Market Booms for Code-Compliant Swing Doors

Apr 1, 2018

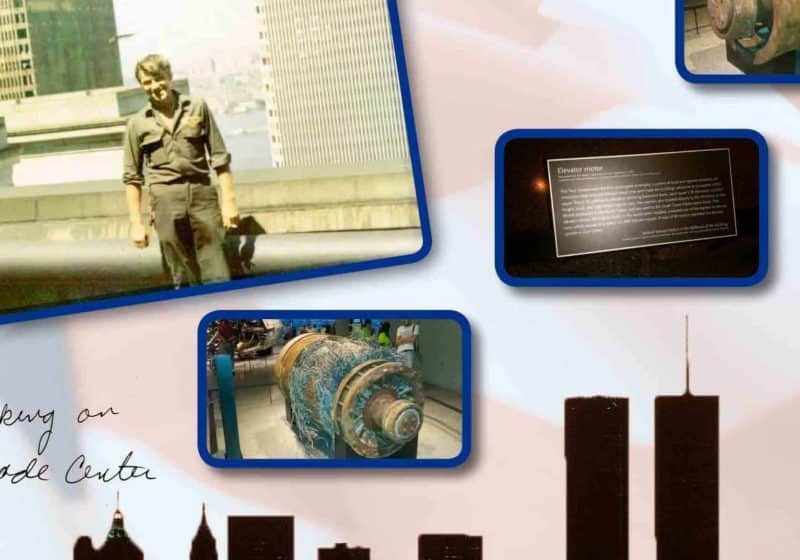

Niagara Belco positions itself to take advantage of growing trend

The boom in residential elevators is bringing a burgeoning demand for code-compliant swing doors, and as North America’s oldest and largest elevator swing-door supplier, Canada’s Niagara Belco is positioned to be an authoritative voice in the elevator door industry. Formed in 1983, the company has been engineering, manufacturing and supplying fire-rated elevator swing doors for more than 35 years. During this time, it adapted to frequent code changes and building-code revisions, as well as a diverse application marketplace, emerging in a prosperous position within the elevator industry.

Hamilton, Ontario-based Niagara Belco provides standard and highly customized entrance solutions to all major elevator OEMs, as well as many smaller companies. It has installed equipment for solar-power electric-generation plants, historic 1920s replica high rises, oversized stage entrances, NEMA 7 explosion-proof stainless-steel units, correctional-facility security doors, blind-hoistway applications, custom residential and other unique situations. Company jobs range from the smallest dumbwaiter entrances to massive dual-door assemblies.

There is a fast-growing demand for flush-mount residential doors. Updated elevator code in much of the U.S. and Canada has moved toward a 3/4-X-4-in. clearance rule that replaces the outdated 3-X-5-in. rule. As introduced in Florida, this rule references ASME 17.1 Section 5.3.1.7.2 and stipulates that the clearance between the hoistway doors or gates and the hoistway edge of the landing sill shall not exceed 3/4 in. In addition, the rule mandates that the distance between the hoistway face of the landing door/gate and the car door/gate shall not exceed 4 in. Niagara Belco’s flush frame design allows elevators to meet this new rule, which was modified because of serious safety concerns regarding space between the cab and landing being great enough to allow a child to fit between the closed doors. In such a scenario, movement of the elevator could cause severe injuries or worse.

General Manager Derek Moorse said Niagara Belco meets code requirements with its innovative products and works with partners to create even safer products:

“We have a code-compliant flush frame for any approved electromechanical interlock, and we are now working with a great start-up company in Edmonton, Alberta, Canada — GoodGate.ca — to develop a rigid car gate to enhance this safety component of the assembly even further.”

“Zero-clearance” doors represent another product area growing in popularity, as many residential/commercial applications have an opening into a space that requires an additional locking swing door. Such systems might include a commercial elevator with a stop at a personal residence or a home elevator with an exit into the owner’s workplace. This type of elevator requires a door system that mounts to the sliding elevator landing frame. In actuality, the industry term “zero clearance” is misleading, as the space between the sliding-door system and swing door is actually closer to 6 in. The industry, including Niagara Belco, is moving toward a safer method. This includes additional light curtains in that cavity and/or having the door mounted closer to the elevator sliding door to minimize this space.

One requirement that has not changed is that for fire-rated elevator swing doors, but this requirement can be challenging to impress upon customers. Legally, fire-rated doors are required, but, for the customer, it can be tempting to try to save money. But, even if it’s a question of the customer simply being uninformed, at some point, noncompliance will prove costly. If the building inspector discovers noncompliant doors, they will have to be removed and replaced, leading to elevator shutdowns or denial of occupancy. This could fall back on the elevator installer, translating into significant cost for the contractor. But, this could be the least-expensive result of using nonrated doors. If there were a fire in the building, non-rated doors could fail, making the hoistway the easiest route of travel for the spreading fire. If insurance-company inspectors discover the doors were not properly “Elevator Approved — Swing Door Fire Labeled,” it will affect the claim. This could expose the elevator company to litigation, not to mention the burden of dealing with injuries that could have been avoided. Niagara Belco implores its customers to use properly rated doors and rely on experts to inform them on which type of door is appropriate for each application.

One problem the company has come up against is the notion that, in an elevator installation, the door systems are often an afterthought or “minor” portion of the project, but, in reality, door integration and proper lock selection is one of the most important elements of the entire elevator system. Niagara Belco technicians frequently encounter door strikes and interlocks that are neither rated for elevator use nor in compliance with the code being used. ASME A17.1/CSA B44 and A18/ B355 are very specific on the type of locks allowed. Code and operational factors also come into play with power door operators. For example, to meet elevator swing-door fire-label requirements, power door operators must be equipped with a spring-return closing mechanism. Otherwise, a power failure could result in the swing door remaining open during a fire.

Joe Hickey, Niagara Belco vice president for Mechanical Design, summed it up this way:

“This is our wheelhouse. This is where our expertise lies, and if you are not positive, you should consult a company such as Niagara Belco for the correct guidance. We realize that some applications make it impossible to order an off-the-shelf product, and, with some elevator companies, the doors are sometimes an afterthought. We don’t see it that way, and experience on both sides of that fence has educated us on the importance of ensuring all details are crystal clear. For that reason, we also offer onsite design consultation anywhere in North America.”

Accessibility regulations are also frequently changing, so even if an elevator company is disciplined in keeping up with current elevator codes, it’s possible that a building code amendment will be introduced and enforced without elevator contractors being aware. For example, Ontario recently made a building-code change mandating clear opening of 33-7/8 in. (860 mm) between the inside surface of the door slab and the jamb post. This meant the standard 36-in. door would no longer provide a code-compliant clear opening. In response, Niagara Belco now offers a 37-in. fire-rated elevator swing door that meets this building-code condition.

Get more of Elevator World. Sign up for our free e-newsletter.