitor any elevator built by any manufacturer.

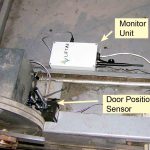

To install remote monitoring on an elevator, a LiftAI hardware unit is placed on top of the elevator car and travels with the elevator (Figure 1). This unit then collects data from a variety of sensors, and, due to the open-platform approach, additional sensors and even other equipment can be connected as needed. The system then measures and analyzes the actual performance of the elevator using the data from these sensors, rather than looking at controller signals.

Sensors at the car top include accelerometers that determine acceleration, speed and vibration, and a non-contact optical door sensor to accurately determine the position and timing of the door. The door sensor does not interfere with door operation and works with harmonic or linear operators. We are able to identify the most common problems of elevators, including, but not limited to, abrupt stops, abnormal door operation and speed issues, with the data from these sensors alone.

For some elevators, users choose to add an additional LiftAI unit in the machine room (Figure 2) that monitors temperatures, current draw, hydraulic pressure and power consumption (Figure 3). In these installations, readings are communicated wirelessly to the unit on the car, where they are combined with the motion information to characterize every trip.

Data Analysis

Another issue we took into consideration during design was the volume of data remote monitoring can generate. While an elevator mechanic might watch a unit once a month for a relatively brief time period, a remote-monitoring system watches 24 hours a day. That generates a massive amount of data, which can be overwhelming. We have seen that too much data can be just as problematic as not enough data. To address this, the LiftAI system continually analyzes the data it collects but only reports when there is an exception to normal operation or when the user asks for specific data. In doing so, we help users focus on critical insights that can be easily understood and acted upon.

Once we designed around the problem of too much data, we were still challenged with making the data useful. Elevators are complex machines that behave differently based on their state (moving, stopped, door open, etc.). Therefore, the data presents unique challenges in learning and gaining insight. To meet these challenges, we turned to artificial-intelligence techniques and built the LiftAI system with an ability to alter its analysis based on past results.

In effect, the system will change the rules it uses to analyze the data based on how the data and results change. For example, a rule might send a warning message when the door is open for more than 10 s. However, the system may observe that this often happens at rush hour. The rule should change to accommodate the time of day. While this is a simple example, LiftAI automatically responds to elevator data by altering its analysis and constantly “learning” in a similar fashion.

To do so, it uses a rule-guided approach for decisionmaking. A central server looks for trends in the data for each elevator and establishes which conditions are indicative of normal operation. The system can then compare the operation of multiple elevators based on usage, type of installation and age. As the central server refines these parameters over time, they are sent to the monitor unit on the elevator, which allows the system to continually refine its diagnoses. Based on these diagnoses and user-defined parameters, warnings can be sent to the user if certain conditions are met.

Data Processing

With all of this data being collected from a wide range of elevator types in a variety of locations, the issue of processing and accessing the data became a significant challenge in the design of LiftAI.

The term “cloud” is in vogue these days and is commonly used to mean the World Wide Web with web servers communicating with browsers on personal computers and mobile phones. But there is much more to this, including the Internet of Things and machine-to-machine applications, which require devices to talk to one another or to talk with servers located “in the cloud” — which is simply another way of saying they are not located on the premises with the machines to which they are connected.

The advantage to using the “cloud” is that setup is far simpler for the user, as there is no need to worry about how messages get from one device to another. This is what we have integrated into LiftAI. The disadvantage is you have less control over it, and communication failures can occur, or others can interfere with your system. Fortunately, there are ways to deal with these issues.

LiftAI addresses these issues by distributing the processing among the hardware modules on each elevator. Based on Qameleon’s QarVision™ technology, each monitor unit performs much of the analysis locally and communicates only when necessary. This is known as operating on the “edge of the cloud” (Figure 5) and allows for a very powerful feature: communications can be inconsistent and unreliable without disrupting the LiftAI system. Simply put, the system will collect and analyze data successfully and wait patiently to send this data as communication becomes available. In an elevator that is moving constantly, often closer or farther away from communications signals, this proves not just helpful, but often critical in establishing a reliable system of data delivery.

To do this, each monitor unit handles its own sensor signals as quickly as it is able, analyzes the sensor readings according to a set of rules, and sends data in the form of alerts/warnings or simple summaries to the LiftAI central server. Data is retrieved from the monitor units on demand but is never erased; thus, every unit becomes its own offsite repository.

The central server is the global interface for the LiftAI system. A database server maintains data about all of the elevators, and this data can be aggregated from multiple elevators across multiple locations to allow the user to see how all of their elevators are performing using a dashboard accessed via any web browser (Figure 4).

The central server can also retrieve data from the monitor systems as necessary to provide the user with the specific information they need. Both the central server and monitor units can send email and text warnings to users, depending on the type of issue. Summary reports are automatically generated by the central server and tailored to the user’s preference.

There are several advantages to the distributed architecture of the system, including ease of setup, lower costs and access to information for users. Perhaps the two biggest advantages, however, are in the redundancy and security issues it helps address. Because there is no single point of failure, a disruption in one part of the system will not affect the others, and little or no data will be lost; processing will continue uninterrupted.

From a security standpoint, LiftAI offers significant advantages by simply not connecting to the controller, which means it is impossible for someone to take control of the elevator remotely via nefarious hacking. The distributed architecture also means that even if someone simply wants to cause a disruption, the hacking targets themselves are smaller, offering hackers less reward for their efforts.

Communication

Finally, when establishing our design philosophy and criteria, we focused on communication. Communication is possibly the most important part of any remote-monitoring system and represents three key challenges: ease of setup, cost and reliability.

For ease of setup, we chose cellular as the default communications protocol. By doing so, there is no need to work with the building owner/manager to access the building Wi-Fi or a wired network. Instead, elevator companies have full control with LiftAI’s plug-and-play setup that allows instant communications once powered up.

While cellular is the easiest system to set up, data costs are a very real concern, as anyone who has watched one too many YouTube videos on their iPhone can attest. However, because of the distributed architecture that allows LiftAI to perform analysis locally on each unit before it is sent to the cloud, it can send simple summary data reports that allow for extremely low monthly data transmission costs. As a secondary means of communication, LiftAI can also use existing Wi-Fi networks in buildings to access the internet, eliminating monthly communication fees altogether.

Regardless of the wireless communication method used, failures will occur. Cellular and Wi-Fi traffic, power failures, cellular carrier strategies and weather can all cause loss of communications that can dramatically impact the reliability of a remote-monitoring system. As such, any robust remote-monitoring system will have built-in mechanisms that are fault-tolerant and allow for automatic recovery from failures. In LiftAI, the distributed architecture was designed to expect failures, and mechanisms for recovery are built into the hardware and software. Automatic problem detection and recovery features, in addition to communications design, all contribute to provide maximum reliability within the LiftAI remote-monitoring system.

Conclusion

Used effectively, remote monitoring has the potential to significantly impact the elevator industry in many positive ways. It can help smaller companies compete, property owners increase elevator uptime while reducing liability and provide data that helps qualified mechanics perform maintenance more effectively. When these benefits come together, the riding public benefits.

With the development and advancement of new technologies and the evolution of the elevator industry itself, remote monitoring as a tool is worth revisiting for the ambitious, innovative and forward-thinking elevator contractors, property managers and consultants. Its time has finally come for the elevator industry, and it offers significant benefits to those who choose to leverage it.

- Figure 1: The LiftAI hardware is placed on top of the elevator and travels with it.

- Figure 2: Some users choose to add an additional LiftAI unit in the machine room.

- Figure 3: An additional machine-room unit monitors temperatures, current draw, hydraulic pressure and power consumption.

- Figure 4: Summary reports can be tailored for the individual user.

- Figure 5: There are several advantages to the distributed architecture of the system.

Get more of Elevator World. Sign up for our free e-newsletter.