Mitsubishi Elevators is building on a legacy of remote maintenance services.

by Dr. Naohiko Suzuki, Shin-ichi Kuroda and Kenji Serizawa

This article was frst presented at the 2019 International Elevator and Escalator Symposium in Las Vegas. For more information on December 7-8, 2020’s event in Amsterdam and to participate, visit www. elevatorsymposium.org.

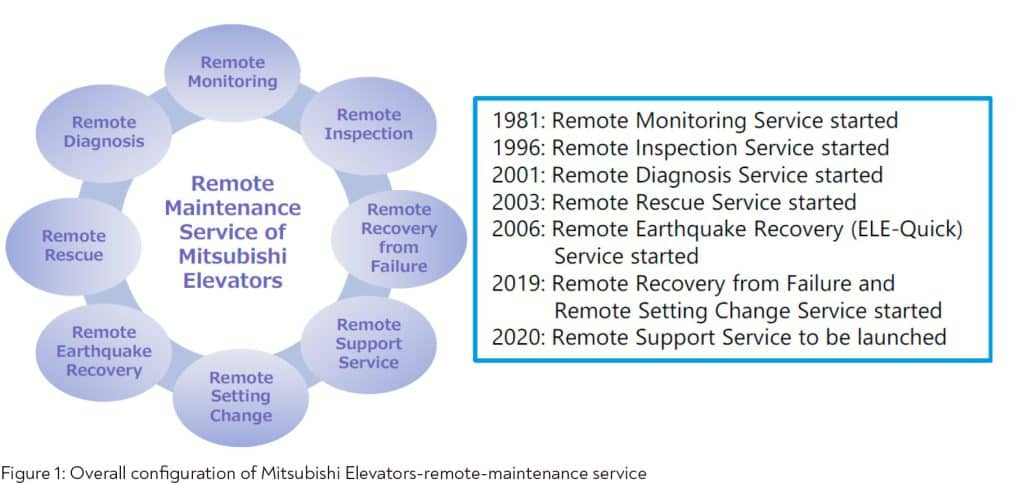

In the early 1980s, Mitsubishi Elevators began a remote-monitoring service, which was an automatic alert service of problems or entrapment of elevator passengers to the information center by using telephone lines to improve safety and security. Mitsubishi Elevators has since introduced a variety of remote-maintenance services to the market to improve safety and security and operation availability of the elevator, such as remote-inspection service, which takes the place of the general inspection work of maintenance engineers; remote- diagnostic service, which is an automatic diagnosis for the deterioration of important equipment in maintenance operation mode during of-peak, nighttime hours; and remote rescue and remote recovery-from-failure services, which determine failure remotely and conduct the rescue operation or the operation to recover from a failure.

In this article, your authors would like to introduce a part of our future eforts in Mitsubishi Elevators maintenance services by integrating the remote-maintenance technology accumulated from 150,000 units in Japan over the past 40 years with the latest communication and sensing technologies.

Introduction

In the global elevator market, user demand for safety increases year by year. In addition to the performance of products, the importance of maintenance and management for elevators, such as remote-maintenance services using advanced technologies of the Internet of Things (IoT), information and communications technology, etc., has been drawing more attention than ever.

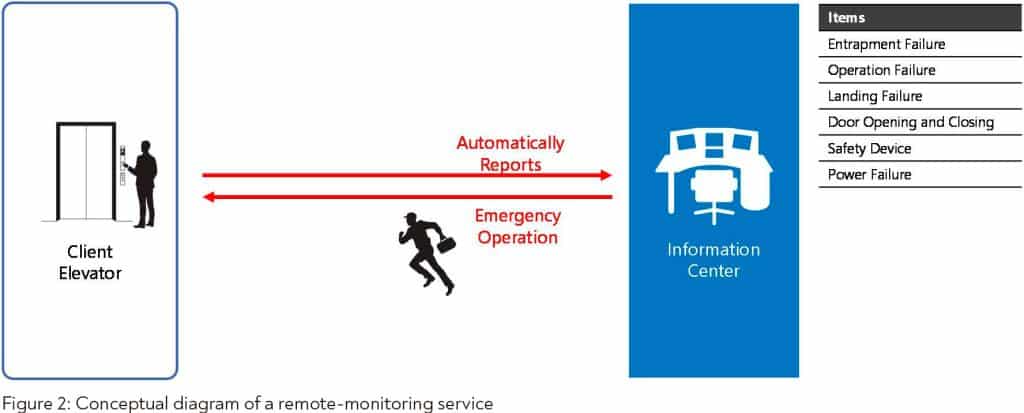

In 1981, Mitsubishi Elevators began providing a remote elevator monitoring service in Japan. This is a service that, in the event the passenger is trapped in the elevator car or if any other malfunction occurs, the details of the error are automatically reported through the public telephone line to an information data center, the system immediately logs which elevator is afected and the kind of failure that has occurred, and a maintenance engineer is dispatched to the site. Since then, various remote services have been developed, and, as of 2019, remote-maintenance services have been provided for approximately 180,000 elevators in Japan.

In addition, the development of “M’s BRIDGE™” (ELEVATOR WORLD, November 2019) has advanced remote-monitoring services for Mitsubishi elevators in various countries. This article explains the remote-maintenance services and latest global remote-monitoring services from M’s BRIDGE.

Historical Development and Functions of Remote Maintenance Services for Mitsubishi Elevators

Overall Structure, Transition and Function Details

Figure 1 shows the overall confguration and transition of remote-maintenance services with years of introductions to the market.

Remote Monitoring Service

This frst remote service of Mitsubishi Elevators has been available since 1981. As a background to the development of this service, for ofce buildings and condominiums in Japan, the building manager and management company have been permanently stationed in the building. However, the chance the building manager is not always onsite has increased. This is mainly due to changes in the market environment, with the increase of (mainly small and medium-sized) buildings.

As a result, if a passenger is trapped in the elevator due to a malfunction, there is an increased possibility they cannot communicate with anyone on the outside, even if the passenger presses the intercom button. Therefore, the service monitoring the system 24 hr a day, 365 days a year from a remote location on behalf of the building manager or management company is required so the passenger in the car and information data center can make direct contact. In the event of an emergency, a maintenance engineer is immediately dispatched.

Figure 2 shows a conceptual diagram of a remote- monitoring service. If an error is found in any of the monitoring items, it is automatically reported to an information data center, and an engineer is dispatched.

Remote Inspection Service

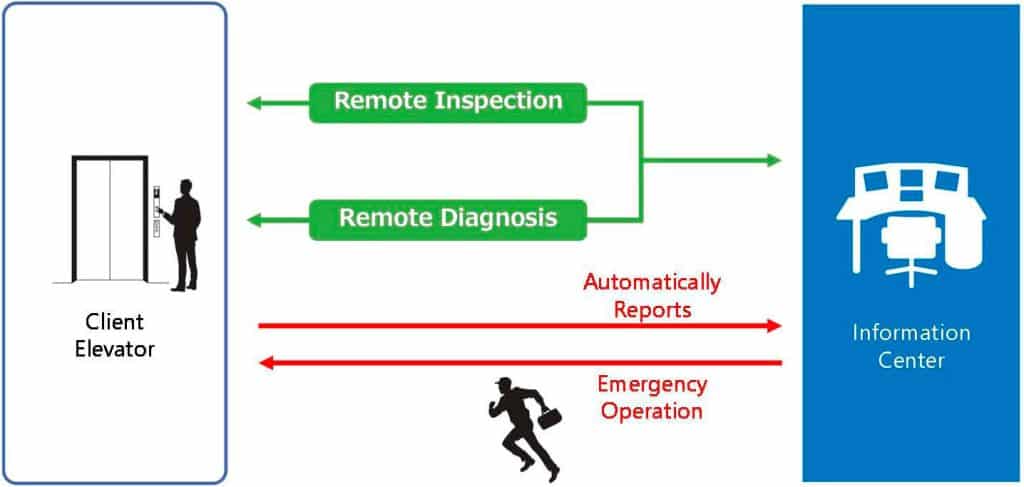

Remote inspection service checks the condition of the equipment constituting the elevator to prevent failures. Along with normal elevator operations, the operation of the equipment and systems is constantly checked, and the data is accumulated. The accumulated data is collected and analyzed at the information data center, and the results are confrmed by a maintenance engineer who can take measures such as extra onsite visits as necessary and refect the data in subsequent maintenance plans.

Since the guidelines in Japan stipulate items to be inspected once a month, remote inspection of these items eliminates the need for monthly onsite inspections by a maintenance engineer (extending the visit inspection interval), and the continuous inspection function is utilized to improve the quality of maintenance and operational availability of elevators.

Remote Diagnosis Service

In remote diagnosis service, the elevator automatically carries out the inspection operation equivalent to onsite maintenance work by a maintenance engineer. For important equipment and systems such as brake performance and door opening/closing conditions, the system is switched from the normal service mode to the dedicated operation mode in a preset time zone with few users. The performance and functions are automatically diagnosed, and if there is any modulation or unusual behavior, it is automatically reported to the information data center. As a result, it is possible to not only detect the modulation and unusual behavior of the elevator at an early stage, but also indicate equipment requiring prioritized maintenance in the maintenance work plan to realize advanced preventive maintenance.

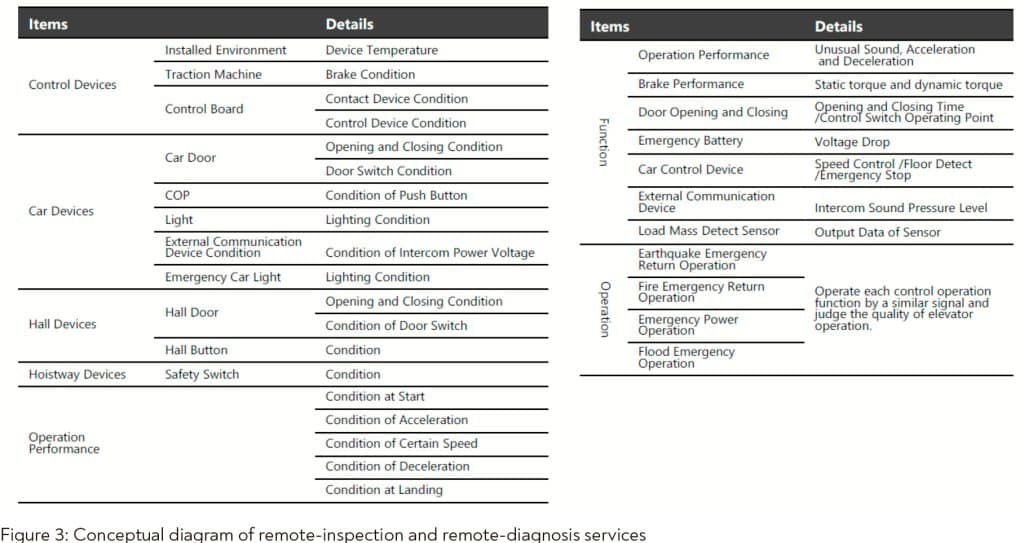

Figure 3 shows a conceptual diagram of remote-inspection and remote-diagnosis services. An automatic report is made to the information data center when any modulation or unusual behavior is found in the items inspected or diagnosed by each service.

Remote Rescue Service

Remote rescue service restores the elevator remotely and rescues the passenger(s) trapped inside before the maintenance engineer arrives. This service was developed to meet market demands, such as how to avoid the entrapment of passengers and how to reduce elevator downtime, which is a shift from how to stop elevators safely in the event of passenger entrapment. The development was also prompted by a sense within the company that the entrapment of passengers and elevator downtime must be kept as close to zero as possible.

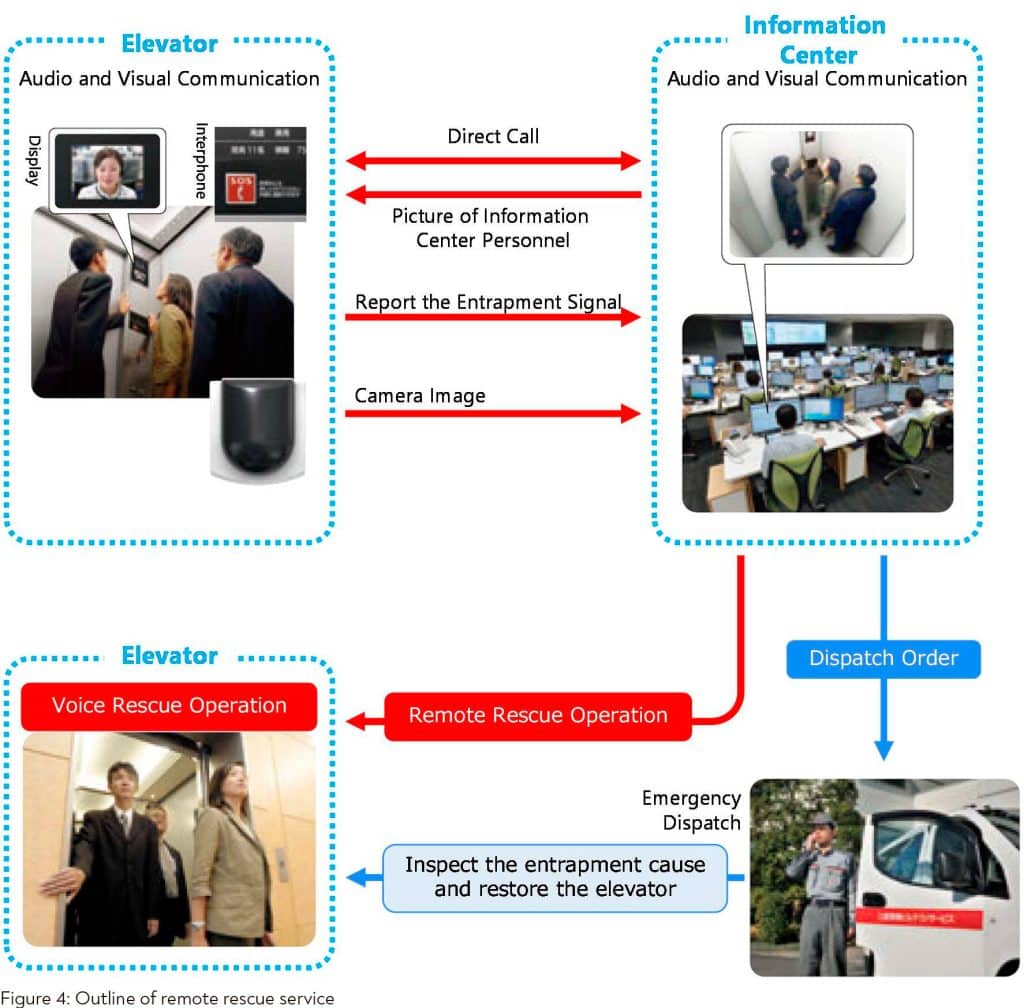

Figure 4 shows remote rescue service. In addition to conventional direct communication through the interphone call, this service equips a camera and display in the car. This enables the operator at the information data center to check the situation in the car, caution and give instructions to the passengers and start the rescue operation. With this operation, the system at the information data center automatically transmits the best rescue operation command, depending on the elevator state, to the elevator, which then starts the rescue operation.

Remote Earthquake-Recovery Service

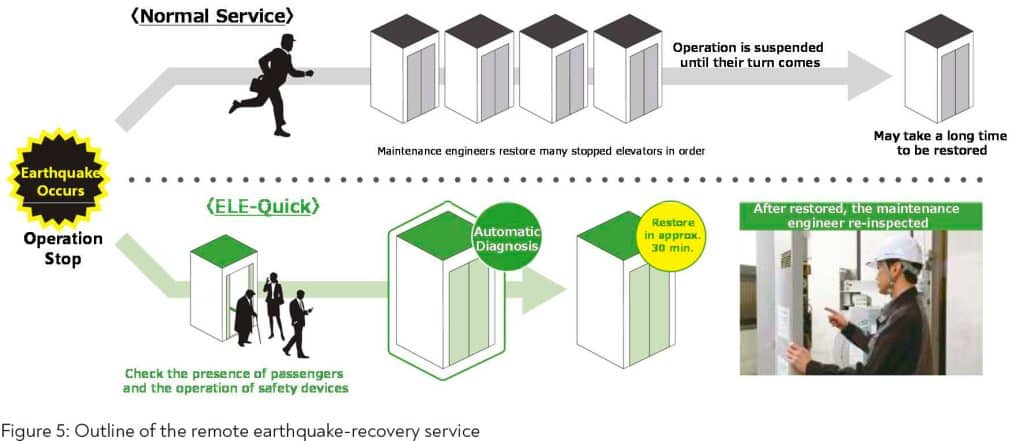

Remote earthquake-recovery service ELE-Quick automatically diagnoses elevators that have had their operation suspended by earthquake emergency-return operation and temporarily restores them within approximately 30 min after checking and confrming no unusual behavior and safety. Normal operation is then resumed.

The function was developed in the same way remote rescue service was described earlier: based on the concept of how quickly the operation of the elevators that was suspended due to the earthquake sensor alert can be restored. Figure 5 shows the outline of the remote earthquake-recovery service. Tens of thousands of elevators can be damaged by an earthquake, which increases recovery time. This is a challenge for the entire elevator industry in Japan, known as the earthquake country. However, this system enables early recovery and reduction of the burden on the maintenance engineers by simultaneously inspecting and restoring the elevators waiting for their turn.

Remote Recovery-From-Failure Service

When the elevator stops or is not in service, the remote recovery-from-failure service automatically releases the failure state and operates a test run by a remote command from the information data center. If no unusual behavior is found, the elevator continues normal operation (provisionally restored). This service can provide these operations until a maintenance engineer arrives at the site. This system is developed to improve convenience by reducing downtime caused by the failure.

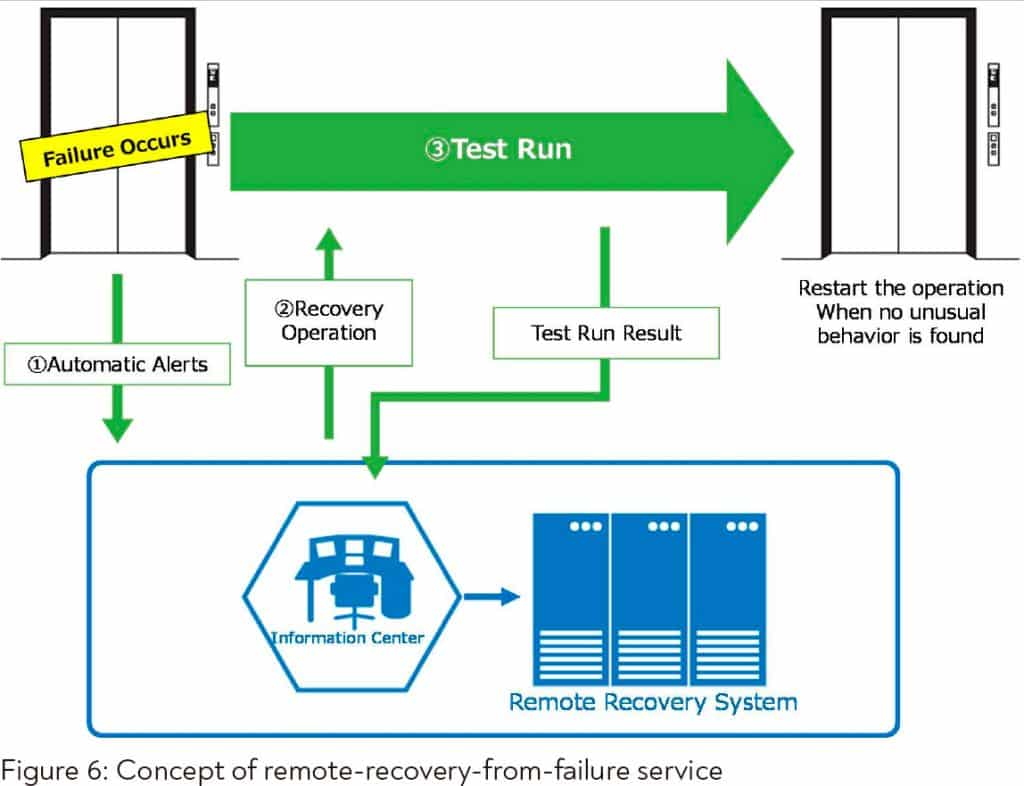

Figure 6 shows the concept of remote recovery-from-failure service. This system automatically judges whether remote recovery is possible based on the details of failure automatically reported from the elevator. Then, it automatically transmits a failure-recovery operation command to the elevator via the information data center.

The elevator that receives the failure-recovery command performs the test run equivalent to that performed by the maintenance engineer after releasing the failure state. As a result, when no malfunction is found, the elevator is shifted to normal operation mode.

Remote Setting-Change Service

Remote setting-change service provides various setting changes remotely, such as turning on/of the fan in the elevator and evacuating the elevator to the top foor in the event of a typhoon or heavy rain. Before this service was introduced, the elevator maintenance contractor had to send a maintenance engineer to the site to change the settings and respond to the user’s other requests.

However, this service enables the contractor to change the settings of the elevator without sending a maintenance engineer to the site. This helps a contractor respond to a user’s request in a timely manner and without being at the site (Figure 7).

Remote Support Service

Remote support service, currently under development, records and analyzes the main signals of elevators that change during the operation in chronological order, mainly from the viewpoint of ensuring the maintenance engineers’ safety. By utilizing the data, it provides a function that warns and alerts the maintenance engineers and transmits the data to the information data center when danger is detected due to misoperation of the switches by the maintenance engineer. The information data center can then understand the characteristics of each maintenance engineer, allowing them to improve the operation procedures and instruct the engineers.

The story behind this function development is a series of accidents during elevator maintenance work. Although various safety protection measures may be taken, it ultimately depends on the safety awareness of each engineer to ensure their own safety during elevator operations. Therefore, we are planning to understand the behavioral characteristics of engineers from a macro perspective and introduce appropriate safety protection measures, as well as provide continuous instructions for improvement by utilizing this function.

Latest Mitsubishi Elevator Remote Monitoring Service for Global Market — M’s BRIDGE

Outline of M’s BRIDGE

In the expanding global elevator market, the demand for not only safety for users, but also convenience and comfort, is increasing, and the importance of maintenance services to support them has been drawing attention.

Therefore, to apply the maintenance service knowhow accumulated in Japan to the maintenance service of Mitsubishi elevators operating in more than 90 countries and regions around the world, we developed M’s BRIDGE, which uses the “connect” technologies all over the world and big data technologies integrated by unifying the data servers (Figure 8).

M’s BRIDGE System Confguration

Figure 9 shows the M’s BRIDGE’s confguration. The information of elevators to be maintained is stored in the data server of the Global Data Center managed by Mitsubishi Electric via the global machine-to-machine network. In addition, data such as maintenance work results managed by local base stations using a basic business system/enterprise resource planning or the like is also successively updated in the data server. The data thus collected is continuously used as learning data using Mitsubishi Electric’s artifcial-intelligence (AI) technology.

M’s BRIDGE will provide the remote monitoring and inspection services mentioned above, and expand various maintenance services based on the needs of overseas markets and customers by utilizing technologies cultivated in Japan and Mitsubishi Electric’s AI technology.

Summary

This article explained the remote elevator-maintenance and global-maintenance service M’s BRIDGE, using the latest IoT platform developed in Japan. Going forward, starting with Asia, Mitsubishi Elevator will provide M’s BRIDGE globally. This service uses the remote-maintenance technologies accumulated by Mitsubishi Group over many years. We aim to expand our presence in the global elevator market by providing safe, secure and high-quality maintenance services for Mitsubishi elevators around the world.

Get more of Elevator World. Sign up for our free e-newsletter.