This article was flrst presented at the 2018 International Elevator & Escalator Symposium in Istanbul. For more information on December 3-4, 2019’s event in Las Vegas and to participate, visit www.elevatorsymposium.org.

This article was flrst presented at the 2018 International Elevator & Escalator Symposium in Istanbul. For more information on December 3-4, 2019’s event in Las Vegas and to participate, visit www.elevatorsymposium.org.

The safety code for elevators and escalators in the U.S. and Canada, ASME A17.1/CSA B44, includes Section 8.6, “Maintenance, Repair, Replacement and Testing.” It applies to all new and existing equipment to ensure maintenance is performed on critical applicable components. It prescribes a maintenance control program (MCP) with very specific requirements for tasking maintenance, repairs, replacements and recordkeeping. This article details an electronic MCP that complies with all the safety requirements, utilizing electronic devices to input and access all the required records for owners, contractors and AHJs.

Maintenance and Verification

Unlike any other elevator standard, the harmonized elevator safety code in the U.S. and Canada, A17.1/B44, incorporates prescriptive maintenance requirements. It defines maintenance as “a process of routine examination, lubrication, cleaning, and adjustment of parts, components, and/or subsystems for the purpose of ensuring performance in accordance with the applicable Code requirements.” It requires doing something — observing, lubricating, cleaning or acting on systems, subsystems, components and functions. The technician could find noise, smoke, high temperature, damage or other conditions indicating housekeeping is necessary. Once found, any defects are to be corrected, and any specific manufacturers’ recommended items are to be addressed. Simple examination can determine problems by a technician being in proximity to the component, seeing a problem and taking the appropriate action in the form of a procedure. Knowing what to do is critical, both in training and written procedures.

The success of such a preventive- maintenance system is critically based on the frequency of visits or the interval between maintenance visits. This is addressed in A17/ B44 by establishing metrics to determine the interval by analyzing several criteria — age, usage, environment, condition, quality, technology and any special considerations — and where the use of IEC 61508 Safety Integrity Level (SIL) rated devices are employed. Often overlooked in this analysis is an overreliance on “maintenance-free” components to increase the intervals. The environment is sometimes not considered when determining when the housekeeping task “must” be performed: for example, how dirty the equipment becomes before this must be done. While many components can be designed to withstand a filthy environment, most other operating components, e.g., gibs, rollers, doors, governors, etc., cannot. Degradation of these components leads to failure and extreme hazards, as history has shown.

The elevator industry has been doing maintenance for more than a century, and recent changes in maintenance practices have resulted in making Section 8.6 mandatory due to these poor practices. Even with code-mandated maintenance, there are current company practices that still do not follow the intent of the code, and equipment in the U.S. and Canada is deteriorating at an alarming rate. These company practices assume nothing will “probabilistically” go wrong, and if something does, it “likely” will not create a hazardous condition. This is not the case; accumulations of debris, leaks of water into the hoistway, leaks of equipment lubrication and lack of housekeeping have led to fatal incidents when intervals between visits get excessive.

Monthly visits were the norm for more than a century. Experience has shown that equipment deterioration to components that leads to failure and fatalities is less likely to occur if the job is visited frequently. In the last 20 years, extending intervals, while relying on “maintenance-free” components and “remote monitoring” to bridge the frequency gap, have crept into the marketplace. These practices are leading to early equipment failure, increased incidents, reduction in technician morale and customer dissatisfaction.

The quality of maintenance can be measured in objective and subjective ways. Objectively, it can be measured by consultants visiting the building and evaluating the condition of the equipment, getting feedback from the customer/owner/users, measuring the rates of call-backs, and measuring key performance indicators, such as brake-to-brake time, door times, equipment noise and ride quality. Subjectively, it can be measured by the longevity of the device, early replacement of major components and more frequent repair of components. How long the equipment should last is debatable; however, what is not debatable is that proper housekeeping will increase the lifespan of the equipment; housekeeping or cleaning is the hallmark of good maintenance.

When the equipment becomes inconsistent, misuse callbacks increase due to user frustration when the conveyance performs incorrectly. There is no doubt that equipment allowed to wallow in debris, machines allowed to leak lubricant and exposure to the environment all reduce the life of equipment. It also introduces hazards to users; this must be prevented.

Many maintenance companies in the U.S. and Canada claim reducing the frequency of visits, thereby reducing elevator personnel visits, is an acceptable practice. Your author believes this is an error and is leading to unintended negative consequences. Components degrade faster once the degradation process starts, and the component is left to operate for months at a time without a maintenance visit. For example, when not visiting a job for several months, the gibs may degrade to the point they wear through the nylon material. The steel frame then damages sills or becomes worn to the point it allows hoistway doors to swing into hoistways with little or no force. This exposes users to horrible falls into hoistways. Allowing machine components to lose lubrication and degrade to where they require replacement exposes the mechanical hazard of failure; for example, a stripped gear of an escalator allowing people to be thrown off a freewheeling step band. This is bad maintenance in any sense, and this practice can be very hazardous.

Moving and wearing components in any system will degrade when no cleaning is performed; hence, the A17.1/B44 code is replete with housekeeping requirements. When the frequency of visits is reduced, these wearing components will ultimately cause a vibration in the car, resulting from a decaying roller-guide wheel, for example. When the roller is not replaced upon seeing its cracking and drying out, the roller further degrades, shedding material. Then, an elevator can begin clipping door locks, or an escalator step can come in too low, exposing the underside of comb teeth. These conditions are real; they have been for a century or more, yet we still see these hazardous incidents in the marketplace.

In an attempt to ensure maintenance is performed on all the code-required “applicable components,” A17.1/B44 requires identifying them on a chart by requirement number, and requires a record to indicate the maintenance task is completed and available for five years. Later, retrieval of this written documentation can be used to verify the completion of maintenance.

A check chart alone does not complete the MCP requirements. Maintenance tasks and procedures must be written and available to the mechanic; the interval between maintenance visits must be analyzed, considering age, usage, environment, quality, technology and other metrics. Using this judgment, a task may need to be done, for example, monthly or annually. While individual tasks may be spread out for up to 12 months, visiting a unit should occur every month.

The code clearly identifies the records to be retained for five years. These include the maintenance, callback, testing, repair, replacement and alteration records. Oil additions must be logged, and Firefighters’ Emergency Operation (FEO) must be checked monthly. There are several more items to now include: SIL-rated devices conforming and listed to IEC 61508 Programmable Electrical, Electronic Systems in Safety Related Applications for lifts.

The intent of the code is fully realized when the maintenance procedures are provided, the tasks and tests are completed, and the records are retained and accessible for five years. Not all the records are required to be kept on paper; the code allows most to be maintained electronically, provided clear instructions and unfettered access to them is provided.

The thoroughness of any maintenance and recording system can be debated; however, the framework and records requirements are not. Given the very prescriptive details of the necessary records required by A17.1/B44, the compliance of any system can be determined by those knowledgeable of the requirements. This article will detail the A17.1/B44 requirements and illustrate compliance of one such system, eMCP.

Transparency

To ensure maintenance completion, systems that provide full transparency would solve many of the shortcomings of many MCPs in the marketplace.

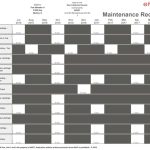

If owners, maintainers, and AHJs could all see the same information, in real time, they could quickly and correctly estimate the status of maintenance. Figure 1 is from a project with 592 units maintained by five maintenance contractors. The status of incomplete maintenance is easily displayed when all maintenance contractors use a system to record the completion of the work.

Here, maintenance work is identified by task and frequency, and provided with an expected time to perform the task. The goal is to complete 100% of the work contracted to be performed. The contract penalty may be incurred when incomplete maintenance is noticed at month’s end. This measure alone will motivate all maintenance companies to perform if transparency shows all the work completed.

The same report can be called at any time; for example, a mid-month view should be at the midway mark, verifying the job is on track, and the maintenance is being completed (Figure 2). Contractors could use this tool to monitor the work and the individual technician.

Getting to this data is complex in nature but simple to implement using the intuitive power of smartphones and the eMCP system.

Analysis

The code specifies:

“ASME A17.1-2016/CSA B44-16 8.6.1.2.2 The maintenance procedure and intervals shall be based on:

- a. equipment age and accumulated wear;

- b. design and inherent quality of the equipment;

- c. usage;

- d. environmental condition;

- e. improved technology.”

This requires an analysis to determine the interval in which a maintenance procedure is done. It is generally trying to say to look at the conditions that affect the amount of maintenance required. Similarly, if you drive your automobile 15,000 km per year, you do not need to change your oil as frequently as you would if you drive 50,000 km per year: we change our oil to eliminate metal particles and acids that have accumulated in the oil to prevent engine damage. We should also consider the environment, humidity, dust, temperature, etc.

These terms essentially describe the same evaluation made when asked to take on maintenance. You visit the job, open the machine-room door to view the equipment and either see clean, familiar equipment or filthy, old and/or unfamiliar equipment. The latter conditions invariably require more maintenance and/or more frequent visits to bring the site up to a standard of cleanliness and operation.

How long the equipment should last is debatable; however, what is not debatable is that proper housekeeping will increase the lifespan of the equipment; housekeeping or cleaning is the hallmark of good maintenance.

Establishing the intervals must be the foundation for maintenance, though, in years past, the simple rule of 1 hr. a month for a hydraulic elevator was adequate. However, if this same elevator were in a sugar refinery, for example, the cleaning demand from the environment alone would require more than 1 hr. If a system could determine the actual time needed, bidding would be simpler and justified, as opposed to guesswork and averaging the whole to take a loss on some units, while profiting on others.

Because of safety hazards, the code has established it must be determined each unit has an adequate amount of time to ensure the applicable components are operating to code requirements.

An excerpted page from an example of the interval spacing from an eMCP-maintained hydraulic elevator is shown in Figure 3. This is a partial screenshot of the “Year” view from a smart device. Column 1 is the code requirement by number with a short title. Figure 4 shows a typical maintenance screen on an iPad. Column 1 has the code requirement number and short description required to be satisfied. Touching a cell will cause a dropdown procedure box to appear.

The tasks selected in Column 1 are only for the unit, determined by a survey and an analysis of the eight metrics required by code to be considered when determining the intervals. The procedure window, shown in Figure 4, is available without live internet; it is built into the unit information. This information is made available to technicians with a valid login and password to access that unit.

The remaining columns are the last month, the current month and the next month. It is important to understand that the first principle of eMCP is that the job must be visited every month. The tasks are different; however, the presence of the technician to use all their senses to discover problems before they grow into hazardous situations or degradation of equipment is the priority.

If a task is complicated, eMCP can provide specific manuals that relate to the unit. As an example, Elevator World, Inc. has provided permission to have the Elevator Industry Field Employees’ Safety Handbook as a reference in eMCP. This reference can be opened any time it is needed, regardless of WiFi signal. Manuals for door operators, driving-machine brakes and controllers, and any other PDF can be added and accessed while the technician is at the site without internet access.

Procedures can be added, modified or edited at any time and, upon daily syncing, are provided to the technician. Special procedures/components can be added to the system to have a complete and permanent record for the mechanic’s availability.

Access to the maintenance records is through a web portal with login and password access, or on site via a web portal access number or QR code (Figure 6). This is an adhesive plastic sticker provided for every unit using the eMCP system.

Call-backs; repairs; alterations; replacements; Category 1, Category 3 and Category 5 testing; oil logs; and monthly FEO checking are also recorded into the smart device and can be viewed through the web portal. The premise of the system is that only work performed by a technician can be added through their smart device, and web-portal access can only display the information — not enter or change any data. This is the check and balance to ensure work recorded as being done is tied to the smart device, which is tied to each approved technician who logs in and uses their smart device to record the work done.

To ensure all maintenance tasks are recorded, any maintenance system must provide the technician access to all the required tasks and procedures, and a method of recording all tasks and their completion. Access to the completion data must be available to owners and maintenance companies for maintenance management. eMCP provides all the code-required records and procedures, can be used to survey the equipment and establishes the intervals according to the code criteria.

eMCP provides procedures for category tests and dropdown selections for replacements, repairs and alterations. Its features include a complete code-compliant MCP and data organization designed to be intuitive and informative.

One major university with 590 units has used eMCP for more than two years and experienced a reduction in call-backs of 37%, and all units are well-maintained, incident free and fully operational. The initial cost of maintenance rose 17%, but, after year two, with the reduction of call-backs, the overall costs of vertical transportation were down 10%. Of equal importance, the technicians report much less stress, and appreciate the clarity and ease of use of the eMCP system. The owner has safer and better- running elevators and escalators, and users have more reliability.

- Figure 1: Completion report

- Figure 2: Mid-month completion report

- Figure 3: Sample page of intervals

- Figure 4: Displaying the maintenance procedures

- Figure 5: Showing manual access

Get more of Elevator World. Sign up for our free e-newsletter.