Morumbi Corporate: A Green Job

Oct 1, 2014

Energy efficiency and style characterize São Paulo project.

by Atlas Schindler

by Carmen Maldacena, EW Correspondent

Elevadores Atlas Schindler in São Paulo, Brazil, has installed 37 pieces of equipment — 35 elevators and two escalators — in Morumbi Corporate, a pair of commercial towers that is part of the Morumbi Shopping Complex in the southern part of São Paulo.

Towers

Morumbi Corporate consists of 18- and 26-floor commercial towers totaling 74,198 m². The buildings are joined by an elevated plaza featuring stores, restaurants and amenities. The project, designed by Aflalo e Gasperini Arquitectura, complies with “green seal” parameters in preparation for achieving a Leadership in Energy & Environmental Design (LEED®) certification. This certification is granted by Green Building Council Brazil, an entity that disseminates LEED ratings adapted to Brazilian culture to promote building efficiency.

Vertical Transportation

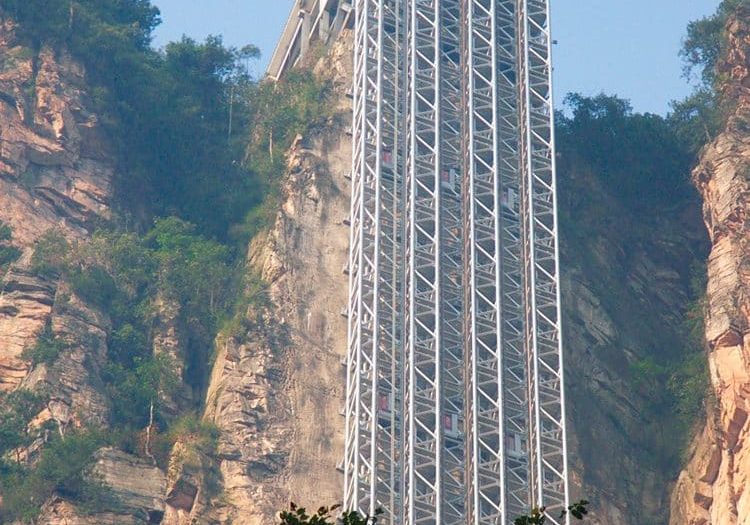

To meet the vertical-transportation needs of the towers, Atlas Schindler installed 22 Schindler Model S 7050 elevators engineered to handle heavily trafficked buildings and fulfill energy-efficiency requirements. Operated by variable-voltage, variable-frequency gearless machines with asynchronous permanent magnet (PM) motors, they run from 2.5 to 10 mps. The model has an aerodynamic design to resist air pressure. Consequently, passengers enjoy a silent and comfortable trip without perception of equipment speed.

Since the car features LED illumination, the elevator also contributes to the project’s LEED certification. Additionally, when not in use, the elevator’s lights turn off, and the unit remains in a standby position at the ground floor.

The cars’ design is simple but luxurious, in accordance with the elegant building. The cars’ ceilings are made of white acrylic with indirect illumination; panels feature white marble, as does the floor, but are combined with brown marble. The automatic doors and the car operating panel are outfitted with brushed stainless steel.

Installations at Morumbi Corporate also include 13 Schindler Model S 5500 elevators. This is a modular series/product with a highly flexible configuration that can be adapted to different market segments. The units travel from 1 to 3 mps, attending up to 50 floors, with a 2500-kg capacity. Their gearless machines are furnished with asynchronous PM motors. Wire ropes have been eliminated and replaced by Schindler’s new developments in traction media that are similar to rubber belts. This system enhances riding comfort.

Installations at Morumbi Corporate are outfitted with Miconic 10, Schindler’s destination dispatch system for traffic handling. Another feature is Schindler ID, an electronic key card that identifies and registers users who travel to one or more destinations. The system identifies the user and permits access to a registered floor. Use of the electronic card also directs the passenger to specific elevators, in turn reducing unnecessary stops, saving energy and shortening wait time. This technological combination facilitates the transportation of more passengers on fewer elevators. Two Schindler Model S9300 AE escalators complete Atlas Schindler’s installations at Morumbi Corporate. This model is the result of optimized manufacturing and installation processes aimed at inexpensive operation and easy maintenance. These escalators rise up to 6 m, feature stainless-steel balustrades and boast efficient operation: they adjust speed based on the ebb and flow of passengers, saving up to 30% energy.

About Elevadores Atlas Schindler SA

The company is a member of the 135-year-old Swiss Schindler Group. Present in Brazil since 1918, it incorporated the Atlas name after a merger with Brazil-based Atlas in 1999. The company’s main factory is located in Londrina, Brazil. Small-component manufacturing is carried out at its premises in São Paulo. Atlas Schindler employs 4,800 people, including 3,000 technicians, and has 150 maintenance centers throughout the country. In addition to elevator and escalator services, the company refurbishes technologically and aesthetically outdated equipment.

S 7050 Elevators

- Locations: Social areas in Towers A and B

- No of units: 22: 12 in Tower A (four each of low, medium and high units) and 10 in Tower B (five low and five high units)

- Capacity: 23-24 passengers

- Speed: 3.5 to 6 mps

- Stops: 10-11

- Machine-room location: Above

Get more of Elevator World. Sign up for our free e-newsletter.