Obstruction Detectors – A Historical Review

Feb 1, 2012

A review of door sensors from the 1950s to the present

A major issue with automatically powered elevator doors is the risk of passenger injury from door impacts. Elevator companies have used various alternative devices to protect passengers, ranging from simple mechanical safety shoes to sophisticated infrared beam systems. This is a review of such devices from about the 1950s to present day.

Mechanical Impact Sensors

One of the most common methods of passenger protection is to attach a soft-edged buffer strip to a micro-switch pressure sensor. This device reverses door motion if the switch is activated by contact of the buffer with a passenger. It relies on a mechanical impact and, therefore, not a “non-contact” sensor. However, it does limit the force applied and avoids the dangerous trapping of limbs in the doorway. Such safety shoes are still commonly used in older installations, but their bulk and cost have eliminated them from modern lightweight elevator cars. Mechanical shoes are prone to damage or wear and tear due to day-to-day operation and their electrical contactors can corrode. This can lead to significant downtime and expense, while repairs are performed. Electronic solutions (initially capacitance-based and now primarily infrared- (IR) based), that can be quickly installed without on-site adjustment and with the advantages of protecting the doors themselves from damage have been developed. Therefore, the need for expensive unplanned maintenance is reduced. Some dual-safety devices combine a mechanical shoe with an infrared beam system, providing non-contact sensing and mechanical backup in case of electronic failure of the IR beams.

Capacitance Proximity Sensors

Some of the earliest non-contact devices used capacitance between the sensor and a passenger as a means of detecting the presence of an obstruction. The earlier Otis “A” and “B” model sensors used this technique to detect passengers by unbalancing a capacitive bridge circuit. The bridge was driven with a 50-kHz square wave, and the sensing was performed by detecting a difference of 50 kHz signal level in the two halves of the wire bridge antennas on the door edge. This device had a short range of about 50 mm, and the doors would often still hit each other due to the run-on of the door momentum, but the impact was relatively gentle. The biggest problems with the earlier devices were drift of the bridge balance and the bad effects of poor door grounding. The metal door skin would often be in poor and intermittent ground contact, due to resistive bearings in the operator arm or wire drive rope, and the variation in contact resistance would inject large noise signals into the bridge, often causing false triggers.

Some improvement was seen with the introduction of the Memco “R” model in 1980, which used a more stable AC-coupled detection circuit, and could achieve about 100 mm of range. However, since the late 1980s, the capacitive proximity detector has faded into obscurity as more reliable IR systems have been introduced, but the technology has the potential to reappear as improved microprocessor-based touch switch devices make capacitance sensing more practical.

Proximity Infrared

While capacitance-based detection is short range and prone to instability, it is possible to design a reflective infrared proximity detector with generally good performance. The late 1980s saw the introduction of reflective proximity devices, which had some success in the largely capacitance-based market at the time. Sometime later, Memco introduced the Panaflect, an infrared proximity system with a range of about 200 mm, which was good enough to overcome the door run-on issues of capacitance detectors. These detectors emitted multiple infrared beams in a vertical fan pattern and used photodiodes to sense IR reflections from nearby passengers. A strong signal, present on just a few receivers, was interpreted as a valid obstruction, while an approximately equal signal on all receivers was seen as an approaching slam post. The proximity system does help speed up elevator transit times (a detection is not generated for every passenger entering the doorway, unlike normal infrared detectors), but these reflective devices were expensive to manufacture and have since fallen out of favor.

Infrared Beam Systems

Infrared beam-based detectors have become one of the most popular types of obstruction sensors in use today. Infrared beams provide excellent coverage of the door aperture, are insensitive to electronic noise and have become inexpensive as technology has improved. The first such devices used little more than a filament lamp as a transmitter and a selenium cell as a receiver, and were pretty unreliable, but the filament lamp is now replaced with an infrared LED and the selenium cell with a silicon photodiode, giving an improvement in performance and reliability.

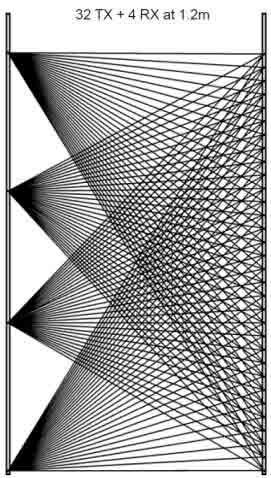

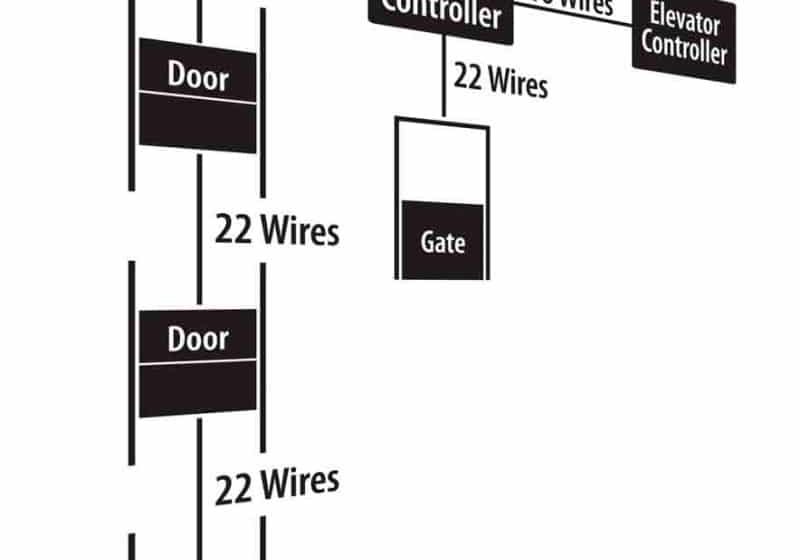

Most IR beam systems consist of a column of multiplexed arrays of IR LEDs on one door, with an equal number of multiplexed photodiodes on the opposite door. The sensitive zone is essentially continuous from just above the car sill to about 1.8 m high. Microcontroller chips in each edge generate the scanning patterns required and measure the strength of the signal for each beam in turn. Any beams that measure below a preset threshold are assumed to be blocked by a passenger or other obstruction, and the system will then operate the door-open relay. It is important to clarify the difference between the number of diodes and beams. Figure 2 shows the beam pattern for a typical 18-diode detector. When operating in parallel-only mode, the number of beams is equivalent to the number of diodes.

There are several different combinations of scanning patterns available to designers, but the most common is a mix of parallel and slightly diagonal beams to achieve the best beam grid density. The use of diagonal beams gives a much greater beam density, and, therefore, smaller objects are detected over the majority of the detection area. However, due to the nature of the beam pattern, the minimum obstruction size that will always be detected is usually slightly larger than the diode spacing at one of the detector edges. The minimum detectable object size largely determines the number of LEDs in the system. Older beam devices often have large diode spacing with as few as eight diodes per side, as the cost of these components was a large factor in their design. Modern versions are typically fitted with 32 or 40 diodes. A 40-diode system should be able to reliably detect objects of 50 mm in diameter. A minimum detection size of 50 mm is currently being proposed as an official Comité Européen de Normalisation interpretation of the European Standard EN 81-70 Safety Rules for the Construction and Installation of Lifts.

Recently, it has become popular to install beam systems on fixed brackets, usually to the extreme ends of the door tracks. Such installations are well protected from vandalism and casual damage, and cables no longer need to resist the continual flexure from door movements. As large portions of the beam grid are hidden by the doors, even when open, it is possible for unusual scanning formats to be used. One of these is typified by the Memco Panatech, which reduces the receiver diode count to only four, while maintaining a high-density beam pattern across the accessible door aperture.

European Regulations

EN 81-70:2003 5.2.4 states:

“The protection device as required by 7.5.2.1.1.3 of EN 81-1-2:1998 and EN 81-2:1998 shall cover the opening over the distance between at least 25 mm and 1,800 mm above the car door sill, e.g., light curtain. The device shall be a sensor which prevents physical contact between the user and the leading edges of the closing door panel(s).”

For an infrared detector, this effectively sets the maximum height of the lowest diode and the minimum height of the highest diode. As can be seen, the European regulations covering the protective devices on elevator car doors are extremely limited. This is untrue for non-elevator light curtains designated for safety-related applications. Such applications are covered by IEC 61496. The first part of the standard, IEC 61496-1, sets out the general requirements and necessary tests for electrosensitive protection equipment (ESPE), including testing for functionality (e.g., response time and number of outputs), design (e.g., electrical supply and software) and environmental stress (e.g., stress and mechanical vibration).

The standard’s second part, IEC 61496-2, deals with active optoelectronic protective devices, the most common type of ESPE. The optical requirements for such devices are specified in this part of the standard, including immunity to various types of lighting and bypass reflection, both of which are important in elevator applications. Until there is a fundamental review of the applicable design and testing requirements for the elevator industry’s light curtains, it will remain up to equipment specifiers to feel confident their light curtains will protect customers in an increasingly litigious environment.

Advanced IR Beam Systems

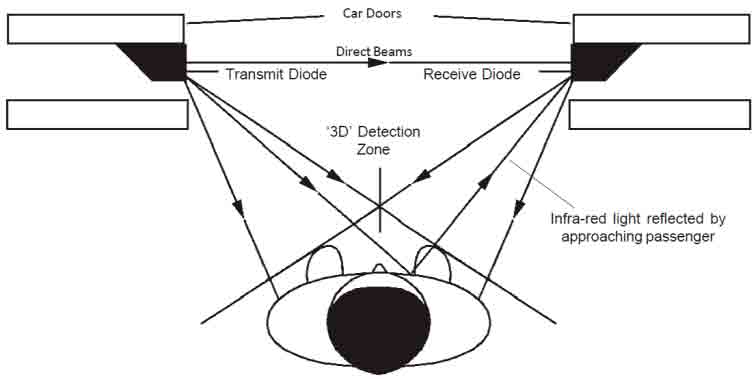

The nature of basic beam systems precludes the detection of objects that do not intersect the narrow plane that links the TX and RX detector strips. This leaves the landing door relatively unprotected, as the beam pattern is usually 50 mm or more behind the landing-door leading edge. To overcome this problem, Memco introduced the 3D concept in the mid 1990s. A 3D detector extends the sensitive region into the area ahead of the landing doors by using infrared light reflected from approaching passengers. An array of infrared LEDs and photodiodes are angled at about 45° to the 2D detection plane in such a way that the photodiodes cannot receive a signal unless the infrared light is reflected from a vertical surface in the approach area on the landing.

As the 3D system relies on infrared reflection, its sensitivity is somewhat affected by the color of clothing worn by passengers, but it has been discovered that even dark dyes are often very infrared reflective. The 3D is especially useful for environments with slow moving passengers, such as in hospitals and sheltered housing, but has also become popular in shopping malls and office blocks. It is best used in low-traffic areas to avoid unnecessary holdups due to people passing the doors and triggering the 3D. Various formats of detector mounting are available, but all require the edges be placed on or near the leading edge of the doors, so that the reflective system can “see” into the landing zone (Figure 4).

A development of the 3D system (although not restricted to 3D detectors) is the Memco-patented Panachrome series of “visual warning” detectors. These variants were first introduced in early 2000s’ Chromaline light strips and detectors, but were rapidly superseded by integrated versions. Panachrome incorporates visible LED lights and light guides to display the status of door movements to approaching passengers. Light guides are typically in the form of 100 mm X 6 mm bars in a vertical column that switch between steady green for “safe to enter” and flashing red for “doors closing.” Panachrome is popular for high-end applications in luxury hotels and offices but is also well suited for hospitals, etc., where a warning system can be helpful for slowing moving passengers.

For the foreseeable future, the infrared beam detector is unlikely to be replaced by a breakthrough technology. When incorporating good design principles and fully tested in a wide variety of environments, infrared technology is safe and effective.

Get more of Elevator World. Sign up for our free e-newsletter.