A detailed examination of how codes and standards guide emergency procedures and equipment

The International Building Code (IBC) defines occupant evacuation elevators (OEE) as elevators used by occupants for self evacuation during fires. ASME A17.1/CSA B44 elevator code does not define OEEs but has a definition for occupant evacuation operation (OEO). It is more specific and describes the operation of an elevator system for occupant evacuation in a building under emergency conditions.

Fundamentally, the IBC outlines design criteria for OEEs in a building, while the elevator code provides requirements for elevator functions under any emergency condition when OEO is necessary. While these divergent descriptions are sound in concept, they may result in confusion when distinguishing the responsibilities of and coordination between building-design professionals, elevator consultants, elevator contractors and elevator inspectors.

In the U.S., not all jurisdictional authorities adopt the same codes at the same time. Verify all codes in effect in the local jurisdiction, as well as other building requirements or local regulations.

All elevators for general public use in a building designed for occupant self evacuation must be in compliance with the special provisions required by Section 3008 of the IBC. While the voluntary incorporation of OEE provides new tools for the architect or design professional to consider when planning buildings, under no condition is the installation of such OEEs compulsory.

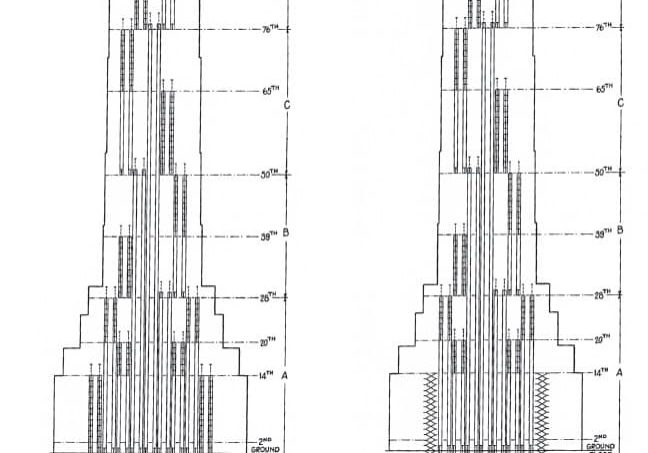

OEEs can be used for buildings of any height. When OEEs are incorporated into design criteria for buildings taller than 420 ft. (128 m), the additional interior exit stairway required by the IBC can be eliminated. Buildings designated as R-2 (which house permanent residents) are exempt from this rule.

This paper is intended to provide a general view of code requirements. In the U.S., not all jurisdictional authorities adopt the same codes at the same time. Verify all codes in effect in the local jurisdiction, as well as other building requirements or local regulations.

OEE Overview

The fire safety and evacuation plan must incorporate specific procedures for the occupants and be approved in accordance with Section 404 of the International Fire Code. Fire safety and evacuation plans must be reviewed and updated annually, or as necessitated by changes, and must be available for tenants and employees to review.

The plan must outline the methods used for evacuation using stairs and elevators and the role of fire wardens. It must include routine training and drills for occupants. It must provide schedules to regularly and systematically maintain building elements related to OEE performance, such as machine rooms, lobbies, public-address systems and the reliability and safety of OEO. Copies of the safety and evacuation plan must be provided to the fire-code official upon request.

Activation is initiated by:

- The action of an automatic fire-alarm initiating device, installed in any location outside the Phase I recall system (elevator lobbies, machine rooms, control rooms, control spaces and hoistways), will instruct the fire-alarm system to provide signals to the elevator system, thus indicating which floors are affected and must be evacuated.

- Approved manual controls are to be initiated by authorized or emergency personnel

- A fire command center has a means of manual control to initiate total building evacuation: When manual control is actuated, the fire-alarm system will provide a signal to the elevator system indicating all floors are to be evacuated.

Termination is achieved by:

- Resetting the fire alarm: OEO will be terminated, and the elevator system will return to normal operation.

- Initiating firefighter emergency operation (FEO): The activation of an automatic fire-alarm initiating device inside the Phase I recall zones (elevator lobbies, machine rooms, control rooms, control spaces and, when required, hoistways) will cause the elevator system to terminate OEO and initiate FEO.

- Initiating car fire recall: The action of placing the individual car fire recall switch in the on position will cause the elevator system to terminate OEO for the individual car it controls and initiate manual FEO.

- Initiating group fire recall: The action of placing the group fire recall switch in the lobby at the designated level in the on position will cause the elevator system to terminate OEO for the group of cars it controls and initiate manual FEO.

OEE Building Code Requirements

Automatic Sprinkler System

- Approved type, electrically supervised and installed throughout the building in accordance with National Fire Protection Association (NFPA) standard 13. The automatic system is equipped with a sprinkler control valve supervisory switch and a water-flow initiating device installed on every floor and monitored by the building’s fire-alarm system.

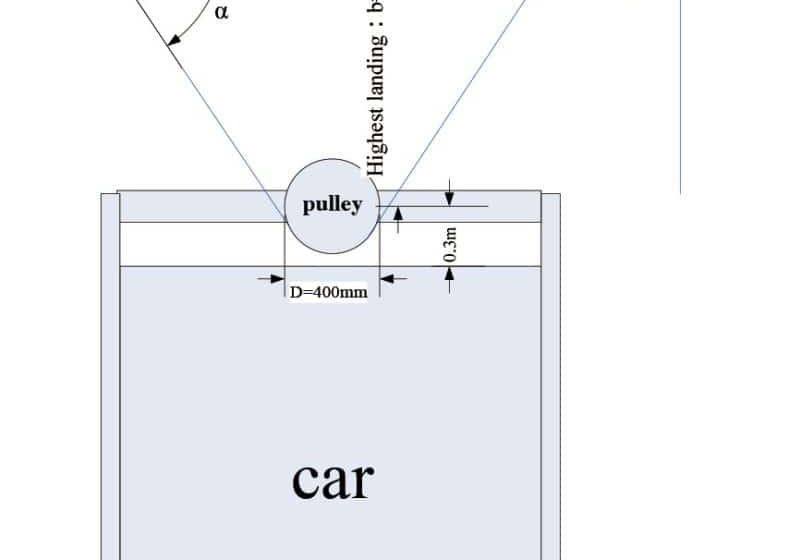

- Sprinklers are prohibited in machine rooms, elevator machinery spaces, control rooms, control spaces and hoistways.

- Shunt tripping prohibited. Means for elevator shutdown (also referred to as shunt trips) are not installed if OEEs are specified.

- Hoistway protection from water released by sprinklers is required. Water will be directed to drains, or other approved means, to protect the hoistway from all sides.

Hoistway Enclosure Protection

- In accordance with Section 713 of the IBC, a fire resistance rating of not less than 2 hr. must be provided when connecting four stories or more.

- In accordance with Section 403.2.3 of the IBC, structural integrity is dictated by building height. For buildings taller than 420 ft. (128,000 mm), Soft Body Impact Classification Level 2 must be achieved or exceeded.

While the voluntary incorporation of OEEs provides new tools for the architect or design professional to consider when planning buildings, under no condition is the installation of such elevators compulsory.

Elevator Lobbies

- The lobby must be enclosed at each floor, with the exception of the elevator discharge level, and must have a smoke barrier with a fire-resistance rating of not less than 1 hr. Lobby doorways are provided with a 3/4-hr. fire-door assembly that complies with Section 716.5 of the IBC.

- The fire-door assembly complies with the smoke and draft control assembly requirements of Section 716.5.3.1 of the IBC, with a UL 1784 test conducted without an artificial bottom seal.

- A vision panel is installed in each fire door assembly protecting the lobby doorway. The vision panel shall consist of fire-protection-rated glazing and must be located so it permits a clear view of the lobby.

- Each fire-door assembly protecting the lobby doorway is required to automatically close when it receives any fire-alarm signal from the emergency voice/alarm communication system serving the building.

- Door assemblies for hoistways, elevator machine rooms, machinery spaces, control rooms and control spaces within the lobby shall comply with 1-1/2 UL “B” label or building codes.

- Direct access from each elevator lobby to an interior exit stairway must be provided. The exit stairway enclosure is designed with a second door at each floor, allowing access to the floor without requiring travel through the elevator lobby.

- Interior exit stairway doors automatically unlock, allowing both exit and re-entry upon any alarm, in accordance with the options permitted by the building code.

- Lobbies and hoistways are jointly pressurized. Any adjacent exit stair enclosure is pressurized separately.

- Minimum size/floor area. The lobby is designed to accommodate 3 sq. ft. (0.28m²) per person at not less than 25% of the occupant load of the floor area served by the lobby, plus one wheelchair space of 30 X 48 in. (760 X 1220 mm) for each group of 50 people. The size of lobbies serving multiple banks of elevators has the minimum floor area approved on an individual basis, and must be consistent with the building’s fire-safety and evacuation plan.

- Signage. An approved sign indicating elevators are suitable for occupant self evacuation must be posted on all floors adjacent to each elevator call station serving an OEE.

- A two-way communication system is provided for the purpose of initiating communication with the fire command center at an alternative location approved by the fire department.

- Notification appliances. No less than one audible and one visible notification appliance meeting the requirements of NFPA standard 72 must be installed in the lobby and connected to the emergency voice/alarm communication system.

Elevator System Monitoring

- The elevator system is to be continuously monitored at a fire command center or central control point approved by the fire department.

- The system should display all information for each elevator car, including: floor location, direction of travel, and occupied/empty status and for each elevator group. This includes the status of normal power to the elevator equipment, elevator machinery and electrical-panel cooling equipment, elevator machine room, control room and control-space ventilation and cooling equipment.

- Displays the activation of any fire-alarm initiating device in any elevator lobby, machine room, machine space containing a motor controller or electric driving machine, control space, control room or hoistway

- Means to manually initiate FEO are included in the fire command center or at an alternate location approved by the fire department.

- An emergency voice/alarm communication system, designed and installed in accordance with NFPA standard 72, is provided to inform occupants on each floor of the current situation and the action to take during an emergency. Announcements include information about whether elevators are available or unavailable for use. The system, triggered by the operation of any automatic fire detector, sprinkler waterflow device or manual fire alarm box, will automatically sound an alert tone followed by voice instructions. It will provide approved information and directions for a general or staged evacuation in accordance with the fire safety and evacuation plan. The system must be accessible to the fire department.

Electrical Power

The following is required:

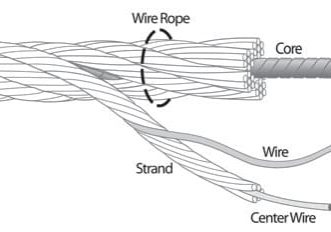

- Normal power and minimum Type 60, Class 2, Level 1 standby power sufficient to operate all elevators and associated systems simultaneously

- Emergency power for lighting, signals, signs and communication

- Power supply for elevator equipment and signage, ventilation and cooling equipment for elevator machine rooms, control rooms, machinery spaces and control spaces and elevator car lighting

- Power supply for variable message sign, voice notification, fire alarm, two-way communication and pressurization systems

- Power supply for hoistway and pit lighting, machine-room lighting, lobby lighting, sump pumps (if provided) and any associated systems.

- A system to separate and protect both standard and backup power feeders. Each should be contained in its own 2-hr., fire-resistance-rated enclosure.

- A system to protect wires or cables located outside of the hoistway, machine room, control room and control space that provides power to control signals, car communication, lighting, heating, air-conditioning, ventilation and fire detection. Its circuit-integrity cables must have a fire-resistance rating of not less than 2 hr. or be protected by a listed electrical-circuit protective system with a fire-resistance rating of not less than 2 hr.

Hazardous-Material Areas

Hazardous materials for cleaning or maintenance exceeding the maximum allowable quantities per control area, as addressed in Section 414.2 of the IBC, are not permitted in any building areas.

OEO Elevator Code Requirements

OEO is designed to function only prior to FEO. Modifications required to standard Phase I Emergency Recall Operation when using OEO include:

- The three-position switch in the lobby at the designated level and two-position switch at the fire command center be labeled “Group Fire Recall.”

- That an additional three-position, key-operated, individual “Car Fire Recall” switch assigned to each elevator be located in the lobby at the designated level adjacent to the elevator it controls. Each switch must be labeled “Car ___ Fire Recall,” with the individual car’s alphabetical or numerical identification inserted. Each switch controls the associated elevator but does not control other elevators controlled by the “Group Fire Recall” switch.

- That each individual “Car Fire Recall” switch be provided with an illuminated visual signal to indicate that Phase I Emergency Recall Operation is in effect for that car.

To remove an individual elevator from Phase I Emergency Recall Operation, the individual “Car Fire Recall” switch must be properly rotated to the off position. Additionally, the two “Group Fire Recall” switches must be in the off position. No fire-alarm initiating device must be activated. Additional points to remember include:

- A car with its individual “Car Fire Recall” switch in the on position cannot be removed from Phase I Emergency Recall Operation when the “Group Fire Recall” switch is rotated to the off position.

- A sign reading, “In case of fire, elevators are out of service” is not allowed. A variable message sign, as defined in ANSI/ICC A117.1, will be installed for each elevator group on each landing served. It should be located in a centrally visible location within the elevator lobby.

When hoistway pressurization is provided, a car on Phase I Emergency Recall must conform to the following, additional requirements:

- Car door should close after 15 s.

- Door reopening devices, door force limiting devices and the door-open button should remain active.

- The action of a normally used operating device to call the elevator at the discharge level should cause recalled cars to open their doors for 30-45 s., then reclose.

- Position indicators should be installed at the discharge level above or adjacent to the entrance of each car.

Fire Alarm System Interface

- Upon activation of an automatic fire-alarm initiating device outside the FEO recall area, the fire-alarm system provides signals to the elevator system indicating the floors to be evacuated. Evacuation will include the floor with the active alarm plus two floors above and two floors below, for a block of five floors.

- Upon receipt of the signals, the elevator system will initiate OEO mode. If additional floors are activated, the evacuation zone is expanded in the same manner. If activation occurs at the elevator discharge level, OEO is not initiated.

- Manual initiation of OEO is permitted by authorized or emergency personnel. Additionally, the fire command center can manually select an “elevator total building evacuation” that will provide a signal to the elevator system and initiate OEO for an “elevator total building evacuation” mode.

The system, triggered by the operation of any automatic fire detector, sprinkler waterflow device or manual fire-alarm box, will automatically sound an alert tone followed by voice instructions.

Occupant Evacuation Operation

Upon receiving a signal from the fire-alarm system:

- Landing calls outside evacuation floors are canceled and disabled.

- Security systems are made ineffective.

- Landing calls within the affected evacuation zone will call an elevator. When the call is answered, the elevator system will automatically register a call to the elevator discharge level.

- Floors with active alarms are given higher priority than floors above or below.

- Car calls are disabled, except for at the discharge level.

- Unoccupied cars move to the incident floor and park with doors closed until the landing call is registered.

- Occupied cars proceed to the discharge level, then move to the incident floor.

- New calls will not prevent a car loaded at 80% capacity from leaving.

After evacuation of the affected floor(s) is completed:

- After a 60-s. interval with no landing calls, one car will park with its doors closed at the lowest floor of the incident zone to answer possible calls. The remaining OEE proceeds to the discharge level and parks with doors closed ready to replace the one car, if moving from incident zone.

- OEO is terminated when the fire-alarm system is reset or a dedicated elevator system fire-alarm initiating device, manual or detected, is actuated.

During OEO to FEO recall:

- A car fire recall turned to the on position terminates OEO on that car only, and FEO is initiated on that car only.

- A group fire recall turned to the on position terminates OEO on all cars in the group, and FEO is initiated on all cars in the group.

Lobby variable message signs should:

- In the evacuation zone, indicate that elevators are available for evacuation and the estimated time (in minutes) for the next elevator to arrive. Sample text: “Elevators and stairs available for evacuation. Next car will arrive in about 2 min.”

- On all floors not being evacuated, indicate that service is not available. Sample text: “Elevators temporarily dedicated to other floors.”

- On the elevator discharge level, indicate that the cars are in evacuation mode and that passengers should not use elevators. Sample text: “Elevators dedicated to evacuation. Do not enter elevator.”

- If no elevators are available, indicate that elevator service is not available. On all floors being evacuated, also indicate that occupants must use stairs. Sample text for floors being evacuated: “Elevators out of service. Use stairs to evacuate.” Sample text for other floors: “Elevators out of service.”

Car visual signal or variable message sign and voice notification guidelines:

- Each car must indicate that it is being used to evacuate the building.

- If a car stops to pick up passengers at a floor other than the elevator discharge level, signals must instruct the passenger to remain in the car.

- Prior to arrival at discharge level, passengers are notified they have arrived at the exit floor and that they must exit quickly.

Conclusion

The evolution of building technology has afforded the public taller and grander buildings. With complex developments in the industry, it has become obvious to design professionals and emergency responders that using stairs as the only means of egress during emergencies is neither practical nor safe, particularly when partial or total building evacuations are necessary. Responders must have safe, reliable and unobstructed access to upper floors when handling emergency situations. Concurrently, building occupants and visitors must egress evacuation zones safely, orderly and rapidly.

The OEE system is the first vertical-transportation technology that combines OEO and FEO to accomplish the simultaneous critical missions of containment and prevention of further damage to structures, while offering safe, rapid clearing of evacuation zones by the public. With the continuous information provided by lobby variable-message signs, car variable-message signs and voice notification, the OEE system has become an interactive mechanism assisting building occupants and visitors in their decisionmaking process during emergency conditions.

Additional requirements for OEE systems in the building and fire codes contribute greatly to the safety of the public by eliminating conditions that could adversely affect the operation of the elevators — in particular, the automatic sprinkler system, hoistway-enclosure protection, elevator lobby design, elevator system monitoring, electrical power protection and limitations on hazardous material.

It is the author’s opinion that OEE system requirements represent the future of elevator design. Your author envisions an imminent time when all buildings defined as “high rise” are designed in compliance with the OEE system, a time when elevator notifications are sent to occupants’ cell phones so they are informed of both normal traffic patterns and emergency situations. Elevators interacting with the public — what’s wrong with that?

This article will be part of an online series of continuing education code updates.

Get more of Elevator World. Sign up for our free e-newsletter.