Matot Celebrates 125 Years of Lift Solutions

Aug 1, 2013

This Chicago elevator company celebrates its humble beginnings and growth from a two-person operation in a woodworking shop.

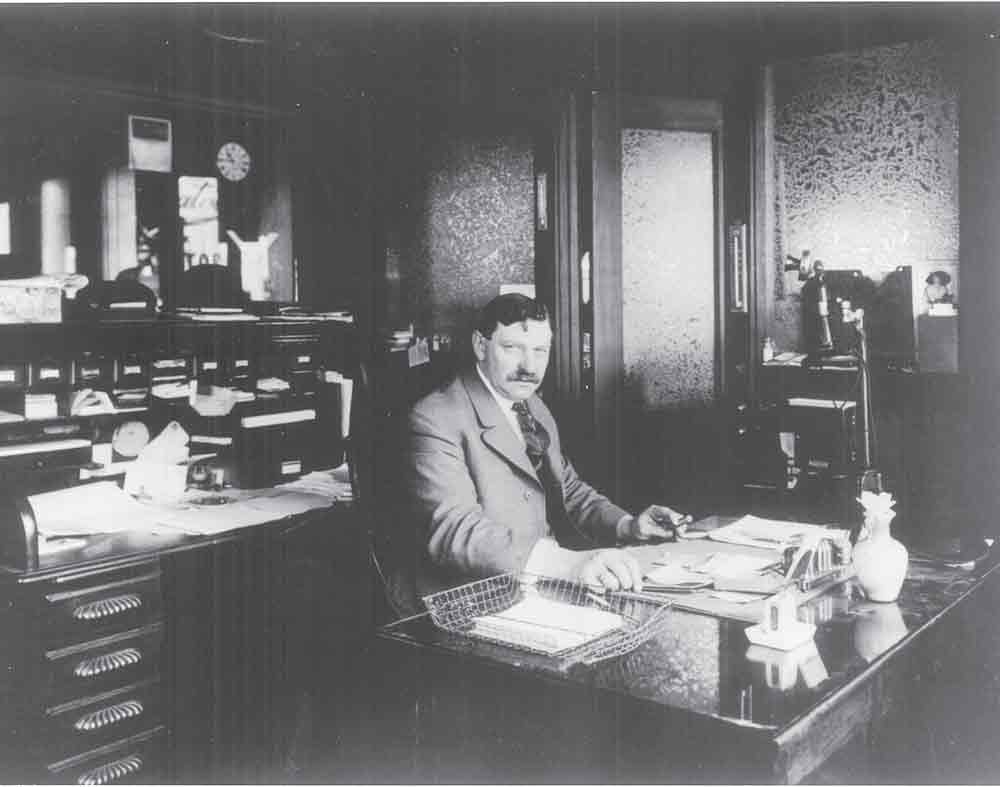

Since 1888, Matot, Inc. has been thinking “inside the box.” It all began on the north side of Chicago when Duffy Adolph “D.A.” Matot, a master carpenter, made his vision of providing refrigeration equipment and functional dumbwaiters to area taverns and shops a reality. From this dream, D.A. Matot Inc. was founded in a woodworking shop that began with just two employees servicing the local Chicago area.

Today, Matot offers commercial and residential dumbwaiters, modernizations, and residential elevators, and has an elevator showroom where customers can test and compare products. “Our technology is truly cutting edge. We have helped revolutionize how elevators and dumbwaiters are produced. 3D models can now flow from an engineer’s computer to the Matot shop floor’s fully automated machinery,” Matot Co-President Cece Matot said. With 60,000 sq. ft. of space, the company designs and builds every model at its facility in Bellwood, Illinois, a suburb of Chicago, and has more than 25 employees design and custom build lift solutions.

Cece Matot, D.A.’s great-granddaughter, joined the company 27 years ago and serves as co-president with her sister, Anne Matot. Cece Matot said:

“It has been said my great-grandfather believed that experience is true learning. There is a preamble to his old catalogs titled ‘Experience is the most valuable teacher.’ It talks about how initiative and perseverance were the true marks of demonstrated success.”

Anne Matot joined the company 25 years ago. She said:

“We are not only a family business, but a business that employs families. Our longest-tenured employee has worked here for more than 40 years and our shortest for 10 years. We care about our product, because it is our family’s reputation.”

D.A. Matot had a knack for inventions, and although he did not patent it, he was said to have been the originator of the long-draw beer system. The system allowed barkeepers to store barrels of beer in Matot’s basement refrigerator and serve it on the main level of the establishment. The founder also invented a hand-powered dumbwaiter.

Matot’s business grew as Chicago prospered, meeting the demands of the growing population and productivity. The company weathered the Great Depression and performed U.S. Department of War work during both world wars. After World War II, Matot began to shift its manufacturing and sales emphasis. Nearly 50 years after Matot was founded, D.A. Matot’s son, Edward Joseph Matot, I, took over management, and began manufacturing electric dumbwaiters in 1952. Two years later, his son, Edward Joseph Matot, II, joined the family business as Matot transitioned to manufacturing dumbwaiters exclusively.

Electric dumbwaiters and vertical-material handling equipment became an integral business asset to many of Matot’s early elevator-industry clients, including Otis, Dover (now ThyssenKrupp Elevator), Montgomery (now KONE) and Westinghouse (now Schindler). These companies continue to be loyal customers today.

By the early 1980s, Matot had begun manufacturing residential elevators. The new product line proved to be successful, and Matot entered into a partnership with another family business, American Crescent. The alliance increased manufacturing capacity, reduced lead times and provided a range of home elevators at affordable prices. Five years ago, Matot merged with Atlas Elevators, uniting the two producers of commercial dumbwaiters to provide a more robust offering of customized, commercial-grade dumbwaiters and lift solutions.

New Products

Among Matot’s new products are the 300- and 800-model dumbwaiters. The 300 features a compact design with stackable modular rails, a drop-in preassembled car and sling, and prewired switches and car. The 800 is a type-A material lift and has the same size and capacity as some commercial elevators without the same code requirements.

Residential Elevators

Matot and American Crescent design and manufacture several models complete with custom cab styles, accessories and finishes. Two of the most popular designs are the Regal® roped hydraulic elevator and the Elite® winding-drum elevator. The Advantage model, a 500-lb.-capacity elevator without a machine room or pit, was recently introduced to the market and is considered an economical solution.

The Elite is designed to be installed either adjacent to the elevator shaft or overhead and features a battery-operated emergency-lowering system. It is also available without a pit. The Regal utilizes the same hydraulic-drive technology built into many commercial low-rise elevator systems. Its flexibility allows users to install the machine room adjacent to the shaft or in a remote location at any floor.

For cab interiors, Matot offers a variety, including the Sierra, Executive, Presidential and Plantation. For accessories and finishes, various panel and trim designs, raised ceiling panels, glass inserts and custom laminates are also available.

Modernization

Matot also specializes in a variety of upgrade solutions, including:

- Replacing old controllers, motor-generator sets and obsolete floor plans with modern programmable-logic controllers, variable-frequency drives and tape selectors

- Replacing old selective vertical conveyors with modern vertical material-handling systems

- Replacing worn hoistway entrances

- Renovating or replacing power door/gate entrances

- Restoring material-handling equipment to current code compliance

- Changing non-operating or obsolete automatic-cart transfer systems to manual load systems or restoring the transfer operation

As fourth-generation family owners, Cece and Anne Matot believe past success has been based on caring about their products and the clients that use them. Matot plans its future success to be built on the same values, and for its vision to continue with the commitment to grow and utilize modern technologies and systems.

Get more of Elevator World. Sign up for our free e-newsletter.