This Product Spotlight features a selection of reliable safety components, especially safety brakes.

by Alexander Hutler; images courtesy of mayr power transmission

Everywhere people are transported via elevators, the safety of the passengers has top priority. Safety-relevant components such as the elevator brakes must, therefore, align with the highest quality requirements. However, due to the intensive global competition in the elevator sector, price repeatedly plays a primary role, even for safety-relevant components. In spite of this market situation, a well-founded selection of reliable products must be made — as safety does not allow for compromises.

Passenger elevators are still one of the safest means of transportation. The accident and fault statistics verify that technically high-quality products are used, which have been tested reliably in advance — and this must also remain the case in the future. Especially in the field of elevator brakes, selection of the correct product is becoming increasingly difficult. Ten years ago, only a few brake manufacturers, mainly medium-sized companies with a lot of experience, were active on the market. Their competence ensured the required quality and reliability. The globalization of the market for elevator traction machines, motors and drives, as well as the enormous intensity of the competition and the related problems with copies from Asia, however, have led to massive competitive pressure developing over the past decades, even regarding safety-critical components such as elevator brakes.

Whereas in the past, clear commitment to reliability and optimum quality was shown, market participants today repeatedly state the price first during dialogues. However, rapid developments conceal a huge risk potential. Young market participants offering products at low prices but having little experience in the field have radically altered the situation — in particular for elevator constructors and manufacturers of motors and traction machines in all regions: These are currently increasingly focused on gearless technology, and are selecting the so-called “shaft brakes,” featuring new brake technologies, which offer several technical advantages in comparison to traditional drum brakes. And yet, precisely in this application, reliable elevator brakes from manufacturers with experience are essential. Inexpensive brakes of low-quality material that are less safe conceal an incalculable risk.

Specifying and Testing Brakes

The collaboration with globally active elevator manufacturers shows that these companies increasingly rely on quality components and orientate themselves to industry standards. The leading large companies also make substantial efforts to specify the requirements on safety-relevant components as precisely as possible and to align them in complex testing procedures. In addition, these companies have appropriate input from the market, which makes it easy to continuously provide more details for products or product requirements, and to incorporate critical points into the qualification process.

However, this cannot be completely transferred onto the supplier industry. Smaller elevator companies and motor manufacturers, for example, who themselves receive no feedback through field data and who do not possess the resources to employ a large engineering team, generally work using simpler methods of specifying a brake and testing it. They frequently lack the bandwidth and supply only regional application areas in which certain issues may not occur very often. Therefore, if such a manufacturer of motors and traction machines requires reliable brakes, they will orientate themselves to the points hitherto known to them. Over the course of business development in other markets, however, they may well be confronted with other conditions, which reveal new issues.

Which criteria can a manufacturer of elevator motors — in particular in gearless technology — apply in order to select a reliable brake?

Production Competence and Certified Quality Process

As is generally the case in the field of purchasing, the prospective supplier should first be looked at in detail. A company does not qualify itself simply through the fact that it can manufacture brakes. Appropriate production competence and a certified quality process are essential prerequisites, as is well-founded experience with brakes for elevator motors and traction machines. For this purpose, the company must have had a large number of elevator brakes on the market for many years. Only in this way is it in a position to know the risks and to supply reliable products. Prototype tests in which elevators are tested once for their functionality say nothing about the quality of the brakes when large quantities are produced.

Johann Eberle, chief strategy officer and member of the Management Board from mayr® headquarters in Germany, said:

“Every single brake must be supplied to the required quality. For this, an appropriate test routine is required. The risk often lies in the fact that manufacturers with less experience are, so to speak, unaware of what they don’t know. In order to guarantee the required safety, clear processes, comprehensive testing possibilities, years of experience and highly qualified employees represent essential prerequisites. This costs money; but only in this way is safety achieved. In the future, not the cheapest, but rather the most reliable, provider will prevail in global markets.”

100% Quality Controls

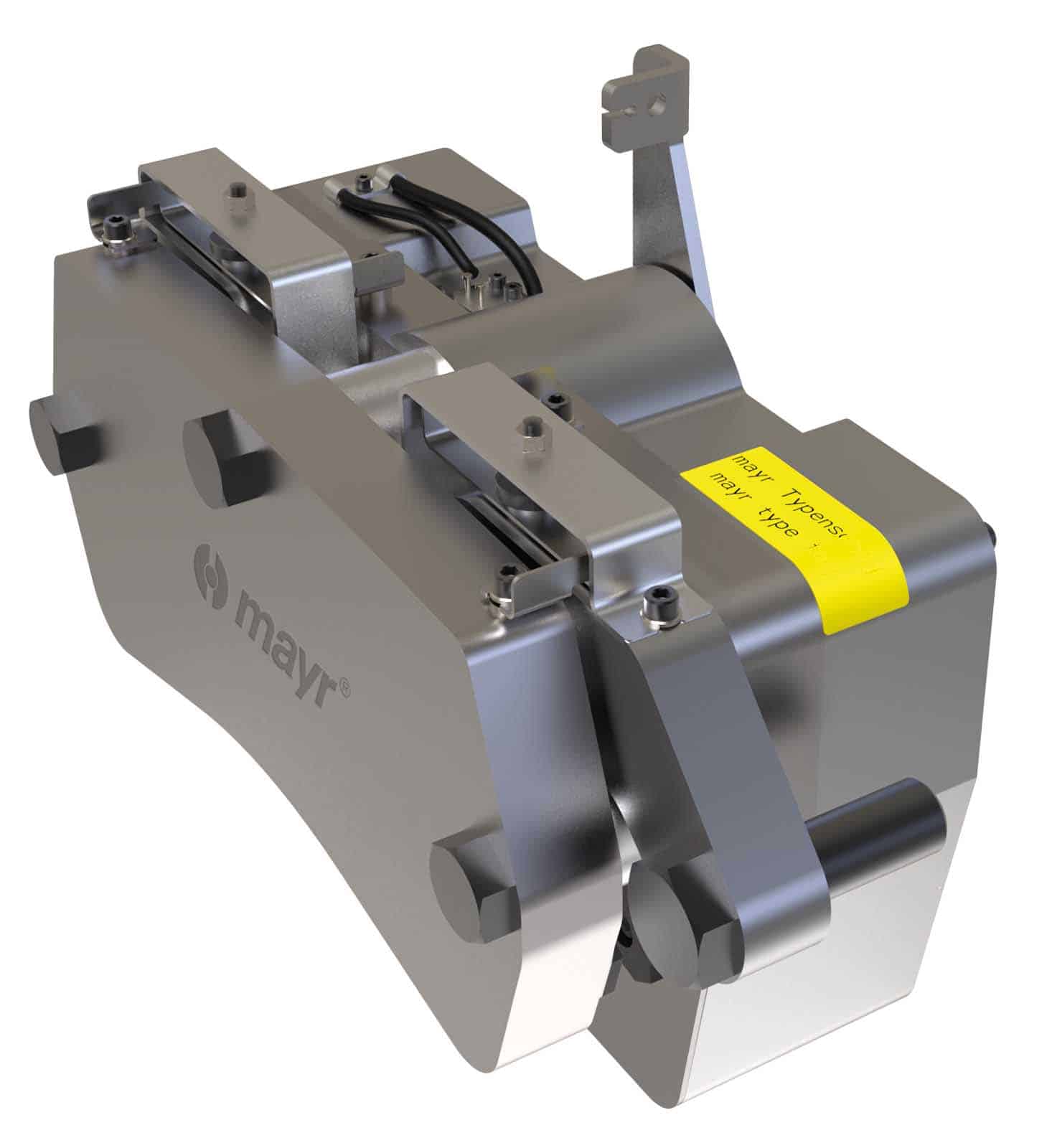

mayr power transmission has developed and produced elevator brakes for nearly 20 years. The company’s headquarters are in Germany, and its North American subsidiary is based in New Jersey. mayr brakes have proved their worth on the market umpteen times over the years. With the market launch of the product series ROBA-stop®-silenzio®, ROBA®-diskstop®, ROBA®-duplostop® and ROBA®-twinstop®, as well as with countless application-optimized brake solutions for leading OEMs, the company has installed technologically superior elevator brakes on the global market, which meet all the requirements of existing and modern traction machine concepts for MR (machine room) or MRL (machine-room-less) installations.

All mayr brakes are tagged with CSA (Canadian Standards Association) approval. Also, all mayr safety brakes are subjected to careful quality checks: These include quality assurance measures during the design process, as well as a comprehensive final test. Prior to delivery, all brakes are extensively tested on test stands, and function-relevant values are documented. An electronic database, in which the measurement values together with the associated serial numbers of a product are stored, ensures 100% traceability.

The mayr company quality management system is certified according to ISO 9001. This confirms the quality consciousness of the employees at all levels of the company. In North America, the Germany-based company supports its customers with local technical engineers. With native language and technical know-how not only on elevator brakes but on the whole mayr product range, they stand for competent consultation and quick, controlled and reliable support. A close contact to the customers in the local markets is seen as a key to success by mayr, which serves elevator customers world-wide.

Conscientiously Designed To Last Its Intended Lifetime

When selecting a brake supplier, both the evaluation of the company with regard to quality and reliability and the product specifications and their adjustment to the required criteria are of the utmost importance. Here, it is especially important that elevator brakes are also considered under critical conditions, such as high outside temperatures or high air humidity. Furthermore, it is important that specified values are not only achieved in new conditions, but that their characteristics are assessed over the entire service lifetime. Eberle said:

“The years of experience and countless tests conducted by our Development and Research Department at our German headquarters form the basis for a conscientious product designed to last its intended lifetime, taking into account realistic and verified braking torque tolerances. All the brake components are reliably dimensioned and are only produced from high-quality, known and proven materials. Our brakes are dimensioned so that they can reliably achieve the required nominal torque under all occurring operating conditions, independent, for example, of the ambient temperature or the air humidity.”

Safety Does Not Allow for Compromises

Global elevator manufacturers are increasingly making use of quality products. However, unfortunately it cannot be ruled out that, in addition to certified quality products, copies that do not provide the necessary reliability are used. For this reason, it is better to specify the appropriate brakes from renowned manufacturers and to ensure that these are also used, for example, through the inspection of the type tags. This ensures that these important components provide the reliability one expects. Appropriate production competence and maximum care are essential for the reliable transport of passengers — as safety does not allow for compromises.

About mayr power transmission

Get more of Elevator World. Sign up for our free e-newsletter.