Make Way for Modular

May 5, 2023

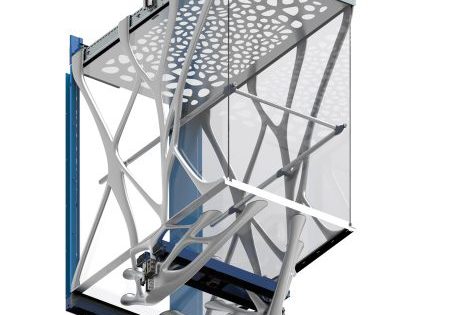

Modular Elevators Manufacturing, Inc. offers solutions to meet increasing demand for modular elevators.

California-based TL Shield & Associates, Inc., a full-service vertical-transportation company owned by Tom Shield, began distributing modular elevators soon after their invention in the 1990s. The team noticed some design flaws, and when their call for revisions was unheeded by the product’s manufacturer, TL Shield decided to use its experience to create a new company and improved line of modular units: Modular Elevator Manufacturing, Inc. (MEM) and the MEM elevator system.

Since 2004, MEM has provided conventional, commercial-quality elevators, delivered in an unconventional way, for low- and mid-rise applications. Marketing Director Russ Ward says the two greatest benefits of modular elevators are reduced time and investment. The MEM Elevator System arrives at the jobsite fully assembled and ready to be placed in the hoistway, allowing faster project completion. According to Ward, MEM enjoys a 98% first inspection pass rate for its units. Costs are lowered by shorter construction timelines and standardization across similar projects. The product can be fully operational two days after delivery, and Ward said one project supervisor estimated the MEM Elevator System saved approximately US$40,000 in construction costs per entry.

Ward has spent the last decade of his 30-year marketing career in the modular elevator industry. Over the years, he has seen major changes in demand, saying:

“When I first started, you had just two companies producing around 15 to 20 units annually. Now, there are three manufacturers in the U.S., and the MEM Elevator System has tripled [production numbers across] the entire industry annually. We have had true exponential growth, and it will continue.”

When MEM began production, their largest market segment was schools looking to quickly meet Americans with Disabilities Act of 1990 (ADA) requirements. Today, MEM has customers across multiple industries, providing solutions for affordable housing, commercial projects, the healthcare sector and more.

MEM reports an 80% return customer rate, and Ward notes that many of those who did not return simply had one-off projects. With approximately 40 employees, the MEM team’s core values are innovation, consistency, quality and simplicity. “We understand the need for quality and do our utmost to produce it day in and day out,” said Ward. “As a result, the MEM system is the gold standard when it comes to modular elevators, as we revolutionize the entire elevator industry.”

Ward anticipates MEM will once again double production, but in half the time, as modular elevator product acceptance is now mostly nationwide across all building sectors. He feels the elevator industry is overdue for a change, and going modular is the solution. MEM is a company that likes to show its work and welcomes anyone with questions to take an in-person or live virtual tour of its San Fernando, California, manufacturing facility.

The MEM system is the gold standard when it comes to modular elevators, as we revolutionize the entire elevator industry.

— MEM Marketing Director Russ Ward

Get more of Elevator World. Sign up for our free e-newsletter.