Material Selection and Design for Lift Door Panels:

Apr 2, 2024

Evaluating Safety, Durability and Performance

Summary

This article focuses on the material selection of lift doors, addressing general developments in the lift industry, technological advancements and comparisons of different material options. The introduction section of the article provides an overview of general trends and technological advancements in the lift industry. This section emphasizes the evolution and modernization of lifts, the increasing safety standards and the efforts aimed at enhancing user comfort. Following that, the article focuses on the material selection of lift doors. Traditional materials, especially metal materials like DKP sheet DKP, are thoroughly discussed in terms of their technical specifications and advantages. The durability, strength and fire resistance of metal materials are analyzed to explain why they are still preferred. Following that, the use of composite materials for lift doors is discussed. The advantages of composite materials are explained in detail, particularly highlighting their lightweight nature, corrosion resistance, ability to offer various color and texture options and fire resistance properties. Additionally, the malleability of composite materials and their capability to provide aesthetic diversity are emphasized. Lastly, the article addresses the selection criteria for composite materials for lift doors. Among these criteria are factors such as cost-effectiveness, durability, design flexibility and safety standards. The advantages and disadvantages of composite materials compared to traditional metal materials are compared, with emphasis on the circumstances in which each material should be preferred. In this manner, the article comprehensively covers the significance of materials used for lift doors, along with the advantages and disadvantages of different options.

1. Introduction

Today, the importance of lifts in our lives is increasing steadily. Every day, both in residential buildings and commercial centers, more comfortable, secure and faster lifts are starting to be used. These lifts are designed to enhance people’s quality of life, streamline daily activities and accelerate workflow. With advancing technology, standards in the lift industry have continuously improved. With the advancement of technology, areas such as safety features, operational technology, compliance, usability and ease of installation have been continually evolving. Research and development activities are a rapidly advancing field in the lift industry because keeping track of and implementing technological innovations is a significant necessity in the industry.

In the lift industry, materials science plays a crucial role because selecting and developing suitable materials that meet safety, durability and performance requirements ensure the safe and efficient operation of lifts. Materials science is a dynamically evolving field that constantly shapes itself with technological advancements. The discovery of new materials and the improvement of existing ones bring significant innovations in both industrial and scientific applications.

2. Lift Material Diversity and Usage Areas

The lift industry is an area that offers a wide variety of materials; different metals, alloys, plastics and aluminum are commonly used in the industry. Firstly, steel is commonly used in the construction of lift door panels and guide rails. Steel provides safety in lift structures due to its strength and durability. Additionally, aluminum is frequently preferred for lift cabin panels and doors. The lightweight and malleable properties of aluminum allow for the creation of aesthetic and modern designs. Glass is also commonly used in modern designs; glass panels provide a spacious and modern look to interior spaces. Additionally, plastic materials are commonly used in the interiors of lifts. Plastic is preferred for making parts such as buttons and control panels due to its lightweight nature and various color options it offers. The lift ropes responsible for the movement of the lift are typically made of high-strength steel. Motors and other electronic components are essential elements that enable the operation of lifts. These components are manufactured from strong and durable materials and ensure the efficient operation of control systems. Materials used for sound and wear insulation ensure the lift operates quietly and efficiently. Fire-resistant insulation materials are used in the lift shaft for fire safety purposes. These materials ensure the lift operates safely in case of a fire and prevent the spread of fire to other areas.

3. Lift Automatic Door Systems

Lift automatic doors are characterized by complex system integration and various material components. Typically, the materials of choice for door panels include high-strength materials such as steel, aluminum and glass. These materials possess important characteristics in terms of durability and robustness and are designed for long-lasting use. The special guide rails designed to facilitate the movement of the door panels are typically made of high-quality steel. These guide rails precisely direct the movement of the door panels and also provide high strength to ensure safe operation. The opening and closing functions of the doors are typically controlled by electric motors. These motors ensure smooth movement of the door panels with precise control and regulation capabilities. Additionally, electric motors enhance user comfort by controlling the opening and closing speed of the doors. In terms of safety measures, sensors are used to detect whether the door is open or closed. These sensors ensure the door opens and closes safely for users and also verify that the door is in the correct position. The operation and control of the doors are typically conducted through a control panel. These control panels manage the opening and closing times of the doors and regulate movements based on user requests. Additionally, there are also lock systems that ensure the doors are locked in case of emergencies. These systems ensure the safe and effective operation of lifts, providing a safe evacuation option in case of any emergencies. In conclusion, lift automatic doors are equipped with complex system integration and various technical features, ensuring safe, efficient and seamless operation.

4. Material Selection for Lift Doors: Comparison of Steel, Aluminum and Glass

Comparing the technical specifications of materials such as steel, aluminum and glass, which are used in the production of lift doors, is crucial for evaluating the durability, safety and performance of these doors. Steel is known for its high strength and tensile strength. Thanks to these properties, it provides structural integrity and durability for lift doors. On the other hand, aluminum is also a high-strength material but it has a lighter structure compared to steel. Aluminum increases the design flexibility of lift doors due to its resistance to corrosion and its malleability. Glass, on the other hand, provides a modern and aesthetic appearance and adds a sense of spaciousness to interiors. Durable tempered or laminated glass versions meet safety standards, and offer robustness and safety. Thoroughly assessing the technical specifications of these materials ensures that lift doors function safely and efficiently over a long lifetime. Therefore, lift door manufacturers meticulously work on the selection of materials for their doors, ensuring they meet quality standards by making the most appropriate material choices.

5. The Importance of Using DKP Sheet in Lift Door Panels and Evaluation of Its Mechanical Properties

The DKP (Low Carbon Cold Rolled Sheet) sheet used in the manufacturing of lift door panels is a material widely preferred in the steel industry. This sheet typically has a low carbon content ranging from 0.15% to 0.6% (Jones, 2019). This low carbon content ensures that the sheet plates are soft and malleable. The malleability of the sheet is of great importance in the production process of lift door panels as it provides assembly flexibility. Additionally, the low carbon content of DKP sheet enhances its weldability and facilitates the assembly of door panels. The production of DKP sheet plates is typically carried out using the cold rolling method. This process allows steel sheets to be produced by rolling at low temperatures. The proper shaping and achieving the desired thickness and smoothness of cold-rolled sheet plates enhance the quality of lift door panels and ensure compliance with industrial standards (Smith, 2020).

In terms of mechanical properties, the tensile strength of DKP sheet plates typically ranges between 270-310 MPa, while the elongation rate is approximately 25% (Brown, 2018). These values determine the durability and flexibility of the sheet plates, thereby enhancing the safety and functionality of the door panels. The economic affordability and widespread availability of DKP sheet contribute significantly to its prevalence in the lift industry. The availability in large quantities helps to reduce production costs and optimize the cost of lift doors. This is one of the reasons why DKP sheet is preferred in industrial applications (White, 2021).

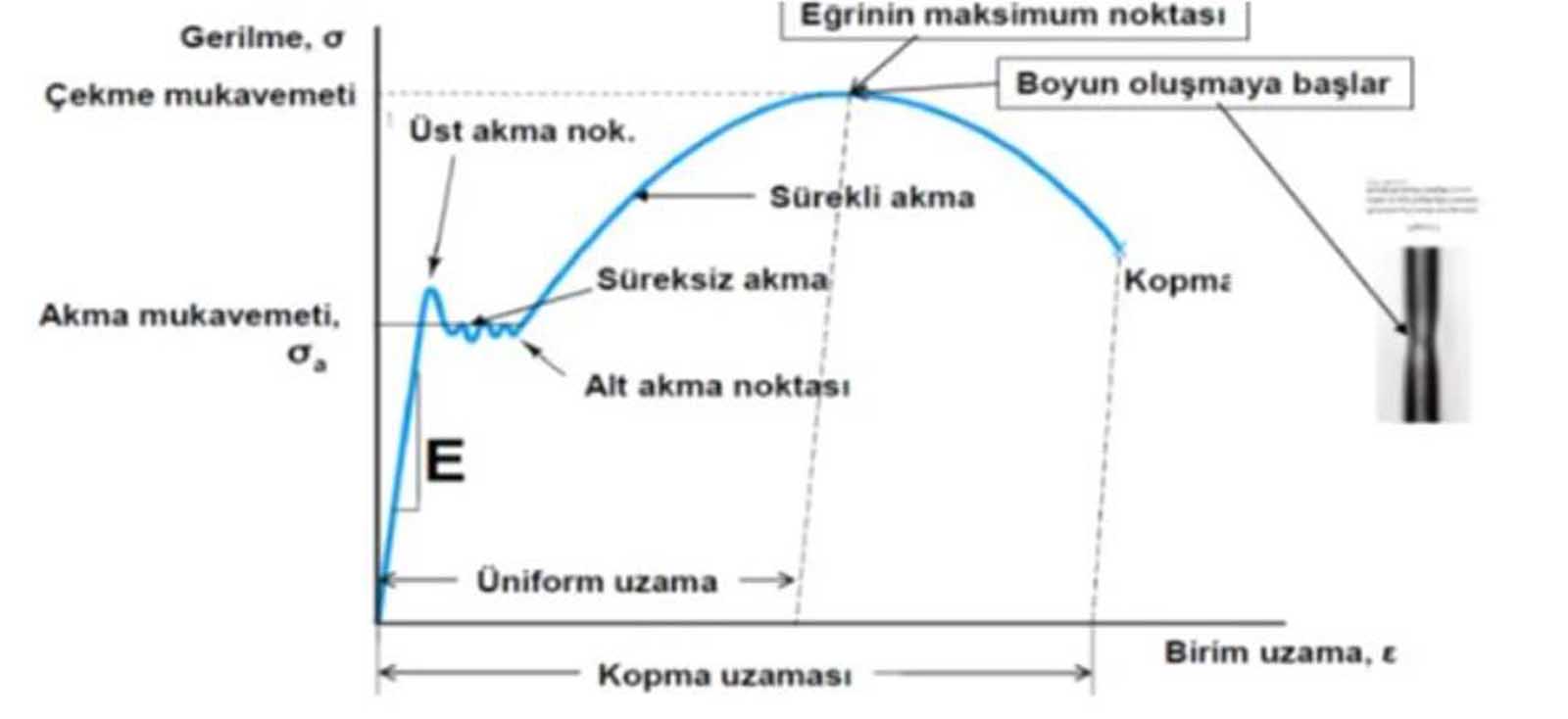

6. Importance of Mechanical Properties of DKP Sheet in Lift Door Panels

Tensile strength expresses a material’s ability to withstand tensile stress. Sufficient tensile strength of DKP sheet used in lift door panels ensures the panels are resistant to external forces. Especially, it can absorb the effects of mechanical loads that may occur during the opening and closing process of the door and prevent the panels from bending or deforming. This ensures that lift doors have a long lifespan and maintain compliance with safety standards. The elongation rate expresses the material’s ability to undergo plastic deformation. The high elongation rate of DKP sheet used in the manufacturing of lift door panels enhances the malleability of the panels. This allows the sheet plates to be easily processed in various ways, facilitating the shaping of panels into desired forms and dimensions. Additionally, the high elongation rate enables the door panels to flex and shape during assembly, thus allowing for the creation of solutions tailored to different design needs. For these reasons, the tensile strength and elongation rate of DKP sheet are of critical importance for the safety and durability of lift door panels. Properly determining these mechanical properties of the material increases the service life, ensures safety and ensures compliance with industry standards for lift doors.

There are specific standards for the forces to be applied externally to lift door panels, and these standards are typically determined by building safety codes and guidelines set by the lift industry. For instance, in the European Union, standards such as EN 81-20 and EN 81-50 establish requirements concerning the safety and durability of lift doors. These standards encompass various tests and criteria to ensure the resilience and safety of lift door panels against externally applied forces. For instance, factors such as the tensile strength of the door panels, resistance to bending, impact resistance and reliability of locking mechanisms undergo testing, and they must be within the specified limits. The significance of DKP sheet in this regard is directly related to its mechanical properties. DKP sheet has sufficient performance in terms of mechanical properties such as tensile strength and bending resistance due to its low carbon content and appropriate hardness level. These properties are important to ensure the resilience and safety of lift door panels against externally applied forces. Additionally, the homogeneous structure and smooth surface of DKP sheet facilitate the production of lift door panels in accordance with tested and approved standards. In conclusion, the importance of DKP sheet for the safety and durability of lift door panels against externally applied forces is significant. Its robust mechanical properties and malleability ensure that the door panels are manufactured in compliance with standards and can be used safely.

7. The Role of DKP Sheet in the Design of Lift Doors: Critical Factors for Safety, Comfort and Functionality

The design of lift doors is of great importance for the safety, comfort and experience of users. First, the functionality and durability of the doors should be considered. Doors should open and close smoothly while also being resilient to external factors. Therefore, it is of great importance that the doors are designed and shaped correctly in terms of form and size. The type of product greatly influences the design of the doors because different types of lifts have different requirements. For instance, doors designed for passenger lifts prioritize aesthetics and comfort, therefore thinner and lighter materials can be used. On the other hand, doors designed for freight lifts prioritize durability and safety, so thicker and sturdier materials are preferred. Appropriate form ensures that the doors operate correctly and minimizes safety risks. For example, properly shaped doors open and close smoothly, ensuring the safety of users. Additionally, doors with the appropriate form provide convenience during both installation and usage. In conclusion, the proper design and shaping of lift doors constructed using DKP sheet are crucial, both in terms of aesthetics and functionality. User expectations, industry standards and safety requirements should be taken into account in the design of the doors. This enhances the user experience while also ensuring the safe and efficient operation of the lift.

8. Composite Materials for Lift Doors

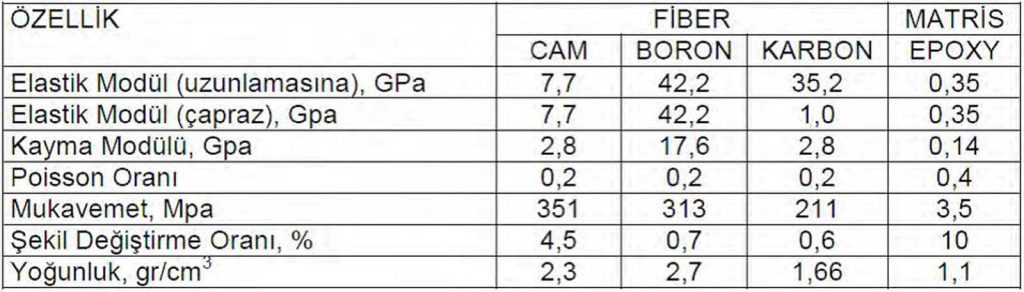

Composite materials can be defined as complex structures that offer various advantages in different engineering applications. Choosing composite materials for lift door panels offers a number of engineering and design advantages. Composite materials are typically created by combining two or more components, with these components usually consisting of a matrix and reinforcing fibers. Reinforcing fibers are typically glass fibers, carbon fibers or aramid fibers, which are integrated into the matrix to provide the desired strength and rigidity (Smith et al., 2019). Among the advantages of composite materials are their lightweight nature, high strength, resistance to corrosion and design flexibility. These features allow lift door panels to be sturdier, lighter and more durable.

The advantages of composite materials include a high strength-to-weight ratio, corrosion resistance, low weight and flexible design options. Particularly, composites created with combinations of materials such as glass fibers, carbon fibers or polymer matrices can provide high durability and offer a variety of aesthetic options. However, composite materials also have disadvantages such as high cost, production complexity, difficulty in recycling and limitations in certain industrial applications.

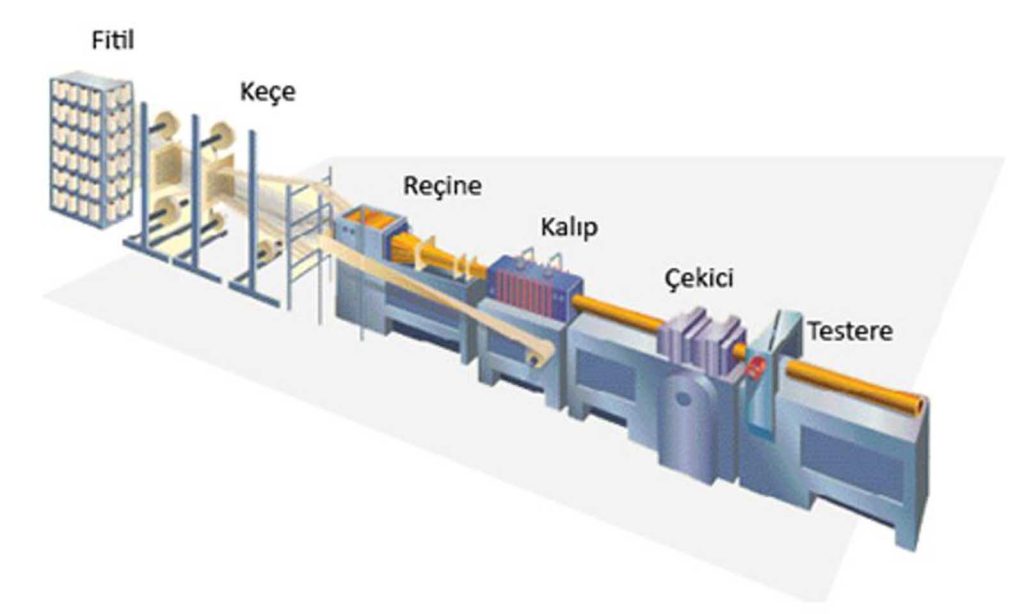

9. Use of Composite Materials in Lift Door Panels: Production Methods

Various manufacturing methods exist for the production of composite materials used in lift door panels. Among the most common methods are injection molding, filament winding and pressing (Jones, 2020). The injection molding method involves injecting a mixture of matrix resin into a mold and then allowing it to harden. This method is used in the production of parts with complex geometries and offers high production speed. The filament winding method involves wrapping filaments around a mold, resulting in parts with higher strength and rigidity. The pressing method involves placing fibers into a matrix and compressing them, making it less costly and suitable for parts with simple geometries. The panel forming process involves shaping the composite material into the desired shape and size. This process is typically carried out through molding or cutting operations. Molding involves placing the composite material into a mold and allowing it to harden, making this method suitable for the production of parts with complex geometries. The cutting process, on the other hand, is used in the production of parts with simpler geometries and is carried out using cutting machines or laser cutting technology. Selection of composite materials for lift door panels should be made depending on various factors. Firstly, the design requirements and usage scenarios of lift doors should be taken into consideration. These requirements include factors such as the strength, durability, weight and aesthetic appearance of the door panels.

10. Composite Material Selection in Lift Door Panel Design: Factors and Applications

Lift door panels generally need to be lightweight so that they do not create unnecessary load during the opening and closing of the doors. Therefore, lightweight materials such as fiberglass composites may be preferred. In addition to being lightweight, fiberglass composites provide durability and offer aesthetic appeal with various colors and textures. However, higher strength and rigidity may be required in some cases. Especially for larger lifts or buildings experiencing heavy traffic, it may be necessary to install more durable door panels. In such cases, carbon fiber composites may be preferred. Carbon fiber is known for its high strength and rigidity, and these properties allow for the production of more durable and long-lasting door panels. Additionally, the safety factor should also be taken into account. Especially, composite materials made from aramid fibers provide high impact resistance, thus offering better protection in emergency or collision situations. Such materials can be preferred in safety-critical applications. The production process and panel form also play a significant role in material selection. For example, fiberglass composites are typically shaped using molds, while carbon fiber and aramid composites may require more complex production processes. Therefore, the production process and panel form can be decisive factors in material selection.

The factors that need to be considered when selecting composite materials for lift door panels are quite diverse and include many factors such as design, use, safety and production. Design requirements encompass features such as the aesthetic appearance, dimensions, shape and functionality of the door panels. Door panels designed for a modern and luxurious building should be visually appealing and prestigious. Therefore, the selection of composite materials should align with these design requirements. Usage scenarios determine the usage density, traffic and security requirements in the environment where the lifts are located. In areas with high usage, durable and impact-resistant materials should be preferred. Especially in lifts located in public areas, door panels should be durable and resistant to long-term use and wear. Security concerns include the fire, impact and chemical resistance of door panels. Fire resistant door panels are important for safety in lifts used in public buildings or high-rise buildings. Impact resistance should also be taken into account as door panels must be durable due to frequent use and provide safety in case of accidents. The production process affects factors such as the cost, malleability and production speed of the material. Composite materials generally require specialized production processes, which are costly. The complexity and cost of the production process should be taken into account in material selection. For example, according to a study by Smith (2020), fire-resistant composite materials are produced using high-temperature resistant resins and glass fiber-reinforced structures. These materials enhance durability in case of fire and alleviate safety concerns. A study by Brown (2018) demonstrates the effectiveness of aramid fibers in impact resistance and energy absorption. Therefore, composite materials containing aramid fibers may be preferred for safety-focused applications. Taking these factors into account helps designers and engineers select the most appropriate materials, allowing them to find the best solution for the safety, durability and aesthetic appearance of lift doors.

11. Conclusion

Lift doors are important components that ensure the safe and efficient operation of lifts. This article focused on the material selection and design of lift doors. The technical specifications, applications and advantages of various materials (steel, aluminum, glass, cold-rolled steel sheet, composite materials) are discussed.

Steel is a traditional material known for its durability and strength, and it is commonly used in the production of lift doors. Aluminum, on the other hand, is preferred for its lightweight nature and easy malleability, allowing for the creation of modern designs. Glass provides an aesthetic appearance and adds a sense of spaciousness to interiors. DKP sheet, with its low carbon content and malleability, is used in the production of lift door panels, providing security and durability thanks to its mechanical properties. On the other hand, composite materials offer advantages, such as light weight, high strength and aesthetic versatility, despite their more complex production process and cost.

The safety, comfort and experience of users should be taken into consideration in the design of lift doors. Design requirements encompass features such as the aesthetic appearance, dimensions, shape and functionality of the doors. Additionally, factors such as usage scenarios, safety concerns and the production process should also be considered in material selection.

In conclusion, the correct material selection and design of lift doors are crucial for the safety, comfort and experience of users. Designers and engineers should consider factors such as material properties, usage requirements and production processes to find the most suitable solution for lift doors and ensure the provision of the best solutions for safety, durability and aesthetic appearance.

Get more of Elevator World. Sign up for our free e-newsletter.