An automotive factory’s large loads and security requirements call for a jumbo elevator.

submitted by Marius Paraipan, ELMAS

A need to move heavy industrial machinery and production lines from level to level within an automotive factory in Tel Aviv, Israel, called for a mega elevator. ELMAS engineers were challenged to fnd the best technical solution that would meet all security requirements, combined with the requests of the client and his technical consultant.

The mega elevator was specially designed for the customer’s application and factory plan. It is designed to last through at least 25 years of daily use. The unit is unique in its dimensions and special pawl devices (hydraulic locking devices) that ensure additional support at the landings for the cabin’s own weight and the load inside.

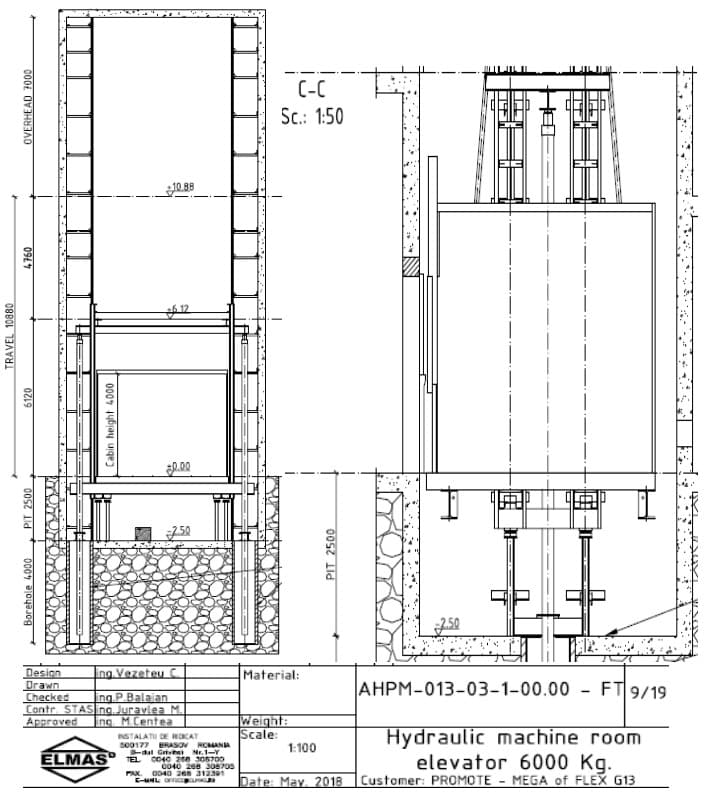

The hydraulic machine-room elevator can transport up to a 6000-kg load (nominal load) with a car frame designed for a capacity load of 11,875 kg. It has three stops, two opposite accesses in the cabin at the main landing, 11-m travel and 0.38 m/s speed.

The shaft of the elevator is 7.4 X 4.8 m and 20.38 m tall. The cabin size is 5 X 4 m and 4 m tall. The cabin fnish is 304-grit 240 stainless steel, and each part of the cabin is made from one sheet. This design created challenges, because the 6-m-long sheets had to be laser cut and bent with special equipment that allows the processing of large sheets. The overhead has 7 m, and the pit is 2.5 X 4 m (borehole).

Inside the cabin there are two 304 stainless-steel control operating panels, with a close-door button, an alarm button, an LCD display with the cabin location, a direction indicator, a three-way intercom, an overload device and distance monitoring using global system for mobile communications signal. The landing operating panels, also made of 304 stainless steel, also have an LCD display with direction indicators.

In case of power failure, the lift is equipped with an uninterruptible power system (UPS). It is a true online, continuous duty, double-conversion, solid-state, three- phase system, providing conditioned and uninterruptible AC power to protect against power failure. It also allows the cabin to go to the lowest landing, where the doors open, and the emergency cabin light activates. For the UPS, ELMAS chose the PowerScale 10-20 kVA with dimensions of 345 X 720 X 710 mm, with fexible battery management, decentralized parallel architecture and single/parallel confgurations.

To ensure a high degree of safety, the control panel does not allow the doors to be closed or the elevator to leave the foor if the safety circuits are not all acknowledged.

The doors of the elevator — having an unusual dimension — were another challenge for the design team, because they needed to use a product that could provide a door solution with reliable access, allowing for a free fow of freight movement up, down and through the facility.

After an analysis of the options, ELMAS decided, together with the client, to use Canada-based The Peelle Co. and its vertical two-section side-up entrance doors. They are designed and manufactured with a control system integrated with the ELMAS elevator controller, designed to withstand high levels of daily duty and provide reliable access to the elevator. The doors’ dimensions are 5 X 3 m. They are equipped with a light curtain, a limit system buzzer, a leaf chain and rods, a safety mechanical lock, an interlock, a zone switch and an unlocking device.

Due to the heavy load the elevator was designed to transport, the engineering team had to think of an additional measure of security during the loading. Therefore, the elevator was also equipped with four Algi GmbH hydraulic locking devices beneath the cabin to limit spring defection during loading.

The hydraulic drive mechanism of the elevator is a Bucher Hydraulics, central borehole type with two 11.26-m-long cylinders, two valves and two power units.

The delivery was made by sea. Due to the equipment’s dimensions, more than four 40-ft open-top containers were needed.

Credits

Hydraulic drive mechanism: Bucher Hydraulics

Entrance doors: The Peelle Co. Controller and PLC board: New Lift Hydraulic locking device: Algi Gmbh UPS system: ABB Electronics

Sliding guides and lubricants: ETN Elastomer

Get more of Elevator World. Sign up for our free e-newsletter.