Modern LVDT Position Sensors

Mar 1, 2011

A chronicle of how the LVDT has evolved into a reliable, cost-effective linear feedback device for the positioning of elevator cars.

by John Matlack and Mike Puccio

The linear variable differential transformer (LVDT) has evolved from its limited use as a laboratory tool more than 60 years ago into a reliable and cost-effective linear feedback device, making it an appropriate technology for critical and reliable linear displacement measurements in an array of industrial, dimensional gauging and military/aerospace applications.

Whether implemented as a standalone component or as part of a control or safety system, the LVDT, also known as a linear position sensor, is capable of providing linear displacement measurements from micro inches to 2 feet under various operating and environmental conditions with high accuracy and reliability. Essentially, the LVDT provides the information critical for a control system to perform its job.

For example, the electromechanical control systems used in elevators rely on spring-loaded LVDTs to provide the necessary position feedback for proper alignment of elevator cars at building floors upon arrival. Measuring the difference between the frame and car position, the LVDT linear position sensors provide output to a control system that uses the displacement information to adjust the travel of the frame, so when the doors of the car open, the car floor

is level with the floor upon which passengers are exiting.

LVDT Evolution

While the LVDT linear position sensor can be found in a myriad of critical applications today, this was not always the case. Prior to World War II, LVDTs had limited use as manufacturing tools, such as aligning two pieces of an aircraft fuselage during assembly. Eventually, LVDT linear position sensors found a way into aircraft, submarines and weapons/ munitions systems.

However, despite many wartime application successes, LVDTs were not considered commercially viable linear displacement measurement technology until 1946, when Herman Schaevitz authored a scientific article entitled “The Linear Variable Differential Transformer” published by the Society for Experiment Stress Analysis. This paper became a major milestone in the future development of the LVDT, as it presented complete technical data for linear position displacement technology, along with several potential applications in which these transducers are still used today.

While LVDTs were used in numerous industrial applications such as process control and power generation, it wasn’t until the arrival of affordable microcontroller-based electronics and new corrosion-resistant/high-temperature materials over the last decade that LVDTs became a more competitive displacement sensing technology, both in terms of performance and price (Figure 1).

In the past, the electronics necessary to operate an LVDT properly were complicated and expensive, prohibiting its wide use for displacement measurement. However, application-specific integrated circuits and microprocessors combined with new construction materials and manufacturing processes, have driven down manufacturing costs, while simultaneously improving performance, making the LVDT more competitive with other sensor technologies.

New winding techniques and computer-based winding machines are also allowing the sensor body length to be reduced, while maintaining or increasing the stroke-to-length ratio. This smaller size reduces the required installation space, thereby allowing the LVDT to be considered for space-limited applications (Figure 2).

How It Works

In basic terms, a transducer is an electromechanical device that converts a linear position or motion to a proportional electrical output. More specifically, the LVDT position sensor produces an electrical output signal directly proportional to the displacement of a separate movable core. Typically, the LVDT body is held in place, and the ferrous core is attached to the moving element on the piece of equipment requiring position feedback.

The basic LVDT design consists of three elements:

u One primary winding

u Two identical secondary windings

u A movable magnetic armature or “core”

The primary winding is excited with an AC supply generating a magnetic field which, when the core is placed in the central or “null” position, induces equal voltages in both of the secondaries. The secondaries are wired series opposed so that their combined output represents the difference in voltage indicated in them, which in this case, is zero. As the core is moved left or right, the difference in inducted voltages produces an output that is linearly proportional in magnitude to the displacement of the core. In addition, as the core passes through the null position, the phase relationship between the primary excitation voltage and secondary output voltage abruptly shifts 180°, thereby allowing the user to discern the direction of displacement.

As LVDTs are frictionless, there is no physical contact between the core and internal bore of the coil, resulting in transducers that offer unlimited life, as their mechanical components do not wear out or deteriorate. The corresponding absence of friction also results in truly infinite resolution and no hysteresis. Furthermore, because they have a low mass core, they are ideal for use in dynamic motion measurement situations. In elevator applications, for instance, the constant change in core position due to passengers or cargo being loaded and unloaded and the inertia of the elevator car as it begins to move and then slows to a stop would cause contact devices such as potentiometers to dither and wear.

While a vast majority of applications requiring position feedback can make use of traditional sensors including LVDTs, there are many applications in which an LVDT linear position sensor is, technically, one of the best solutions. Compared to other displacement technologies such as the contacting potentiometer, magnetostrictive transducer, optical sensor and capacitive sensor, the LVDT can perform in extreme environmental applications such as power generation, down-hole oil and gas exploration, steam valve control systems, actuators, blast furnaces, and aircraft engine and flap controls.

In an elevator, vibration, shock and dirt/grease are present. Potentiometers, as previously discussed, can wear. Optical sensors will have issues if blinded by dirt or grease, and magnetostrictive sensors typically do not handle vibration and shock well over time due to the internal wires in their tubes breaking.

Using off-the-shelf materials and components, Macro Sensors can design an LVDT to operate from -60°C to 200°C. With modifications to the LVDT core, housing, electrical interface and winding materials, the temperature range can be extended to -200°C to 500°C.

With its hermetic seal and non-contacting operation, LVDT linear position sensors are among the only technology that can deliver accurate and reliable performance, while operating at pressures up to 7,500 pounds per square inch (500 bar) with mean time between failure of 5 million hours. Even at stroke ranges of +/-0.050 to +/

-2.0 inches, these hermetically sealed sensors (IEC IP-68) can survive heavy shocks common with elevators, as well as the effects of dirt, water, steam and other corrosive elements without affecting performance.

Remote Monitoring with Modern Electronics

In certain critical and demanding applications such as high temperature, radiation, shock and vibration, signal conditioning electronics may need to be located remotely from the sensing device. Some elevator manufacturers prefer that the signal conditioning electronics be contained inside the LVDT body, while others prefer them to be located in the elevator control system.

In comparison to capacitive, magnetostrictive and other high-frequency technologies in which the electronic circuitry cannot be segregated from the sensing elements, the LVDT can be installed up to 100 feet (31 meters) from the conditioning electronics. The low drive sinusoidal frequency operates below the radio frequency spectrum and does not radiate electrical noise.

Signal conditioning and processing functions can also be put inside the LVDT housing, rather than requiring a secondary external box. Modern microcontroller-based electronics allow complete drive and processing circuitry for the compact, easy-to-use LVDT linear position sensor. These electronics allow the customer to select the drive frequency, filtering options for speed and noise. And, LVDTs can produce digital outputs directly compatible with computer–based systems and standardized digital buses.

LVDTs Help Ensure Accurate Floor Landing

Spring-loaded LVDT position sensors serve an integral role in ensuring the accurate positioning of elevator cars at building floors. As passengers travel on elevators at speeds upwards of 2,000 fpm, electromechanical control and safety systems rely on sensors to provide the necessary feedback to ensure that elevator cars and building floors are properly aligned upon arrival.

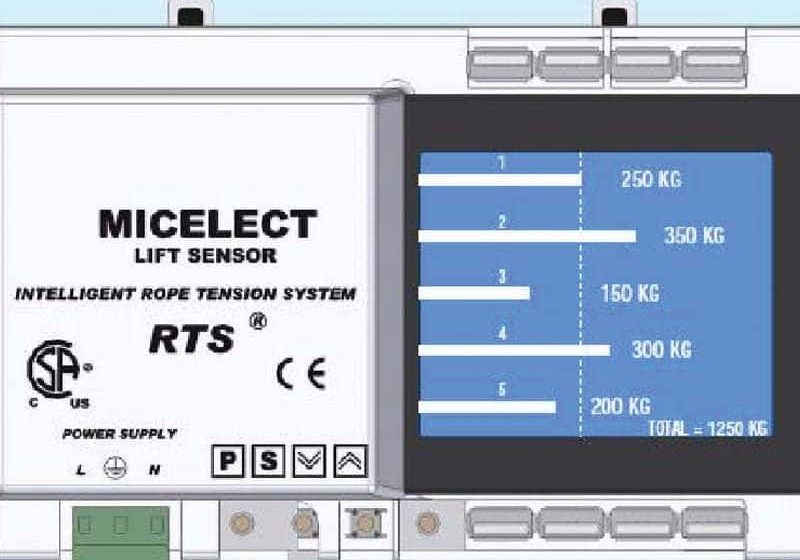

To ensure a smooth and comfortable ride, the elevator car is suspended by springs within an outer frame that provides cushioning against the effects of acceleration/ deceleration and initial starting and stopping jerks to overcome inertia. As an elevator is loaded with passengers the springs compress, changing car position within the frame. This can affect the final car position at the destination floor. To ensure that both the car and building floor are properly aligned at arrival, a Macro Sensors spring-loaded LVDT position sensor is used to measure the difference between frame and car positions. Specifically, the sensors are measuring spring deflection as a result of the load.

Depending on the elevator manufacturer, sensors are mounted under or above the elevator platform. When measurement is made from above, the probe of the spring-loaded LVDT position sensor typically compresses and extends as the load increases. When sensors are installed below the elevator platform, measurement is made in an opposite application where the sensor compresses as load increases. Output is fed into a control system that uses the displacement information to adjust the travel of the frame, so when the doors of the car open, the car floor is level with the floor upon which passengers are exiting.

About Macro Sensors

Macro Sensors manufactures an extensive line of linear and rotary sensors used for position measurement and feedback in a variety of industrial applications, including factory automation, motion control systems (such as elevator control systems), metal fabrication and automotive assembly, as well as power plants, and gas/ steam turbines. Incorporated in 1994 and headquartered in Pennsauken, New Jersey, Macro Sensors traces its origins directly to Herman Schaevitz, who founded Schaevitz Engineering in 1945 and commercially introduced LVDT technology.

Schaevitz is widely recognized as the pioneer developer of LVDT technology. He transformed the LVDT from a hand-made laboratory device to the position sensor it is today and built Schaevitz Engineering into a successful enterprise with the LVDT as its core product. Following Schaevitz’ retirement, he was succeeded as CEO by his son, Howard, who presided over a decade of corporate growth and product expansion.

After the sale of Schaevitz Engineering to a larger firm, several members of the Schaevitz “brain trust” formed Macro Sensors, a division of Howard A. Schaevitz Technologies, to design, manufacture and market position sensors and related products. Macro Sensors’ personnel bring knowledge and experience to the position-sensor industry with more than 500 cumulative years of design and manufacturing knowhow.

Supported by a worldwide distributor network, Macro Sensors employs an internal engineering staff of design, mechanical and electrical professionals with application knowledge and design expertise to work alongside customers to engineer solutions to position measurement problems. Macro Sensors has designed more than 800 custom designs to meet customers’ particular applications.

In 2005, American Sensor Technologies, manufacturer of Krystal Bond™ Technology micro-electro-mechanical pressure sensors, acquired Macro Sensors, thereby creating a single source offering customers both pressure and position sensing expertise. Macro Sensors recently redesigned its website to make it easier for design engineers to find LVDT linear position sensors and rotary variable-differential transfomer position sensors that meet the performance criteria of applications in specific industries. Finding that many engineers were unsure of what type of sensor might meet their application requirements, Macro Sensor segments LVDT and rotary variable differential transformer position sensors into application categories.

Get more of Elevator World. Sign up for our free e-newsletter.