The endura MRL is released in the Americas for the low-rise market.

photo courtesy of ThyssenKrupp Elevator

In February, ThyssenKrupp Elevator Americas introduced a new elevator, the endura MRL, which combines the functionality of hydraulics and a machine-room-less (MRL) design. Intended for low-rise buildings, the unit is expected to save space and preclude restricting the use of space that would otherwise provide access to a controller closet. The company maintains that the intrinsic ability of a hydraulic elevator to lift larger loads provides owners, contractors and architects freedom to design with such finishes and options as high cabin ceilings, glass and oversized doors.

The endura MRL offers the lowest pit and overhead requirements among ThyssenKrupp Elevator’s product line.

Rich Hussey, ThyssenKrupp Elevator Americas president and CEO, explained:

“For a decade, low-rise building owners have been installing over-engineered traction elevators to move tenants just a few floors. With the launch of the endura MRL, now there is an elevator that saves building space, takes less effort and cost to install and saves thousands of dollars on elevator operations over the product’s life. Compared with hydraulic solutions, the endura MRL uses 95% petroleum-free hydraulic fluid, has no machine room to construct and requires less installation coordination.”

Above-Ground Versions

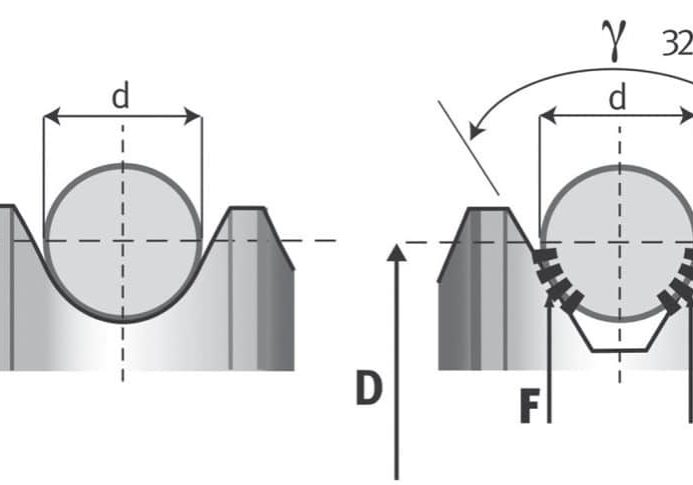

The above-ground version of the elevator features a twin-post jack connected to the top of the elevator car sling. This design exists to achieve the travel necessary to reach a building’s top floor without having to drill down below ground. The endura MRL offers the lowest pit and overhead requirements among ThyssenKrupp Elevator’s product line. This version of the elevator comes in three different configurations: twin-post one, two and three stage.

The one-stage configuration for the above-ground endura MRL has only one section of plunger that extends out of the cylinder. It is intended for a two-stop building with travel below 12 ft., 8 in. with minimum pit and overhead, or up to 18 ft., 11 in. with a small increase in pit and/or overhead.

The two-stage above-ground configuration offers greater travel capabilities with its telescoping sections. Instead of one section of plunger to extend, there are two sections to allow for almost twice the distance in travel being reached. This series is intended for buildings with travel up to 23 ft., 2-1/2 in. with minimum pit and overhead, or up to 28 ft., 6 in. with a small increase in pit and/or overhead.

ThyssenKrupp Elevator considers the endura MRL’s pump unit compact and environmentally friendly.

The three-stage above-ground configuration provides the maximum height for the company’s hydraulic elevators, with telescoping capabilities enabling travel distances of up to 33 ft., 6-1/2 in. of travel with minimum pit and overhead. Travel heights up to 48 ft., 3-1/2 in. are obtainable with a small increase in pit depth and/or overhead height.

Below-Ground Version

The below-ground endura MRL features a single plunger connected to the bottom of the elevator and contained in a cylinder that extends under the earth. This is the easiest method of lifting an elevator, but a hole deep enough to allow the elevator to reach the top floor of the building must be dug. This model can reach 79 ft. of travel. It uses a plunger within a cylinder that rests below ground level.

Pump-Unit and Lighting Advantages

ThyssenKrupp Elevator considers the endura MRL’s pump unit compact and environmentally friendly. Fit tightly in the elevator pit to improve ride quality and eliminate the coordination of oil lines and electrical conduit throughout the building, its electronic valve requires little to no adjustment and allows for improved leveling accuracy. Additionally, special sound deadening in the pump’s tank and under the lid promote a quiet ride. Vegetable-based hydraulic fluid is recommended to prevent unpleasant oil odors.

The product’s lighting consists of mercury-free LED fixtures that last up to 50,000 hr. Its standard version includes automatic-off lights and cabin fan.

endura’s Endurance

ThyssenKrupp Elevator has conducted lifecycle analysis and costing on its low-rise elevators and states that, when compared with traction MRL units, the endura MRL saves up to US$100,000 on initial, building and operating costs over the product’s 25-year life. These costs are based on the comparison of three-stop, 2500-lb.-capacity hydraulic and traction elevators with the same interiors and settings.

Get more of Elevator World. Sign up for our free e-newsletter.