Macquarie Bank Headquarters

Jan 1, 2015

Former “pride of Sydney” returns to glory with opulent new additions.

Sydney, Australia

submitted by Nima Bahadori, Schindler Lifts Australia Pty. Ltd.

Project Description and History

48-50 Martin Place is one of the most prestigious addresses in the Sydney Central Business District. Located on the corner of Elizabeth Street and Martin Place, this unique 11-story historical building is the new global headquarters of Macquarie Bank Ltd. (MBL).

Construction on the original building was completed in 1928, with its exterior in the Inter-War Beaux-Arts style. It served as the headquarters of the Commonwealth Bank and was owned by the Australian Government. Internally, the banking chamber displayed an extravagant Neoclassical style with ample use of marble and scagliola on imposing, stylized columns. In its day, this space was one of the largest banking chambers in the world and the pride of Sydney.

In 2011, MBL purchased the building from the Commonwealth Bank with plans to use the premises as its new global headquarters. Widely renowned as leaders in development of contemporary, functional workspaces, MBL had big ambitions for its new home, which still includes fully functioning Commonwealth Bank banking chambers. Much of the space was meticulously restored by Commonwealth Bank in the 1980s and in 2013-2014 by MBL.

The new interior of the building, which is the bulk of the 2014 refurbishment, features some new additions: a light-filled open atrium, an internal staircase at the eastern end of the premises to improve interfloor connectivity, expansive use of glass walls in meeting rooms to capitalize on the natural light, glass floors in some of the top-floor meeting rooms, an ornate seating area on level 10, and two new custom, round glass elevators that serve as the executive express elevators from the banking chamber to levels 10 and 11.

Challenges

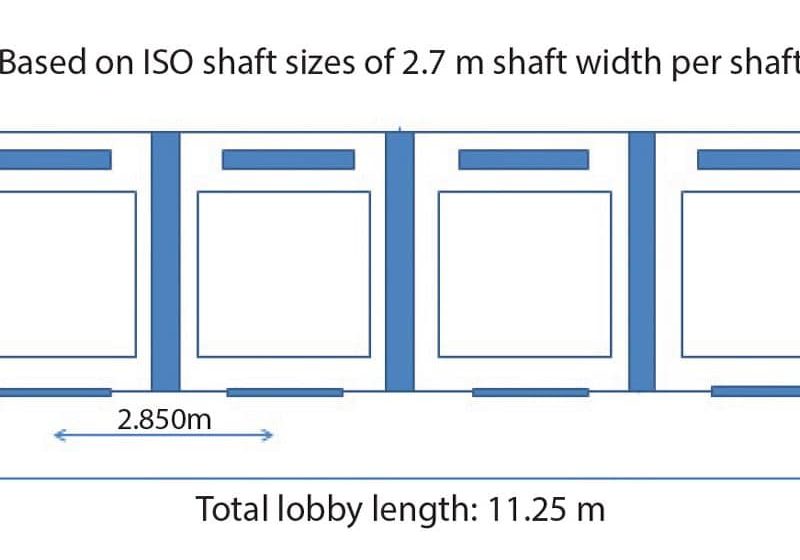

48-50 Martin Place has a strict heritage listing. When first opened in 1928, there was no allowance or consideration for the modern workspaces we see today and in which MBL is a leader. The existing vertical-transportation services were inadequate for a building where a proposed 2,000 people would work. All elevators were operating on conventional elevator control systems and scattered between two elevator lobbies at the southern and northern ends of the building.

To ensure the premises would achieve its A-Grade status for vertical-transportation services, there were a number of requirements outlined by the client and the vertical-transportation consultants, including:

- Modern controllers

- Waiting times no longer than 30 s. (up-peak) and 40 s. (lunch peak)

- Handling capacity of at least 13% (up-peak) and 11% (lunch peak)

- Shuttle service for the first, 10th and 11th floors

- Personalized passenger movement and integration with speed gates and security

The highest level of compliance with Heritage Council requirements, such as utilization of as much of the existing elevator spaces as possible and maximizing natural light within the glass shafts and elevator cars via integration of a new equipment room with a new glass dome, with minimal visibility of elevator components in open shafts

Minimal Visibility of Elevator Components

To ensure the vertical-transportation services met the specification for minimal visibility of elevator components in the open shaft, the project team developed a number of complex engineering solutions. First, a cutout in the center of the building had to be made and reinforced, as it was part of the existing building structure. Cantilever rails were also fixed at each floor to minimize visible joints and brackets. All rails were cut to nonstandard sizes to match the existing floor-to-floor distances. Additionally, intermediate supports were made in the elevator shaft and are pinned to the top and bottom slabs of the heritage building. The deflection of the rails was minimized to ensure smooth travel over approximately 48 m.

Dual counterweight diverter sheaves with a dual hitch-point arrangement allowed placement of the counterweight directly centered with the elevator car so that the car is the only visible moving part of the installation from the banking chamber. Counterweight buffers were installed between the slab separating level 2 and the main banking chamber.

Power and communications were sourced from the elevator shafts in the western end of the building and run approximately 30 m under the floor to the glass shafts on the three levels served by the panoramic elevators. A minimal number of items were connected and visible on top of the elevator car, and a creatively concealed half-moon glass trap door was made in the elevator-car ceiling.

Round Panoramic Elevator Cars

The new glass elevator shaft was one of the most significant components in the project. In fact, it has been stated the project would not have been possible without this new shaft and two new glass panoramic elevators. To successfully deliver this component, the project team developed a number of complex engineering solutions:

- Round panoramic elevator cars (custom built and assembled at the Schindler R&D Centre in Locano, Switzerland) to reduce total superstructure size, while maximizing car space

- Glass walls, floors, doors and ceilings to maximize the flow of natural light in the cars and in the shaft

- All elevator car electrical and communication wiring located underneath the car

- Decorative stainless-steel cladding used throughout the elevator-car design

- Elevator-car door operators and spears installed underneath the elevator car to maximize the height of the elevator car and minimize the visible mechanical components.

- A minimalist interior design to reduce clutter and increase the amount of glass used in the elevator cars

- The installation of a cylindrical, stainless-steel handrail on top of the elevator car for technicians’ safety

MRL Installations

The complete removal and installation of new machine-room-less (MRL) elevators at the eastern and western ends of the building were a less visible part of this project. The main complexity was minimizing damage to the elaborate marble cladding adjacent to the elevator entrances. It was also critical that all new fixtures kept with the surrounding spaces. New MRL elevators were installed with offset rails to sit behind the door entrances utilizing the existing landing doors.

New Machine Room

The newly installed glass dome sitting atop the building presented the project team with a number of challenges when it came to the design and installation of the new glass panoramic elevators. Things to consider included height restrictions, the impact on natural lighting, the aesthetics of an open machine room adjacent to the executive floors and even the elevators themselves. The machine room was built with glass walls, floors, doors and ceiling to, again, maximize the natural light in the building. It also had minimal cabling and lighting to keep with the bright, open atrium design and a consistent components color scheme.

Conclusion

With work taking place in an existing building with members of the general public continuing to access the main banking chamber in an open elevator shaft, the team had to take special safety measures. For example, a customized lifting frame was designed to move the 4.5-mT elevator cars into position. Safe work methods were developed and continuously reviewed in daily team meetings and briefings. Day and night shifts were in effect to meet time requirements, but no lost time due to injuries occurred.

Specifications

- Elevators: Two custom panoramic traction elevators, two 5500 MRL elevators in existing elevator shafts and two 5500 MRL goods elevators in newly built shafts Counterweight-side shaft access: Doors on levels 1 and 2

- Wheelchair Access Platform Elevators: Three Dumbwaiters: One

- New machine room: Cooled by two 7-HP reverse-cycle slim air-conditioning units fitted with climate sensors

- Roping: The counterweight is roped 2:1, and the elevator cars are roped 1:1 Schindler 5500 MRL

- Modernized units: Five, retaining existing machines and adding Schindler PORT Technology

Credits

Owner: Macquarie Banking Ltd.

Builder: Brookfield Multiplex

Architect: Johnson Pilton Walker Mechanical services consultant: Norman Disney Young

Elevator services provider: Schindler Lifts Australia

Get more of Elevator World. Sign up for our free e-newsletter.