If your vintage escalator’s parts are unavailable, there is still a way to get replacements.

ES Escalator & Elevator Parts Co., Ltd., founded in 2013, focuses on the supply of escalator and elevator parts, and can recreate old parts that have already gone out of production. Escalators are used heavily in metro systems of different cities. Some types of these escalators are not produced anymore by the manufacturer because they are very old (30 years or more) and the manufacturer has been acquired by other elevator-manufacturing companies. The maintainer of escalators in metro systems often finds difficulty in finding or maintaining a supply of old parts. One option for the metro station is to replace its escalators, but this can bring high cost and lengthy installation periods that can cause delays for riders or even a temporary shutdown of the station. An alternative, which metros often choose, is to refurbish the escalator through the replacement of the main parts, the steps and step chains. This is usually the more economical way to return the escalator to service.

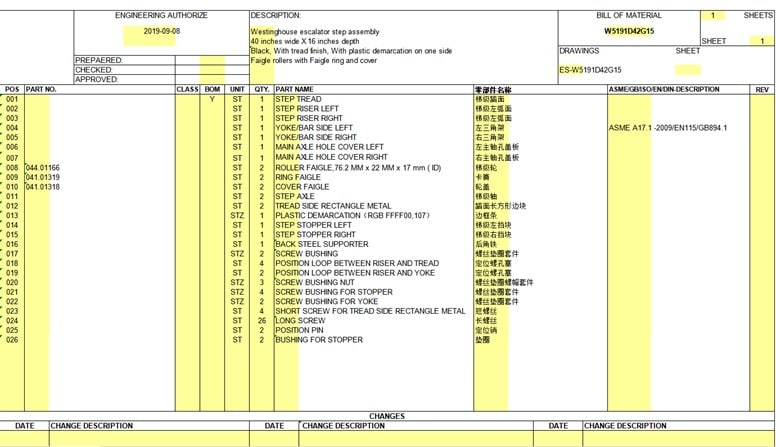

In fact, the recreation of old steps has become very important. Following, we present how to recreate an old-type step for a Westinghouse Modular 100 escalator. As we all know, Westinghouse sold its elevator/escalator business and doesn’t produce its old escalators anymore. If your MOD 100 steps need replacement/repair, following is a description of the process.

Analysis

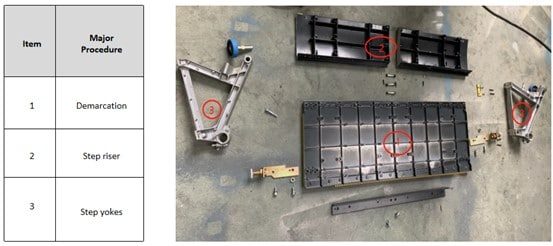

First, the client provides a real step sample, as pictured here.

Next, the sample parts are surveyed by use of a 3D scanner.

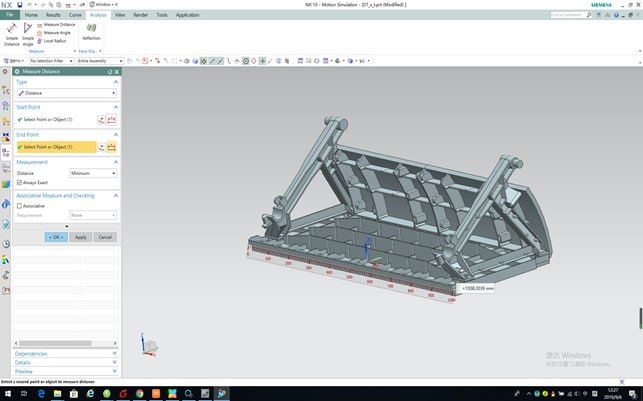

The image can now be manipulated in a computer.

The data is ready for its initial die-casting proposal.

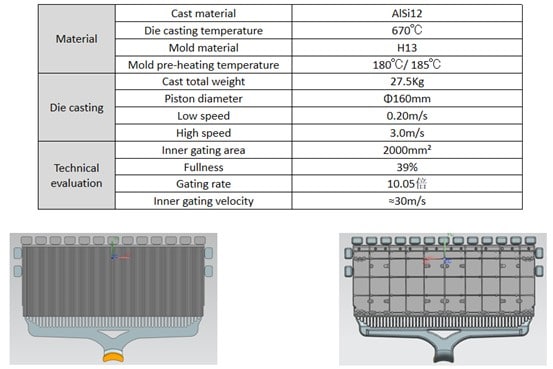

Next comes a mold-flow analysis.

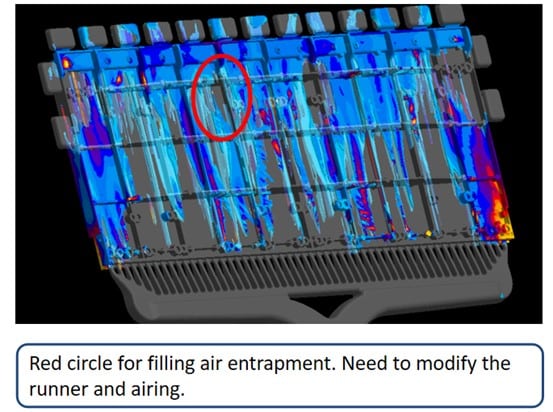

Then, the filling process and air-entrapment analyses.

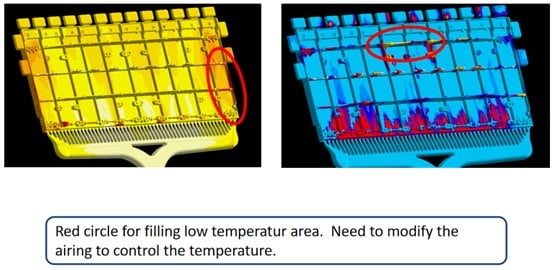

Followed by a temperature trace.

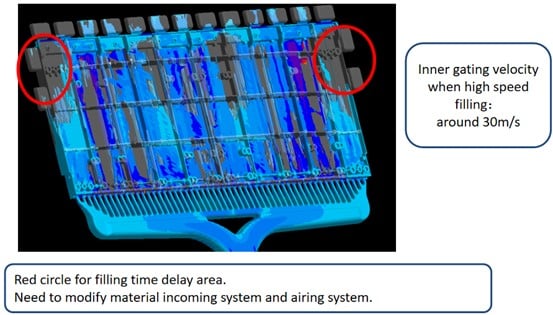

Then, the velocity analysis.

Conclusions

The computer-aided engineering (CAE) analyses above are based on the design of the runner and slag discharge gate of version A-0, which has obviously found problems of filling temperature and velocity, as well as the appearance of air entrapment.

Solutions

- Revise the dimensions of material inlet; increase slag discharge gates

- Improve mold temperature-control system for low-temperature area

- Modify the dimensions of the inner gate to increase the passing velocity of melting liquid aluminum

Manufacturing

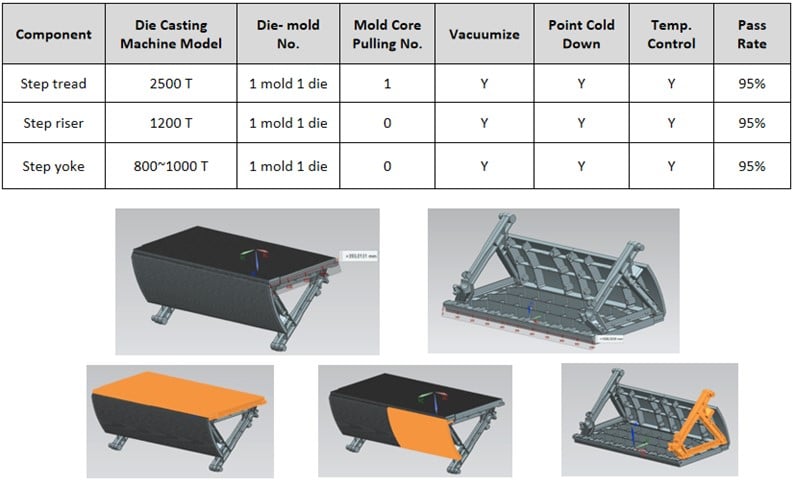

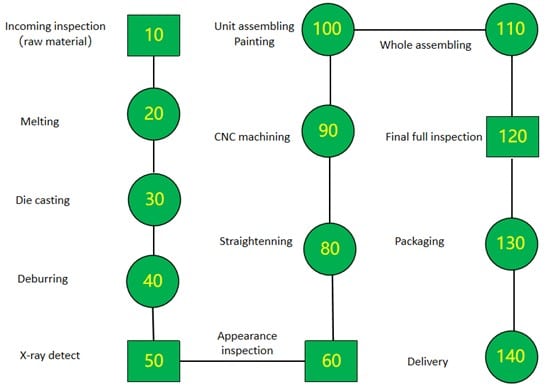

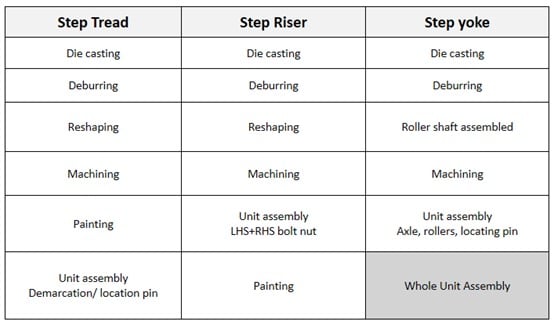

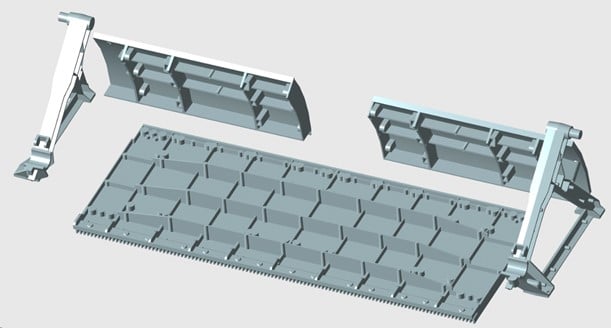

Now, we will discuss the manufacturing process.

Note: In the lab, the assembled final product is tested for compliance with ASME A17.1-2009, Sec 6.1.3.5, Sec 6.1.3.9.4, Sec 6.1.3.10.4, as prescribed by the testing procedure Sec 8.3.11. These tests must be in compliance with EN 115 Section 8.2.2.1.1, and must comply with APTA RT-RP-FS-007-02-Sec 2.04B for heavy-duty escalators.

The first article inspection involves delivery of step samples from the first trial production to the client for first inspection. If approved, bulk production proceeds.

Finally, the approved production parts are packaged and shipped to the client.

Billy Rong, general manager of ES Escalator & Elevator Parts Co., Ltd., is highly experenced in production, design and technical sales of elevators and parts.

Get more of Elevator World. Sign up for our free e-newsletter.