The space-saving design must meet vital criteria for use as firefighter and emergency-evacuation elevators.

by TAK Mathews

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 7-8, 2020’s event in Amsterdam and to participate, visit International Elevator & Escalator Symposium.

The requirement for firefighter elevators has been recognized for many decades. Most countries have adopted norms. These elevators were clearly understood to be for the firefighters to use during a fire. The rule “do not use elevator in case of fire” remained. During the horrific events of 9/11, more than 3,000 people were recorded to have ignored the rule and managed to escape. Naturally, post-9/11, the requirement of elevators to also assist in evacuations became a discussion topic and found its way into elevator and building design code books.

It is your author’s hypothesis that the global requirements for firefighter elevators and occupant-evacuation elevators are broadly based on the machine-room (MR) elevator and do not consider the unique characteristics of the machine-room-less (MRL) elevator. This article will study the requirements for firefighter elevators and occupant-evacuation elevators from ASME A17.1, the International Building Code (IBC), EN 81, CIBSE Guide D and the National Building Code of India (NBC) to examine whether the MRL meets these requirements and other risks that might exist. It will also suggest possible remedial measures that can be adopted to mitigate any gaps and risks that might be revealed.

Introduction

The first MRL elevator was developed and launched by KONE, with the first installation being completed and officially inspected in the Netherlands in 1995. This innovation was aimed at addressing vertical-transportation requirements of shorter buildings with severe height restrictions. In the two-and-a-half decades since the original launch, the MRL elevator has evolved with higher speeds and applications for buildings of 40 stories now possible. However, it is not understood how height could be a real constraint for a building that is 100 m tall.

The general arrangement for a lower-speed MRL elevator for a shorter building or for a higher-speed MRL elevator for a taller building remains the same, but the complexities are exponential. These complexities have been addressed by your author in a paper titled “MRLs, a Practical Alternative to MRs?”[15] presented at Elevcon 2018 in Berlin. The issues were subsequently discussed at the 2019 forum of the International Association of Elevator Consultants in Reno, Nevada. However, for the purpose of this article, only the specific implications of MRL elevators for firefighter and emergency-evacuation elevators will be addressed.

The expectations of firemen and emergency responders have been explored, followed by the technical requirements of some international standards. The next section, “Firemen’s Expectations,” explores the understanding and expectations from firefighters and emergency personnel regarding firefighter and evacuation elevators. The sections that follow, through “ISO/TR 16765 (2003) Requirements,” detail the relevant clauses from standards, codes or recommendations from the U.S., Europe, the U.K. and India.

Firemen’s Expectations

Firemen normally consider elevators as best avoided in a fire or emergency. McGrail cautions, “It was easy to conclude that the elevator can be a dangerous tool that must be dealt with in a cautious and respectful manner.”[16] However, in tall buildings, firemen end up with no option, but depend on elevators. Their standard operating process is based on the following key assumptions:

- The machinery, controller and critical components are enclosed in a fire-resistant machine room or fire-resistant hoistway, the openings of which are protected with a fire-rated elevator landing door.

- As long as the machine room has not been affected, the higher the floor on which the fire is, the safer it is to use the elevator.

McGrail details the understanding of elevators, particularly in a fire situation.[16] Some of them are:

- The hoistway walls are constructed of fire-resistant materials and the hoistway doors are fire-rated.

- Heat from a fire can be damaging to the myriad of sensitive electronic components controlling an elevator (and, therefore, have to be in fire-resistant enclosures).

- If the source of the smoke or fire is inside an elevator machine room, do not utilize the bank of elevators.

- Never take an elevator directly to a reported fire floor.

- Stop two floors below the reported fire floor.

Jarboe and Donoghue[14] provide insights as follows:

- If the fire is reported to be on the sixth floor or lower, do not use the elevators.

- Due to the fire environment, the mechanical or electrical systems can be affected by heat or water.

- An important question about MRL elevators for the fire service to ask is, “Where is the machine room or space located?” Some AHJs have mandated the location be posted at the first-floor entrance.

Inference: Firemen have not fully captured the implications of the controller and disconnect switches of MRL elevators being located at the elevator lobby and outside the 2-h fire-resistant structure of a typical machine room. They do not appear to have recognized that the brain of the elevator, which is one of the most heat-susceptible components, is not protected for an MRL. Knowing the location, while important, does not eliminate the risk.

ASME A17.1-2016 Requirements[1]

- Clause 2.1.1.1.1 states, “Where fire-resistive construction is required, hoistways shall be enclosed in conformance with the requirements of the building code.”

- Clause 2.1.1.1.2 states, “Partitions between hoistways and (a) machinery spaces outside the hoistway (b) machine rooms (c) control spaces outside the hoistway (d) control rooms … that have a fire-resistance rating.”

- Clause 2.1.1.1.3 states, “Hoistway enclosure openings shall be protected with entrances or access doors having a fire-protection rating conforming to the requirements of the building code.”

- Clause 2.3.3.1 states, “The hoistway shall be fully enclosed and shall have a fire-resistance rating.”

- Clause 2.7.1.1.1 states, “Spaces containing machines, motor controllers, sheaves, and other machinery shall be separated from the remainder of the building by a fire-resistive enclosure conforming to the requirements of the building code.”

- Clause 2.7.1.1.2 states, “Openings in room and space enclosures shall be protected with access doors having a fire-protection rating conforming to the requirements of the building code.”

- Inference: A17.1 expects that the machinery and controllers are in a fire-resistive enclosure separated from the remainder of the building.

It is your author’s hypothesis that the global requirements for firefighter elevators and occupant-evacuation elevators are broadly based on the machine-room elevator and do not consider the unique characteristics of the machine-room-less elevator.

ASME A17.4-2015 Requirements[2]

A17.4, in principle, assumes the controller is in a machinery space.

IBC 2018 Requirements[10]

- Clause 3005.4 of IBC 2018 states, “Elevator machine rooms, control rooms, control spaces and machinery spaces outside of, but attached to, a hoistway and that have openings into the hoistway shall be enclosed with fire barriers. . . The fire-resistance rating shall not be less than the required rating of the enclosure served by the machinery.”

- Clause 3007.5 states, “The fire-service access elevator hoistway shall be located in a shaft enclosure complying with Section 713,” where section 713 details minimum requirements for the shaft, including fire-resistance rating.

- Clause 3007.6 states, “The fire-service access elevator shall open into an enclosed fire-service access lobby.”

- Clause 3007.8.1 of IBC 2018 continues to state, “Wiring or cables that are located outside of the elevator hoistway and machine room and that provide normal or standby power, control signals, communication with the car, lighting, heating, air conditioning, ventilation and fire-detecting systems to

- fire-service access elevators shall be protected using one of the following methods:

- Cables used for survivability of required critical circuits shall be listed in accordance with UL 2196 and shall have a fire-resistance rating of not less than 2 h.

- Electrical circuit protective systems shall have a fire-resistance rating of not less than 2 h. Electrical circuit protective systems shall be installed in accordance with their listing requirements.

- Construction having a fire resistance-rating of not less than 2 h.”

The requirements for the fire-evacuation elevator are defined in Section 3008. The protection against the impact of fire is similar to those defined by Section 3007.

Inference: IBC assumes only wiring and cabling could be outside the fire-resistant enclosure consisting of the hoistway and machinery space. Even then, IBC requires the wiring and cabling, when located outside, be protected for 2 h.

NFPA 101 (2018) Requirements[18]

NFPA 101 requires, “Elevator machine rooms that contain solid-state equipment for elevators, other than existing elevators, having a travel distance exceeding 50 ft (15 m) above the level of exit discharge, or exceeding 30 ft (9.1 m) below the level of exit discharge, shall be provided with independent ventilation or air-conditioning systems to maintain temperature during firefighters’ emergency operations for elevator operation.”

Inference: NFPA 101 recognizes the equipment is susceptible to high temperatures and is required to be in a temperature-controlled environment.

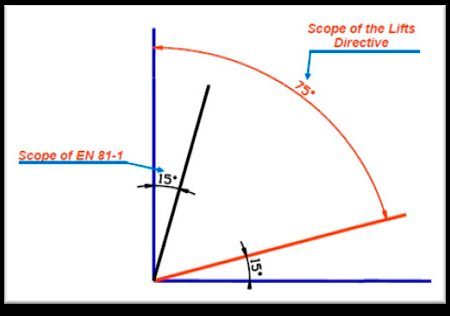

EN 81-72 (2015)[8] and –76 (2011)[9] Requirements

- Clause 5.7.1 of EN 81-72 states, “Any compartment containing the lift machine and its associated equipment shall be provided with at least the same degree of fire protection as is given to the lift well.”

- Clause 5.7.2 of EN 81-72 states, “Wherever any machinery space is located outside of the well and outside of a fire compartment, it shall be protected with at least the same fire resistance as the fire compartment(s). Any connection (e.g., electrical cables, hydraulic pipes etc.) between fire compartments shall be likewise protected.”

- EN 81–76 assumes the lift is protected from the effects of fire and smoke with a fire-resistant structure.

- Inference: EN 81–72 and –76 require all equipment to be protected in a fire-resistant compartment.

BS 9999:2017 Requirements[3]

- Clause 3.72.2 defines an evacuation lift as a “lift used as part of the evacuation sequence for persons with disability and persons requiring assistance, which has appropriate structural, electrical and fire protection and is capable of being taken under control by a trained and authorized person.”

- Clause 3.72.3 defines a firefighter’s lift as a “lift with protection measures, controls and signals that enable it to be used under the direct control of the fire and rescue service in fighting a fire. . . . Lift machinery spaces should be situated over the lift well or within the top of the well whenever possible. . . . Any machine, pulley or other associated equipment located outside of the lift well should still be within the same fire compartment as the well.”

- Clause 15.8 states, “Lift wells should either be contained within the enclosures of a protected stairway, or be enclosed throughout their height with fire-resisting construction. . . .”

- Inference: BS 9999 requires all equipment be protected in fire-resistant compartments.

CIBSE Guide D (2015)[4] and CIBSE Guide E(2010)[5] Requirements

- CIBSE Guide D and CIBSE Guide E cross reference each other and refer to EN 81-72 and BS 9999.Clause 6.3.1 of CIBSE Guide D states, “Electrical equipment on landings, within the lift car and lift well should be protected against effects of water.”

- Clause 6.3.3 states, “For lifts without machine rooms, the equipment should preferably be located away from the pit area to avoid complex water protection requirements.”

- Inference: The impact of fire and high temperature has not been considered. Where a reference has been drawn to the MRL, the concern is about water.

- Clause 6.3.3 states, “MRL lifts are now common; their use is permitted by BS 9999 and EN 81-72.”

- Comment: Your author could not identify the clauses in BS 9999 or EN 81-72 that specifically permit MRL lifts as firemen’s lifts.

ISO/TS 18870 Requirements[12]

- Clause 4.2 states, “Lift shafts and machine-room rooms or machinery spaces located outside the shaft should be fully enclosed. The temperature in the enclosures should be maintained to acceptable levels for the equipment, as determined by the lift supplier in consultation with the building management.”

- Inference: The impact of fire and high temperature has not been considered. Where a reference has been drawn to the MRL, the concern is about water.

ISO/TR 25743 Requirements[13]

The subject technical report prepared by lift engineers and firefighters, which studies the use of lifts for evacuation, is based on the clear assumption that the elevator is an MR elevator. There is no reference to an MRL elevator.

NBC 2016 Requirements[17]

- To ensure fire protection of the lifts, NBC 2016 requires walls of the lift or lift bank to have a fire rating of 2 h, protected with lift landing doors of 1-h fire resistance.

- The requirement for evacuation lifts detailed in NBC 2016 borrows from ISO 18870 and states, “Lift shafts and machine rooms or machinery spaces located outside the shaft should be fully enclosed.”

- Inference: While not explicit for firefighters’ elevators, the NBC in India expects all equipment to be fully enclosed in fire-resistant enclosures.

CTBUH Emergency Evacuation Elevator Systems Guideline Requirements[6]

- The Council on Tall Buildings and Urban Habitat (CTBUH) guideline on Emergency Evacuation Elevator Systems recommends that the perimeter and hoistway for emergency evacuation elevators be constructed to a fire-resistance rating of 2 h.

- Inference: The CTBUH appears to assume elevators for emergency evacuation will be MR elevators.

ISO/TR 16765 (2003) Requirements[11]

While this standard will soon be replaced by ISO/TR 8101-10, it provides some insights into early thoughts on using MRL elevators as firefighters’ elevators. While Japan and South Korea had a definitive “no” to using MRL elevators as firefighter’s elevators, Australia and New Zealand had allowed their use. The rest of the countries covered under the standard had either not considered it or were silent in this regard.

Inference: In the early days of the MRL, with their low available speeds, the application was limited to low-rise buildings, where firefighters’ elevators were not a critical requirement.

Summation

The standards and codes reviewed indicate the following:

- The underlying intent/spirit of all the standards and codes is that firefighting/evacuation elevators will be protected from impact of fire/high temperature and thereby function reliably within the constraints of a fire.

- The standards/codes expect all critical components pertaining to the safe functioning of the firefighting/evacuation elevators to be enclosed in fire-resistant enclosures. The standards and codes recognize enclosed MR and hoistways are the safest places to accommodate critical components.

- The standards/codes do not specifically identify the risks unique to an MRL elevator.

- Where the standards and codes refer to the possibility of controllers and other critical components being outside machinery spaces or the hoistway, the emphasis is on ensuring the critical components are in enclosures similar in fire-resistance characteristics to the machinery space or hoistway.

It can be concluded that the expectations from the

requirements for firefighter lifts and occupant-evacuation elevators laid out globally are based on the MR elevator and do not consider the unique characteristics of the MRL elevator.

Arguments Against the Summation

Argument 1: MRL controller cabinets have been tested to the requirements of EN 81-58 (2018). The introduction to EN81-58[7] states that the standard outlines a procedure to test the ability of landing doors to act as a fire barrier. Even if this standard were to be considered an acceptable prerequisite for controller cabinets, the controller components enclosed by the tested controller door would be required to withstand the average temperature rise of 140-360°K as defined by this standard.

Argument 2: The controller and disconnect switches can be located elsewhere in a fire-protected space. While this could address the immediate risk of a fire impacting the exposed controller and disconnect switches, it enhances the risks involved during maintenance. By virtue of the arrangement, it is not possible to have direct audio/visual access to MRL elevators, thus limiting efficacy of MRL maintenance.[15] Locating the controller and disconnect switches elsewhere increases this limitation. Some suppliers have a very small auxiliary controller behind the hall operating panel, with all other major components installed in the hoistway. This does not eliminate the risk.

Argument 3: Firefighter elevators and emergency-evacuation elevators are expected to be in protected lobbies, and, therefore, the vulnerability of the exposed equipment is addressed. Though recommended for evacuation elevators, protected lobbies are not a prerequisite for firefighter elevators. In any case, if this logic were to be considered a basis for protecting the controller and disconnect switch, it could be extended to eliminate the requirement for fire-rated landing doors. This is not practical.

Recommended Actions for MRL Firefighter Elevators and Evacuation Elevators

- Fire departments around the world should be immediately required to be educated on the specifics associated with MRL elevators and the crucial fact that the controller and disconnect switches are likely to be located at an exposed landing level. They should be required to be educated on the criticalities involved.

- Firefighter elevators or evacuation elevators should be required to be identified as MRL elevators with information at the location of controller and disconnect switches as pointed out by Jarboe and O’Donoghue.[14] Adequate warning notices cautioning on the limitations should be installed.

- With the specific complexity associated with MRL elevators, it is recommended that elevator-maintenance company personnel are also available onsite to guide the firemen/emergency personnel.

- The cabinet, doors and components of controllers; disconnect switches; and any other component located outside of the fire-resistant hoistway and machine room, which are critical to the reliability of the elevator, should be designed to address the possibility that they could be exposed to high temperature.

- Temperature sensors should be attached to exposed controllers and disconnect switches. These sensors should force the elevator to return to Phase 1 when the temperature reaches the critical threshold level.

- It is recommended that MRL controller doors and disconnect switches be provided with a switch that prevents the normal operation of the elevator in the event the controller door is left open. [15] This will also ensure users at the particular lobby are not exposed to potentially hazardous live circuits and protect the elevator from vandalism.

At a minimum, these are required to be enforced for MRL

firefighters’ and evacuation elevators, without which MRL elevators should not be considered for these applications.

References

[1] The American Society of Mechanical Engineers. ASME A17.1, Safety Code for Elevators and Escalators, U.S. (2016).

[2] The American Society of Mechanical Engineers. ASME A17.4, Guide for Emergency Personnel, U.S. (2015).

[3] The BSI Standards Ltd. BS 9999: Fire safety in the design, management and use of buildings – Code of practice, London (2017).

[4] Chartered Institution of Building Services Engineers. CIBSE Guide D: Transportation Systems in Buildings, U.K. (2015).

[5] Chartered Institution of Building Services Engineers. CIBSE Guide E: Fire Safety Engineering, U.K. (2010).

[6] Council on Tall Buildings and Urban Habitat. Emergency Evacuation Elevator Systems Guideline, U.S. (2004).

[7] European Committee for Standardization. EN 81–58 Safety rules for the construction and installation of lifts – Examination and test – Part 58: Landing doors fire resistance test, (2018).

[8] European Committee for Standardization. EN 81-72 Safety rules for the construction and installation of lifts – Particular applications for passenger and good passenger lifts – Part 72: Firefighters Lifts, (2015).

[9] European Committee for Standardization. EN 81–76 Safety rules for the construction and installation of lifts – Particular applications for passengers and goods passenger lifts – Part 76: Evacuation of disabled persons using lifts, (2011).

[10] International Code Council. International Building Code 2018, Illinois, U.S. (2018).

[11] International Organization for Standardization. ISO/TR 16765: Comparison of worldwide safety standards on lifts for firefighters lift, Geneva, Switzerland (2003).

[12] International Organization for Standardization. ISO/TS 18870: Lifts (elevators) – Requirements for lifts used to assist in building evacuation, Geneva, Switzerland (2014).

[13] International Organization for Standardization. ISO/TR 25743: Lifts (elevators) – Study of use of lifts for evacuation during an emergency, Geneva, Switzerland (2010).

[14] Jarboe, Theodore Lee and O’Donoghue, John. Elevator and Escalator Rescue: A Comprehensive Guide, PenWell Corporation, Oklahoma, U.S. (2007).

[15] Mathews, TAK. “MRLs, A Practical Alternative to MRs? Elevator Technology 22,” Proceedings of Elevcon 2018, International Association of Elevator Engineers (2018).

[16] McGrail, David M. Firefighting Operations in High-Rise and Standpipe- Equipped Buildings, PenWell Corporation, Oklahoma, U.S. (2007).

[17] Bureau of Indian Standards. National Building Code of India, New Delhi, India (2016).

[18] Life Safety Code. NFPA 101, National Fire Protection Association, Massachusetts, U.S.

Get more of Elevator World. Sign up for our free e-newsletter.