Growing elevator control valve manufacturer is spotlighted for its development, testing, education and training across 46 years.

by Karl Keller

History

Maxton Manufacturing Co. dates back to 1949, when William M. Shrum, Jr. established a small independent elevator company, Coast Elevator, on which Maxton was later founded in 1968. Maxton has tested and developed valve designs since its inception, ultimately leading to the current elevator control valves in the industry today. After growing out of a multi-building location in California, the decision to relocate in 1995 to Minden, Nevada, provided the company with more opportunities. Since then, Maxton has increased its capacity, control and efficiency within a new 38,000-sq.-ft. facility by utilizing seven programmable-logic-controller-controlled test stands; nine computer-numerically-controlled machines; a machine shop; an assembly shop; a shipping/receiving department; and warehouse/office space, all under one roof.

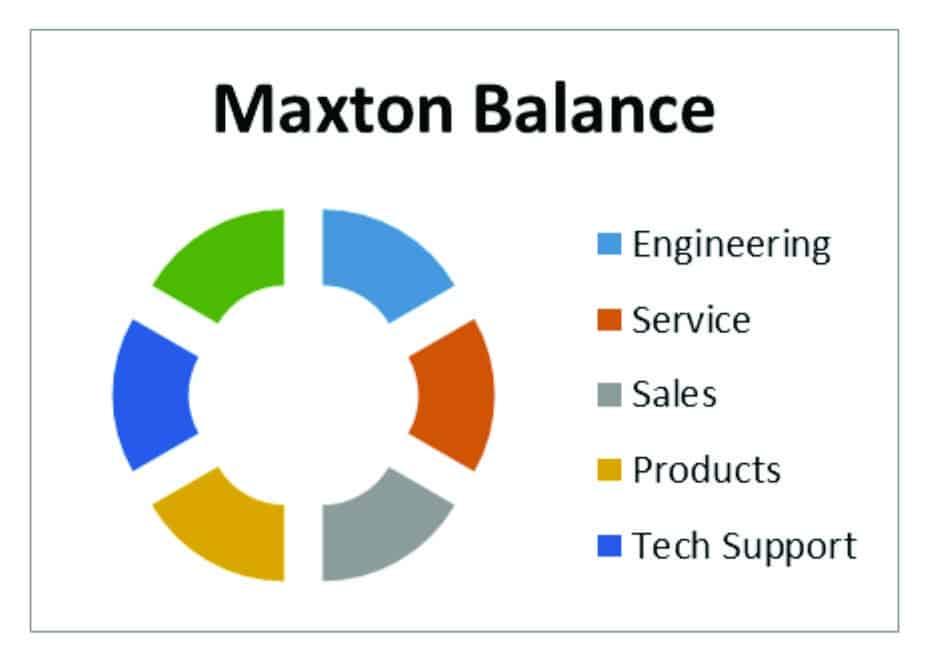

Maxton CEO William M. Shrum, III, continues the multigenerational international family business, along with his son, William M. Shrum, IV, who is acting technical manager. Both follow their fathers’ footsteps as current and future leaders of the company’s 40 employees.

Product Development and Training Initiatives

In the first 20 years following Maxton’s founding, engineering and development of various lift designs in the elevator industry generated a demand for a superior hydraulic control valve. In response, the company created a new design integrating multiple valve technology into a uni-body design. The evolution of Maxton’s elevator control valve has improved ease of use for mechanics, and ride performance and efficiency of the elevator, all while reducing labor time. The company is now reaching beyond just mechanical operation to the next generation of electronically operated valves (ELEVATOR WORLD, November 2014).

The company developed the EMV10 and UC4M HD electronic valves in response to elevator mechanics’ dislikes about working with mechanical hydraulic elevator control valves and the increased volume of work they must manage on their routes. These do not require adjustment knowledge, seasonal revisits for adjustments, or problems with heat and other factors. Maxton’s EMV10 has filled the electronic valve need for residential/limited-use/limited-application systems with similar benefits, including solving a difficult replacement situation for old CEMCO Lift RV100 units with a drop-in conversion kit (EW, July 2014). The UC4M HD, currently in field pilot programs, is a plumbing match to the UC4M for simple replacement or modernization. It is designed to automatically adjust to jobsite conditions for stable year-round performance to minimize high heat and maximize energy efficiency. The pilot program is expected to conclude in late 2015 prior to a full product launch.

Maxton has also brought multiple support products and redesigns to the market over the years, including the SafeTach, isolations couplings, tank discharge filter systems and, most recently, an ASME A17.1/CSA B44 code-compliant elevator shutoff ball valve (EW, October 2014).

The company’s initiatives include providing industry solutions through continued product innovation, maintaining a focus on safety, code compliance and further contributions to the education and training of elevator-industry professionals. Maxton continues to educate and train industry professionals about hydraulic elevator valves and systems to complement its products. Among other topics, Maxton shares how to get the most from valves and hydraulic elevator systems through temperature control, correct adjustment, proper setup and installation, and/or sizing properly to the hydraulic system. Maxton’s regular training sessions have garnered high acclaim. For example, Jersey Elevator Co., Inc. Maintenance Supervisor Dennis Lotter said of them, “I have never had so many of my guys thank me for setting up a training program.”

Training methods Maxton offers include onsite, hands-on Certified Elevator Technician (CET®) classes, U.S.-based tech support and self-directed online website and app tools for 24/7 access to technical and product information.

Our 46 years have come and gone with Maxton making the most of them so customers want to return and prosper as elevator professionals. Maxton would like to thank the elevator industry for giving us this opportunity to work hard, grow and give back.

Get more of Elevator World. Sign up for our free e-newsletter.