Looking Up

Sep 1, 2016

EEVI is on a growth track.

When Elevadores EV Internacional S.A. de C.V. (EEVI) began manufacturing in a 100,000-sq.-ft. facility in Tijuana, Mexico (the result of a partnership with EV Elevator Group of Europe), in April 2001, it had 38 employees. Today, that number has more than tripled to118, and President J. Isauro Barrutia plans to expand the plant by 50,000 sq. ft. within the next year and a half, subsequently adding 20 employees.

Earlier this year, EEVI debuted its 3.0 SS (self-supporting) machine-room-less (MRL) elevator, and it is already enjoying strong sales among independents throughout North America. 3.0 SS is “an MRL designed for a hydraulic footprint,” Barrutia states. The new product reflects how the industry has changed since Barrutia entered it in the early 1980s. He previously served as managing director for EV Elevator Group, responsible for manufacturing and sales in the North American market. He observes:

“The product has evolved substantially. First came the evolution in variable-frequency controls in the early 1980s. Then, we had the other big change, permanent-magnet motors, and lately, the MRL products, which are light and energy efficient, have been desired by many customers. In the past five to seven years, I think all elevator companies would agree, MRL equipment has been the biggest trend. Customers like MRLs since there is no longer a machine room on the top floor, so that space is now available for them to sell or lease.”

EEVI manufactures passenger and freight elevators with capacities of 2500 to 25,000 lb., traveling from 50 to 800 fpm. Complementing its plant, it has a 40-ft.-tall test tower that allows for four stops. When the company started, approximately 90% of the units manufactured were hydraulic, with the remainder traction. Today, that is about 50/50. “Whatever projects used to call for a hydraulic system — basically buildings that are three-four stories — are now opting for MRL equipment,” Barrutia states.

“Putting out a high-quality product on a consistent basis is the cornerstone of keeping existing and winning new business.”

J. Isauro Barrutia, president, EEVI

The EEVI plant manufactures and installs mostly for customers in North America, Puerto Rico and the Caribbean. The remainder go to the domestic (Mexican) market. EEVI has 15 locations in Mexico, handling sales, service and installation. The main branches are in Tijuana, Monterrey and Guadalajara. It exports mainly to independents, but occasionally to major OEMs seeking nonproprietary products. “We ship from San Diego all the way up to New York and Calgary, Canada, and all the way down to Florida,” Barrutia states. “The whole North American market, we cover it.”

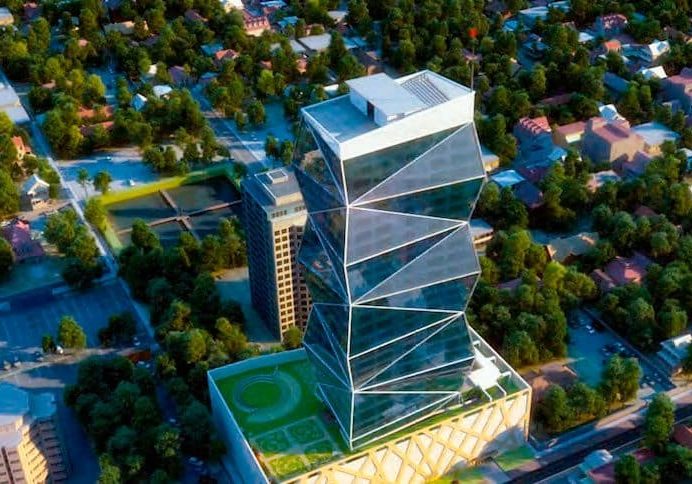

EEVI has made a name for itself in custom work, Barrutia says. Its engineers and customer sales representatives work with customers on solutions involving features such as high-end finishes and nonconventional hoistways. Barrutia credits the strength of his engineering team for the company’s ability to deliver complex, custom jobs. “We train our mechanical engineers right out of school, so they are homegrown,” he observes.

Cabs for custom jobs are often panoramic, and can be flat, faceted or curved. EEVI manufactures elevators for passenger, freight and hospital use. A particularly challenging modernization project took place at a resort on the island of Aruba (ELEVATOR WORLD, October 2003). Heavy equipment was transported by container ship and plane, and an installation crew was flown in. EEVI has done many comparable, challenging jobs since then.

EEVI has found the most challenging part of doing business is keeping up with all the different codes. Barrutia says:

“Codes are being updated constantly, and it’s a challenge for everybody in the industry to keep up with them. Many states, cities and jurisdictions in North America have different codes. One of these days, we may have one single code, like in Europe, but I doubt it will happen anytime soon.”

Although most customers are in North America, EEVI has exported products to as far away as Saudi Arabia and is willing to work with any customer, anywhere, on a project. Barrutia says “putting out a high-quality product on a consistent basis is the cornerstone of keeping existing and winning new business.” EEVI augments consistent high quality by showcasing its products at tradeshows (particularly those put on by the National Association of Elevator Contractors), networking and advertising. “You have to remind people that you’re there,” he states.

Workers assemble components at the EEVI factory in Tijuana.

J. Isauro Barrutia

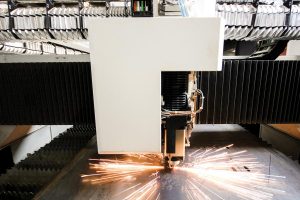

High-tech laser-cutting machines are used at EEVI. More will be added as part of the upcoming expansion.

Laser-cutting machinery in action

Barrutia praises the strength of his engineering team, which uses high-end AutoCAD software.

Get more of Elevator World. Sign up for our free e-newsletter.