Schwelm Symposium celebrates 20 years.

In June, the German small and medium-sized elevator industry met for the 20th time in Schwelm, Germany, for two days at the Schwelm Symposium. Almost 160 participants listened to 20 presentations that offered insights into the general conditions, elevator systems, their components and safe operation. About 20 exhibitors — lined up in the glass corridor between the hotel entrance and the hall entrance — presented elevator components, tools and services.

Prof. Dr-Ing. Wolfram Vogel from Vogel Gut Achten opened and welcomed the participants on both days and moderated the entire conference. The idea for the Schwelm Symposium was born 20 years ago from an in-house exhibition. The conference focuses on products and processes, as well as people who think beyond the box. A more elaborate anniversary celebration took place the evening before. The get-together in the evening between the lecture days featured a traditional barbecue. Many breaks were also taken in the open air, during which the presentations and exhibits were discussed further.

Insights

Building industry 2040: where is the journey heading? Prof. Dr. Adrian Wildenauer, Bern University of Applied Sciences: The objective in Switzerland is for the federal government and all federally related companies, including SBB (Swiss Railroad), to make the Building Information Modeling (BIM) method mandatory for real buildings from 2021 and for infrastructure facilities from 2025 onward. In 2020, in the preparations for the introduction, some processes, standards and norms were missed, and this shortcoming has been addressed, albeit without a nationwide strategy.

Four scenarios were presented and evaluated in detail:

- A balance between people and nature: Systemic building at the neighborhood level, preserving existing buildings, conserving resources via a circular economy.

- The emergence of civil society actors: Citizens become professionals in construction. Small-scale solutions are emerging in the construction world. Digital service models (sharing, crowdfunding) form the basis.

- Sustainability as an imperative: Regulations and sanctions for all economic sectors and citizens lead the way to centrally controlled smart cities.

- Powerful technology companies: Tech giants are tapping into mainstream construction and urban development and displacing smaller firms. Virtual and physical infrastructures merge.

Wildenauer concluded that there will probably be a mixture, with varying proportions of the four scenarios. To achieve this, the course must already be set today, and work must be done on many facets so that opportunities to exert influence can still be utilized. He put forward various theses for the necessary future dialogue in a sustainable construction industry.

Digital change using the example of the medium-sized elevator company LUTZ Aufzüge (Elevators), Hans-Martin Lutz, LUTZ Aufzüge (Elevators): Lutz started his presentation with a retrospective of how digitalization began in his company: with the definition of customers, respectively stakeholders and who talks to whom. In the beginning, this communication was digitalized — just as it was later between the elevator system and the service company with the aim of troubleshooting a system to satisfy customers. Various hardware and software tools nowadays help with this task. Along the way, the warehouse was outsourced, and the invoicing process was shortened to 2 h because processes were optimized in the course of digitalization. An important focus was put on employee acceptance of digitalization. Fears of change or transparency, for example, were allayed and managers were trained; some employees were, nevertheless, lost.

Digitalization was introduced in the form of key technical and organizational projects such as elevator development, configured price quote, customer journey and Internet of Things (IoT) and digital service. Future topics he mentioned include AI-supported processes, in-house chatbots, logistics processes, cloud and IT security, automated customer communication, as well as data quality.

Exoskeletons — ergonomic support in everyday working life — opportunities and challenges, Jan Rupprich, Hunic: In the opening session, Rupprich dealt with one aspect of occupational health and safety to provide inspiration from outside the industry for elevator manufacturers when lifting, holding and carrying loads. Every 10th day of sick leave in Germany is due to back problems suffered by employees; they are usually absent for four to six weeks at short notice. The innovative, ergonomic products offer, for example, up to 50% less strain and up to 25% greater support when lifting. The endoskeleton, consisting of the employee’s spine and intervertebral discs, is comprehensively protected by the exoskeleton, which weighs around 1.4 kg. Rupprich’s aim is not to turn people into robots, so acceptance of the support provided by employees is an important factor. A test phase in the company is possible. The costs can often be covered or at least subsidized by insurance companies.

Standards and guidelines, Franz Watzke, FW Lift-Tech Consulting: Mandate 599 covers the transfer of the EN 81 series to the ISO 8100 series. In October 2023, the first papers prEN ISO 8100-1/-2 were published as drafts potentially following EN 81-1/-2. At the vote in February, the standard sections were accepted overall at ISO level despite rejections from individual countries. At CEN level, they were rejected because approximately 2,700 comments were received, around 10% of which came from Germany. Fifty percent of the comments were related to editorial errors, and many comments related to doors and suspension means were received. CEN/TC10 WG1 has formed 11 task forces to deal with the comments. After formal votes, the final publication is expected in the second quarter of 2025. The paper contains new terms, shifts of content to annexes and technical changes, e.g., requirements for traction brakes, doors and cabins.

- Watzke also provided some information with potentially major, but not yet foreseeable, implications:

- Beuth Verlag, the supplier of DIN standards, has changed its name to DIN Media.

- According to a ruling by the European Court of Justice, harmonized technical standards must be made available free of charge.

- The revision of the EU Lifts Directive continues.

- On behalf of the VFA Interlift, Anne Zerno then briefly presented the current resolution of the EK-ZÜS regarding cybersecurity tests in compliance with TRBS 1115-1 Cybersecurity for safety-related measuring and control equipment.

WEARwatcher CORE — different shell, hard core, Tim Ebeling, Henning: Condition monitoring started at Henning in 2000. Pioneering preventive service projects were carried out at BASF and, most recently, in Singapore. This last tender was won because the company had more than 20 years of experience in acceleration measurement technology for elevators: Based on sensor data without a connection to the control system, conditions, e.g., wear on doors, are analyzed and trends are updated. The comprehensive and complex solution from Singapore has now been “slimmed down” for Europe without restricting the functionalities: wear detection, simple installation, usage-based preventive maintenance, fault detection, automated reporting and cybersecurity.

The Zauberwatte (magic batting): How an accidental discovery saves the elevator industry time and money, Martin Reichl, Uns: Through a coincidence, the new oil binding agent “Zauberwatte” was created, which has been used for several years in hydraulic elevators to absorb oil (residue) in pits. It absorbs 6.5 l of oil per kilogram of batting. It can be recycled three to four times or thermally exploited. In the meantime, the absorbent material is also available as a pressed pad, which can be quickly replaced in a pre-formed tray when fully soaked.

Components

Suspension means for elevators according to EN ISO 8100-1/-2, Prof. Dr. Wolfram Vogel, Vogel Gut Achten: The moderator’s opening presentation dealt with one facet of the new version of ISO 8100-1/-2, which replaces EN 81-20/-50. prEN ISO 81200-1/-2 will also take suspension means into account in the future. The new standard is strongly oriented toward empirical values from type examination certificates. It specifies requirements for steel ropes and plastic-coated steel ropes, suspension belts, toothed belts and traction sheaves, as well as traction sheaves for plastic-coated steel ropes. Key values, e.g., diameter ratio of sheave to suspension means D/d and determination of the safety factor of suspension ropes, are defined respectively calculated. Service life testing and monitoring by, for example, means of bending tests until failure and bending cycle counters are introduced. These and other contents of the standard, including other components, are still in flux. Therefore, Vogel appealed to the audience to stay tuned to the information on the development of the new standard.

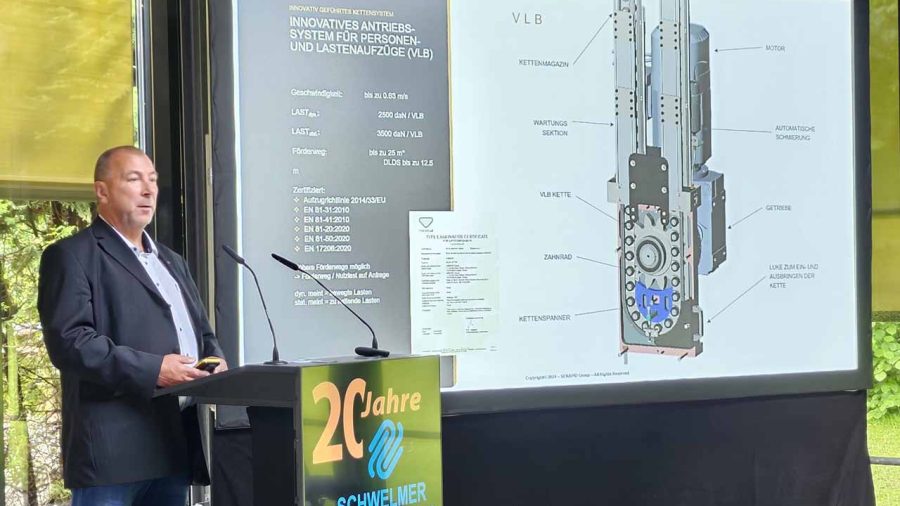

Linear chain on new paths — innovative solutions for passenger elevators in the “low rise segment” with special requirements, Olaf Klingner, Serapid Germany: The design principle Vertical Linear Beam (VLB) with a linear chain is suitable for passenger and freight elevators. The Dual Lift Drive System (DLDS) was further developed for Network Rail in the U.K. It is particularly suitable for low heights in public areas where failures must be avoided at all costs, which is helped by the use of the robust linear chain. The type examination certificate was presented in front of the audience at the conference.

Use of electric safety gears in BMP-tested system elevators, Martin Brey, Johann Schum Aufzugtechnik (elevator technology): The initial situation is characterized by ever smaller shaft pits and heads. The systems are not easy to install due to the large number of shaft components. The new product “electrically triggered safety gear” eliminates the need for overspeed governors, connecting rods, folding supports and shaft switches, making installation easier, faster and cheaper. The type examination simplifies acceptance, as calculations, tests and test reports are reduced and risk analyses are included.

Tableau concept using the example of Deutsche Bahn (German Railroad), Frank Saalmüller, Schäfer: The facilities are exposed to vandalism such as fire, physical violence and bodily fluids, as well as the weather in some cases. Occupants have an important influence. They arrive in large numbers at the same time, require barrier-free accessibility or speak foreign languages, for example. They bring luggage. And since at least the coronavirus pandemic, increased hygiene has also been a priority. The operator Deutsche Bahn (DB) has listed the corresponding requirements. Important solutions include high contrast, remote control, touchless buttons, stronger materials, two-sense emergency call and CANopen. These panel variants, some of which were specially developed for the railroads, were also tested to see whether they could withstand the loads in accordance with DB’s requirements.

Ventilation and smoke extraction systems for elevators and elevator shafts, Jan König, Ing4Lifts, Jens Westphal for Manfred Kock, Ingenieurbüro (engineering office) Kock: The presentation focused on VDI 6211, which regulates this content for elevator systems. A VDI standard is a Recognized Technical Rule (like a DIN standard) that helps to comply with the law. The main reason for creating VDI 6211 was to save energy and CO2 in accordance with the Building Energy Act by using automatic flaps to close the opening in the elevator shaft. The main benefits are the shaft smoke extraction required in the case of a fire and the reduction of CO2 in the car when people are trapped inside. The final version will be published in August 2024. Approximately 450,000 systems in Germany are still awaiting retrofitting.

Systems

Elevator by Amazon? Thomas Lipphardt, KONE: In 30 years, Amazon has grown to 1.5 million employees with revenues of US$30 billion. Today, data is collected via Amazon Alexa; for example: What will it become in 20 years’ time? The Amazon marketplace already has many “faces” today with a wide variety of content such as Pay, Music, Smile, Prime, Fresh plus third-party providers — and perhaps one day (when?) Elevator. Amazon already has a cooperation with Hyundai in the U.S. and sells individually configured automobiles there. A comparable page of planning tools and configurations for elevators can already be found on the website of KONE and others: The software configures in 1 h an elevator ready for delivery.

So why isn’t Amazon offering elevators at the moment (for the next two years)? The investment is too small at the moment. The service business is too complicated, especially because of the old technology, ditto modernization. Finally, Lipphardt painted a picture of the “ideal” Amazon elevator with screens all around for advertising and information, an Alexa function, as well as lockers for overnight Amazon deliveries, among other things.

How much elevator does a building need? Pia Gabor, Hundt Consult: The design of the elevator capacity is based on a transport capacity analysis with a balanced ratio of transport capacity and waiting time, which depends on the operator’s priorities. Other influences on the planning of the elevators are the building itself and the users. Other factors that influence the elevator are payload, car filling level, speed, approach and acceleration, etc. In existing installations, the control system, door and/or travel curve can at least be optimized. The calculations are carried out using various simulations but are often estimated for smaller units using rule-of-thumb calculations with a sufficient fit.

Lift-Link — the current overview of your elevator system, Joachim Klingler, Telegärtner Elektronik: Online monitoring of elevator systems is on the rise and provides data to various manufacturer clouds. Therefore, operators and service companies have many individual portals — without a complete overview and with gaps in unmonitored systems. Klingler presented, as a solution, the Lift-Link portal with a central overview. It is always up-to-date, manufacturer-overarching and contains all important information, including the status of the system and each component. The benefit for operators and service companies leads to improved availability of elevator systems, greater efficiency and leaner cost structures. The overarching software is based on an extensive list of cooperating data suppliers and data users.

Safe Operation

Safety first, Manuel Noe, Rudolf Fuka: The risk of accidents without UCM (uncontrolled car movement) brakes is higher. Therefore, Noe described the UCM brake offered by his company with all the technical details, including calculations and tests for offers.

Elevator emergency call meets AI, Bodo Adamus, Bosch Service Solutions: Adamus began his presentation with definitions such as bot and AI from different perspectives, as well as a picture of an elevator car with passengers painted by ChatGPT. He then presented the often AI-supported services from Bosch, such as Mobility, Monitoring, Customer Experience and Business, which can be purchased “off the shelf” or “customized.” Finally, he described four elevator-related examples: Bot-assisted configuration changes of emergency call devices, multilingual elevator emergency call, automated processing of test emergency calls and automated verification of connection quality.

Networked components — effects on the planning and operation of elevators, Stefan Windeck, aufzug (elevator) management windeck amw: The initial situation included parallel wired controllers, no interfaces to the building technologies, no monitoring, no access to the elevator and rigid service rhythms. Today, controllers and elevator banks contain serially networked components with their own IDs so that they can also be accessed externally via the internet/cloud for the purpose of remote service and diagnostics. Operators have a portfolio consisting of different makes with various technologies from different years of construction. This means that interconnection has to be discussed much earlier in the planning stage of new builds and modernizations, which leads to higher individual solutions. Greater compatibility of the systems would be desirable to simplify planning.

Digital safety circuit — DSS Digital Safety System, Peter Zdun and Henry Knop, Intec: Requirements and solutions according to EN 81-21 must be monitored electrically, which requires extensive safety circuit descriptions and many meters of cable. PESSRAL systems, i.e., digital safety circuit and digital protected areas, offer an initial isolated solution; the DSS, on the other hand, completely replaces the safety circuit. The components are safety master, position gateway and safety-based position system with sufficient inputs. The system offers new technical possibilities and an increase in safety. For example, when moving with the door open, the entire system is no longer generally bypassed and thus paralyzed, but only a single contact is activated and selectively switched off. Installation is carried out via plug-and-play with the necessary pre-settings. A special test mode enables each individual contact to be checked automatically.

Cyber Resilience Act, Jörg Hellmich, Elfin: A single virus software on a single PC is no longer sufficient to prevent malware from taking over all devices in a company. Criminal motives such as blackmail, espionage and war with the broadest possible impact have forced politicians to act at the EU level and thus in the member states. The Act was adopted by the EU Parliament and EU Council in May 2024; the transition periods until 2027 have begun. The Act describes the basic requirements for all products on the market in terms of cybersecurity.

Hellmich looked at the significance for elevator companies. It affects manufacturers and their suppliers, dealers and importers, right through to operators. They must establish cybersecurity for all their products with digital elements when they are placed on the market and ensure it for the entire lifetime of the products. Failure to do so could result in drastic penalties. Hellmich appealed to the audience to come to grips with the topic as soon as possible.

Basics and methods of cybersecurity on elevator components, Katrin Schwickal, TÜV SÜD Industrie Service: TRBS 1115 Part 1 Basics of cybersecurity defines the three objectives of availability, integrity and confidentiality of data, among others. A corresponding risk assessment for operators is mandatory. The rule defines four steps toward cybersecurity: listing the components, impact analysis, defining measures, implementation and maintenance. The documentation of these steps and their results serves as the basis for the inspection by the ZÜSsen. Elevator and component manufacturers can lay the foundations for cybersecurity as early as the development stage in accordance with IEC 62443 Security for industrial automation and control systems.

Get more of Elevator World. Sign up for our free e-newsletter.