Modernize DC Gearless Motors: Do It Right and Reap the Rewards

Oct 1, 2016

Three ways modernization reduces operation expenses for DC motors

As urban populations continue to grow, more and more Americans either live or work in high-rise buildings — defined as buildings 100 m in height or taller. These buildings, most of which were constructed before 2000, primarily have elevators operated by gearless DC machines.

When people encounter a problem with their DC machine, their first thought is to replace the motor — an expensive undertaking. But DC-powered elevator systems, despite already functioning from between 30 and 70 years, can provide decades of additional service if properly maintained. Repairing or rebuilding your DC machine offers substantial cost savings when compared to a complete AC motor replacement, and, by modernizing your DC drive’s technology, you can also significantly reduce energy costs for the building. Selecting the right drive and refurbishing the existing DC motor correctly can set you and your customer up for tens of thousands of dollars in savings.

Life Expectancy

There are three ways elevator modernization proves to be more cost effective than motor replacement. The first way lies in the DC motor itself. When basic maintenance is properly performed, a well-made DC machine can have a lifespan of 100 years or more. AC motors have a much shorter lifespan — generally, in the range of 15-20 years. In the lifespan of a single well-maintained DC motor, an AC motor will have had to be replaced five, six or even seven times.

Upfront Costs

This brings us to the second way in which modernization is a smarter option than replacement: upfront costs. The cost to replace a DC motor with an AC motor is US$20,000-85,000. Many variables can affect that cost, including DC machine breakdown and removal, the size of a compatible AC motor, installation of the motor, hoisting requirements, requisite building work and more.

AC motor systems installed in 1999 in advance of updated code regulations might have already needed to be replaced, and they can be expected to need replacing a number of times. On the other hand, if a reputable refurbishment firm had performed elevator-modernization procedures on similar systems, each job would have cost US$3,000-10,000. Pricing variables in a refurbishment or modernization scenario include part cleaning, part refurbishment and part replacement, as well as the additional installation of modernization technology.

Energy Savings

Finally, there is the consideration of energy savings. Refurbishing an existing DC elevator motor and fitting a modern drive system, instead of replacing an entire system, eliminates expensive costs of equipment removal, producing, shipping and installing a new system. Improved ride performance and control is an added bonus. Installation of regenerative drives will save money in energy costs by capturing the energy and returning it to the grid. By not discarding your old machine, you may also qualify for Leadership in Energy & Environmental Design or Building Research Establishment Environmental Assessment Method credits and ENERGY STAR® points.

A standard geared AC motor operating an elevator weighing 2,200 lb. along 13 floors at 500 fpm 301,000 times a year consumes an average of roughly 13,000 kWh. By contrast, a fully refurbished and modernized DC motor operating an elevator within the same parameters consumes an average of only about 6,000 kWh. This greatly lowered power consumption represents a reduction of more than 50%[1] when compared to a standard AC motor and falls at a level comparable to the power consumption of advanced AC permanent-magnet motors, all for an upfront cost far lower than that of an AC motor replacement.

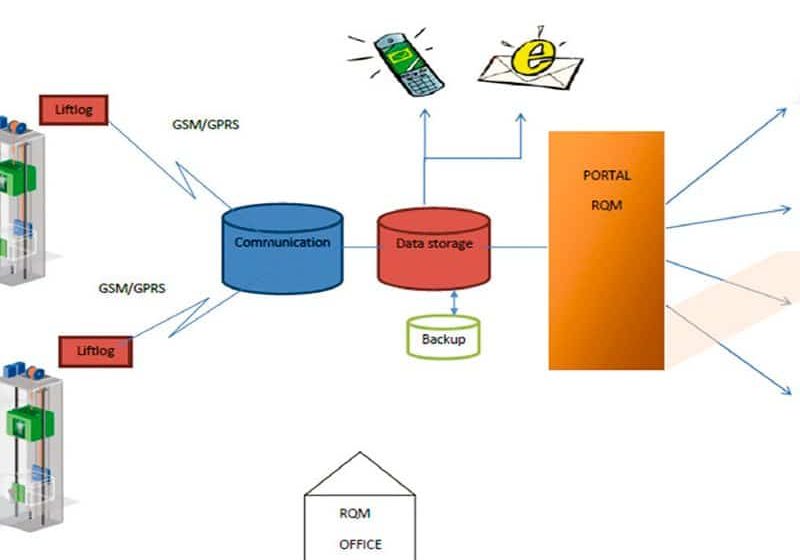

Part of a proper modernization plan includes the installation of a DC drive, such as the Quattro DC from Magnetek, which plays a large role in the reduction of power consumption and ability to effectively return energy to the grid.

Calculate Your Savings

Online energy-savings calculators estimate the electrical consumption of existing elevator equipment and immediately compare results to those of other motor and motor/drive combinations. Based on the operating characteristics of the elevators in your building, a quantitative comparison can then be drawn to determine how energy savings apply to your project.

Many utility companies offer energy-saving rebate programs for reduced peak and average power demand and for clean harmonics. Evaluating the savings for elevator-modernization projects as part of a plan is helpful, as most utility companies will not allow application for these credits once the project has been completed (or even started).

Studies have shown DC regenerative drives can:

- Achieve 25% energy savings over DC silicon-controlled-rectifier (SCR) drives

- Reduce by 45% the energy consumption over using motor-generator (MG) sets

- Save 42% compared to non-regenerative AC drives.

How It’s Done

When regenerative DC drives are utilized, gravity and the high efficiency of the modern drives are allowed to help recover and reuse electrical power that would normally be lost during elevator operation.

Elevators consume energy to move a loaded elevator car but then generate energy in the opposite direction as the car stops. Rather than simply losing this energy as heat through resistors, technology incorporated into modern DC drives efficiently captures this energy to return it to the building power grid for use in other key facility processes, such as lighting; heating, ventilation and air-conditioning; and additional electrical systems. This slows the total power consumption of the building to provide energy cost savings nearly half of the time an elevator runs.

The Good, the Bad and the Truth about DC Gearless Machines

DC gearless machines can run for, literally, 100 years. Your authors have seen many motors in the shop from the early part of the 1900s and returned them back into service, never to hear from them again.

New motors are truly “not made like they used to be.” However, DC gearless machines can run right up to the point of failure with very little warning. Machine surveys should be conducted prior to any modernization work and provided on a non-prejudicial basis to the incumbent, since the information provided from a survey cannot be taken while machines are in operation, and machine monitoring is generally not employed during the active cycle for a machine in operation.

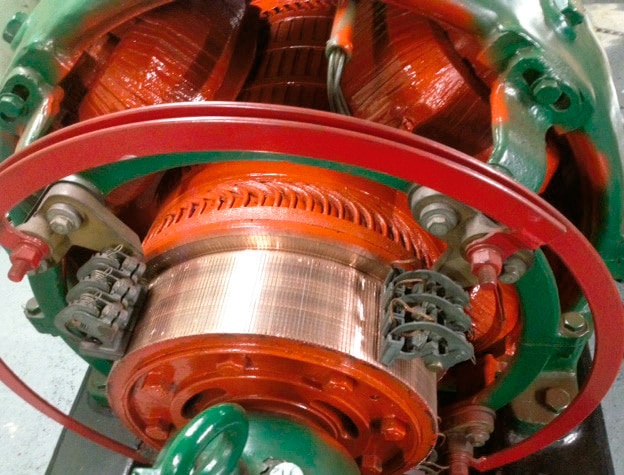

Additionally, a DC armature may fail without warning, and an armature can run with very low resistance values without obviously affecting the operation of the machine. Armature rewinds are very costly, but if done properly, can restore the machine to a condition even better than new. Once the armatures are put onto new drive technology from the old MG set, it becomes subject to harsh conditions that were never present or foreseen during their original design many years ago. It is, therefore, recommended to get maximum life out of a gearless machine modernization that the armature be rewound from Class B insulation to Class H insulation (Table 1). Alternatively, allow for excellent airflow and additional cooling in the machine room if possible. This will help the armature and field coils handle the higher operating temperatures and voltage fluctuations caused by the new DC drive technology.

To achieve maximum life from field coils, it is recommended to rewind the coils with a proper shape-control and tension-control winding machine using Class H insulation and tape. Generally speaking, insulation life doubles for every 10°C of unused insulation temperature capability. For example, if a motor is designed to run with a total temperature of 110°C (including ambient, rise and hotspot allowance) and is built with a Class B (130°C) insulation system, there is an unused capacity of 20°C. This excess margin increases the expected motor insulation life from 20,000 to 80,000 hr. However, for every 10°C above the insulation rating, the motor’s life is reduced by half.

The Ugly Little Secrets — Avoiding Pitfalls

DC gearless armatures, field coils, interpoles and brake coils were generally designed with Class B insulation and originally intended to be run from MG sets to provide the DC voltage to regulate speed and other functions. Modernization packages have included SCR controls and, more recently, insulated-gate bipolar transistor controls for DC motor-speed regulation.

While these controls come with many benefits, the old adage “you don’t get something for nothing” comes into play. In the case of DC drive technology, the old steady DC signal that was once sent by the generator is now replaced with a DC signal generated by “voltage chopping” an AC signal. This chopping creates sharp on-and-off voltage transitions that stress insulation systems and may cause unwanted current to flow through motor bearings. Either more bearing failures or blackened grease in motors after modernization is effectively caused by stray electrical currents flowing intermittently through the bearings.

Luckily, there is a solution for this problem, such as common mode chokes. Common mode chokes may also reduce stray currents flowing through the equipment grounding system that often cause bad encoder counts or other sensor/communication issues sensitive to electronic interference.

Another common element of newer modernization packages is that they generally require a reliable source of utility voltage. A power survey conducted in advance of a job may highlight any voltage fluctuations in the building’s power that will impact the operation of the new elevator control system. Most controllers have maximum and minimum power input requirements for optimum operation. Fluctuations in the voltage to the controller can adversely affect the operation of what would otherwise be a flawless mod. The best modern controllers have an ability to handle a nominal amount of voltage sag without creating undue harmonics on utility lines.

Putting a Plan in Place

A well-laid-out modernization survey forms the basis for any mod to go well. The form needs to be complete to ensure success. Many of the issues that arise after a modernization is commissioned can generally be traced back to incomplete or incorrect information on this survey. All of the controller and motor manufacturers that deal with the elevator trade have very good surveys that include most — if not all — of the information required for a successful job.

Motor Evaluation

In any modernization, the motors should be evaluated in accordance with the American National Standards Institute (ANSI) and Electrical Apparatus Service Association (EASA) standards. These standards are outlined in ANSI/EASA Standard AR100-2015 and should be performed by a competent motor shop with experience with DC gearless machines and their operation in elevator applications. Generally, a good machine survey should include the following.

Identification of the Motor and Control System

Identify the motor, noting all parameters and any limitations that may affect compatibility with the new control systems.

Condition Assessment and Inspection

An inspection of the machine should be performed, making note of:

- Armature, field coil, interpole and brake coil insulation condition

- Commutator condition and commutation

- Brush and brush rigging condition

- Bearing and lubrication condition

- Brake condition (pad, drum/disk, bushings and pins, and linkage)

- Air gap

- Fitment and mechanical integrity (shaft, shaft run-out, laminations and sheave)

Testing

The following tests should be performed:

- Low-voltage electrical testing should be conducted prior to cleaning or repair to indicate suitability of continued operation and quickly locate areas where repair is necessary.

- Low-voltage insulation resistance should measure greater than 2 megohms at 500 VAC/VDC. Insulation-resistance (IR) tests should be performed with acceptable results before the high-potential (HP) tests.

- HP surge tests should only be applied after a machine has been cleaned and dried, and the IR tests are acceptable. Due to the stress placed on the insulation, HP tests may not be advisable during an initial machine survey, and repeated tests are not advised.

- Brush rigging IR tests: the condition of the brushes should be noted to determine if brush grade is compatible with the machine-room environment and machine.

- Brake coil insulation resistance tests and winding resistance tests

- Armature winding tests on the insulation of the armature should be performed to determine the resistance is acceptable. In addition, one or more of the following tests should be performed: growler, winding surge test and/or bar-to-bar resistance test.

- Field coils and interpoles insulation resistance test and one or more of the following tests: winding resistance, winding surge test, AC voltage-drop test and/or impedance test

Once all tests have been completed, the results of the winding analysis should be reviewed to determine the best course of action, in particular for the armature. Field coils are easily replaced and readily available; however, armatures need a plan, answering the following questions:

- Will they be done onsite or in a shop?

- How many will require rewinding, and will that be done onsite or in a shop? (The best cleaning possible will be in a shop, but is that practical?)

Cleaning

Many elevators are not capable of handling the weight of the armature being loaded into the car to have it sent out for cleaning, so, in those cases, onsite cleaning or rewinding is the only option. Environmental controls, such as noise, airborne dust control and odor controls, need to be considered in this cleaning plan. All windings and parts should be cleaned of carbon dust, grit, grease and oil, and cleaning-agent residue must be removed.

Repair (as Necessary)

Electrical repairs and rewinding of the components failing electrical tests (as described in the “Testing” section above) should undergo further evaluation as outlined in AR100, Section 4, and repaired as necessary or rewound per guidelines of AR100, Section 3. Attention should be given to:

- Commutator machining, undercut and beveling

- Brush holders and rigging insulation resistance, “quartering,” seating and setting of the machine neutral

Electrical insulation tests should be repeated after repairs are made to verify insulation quality. Mechanical repairs, including shafts, bearings and seals, lubrication, laminated cores, balancing, and air gaps should be performed in accordance with AR100, Section 2 and OEM specifications.

Dynamic Testing

Upon completion of modernization and prior to returning the elevator to service, a system dynamic test should be conducted to ensure the motor is operating within its optimal performance parameters as produced by drive, controller and system loads. Armature voltage and current readings should be measured under maximum load conditions. Field voltage and current should be measured at standing, forcing and full speed. Temperature of the fields, armature, interpoles, and brake coil and bearings should be measured.

Takeaways

Setting expectations up front and executing a plan will make modernizations run far smoother and have these beautiful older DC machines running even better than new. Achieving results that meet or exceed the customer’s expectations will ensure more work where the plan can be refined and become part of the normal course of action, making this work profitable for everyone.

Customers benefit from modern controllers that capture lost power returning energy to the grid, while rebuilding the old motors keeps equipment that operates like new or better and will last for many more decades from the landfill. Modernization saves everyone time, effort and money. Properly refurbishing the existing DC motor, selecting the best controller and protecting the motor are easily achieved, benefitting all parties in the modernization.

Reference

[1] Magnetek, “Planning a Successful Quattro DC Drive Installation” (www.magnetek.com/~/media/Elevator/EV%20Brochures/EV640_Quattro%20DC%20Installation%20Brochure-flip.ashx).

Get more of Elevator World. Sign up for our free e-newsletter.