Fast-growing sensor-based approach involves innovations in technology and business.

by Rob Wurth

Sensor-based maintenance is an approach to elevator maintenance that involves utilizing sensors to augment traditional maintenance by integrating data and insights into the preventive maintenance plan. It encompasses innovation on both technology and business model fronts.

Technology

From a technology standpoint, it involves permanently installing sensors on an elevator and using the resulting data as a key input to determining when maintenance should be performed and which tasks should be prioritized. Importantly, these sensors are installed in a non-invasive manner and are explicitly not discretely wired into the controller or any other elevator component. Instead, they are generally mounted on the car top, in the pit or in the machine room (or all three) and capture data that is either not measured or not readily accessible via the existing elevator systems. Finally, all of this information is available remotely for analysis without a site visit. Examples of sensors include but are not limited to accelerometers, acoustic sensors, temperature, pressure sensors and cameras. A self-contained sensor-based box (Figure 1) is used in the Lift AI system.

Business Model Uses

Sensor-based maintenance includes optimizing current business models, as well as enabling the creation of completely new ones. The sensor-based approach has broad application in terms of existing business models, such as limited-service and full maintenance contracts, as it can be used to make limited-service plans more cost-effective. Alternatively — and, often, counterintuitively — sensor data can also be applied to premium service offerings. On full maintenance contracts, sensor data can provide a premium level of service that was not feasible before; e.g., the ability to offer premium ride quality with ride-quality measurements automatically captured and emailed to stakeholders at a monthly cost close to what the customer might pay for a good cup of coffee. Without sensors, the cost of providing this premium offering would make it unfeasible for property owners and managers. Most new business models are on the cutting edge and, surely, not all will work. However, we can expect to see things like uptime guarantees or equipment breakdown insurance offerings, which may sound familiar but will look completely different when powered by sensor data.

How Does It Work?

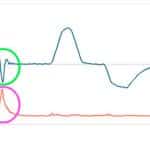

The core idea behind sensor-based maintenance is that common and general-purpose sensors can be used at scale to drive more efficient and effective maintenance of elevators. Instead of being used simply as tools on problematic elevators, these sensors are permanently installed. Their data are usually then sent to a local (on the elevator or in the machine room) edge computing device with a CPU for processing before it is sent to the cloud and, ultimately, relayed to an elevator company via web browser or app (Figure 2).

Why Does It Matter?

At Lift AI, we believe sensor-based maintenance matters for two key reasons:

- The maintenance industry is seeing changing dynamics

- The technology offers dramatic advantages over the alternatives.

On the industry side, elevator service companies are faced with pricing pressure on traditional contracts, difficulty in finding and training qualified mechanics fast enough, and customers who continually expect more and better service at lower cost. The answer to these challenges matter; safety, quality of maintenance and customer service can never be sacrificed. While there is no silver-bullet solution, we believe sensor-based approaches to maintenance can help. Utilizing new business models, companies can use sensors to provide data to their customers at lower cost, expand their geographic reach more effectively and provide increased service through automated technology, such as email and app notifications, which leave the customer with the feeling of getting more at little or no increase in cost.

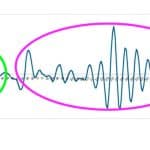

In terms of the advantages of sensor-based maintenance, the benefits are rooted in two key aspects of the systems: software and non-invasive installation. In a sensor-based system designed for elevator maintenance, the unique and most important aspects of the system — processing raw data with proprietary algorithms — happen in software, which means the sensors are low-cost, “off-the-shelf” commodities. Thanks to the explosion in smartphones and other consumer electronic products, costs for sensors are a fraction of what they were a decade ago. This results in dramatically lower-cost hardware that, when combined with powerful software, allows abilities previously thought impossible except through an OEM. For example, Figure 3 illustrates how a Lift AI system installed on a car top was able to record a releveling event (one of many) on a hydraulic elevator with a leaky valve. Lift AI units installed on the car top have no connection to the elevator other than 110-V power, and are thus completely equipment agnostic.

Similarly, Figure 4 shows where a Lift AI system was able to detect a clipped door lock, apparent from excessive acceleration/jerk, combined with a simultaneous spike in vibration.

This was done with inexpensive hardware. Installation time is another strong selling point. Because there is no discrete wiring, sensor-based systems like Lift AI’s can be installed in less than 10 min on any elevator, regardless of age, make or model. After connecting the 110-V power source, the installer is done: no calibration, configuration or communications setup required. The CPU, sensors and cellular modem power up and provide instant connectivity and data collection.

The Future

While Lift AI believes sensor-based maintenance is the future, it is only part of a quality and holistic approach to elevator maintenance, and not a system to be used alone and without other critical components and procedures, such as appropriate preventive maintenance from a qualified elevator mechanic, a well-designed maintenance control program and others. But, with the march of technology, it is clear the time has come for sensor data and elevator monitoring to play a significant role in how we maintain, service and repair elevators.

- Figure 1

- Figure 2

- Figure 3

- Figure 4

Get more of Elevator World. Sign up for our free e-newsletter.