Marina Bay Sands

Feb 1, 2011

Built with inclined towers and unique roof architecture, this Singapore resort proved to be one of the most complicated projects KONE has experienced.

by Simon Barrette

About the Project

The Marina Bay Sands resort in Singapore is adding a new dimension to the concept of a skyscraper, and it is already part of the city’s skyline at a height of 200 meters. Opened in June 2010, the complex offers an environment for leisure and business travelers from all over the world. Marina Bay Sands includes convention and exhibition space, a range of leisure facilities and impressive public spaces. The resort also features three soaring hotels crowned by the Sands SkyPark, which bridges the towers. The lower buildings include a museum, retail space, a convention and exhibition center, two theaters, and a casino.

With its architecture, de-signed by Moshe Safdie and Associates Inc. of the U.S., the complex is considered a land-mark attraction. Due to its advantageous location, the resort is expected to act as a catalyst for other developments in the area and support Singapore in strengthening its position among the world’s travel destinations.

About the Elevators

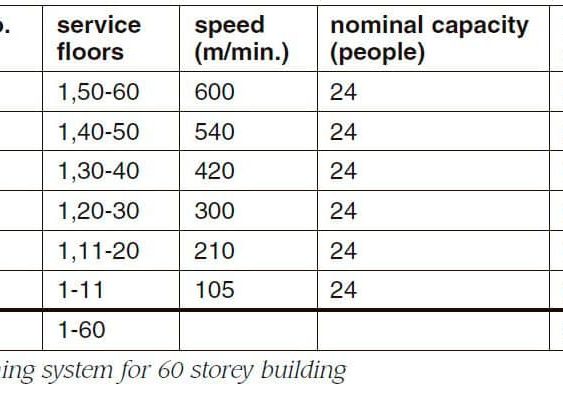

There are 152 elevators serving the hotels and podium, and 10 escalators throughout the hotels. All of the solutions are monitored remotely on two 64-inch screens by the KONE E-Link™ monitoring system. The three 57-story towers are inclined in the lower sections, which presented a hurdle to the accommodation of the elevator shafts. According to Managing Director for KONE in Southeast Asia Arttu Salmenhaara, the project was one of the most complicated KONE has experienced.

Salmenhaara added:

“Nothing was built straight; first, one part of the building was made leaning to one side, and then the other side was built straightening the other side up, literally moving the building. Another fascinating fact is the speed in which the project was completed: [in] only two-and-a-half years, it went from soil to [a] fully functional luxury hotel. KONE completed its first part of the construction within 15 months.”

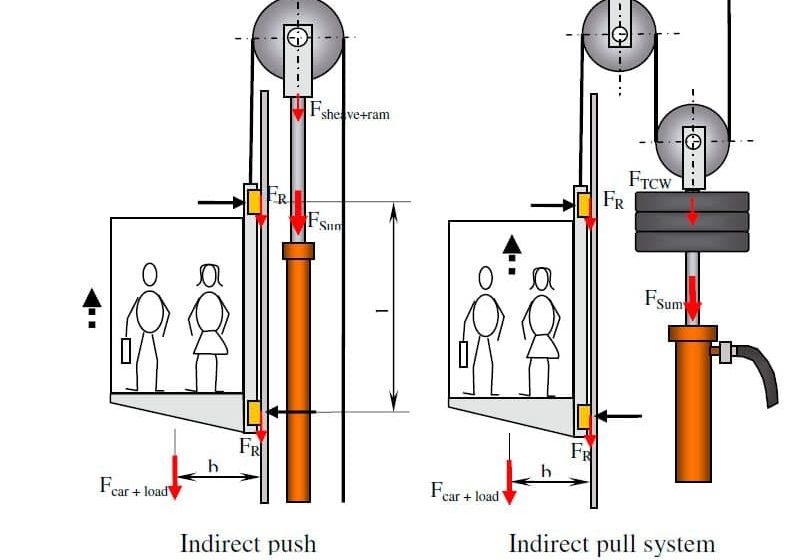

Furthermore, as the roof architecture prevented the use of standard elevator machine rooms, KONE resolved the problem by using machine-room-less (MRL) technology. The elevators are powered by energy efficient KONE EcoDisc® hoisting machines.

Pekka Kemppainen, executive vice president and area director for the Asia-Pacific region, KONE, added:

“For KONE, the Marina Bay Sands project is a showcase of both flexibility and exactness. The elevators range from luxurious high-end solutions to sturdy freight elevators. This uniquely prestigious and demanding project highlighted KONE’s ability to provide a full range of solutions for our customers, all powered by the energy-efficient KONE EcoDisc technology.”

Equipment Summary

- 39 KONE MiniSpace™ passenger elevators with ma-chine room, speed up to 8 mps, travel up to 201 meters.

- 42 KONE MonoSpace® MRL passenger elevators.

- 13 gearless MRL passenger scenic elevators.

- Two gearless passenger scenic elevators for up to 60 passengers with machine room below the pit.

- 13 KONE MiniSpace service elevators, with speed up to 4 mps and travel up to 209 me-ters, used as Jump Lifts dur-ing construction with speed up to 2.5 mps and rated load of 1300 to 1600 kg.

- 41 gearless MRL service elevators.

- Two gearless vehicle elevators with machine room, ca-pacity 9500 kg.

- Four KONE TransitMaster™ escalators.

- Six KONE EcoMaster™ escalators.

- KONE E-Link remote monitoring system

Project Challenges

The customer’s challenge was to develop an entertainment complex with three cascading towers topped by a unique sky park in cooperation with different architects and design teams. KONE contacted the customer at an early stage to see how it could add value to the construction of the project. The tender presentation was well prepared, and the project manager was already present at the first meeting. KONE’s Jump Lift elevators were included in the tender to solve the complex flow of people and goods during construction time, which needed to be short due to the customer’s tight budget schedule.

Construction-Time Solutions

KONE’s Jump Lift construction-time elevator concept proved to be the solution for moving workers efficiently and smoothly inside the building, while it was under construction. When new floors were added to the building, the elevator’s machine room was moved upward in the elevator shaft, making it possible to transport workers and building equipment to the next levels. When the building structure was finished, the construction-time elevator quickly trans-formed into a permanent elevator by installing the final machinery, signalization, interior materials and landing doors. During the construction phase of the resort, a worker averaged eight trips per day per Jump Lift elevator in operation.

Dale Chadwick, Marina Bay Sands’ executive director for Building Services, commented:

“Our construction schedules were aggressive and this solution was both safe and flexible. Generally, Jump Lifts are not a common solution in Singapore, but it is a construction access solution we have used in the region with much success. It brings workers efficiently and safely to the work face on high-rise buildings, which otherwise becomes increasingly time consuming the higher the towers go and ultimately results in lost productivity and delays. It is a cost we feel is justified to meet our aggressive construction schedules. The KONE Jump Lift solution is both safe and flexible in responding to our changing jump levels and needs.”

Project Management

Vincent Teng, KONE’s director for the project’s hotels section, said:

“KONE implemented a defined process, which included handover and checkpoints, as well as a quality- assurance plan with clear roles for all project teams involved. No less than 18,000 workers were working on the project at the highest point.”

Peter Eagling, KONE’s project director for the convention and exhibition center and retail area, added:

“Each of the six sections of the complex had its own architect and design teams. Keeping track of the work was demanding, but we were able to success-fully deliver and install the equipment by constantly communicating with the customer and making sure that we were always on the same page.”

Get more of Elevator World. Sign up for our free e-newsletter.