Mount Tianmen Tourism Tunnel Escalators

Jan 1, 2015

Precision planning, puzzle solving distinguish challenging multiple-unit installation.

Zhangjiajie, China

submitted by Richard Zhu and Ally Wu, Canny Elevator Co. Ltd.

Canny’s installation of 24 escalators to carry visitors between cable car station and Sky Gate Cave on Mount Tianmen (ELEVATOR WORLD, March 2014) represents a feat of engineering, precision planning and use of technology. The project was complex, akin to solving a puzzle in which any mistake could create a domino effect, resulting in loss of credibility, progress and even life. But, the team led by Canny Elevator Co., Ltd. delivered a multifaceted product that is both practical and remarkable.

A “Dream Solution”

Sky Gate Cave penetrates the cliff at the upper ridge of Mount Tianmen. It is located just below the rocky ridge top, measuring roughly 131.5 m high X 57 m tall X 60 m deep. The unique scene is a major tourist attraction. However, prior to installation of the escalators, the only approach to cave level from the parking area was a lengthy flight of 999 steps.

In early 2012, when a vertical-transportation solution was first proposed, a bank of heavy-duty elevators was suggested. According to a veteran consultant, new elevator designs would require lengthy testing before winning approval. Also, the installation would alter the appearance of the mountain – something tourism officials opposed. Tunnel escalators solved both problems. But, while such a plan seemed feasible, it was widely regarded as a “dream solution” due to numerous daunting and unprecedented challenges.

Canny’s solution was a two-way escalator system in the upper tunnel between mountaintop and plateau, easily accessible by the cable car. The upper tunnel escalator would provide a safe, fast and comfortable ride between the cable-car station on the plateau and the cave area. The lower tunnel escalator would be constructed alongside the 999 steps. In addition, the tunnel escalators would be able to move visitors between the plateau and Sky Gate Cave parking area in case of service failure of the cable car.

Challenges

Nineteen escalators in phase one went into service in September 2013. During this phase, the team was tasked with:

- Designing and constructing two separate tunnels for the escalators

- Making the units moisture- and rust-proof, as well as capable of being deconstructed into small sections, in terms of both length and in weight, for transport to the site

- Transporting all 24 escalators by truck on a 12-km-long zigzagging road, known as the 99-turn motorway, up the mountain

- Using a cable system to transport the 14 upper-tunnel escalators up 600 m, then 200 m horizontally over a bare cliff

- Maintaining a strict, fast schedule, since there was no space on the jobsite for materials storage

Escalator Design

The tunnel escalators are based on Canny’s outdoor model for heavy-duty public transportation. Although the maximum rise of the model is 36 m, the rise of the tunnel installation was reduced to 30 m and 20 m, respectively, in consideration of transportation and jobsite limitations. The longest assembling unit did not exceed 7.2 m. Galvanized coating was applied to the trusses to protect them from moisture and prevent erosion. In addition, the escalators have the following features:

- Motor efficiency up to 93%

- Combined drive efficiency up to 82%

- System preheating

- Additional drive for handrail belts

- Internal lubrication

- Real-time brake-wear sensors

- Maintenance-friendly step chain rollers

- Remote monitoring

- IP54-class protection

The Tunnels

The process of opening the tunnels was complex and dangerous. Directional blasting proved key to completing tunnel construction in a timely manner. The upper entrance/exit of the upper tunnel is located by the tourist walkway approximately 750 m from the cable-car terminal on the mountaintop, while its lower entrance/exit opens onto the cliffside of the mountain ridge. Those who ride down from the plateau must turn left at the end of the tunnel to gain access to the Sky Gate Cave level through a 200-m-long trail. To reduce stack effect, both tunnels have turns at their midway points, where the flat spaces are enough for the transportation of material.

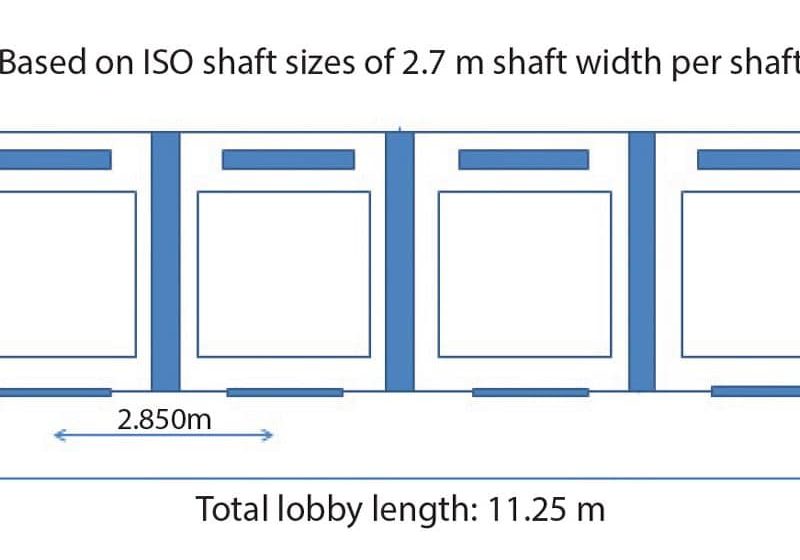

Arrangement

The 14 escalators in the upper tunnel are parallel. Each line consists of one 20-m and six 30-m escalators with a total rise of 200 m. While the 10 escalators in the lower tunnel are also in parallel arrangement, each line consists of two 20-m and three 30-m escalators with a total rise of 130 m. Originally, the lower tunnel was constructed for a single-line arrangement of five escalators, but phase two (a reconstruction project started at the end of 2013 to accommodate another five escalators) meant the lower tunnel would have a parallel arrangement, as well. Between every two pairs of escalators in both tunnels lies a flat space measuring approximately 10 m long, where escalator control cabinets are located.

All escalator materials for the 24 units were delivered by trucks via a narrow, treacherous road, while the 14 units in the upper tunnel had to group farther via cable hoist to the care level. In addition, a path was built using ancient Chinese techniques. Installation was a complex and time-consuming process. Canny states:

“It was an amazing, systematic task, because if anything went wrong, it would cause problems in the transport process on the trail path at the cost of losing time and money. Jobsite safety was given top priority. For example, every acetylene welding or cutting job during the installation had to undergo a rigorous approval process. When welders were at work, a safety supervisor would stand by to watch out for hazards. When the job was done, both had to make sure not to allow a single leftover spark.”

The 14 escalators in the upper tunnel and the first five in the lower tunnel opened to the public in September 2013. Installation of the additional five escalators was completed in July 2014.

Specifications

- Rise: 30 m with five intermediate supports and 20 m with three intermediate supports Inclination: 30°

- Speed: 0.5 mps

- Step width: 600 mm with four horizontal steps Capacity: 6,000 persons per hour Balustrade: Stainless steel with removable covers

- Energy savings: Microwave entrance sensors Safety features: Automatic fault-sensor input, secondary brake by mechanical stopper, step chain and handrail belt breakage protections

- Life expectancy: 146,000 hr. (17 years)

Credits

Owner: Hunan Zhangjiajie Mount Tianmen Tourism Co., Ltd.

Tunnel design: Hunan Zhongda Survey, Design and Research Institute

Escalator design and manufacturing: Canny Elevator Co., Ltd.

Installation: Hunan Huida Elevator Engineering Co., Ltd.

Canny project team: Lu Binyun, Wang Dongsheng and Sun Jianyu

Get more of Elevator World. Sign up for our free e-newsletter.