Ninth European Lift Congress Heilbronn 2022

Dec 5, 2022

Outstanding revival after pandemic

After a long coronavirus break, the European Lift Congress Heilbronn (ELCH) took place on October 11-12 at a new venue, Intersport RedBlue a few miles outside of Heilbronn, Germany. Only 44 participants from 15 European countries (half of them German) found their way to the ninth edition of the ELCH — a pity, as the many others who had been there regularly before the pandemic missed a revival with outstanding presentations. Fourteen speakers from eight European countries — plus China —were invited by Wolfram Vogel, a certified German lift expert, to present their future-oriented ideas, as well as the latest R&D.

First Day: Management and Marketing

The first day was management- and marketing-oriented, providing an overview of markets, technology and influences on both. Georg Clauss from organizer Technical Academy Heilbronn (TAH) welcomed participants. As chair, Vogel dealt in his welcome with a special technical aspect of the ELCH, describing its growing mixture of mechanical, electrical and electronic components.

Esfandiar Gharibaan, chairman, CEN/TC 10, “International Standardization for Lifts – Current Status and Future Trends”

The speech was given by Gerhard Schiffner, the German member of the same standards’ committees. This might have been his last public speech, since he was only a few working days away from retiring. As objectives of standardization, Schiffner listed facilitation of business interactions, international technical harmonization, helping to meet regulatory requirements, hastening introduction of new products, sharing best practices and facilitating efficiency of the supply chain.

The CEN TC 10 work program deals with the following products: inclined lifts, standard lifts, escalators, building hoists, goods-only lifts, lifting platforms, stairlifts, lifts in cranes and wind turbines and lifting tables. EN 81 covers 50 work items, 40 of which are already published and 10 are under development. Sixteen standards are harmonized to the Lift Directive (LD), 18 to the Machinery Directive and 18 to the EMC (electromagnetic compatibility) Directive. In light of these being relatively new standards, Schiffner reported in greater detail on the EN International Organization of Standardization (ISO) 8100-1/-2, EN 81-76, EN 115-5, EN 81-42, -44, -45 and -46. A long list of revisions is underway, mainly due to regulatory alignment, technical updates and alignment with other revised standards.

ISO TC 178 deals mainly with the ISO 810x-x family. Many other numbers will be integrated step by step into this new group comprising, in the end, 43 standards, of which 41 are already published and two are still under development.

As for standardization trends, Schiffner mentioned the increasing use of ISO standards, EU harmonized standards as part of EU legislation, standardization on digitalization and standards from organizations other than EN/ISO, such as BACnet, ETSI (European Telecommunications Standards Institute) and BIM (Building Information Modeling). He observed that standardization work has intensified and added an appeal to experts to participate and contribute to standardization showing concrete ways forward via their national standardization bodies.

Robert Zappa, president of the European Lift Association (ELA), “The World Elevator and Escalator Federation (WEEF) – a Cooperation Means to Reach Global Safety for Users and Workers by Leveraging Globally Enforced Standards and Local Needs”

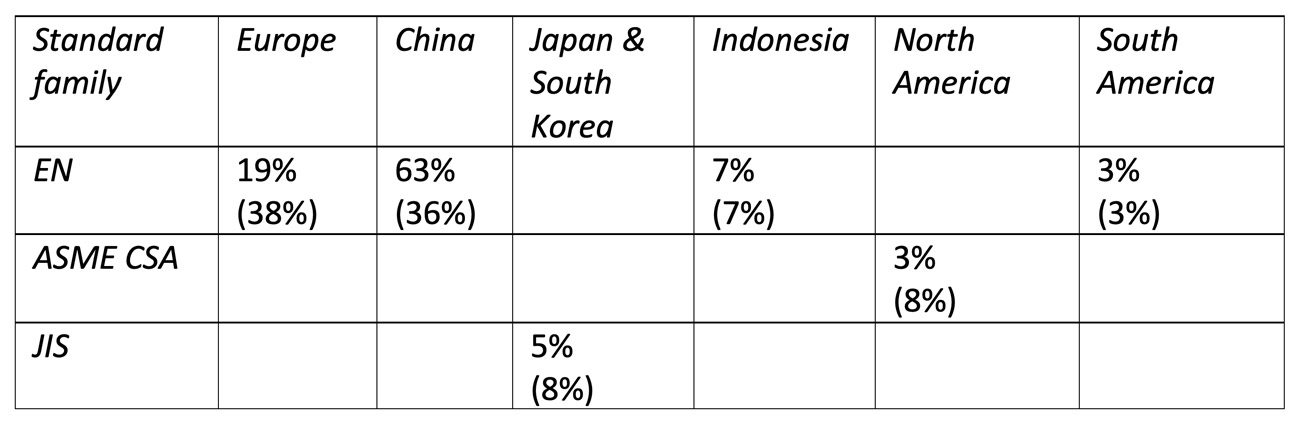

Growing urbanization is the main driver for the elevator industry, with the strongest growth in the Asia-Pacific region. Interactions between CEN, ISO, WEEF and local standards and surveillance bodies/installation and maintenance deal with how to guarantee the same level of safety everywhere. The actual use of safety standards is distributed as follows (new installations, existing installations in brackets):

The number of incidents and accidents cannot be used as justification for having different local safety requirements in the regulations and standards. WEEF is committed to contributing to the resolution of incidents’ root causes, such as proper application of standards in engineering, installation and inspection before putting equipment into service, maintenance throughout the lifetime of the equipment and periodic inspections by the authorities.

The idea for WEEF started in 1995 with the Global Technical Barrier-Free Trade (GTBFT) agreement based on ISO/TC 178 and was realized in April 2020 with the official kickoff of WEEF. The members, all representing the industry, are Assoçiacão Elevadores do Mercosul, China Elevator Association, European Elevator Association, European Federation for Elevator Small- and Medium-Sized Enterprises, European Lift Association, European Lift & Lift Component Association, European Platform and Stairlift Association, National Elevator Industry, Inc., National Elevator and Escalator Association, National Lift Union and Pacific Asia Lift (Elevator) and Escalator Association. The objective of WEEF is “World Technical Harmonization” for elevators, escalators and their components under the motto, “Certify Once and Install Everywhere.”

Stephan Störmer, TÜV Austria Services, Austria, “Testability of Innovative Technologies in Safety Equipment and the Responsibilities of NB-Ls”

Both traditional products and innovative technologies need to be tested to prove that product acceptance criteria are met. Sometimes, this is not possible on-site, so supporting evidence — such as certificates — is required. For safety circuits with Programmable Electronic System in Safety-related Application for Lifts (PESSRAL) components, a procedure was agreed upon. This method (mainly involving lab tests) works quite well, including with other EU safety components and car door locking devices. Alternative suspension, emergency communication and car/landing door panels are still difficult, but possible, to test.

A Conformity Assessment (CA) is defined as an activity to determine whether a standard, technical specification or legal regulation is applied to a product and that the product fulfills criteria related to performance, safety, efficiency, reliability and so on. A CA includes testing, inspection and certification and must ensure consistent and replicable results. A CA may be performed by Notified Bodies for Lifts (NB-Ls), qualified manufacturers or qualified installers of lifts, depending on national legal or EU regulations, mostly the LD. Outsourcing certification services by NBs is possible under certain conditions, but the responsibility remains with the certification body.

Störmer provided some examples, then summed up his speech:

“Although there is no ‘one size fits all’ procedure in place to solve this problem, a common understanding among the stakeholders leads to testing, obtaining evidence and to making the right decisions.”

Paula Cesares, TK Elevator Spain: “Lifecycle Assessment – Environmental Challenges”

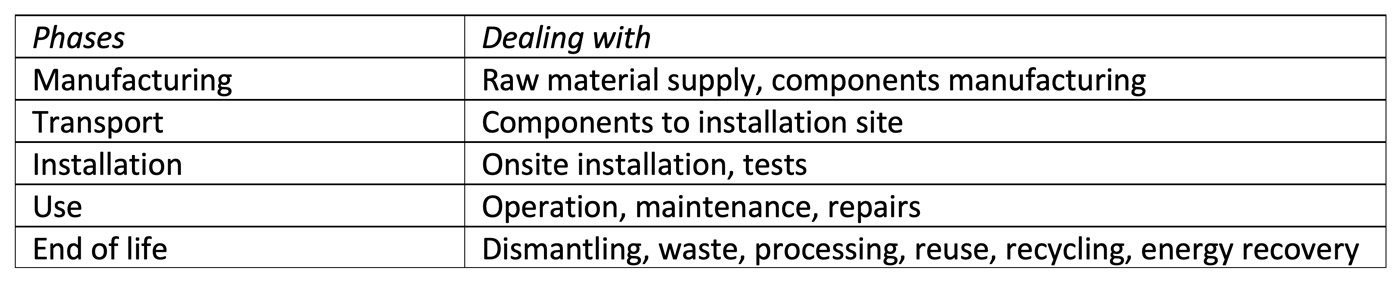

Life Cycle Assessment (LCA) is a method to assess the environmental impacts of a product over its life cycle following ISO 14040/44. The LCA of an elevator includes:

Esfandiar Gharibaan, chairman, CEN/TC 10, observed that standardization work has intensified and added an appeal to experts to participate and contribute to standardization showing concrete ways forward via their national standardization bodies.

Environmental impacts include the potential for global warming, acidification, eutrophication (increase of vegetation in water caused by nutrients) and photochemical ozone creation. Developing an LCA is an iterative process with three steps — goal and scope definition, Life Cycle Inventory (LCI) and Life Cycle Impact Assessment (LCIA) — all to be interpreted.

The inputs (collected data) lead via the calculation (conversion of data) to the results (aggregation of environmental impacts in impact categories). Cesares then gave examples for the input data for each of the five LCA phases, such as weight per material for all components of the elevator, including packaging for manufacturing. The results are global warming potentials of an elevator in kg CO2-equivalent to 48% operation, 33% materials and manufacturing, and 19% others. Electricity consumption in operation, for example, accounts for up to 70% of the energy use of elevators over their lifetime.

The Environmental Product Declaration (EPD) is the document of the environmental performance of a product. It follows ISO 14025 based on the results of the LCA. Product category rules (PCR) are needed to perform an LCA. The complete process contains five steps:

- Find or develop relevant PCR: for elevators, available (PCR 2019:14 on construction products, C-PCR-008 to aforementioned PCR on Lifts)

- Perform LCA according to PCR

- Compile info on EPD

- Verify LCA and EPD

- Register and publish EPDs: for elevators, published.

A comparability of EPDs is only achievable if various performance characteristics are equivalent, which is nearly never the case. TK Elevator (TKE) published 11 EPDs that cover more than 95% of its product offerings in Europe. To achieve this, they developed a simplified LCA tool, SILCA. Elevator companies are responsible for the reduction of the carbon footprint of their products purchased and sold. Strategies to reach TKE’s carbon footprint reduction targets include energy-efficient operations and products, fleet decarbonization and the use of 100% renewable electricity.

Daniel Nyman, Motum, Sweden: “The Nordic Elevator Market”

The elevator market in Northern Europe, nowadays including Sweden, Finland, Denmark, Norway and Iceland, started with the first installations in Sweden in 1881. With 10.5 million people, Sweden has the biggest population. All countries are sparsely populated, with Denmark on top with 138 persons/km2. The Human Development Index (HDI) — a summary measure of average achievement in key dimensions of human development: a long and healthy life, being knowledgeable and having a decent standard of living[1] — in Norway is, at 0.961, second best in the world. New elevator installations in 2021 are highest in Sweden with 3,113; Finland, 2,214; Denmark, 1,661; and Norway, 1,434. Market players include government, public/private real estate/housing associations, consultants/architects, installers (NBs dealing with the last three), wholesale and suppliers (including those organized in elevator associations).

Overall trends are similar to those in the rest of Europe. The trend of new elevators has been quite stable over the last five years. After a growth and a consolidation phase since 2000, the market is now in a consolidation phase of private equity. The GDP prognosis shows a slight growth of approximately 1% across all Nordic countries in the next two years, though the war in Ukraine and the energy crisis make prediction difficult. In total, “the elevator industry is still one of the most stable industries, at least in the Nordic countries.”

Lexiang Zhang, China Elevator Association, China (voice only due to COVID-19 restrictions): “The Status Quo, Codes & Standards, a Regulation Update of China Elevator Industry”

In 2021, the industry produced 1.21 million units, including 85,000 escalators. The market is dominated by multinationals, which make up 60% in terms of units, 80% in sales and 90% in profits. Typical products are permanent-magnet synchronous motor with an average of 17 floors and 800-1000 kg capacity. In China, there are 9.5 million installations, of which more than 80% operate fewer than 15 years. The number of players with government permits is 630, maintenance companies 16,000 and employees 1 million. Future prospects are considered good.

Zhang also reported on problems of deploying the EN and ISO codes, as China has a different history and social understanding of codes. They lack professional buyers and engineering consultants, as well as market surveillance. The country has neither design and manufacturing nor installation and maintenance guidelines. Quality requirements and components standards are missing, too. The New National Standardization Law recognizes the legal status of standards from associations. Also, CEA writes many standards to support good deployment of CEN and ISO codes in China.

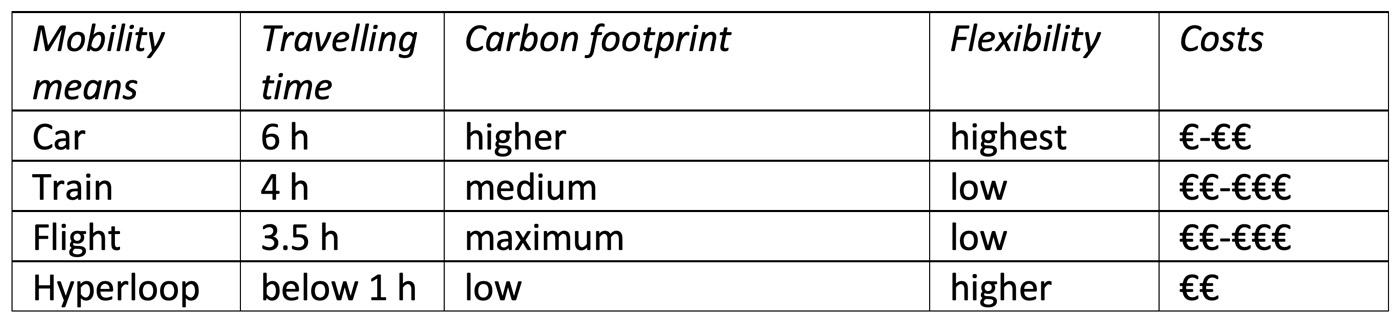

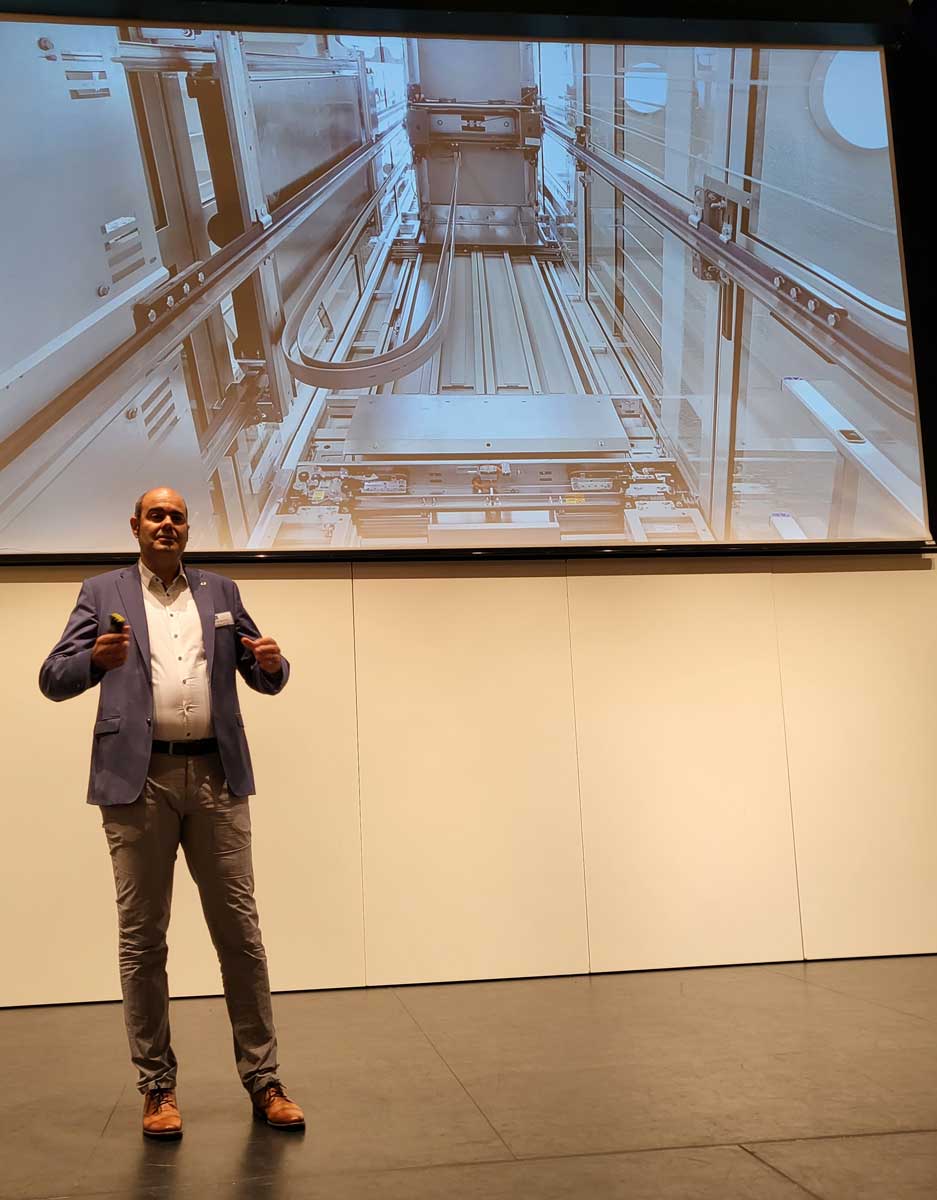

Gabriele Semino, Next Prototypes, Germany: “Inside the Hyperloop Vision”

The worldwide student project is based in Germany at the Technical University Munich (TUM). The aim is to develop ultra-fast, direct connections and emissions-free mobility. Creating a connection between Munich and Berlin via various mobility means led to the following results:

The objective of WEEF is “World Technical Harmonization” for elevators, escalators and their components under the motto, “Certify Once and Install Everywhere.”

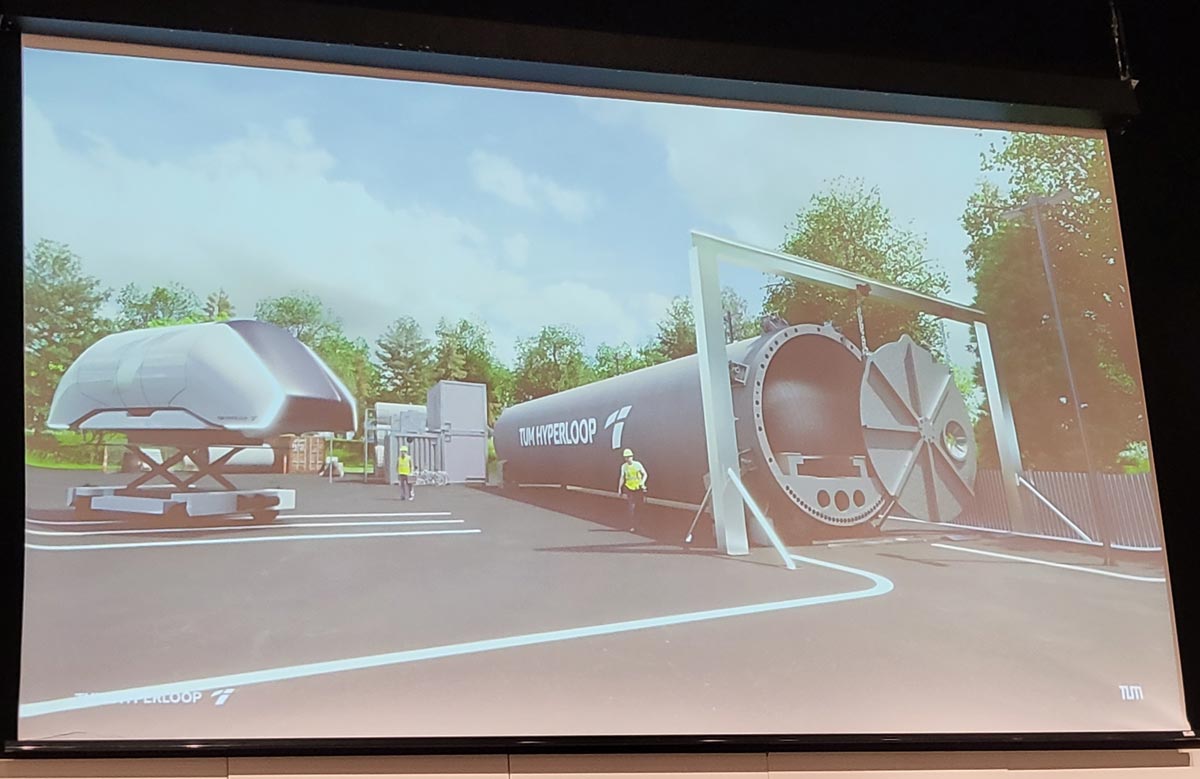

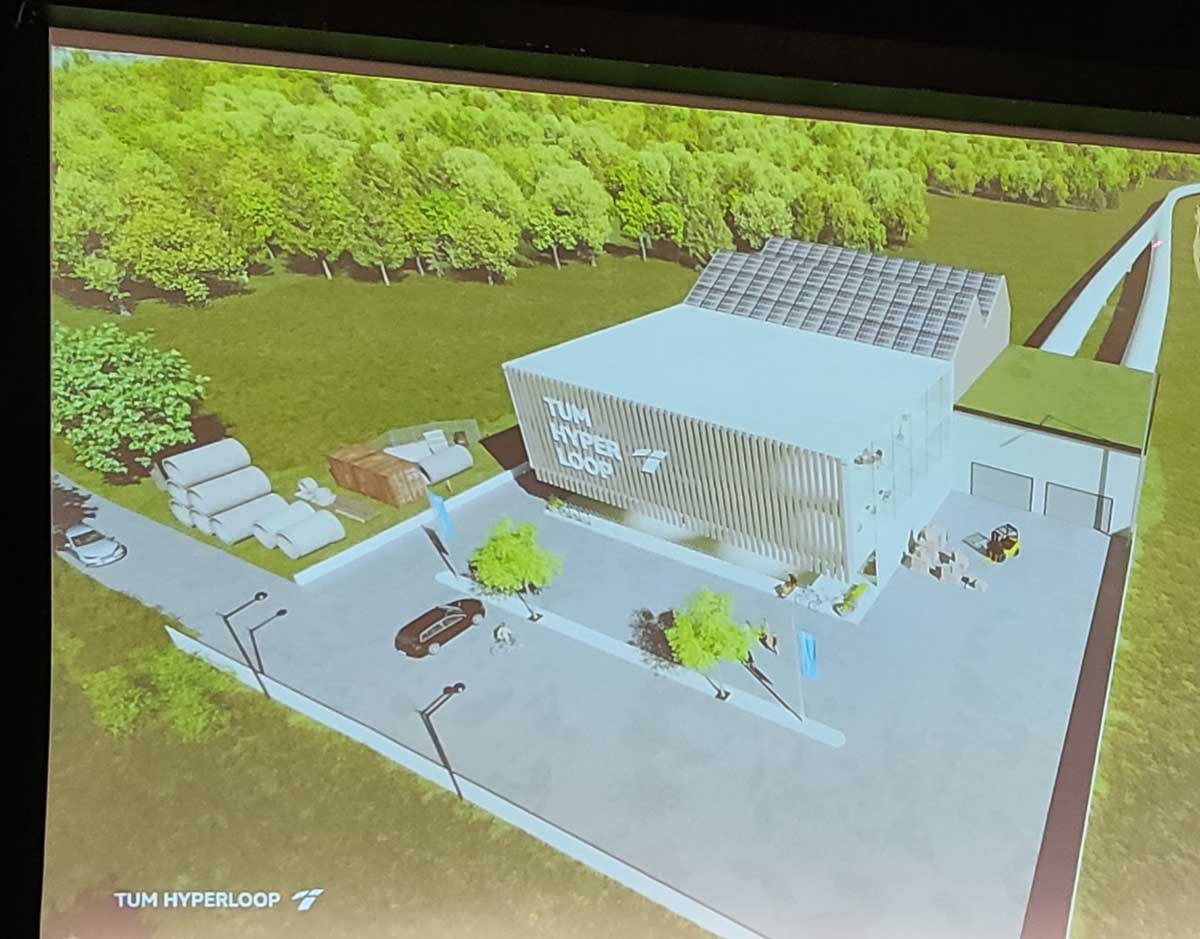

Student teams make cabins (pods) move as fast as possible. The first pod competition took place in California on a 1-km test track. Under the hyperloop slogan “Engineering a World Without the Limits of Distance and Time,” TUM built three pod prototypes. The last and fastest holds a world record, achieving speed of 482 km/h.

Pods move magnetically in a round, closed loop, similar to a model train. The new TUM Hyperloop Demonstrator — for the first time in 1:1 scale — is based near Munich, Germany. The vacuum tube has a length of 24 m, assembled from six airtight concrete segments. It arrived at the end of October. The demo contains a passenger module to demonstrate passenger experience under real conditions, a service module with integrated levitation, propulsion, an electronic system and an operation control station. The objectives of the demo are to test critical key systems, investigate technical feasibility and bring the hyperloop experience closer to the public. More can be found at tumhyperloop.com.

Second Day: Digitalization — Safety and Security

The second day was R&D-oriented, providing technical details of what comes next in digitalization and how it is ensured to be as safe and secure as former mechanical solutions.

Christian Studer, Schindler, Switzerland: “Digitalisation of Existing Installations”

As benefits for remote connectivity, the speaker mentioned:

- Knowing in advance about arising elevator problems

- Accessing information about the cause to inform the technician

- Avoiding visits

- Planning visits better

In a closed-loop diagnosis, the elevator delivers data to the cloud/remote monitoring platform, which passes on information to the technician who then takes action back to the elevator, starting the cycle anew. Diagnostics are based either on rules or on anomaly/degradation or are data driven. The anomaly detection functions in a comparable closed loop, too.

Digitalization of existing installations depends on the data source, controller versus sensor kit, accessibility and/or granularity and/or quality of data, as well as cost. If controller data are available, they usually are the easier and preferred choice. Sensor kits for the digitalization of elevator installations have a multitude of facets with which to deal, including mounting, component identification, failure models, embedment in a diagnostic system, data transmission and energy supply. The new Schindler Sensor Kit Lift Guardian comprises all these functionalities. Digitalization of elevator maintenance plus electric “Schindler Green Service” cars reduce the CO2 footprint from the Co2 equivalent of 73.36 to 0.36 kg.

Roland Hoppenstedt, Ziehl-Abegg, Germany: “Functional Safety — A Core Competence of Future Elevators and Their Components”

The speaker gave a historical review of the company, starting in 1962 with relays and later using contactors. Today, functional safety eliminates contactors. The safe torque off (STO), safe stop 1 (SS1) and safely limited speed (SLS) functions are defined in EN/IEC 61800-5-2. EN 81 follows the STO industry standard.

The STO safety function, a pure hardware solution, for example, is superior to single-channel electromechanical devices such as a contactor, as it has no moving parts, two channels, three-fault safe evaluation of the inputs and an informed micro-processor. The price for additional safety is additional measures: Type examination by a NB, protection of cable routing, performing regular checks during operation and defining a maximum lifetime. Hoppenstedt gave further examples like the brake circuit, which already shows clear adaptations to the elevator, overspeed governor and safety chain. He appealed: “Read the manual!”

Nicola Imbimbo, Prysmian Group, Italy, “How the Number of Installed Ropes Could Influence the Performance Parameters of MRLs”

The speaker explained the system’s effect on suspension wire ropes, taking into account various cabin frames and guide shoes. Suspension means have an effect on elevator design, including load, speed, machine position in a building and number and form of sheaves. The safety factor and specific pressure can be calculated following EN 81-50 chapter 5.12.3. Imbimbo compared the results of his calculations with five, six or seven ropes: With the number of ropes, the safety factor rises, the number of trips increases from 660,000 to 1.1 million and the specific pressure lowers. A test tower or lab delivers more data, such as the elongation-tensile curve. He compared the calculation results with the test results: E-Modulus and elastic movement both go down with the increasing number of ropes. Further lab tests, for example magneto-inductive testing, combined with various rope handling procedures, deal with the potential elongation of the rope and how to hinder it, as well as with other potential damage to the rope.

Aleksey Gorilovsky, LiftEye, United Kingdom: “The Big Picture”

A direct view plus audio gives people a feeling of safety. This is mostly interrupted in the elevator cabin, which additionally moves, reinforcing an unsafe feeling inside. Creating a (visual and audible) connection to the environment for passengers is the solution.

A Conformity Assessment includes testing, inspection and certification and must ensure consistent and replicable results.

Stefan Rohr, ELGO Electronic, Liechtenstein: “SGA/LimaxCP Actuating Safety Gear”

Rohr presented the product range of his company of safety controllers plus Safebox. In the compact version, both components are combined in a single housing. Many safety functions are combined in the component housing, such as unintended car movement, floor-level indication, safety gears of various manufacturers and overspeed pre- and final tripping. Customized functions can be added.

He then presented the Safety Gear Actuator (SGA), describing its working principles and fixation on the car. Advantages are that, for example, the pole can be used on variable length, different springs can work with different forces and the reset time is less than 1 s. Both solutions offer a solid technology. The overspeed governor is removed. All safety functions are built-in, allowing complexity and supervision of the elevator.

The day ended early, with an abbreviated program and a speech from Vogel, Vogel Gutachten, Germany, titled “Thinking and Acting in the System Lift.”

Wining and Dining

The evening of the first day started with a humorous demonstration of Tesla transformers in the ScienceDome of the experimenta Science Center in the city center of Heilbronn, producing rather loud lightning. It was followed by a reception with local “bubbly” and an elegant and elaborate conference dinner at the same venue overlooking Lake Hagenbucher. Breaks during the conference offered healthy vegetarian treats including a coconut-based chocolate.

Reference

[1] Human Development Index (HDI)

Heilbronn All Over Again in 2023

Your author, (USB), talked to Klaus Dietel (KDI) from TÜV NORD Systems, chair of the next national elevator event in Heilbronn in early March 2023, about the hot topics of the elevator industry. These will certainly be covered during Heilbronn Lift Days 2023.

USB: We are all looking forward to the next event in Heilbronn. What’s new?

KDI: Presently, I see two major points moving the elevator industry, and not only in Germany: digitalization and the shortage of skilled workers. Under the motto “Sustainable, Digital, Safe,” next year we will address both topics and more.

USB: Let’s start with the people.

KDI: We will add another dimension to Lift Days: a forum where companies can contact potential apprentices, trainees and employees. As such, the first afternoon will be dedicated to presentations that are attractive to both elevator people and those aspiring to join the industry.

USB: And digital?

KDI: Functional safety — safety based on software — has joined the elevator industry only lately. Thus, we are still not yet as familiar with it as we should be. Therefore, we will focus on PESSRAL — our branch name for functional safety — with an emphasis on practical use: “How do I practically deal with it?” is the main question to be answered, and everybody will take home the latest relevant knowledge.

USB: How do you interpret “practical” in this case?

KDI: We will deal with PESSRAL from the perspective of manufacturers, as well as users, including inspectors. We will handle the facets of technology, safety and costs. Ways to guarantee the integrity of the system will be presented to ensure that nobody touches the hardware and software in such a way that might affect its safety functions.

USB: What else does digitalization include?

KDI: Following PESSRAL is cybersecurity. We already experienced both our enterprises and our elevator units being compromised from the outside. We will hear about relevant standards and receive a “cooking” recipe on how to proceed in terms of protecting our equipment and systems. Additionally, we will address the new perspectives arising with clouds and remote monitoring, to name only a few buzzwords.

USB: Is there something else?

KDI: Oh, yes. There is also the aesthetics of an elevator, including from a historical point of view, which will lead to many beautiful pictures.

USB: How did you tackle the identification of these topics that are crucial for our industry?

KDI: I benefit from my connections to our TÜV NORD customers that include manufacturers of elevators and components, operators and the various bodies with which I interact. All this completes my personal picture of the issues moving the industry nowadays, and it helps identify the best speakers.

USB: Will COVID-19 still be an influence on Lift Days 2023?

KDI: I hope not too much! Hybrid events mostly miss the most important thing at a conference: the networking. It is much nicer and much more efficient to meet new people face-to-face over a cup of coffee; it’s crucial! I sincerely hope that our concept will bring back 300-plus participants to Heilbronn.

USB: Are you personally already living the “new normal” of post-pandemic times?

KDI: I also worked from home before the various pandemic-related lockdowns. Now, I am in my office — mainly to contact colleagues — maybe once a week. As I am still actively working as a technical inspector for elevators, I am at my customers’ locations inspecting their elevators or have external meetings. Chairing Lift Days has been a high priority for me for a decade now, and I would really like for that to continue for some time, although my retirement is not that far away.

Get more of Elevator World. Sign up for our free e-newsletter.