On-Site Revision For Escalators and Moving Walkways

Sep 23, 2023

by Battal Murat Öztürk

Abstract

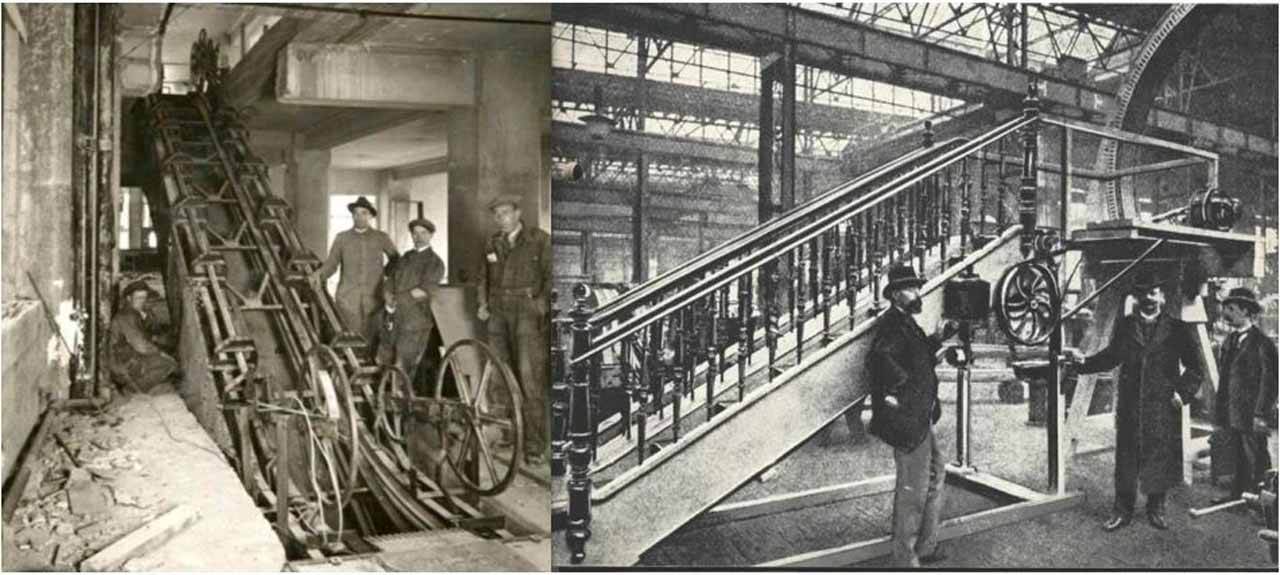

Escalators and moving walkways, which are the most widely used equipment in today’s indoor transportation, have started to age, deform and are no longer able to meet the requirements of our time. Additionally, escalators and moving walkways cannot be dismantled due to the structure of the buildings and are being modernized in their original locations to keep up with the times. The article will discuss this issue.

1. Introduction

In high-traffic buildings, underpasses, overpasses and short distances where elevators cannot handle the traffic, escalators/moving walkways have become a necessity rather than a luxury. However, like any other equipment, escalators are also falling out of step with the requirements of the times. For this reason, improvement efforts are being made in the following areas, which are the requirements of the current age, with Schindler InTruss, i.e. on-site modernization:

- Replacing metal parts that have started to rot

- Compliance with current standards

- Modern appearance

- Energy saving

Today, there are about 50-60 different types of escalator production styles, making on-site modernization a really challenging process in this context. It requires good engineering and craftsmanship.

1.1. Replacement of Steel Components That Have Started To Rot

Steel components of escalators, which are exposed to all kinds of external factors, deteriorate over time and their physical structure changes due to corrosion. These changes must either be stopped or replaced before they cause accidents. These points can be one of the following:

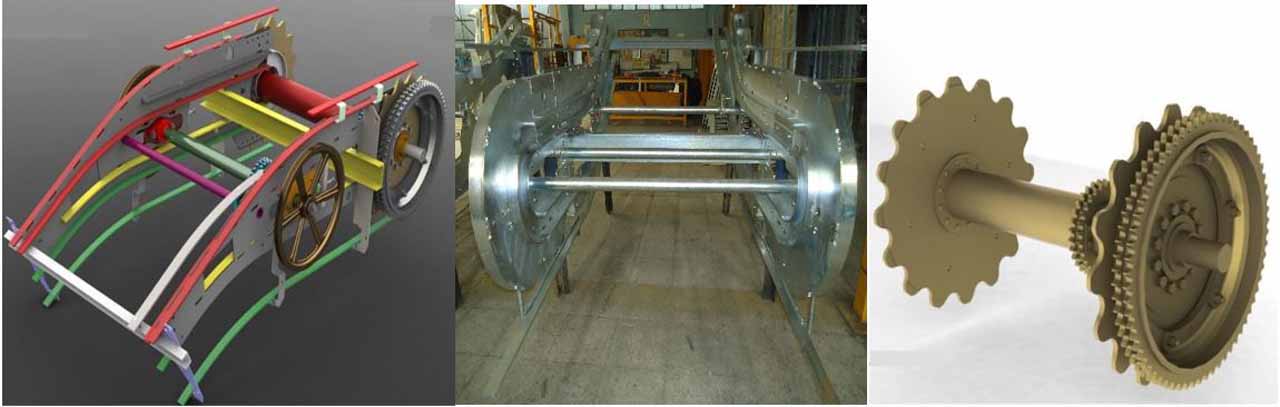

- Top and bottom drive system

- Control panel

- Step chains

- Roller guides

- Step guide rails

1.2. Compliance with Current Standards

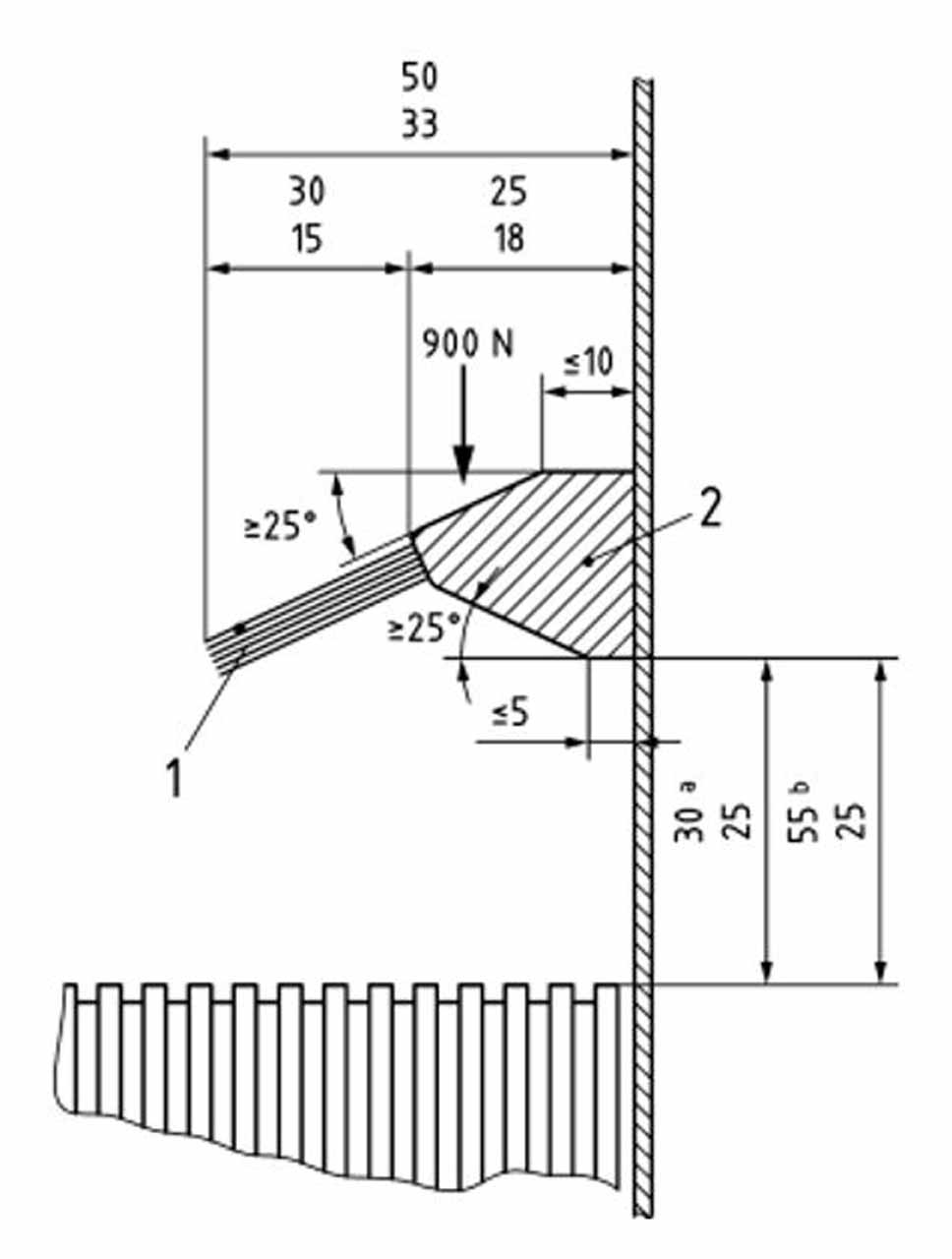

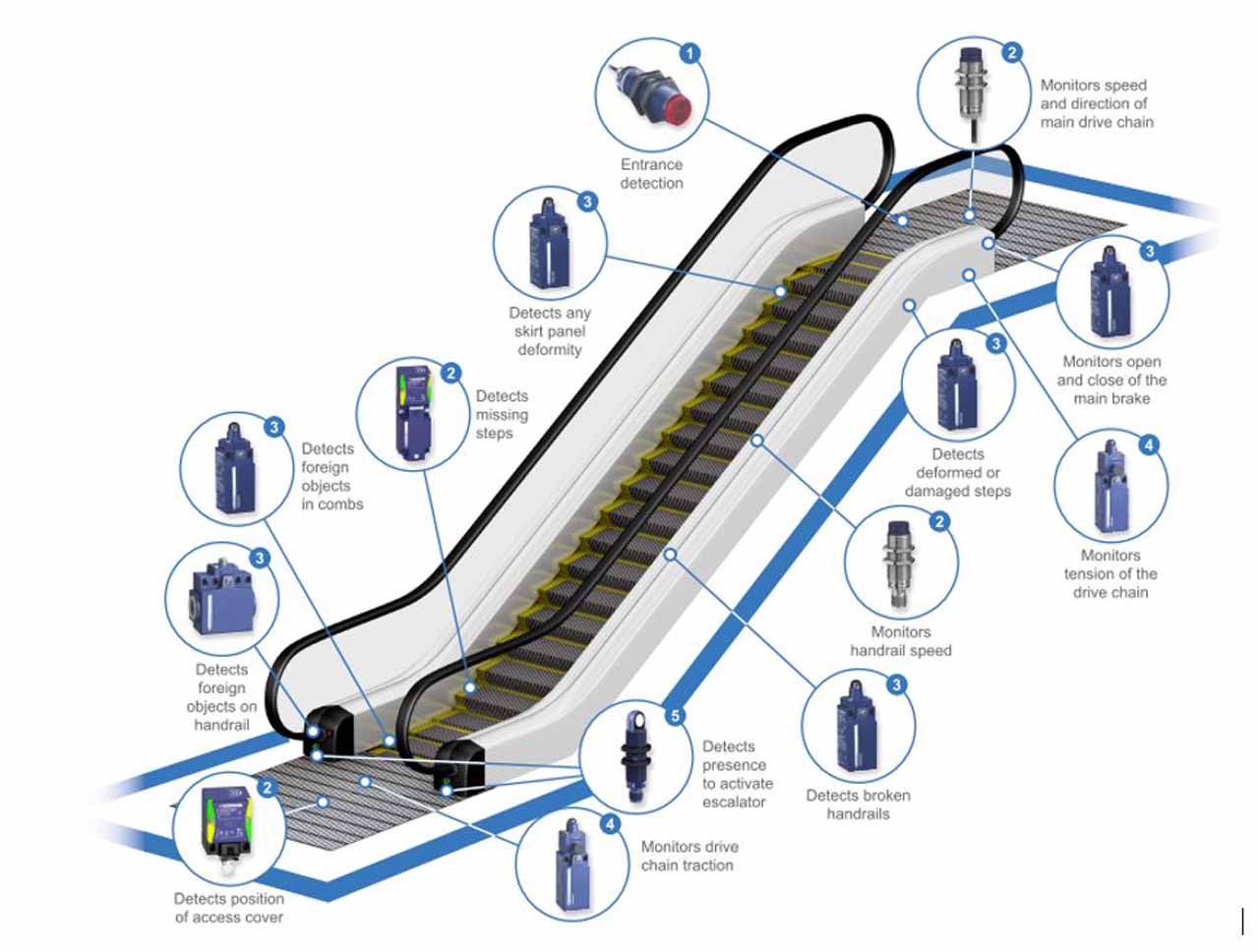

There are major differences between the current standard EN115-1:2017 and the original standard EN115:1995 in terms of safety components and safety gaps. The replacement of the control panel and safety sensors according to EN115-1:2017 (Table 8) will offer a safer operation for users. The risk of accidents has been reduced with the addition of mandatory components (such as skirt deflectors).

Table 8 — Events to be detected by safety devices

| # | Description | Reference | Means of Safety device | Failure lock | Enabled in inspection mode |

| A | Detection of over speed | 5.12.2.7.2 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 [SİL 2) | Yes | Yes |

| B | Detection of unintentional reversal of the direction of travel | 5.12,27.3 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | Yes | Yes |

| C | Detection of non-lifting of the auxiliary brake | 5.12.2.7.4 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | Yes | No |

| D | Detection of breakage or undue elongation of parts immediately driving the steps, or the handrail | 5.12.2.7.5 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | Yes | Yes |

| # | Description | Reference | Means of Safety device | Failure lock | Enabled in inspection mode |

| E | Detection of movement of tensioning device | 5.12.2.7.6 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | Yes | Yes |

| F | Detection of entrapment at comb | 5.12.2.7.7 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | No | Yes |

| G | Detection of the stopping of a succeeding escalator or moving walk or detection of structural measures blockin the exit of the escalator or moving walk | 5.12.2.7.8 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | No | No |

| H | Detection of entrapment at hand rail entry | 5.12.2.7.9 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | No | Yes |

| I | Detection of sagging step or pallet | 5.12.2.7.10 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | Yes | No |

| J | Detection of missing step or pallet | 5.12.2.7.11 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | Yes | No |

| K | Detection of non-lifting of the operational brake | 5.12.2.7.12 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | Yes | No |

| L | Detection of speed deviation of the hand rail | 5.12.2.7.13 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | No | No |

| M | Detection of opened inspection cover | 5.12.2.7.14 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | No | No |

| N | Detection of the ac tutation of the stop device for emergency situations | 5.12.2.7.15 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 1) | No | Yes |

| O | Detection of installed hand winding device | 5.12.2.7.16 | 5.12.2.6.1 or 5.12.2.6.2 or (SİL 1) | Yes | Yes |

| # | Description | Reference | Means of Safety device | Failure lock | Enabled in inspection mode |

| P | Detection of the maintenance and repair stop switch | 5.12.2.7.17 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | No | Yes |

| Q | Detection of the actuation of the stop device on the inspection control device | 5.12.2.7.18 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | No | Yes |

| R | Detection of the absence/presence of a removable barrier intended to prevent access of shoping trolleys and baggage carts | 5.12.2.7.19 | 5.12.2.6.1 veya 5.12.2.6.2 veya 5.12.2.6.3 (SİL 2) | No | No |

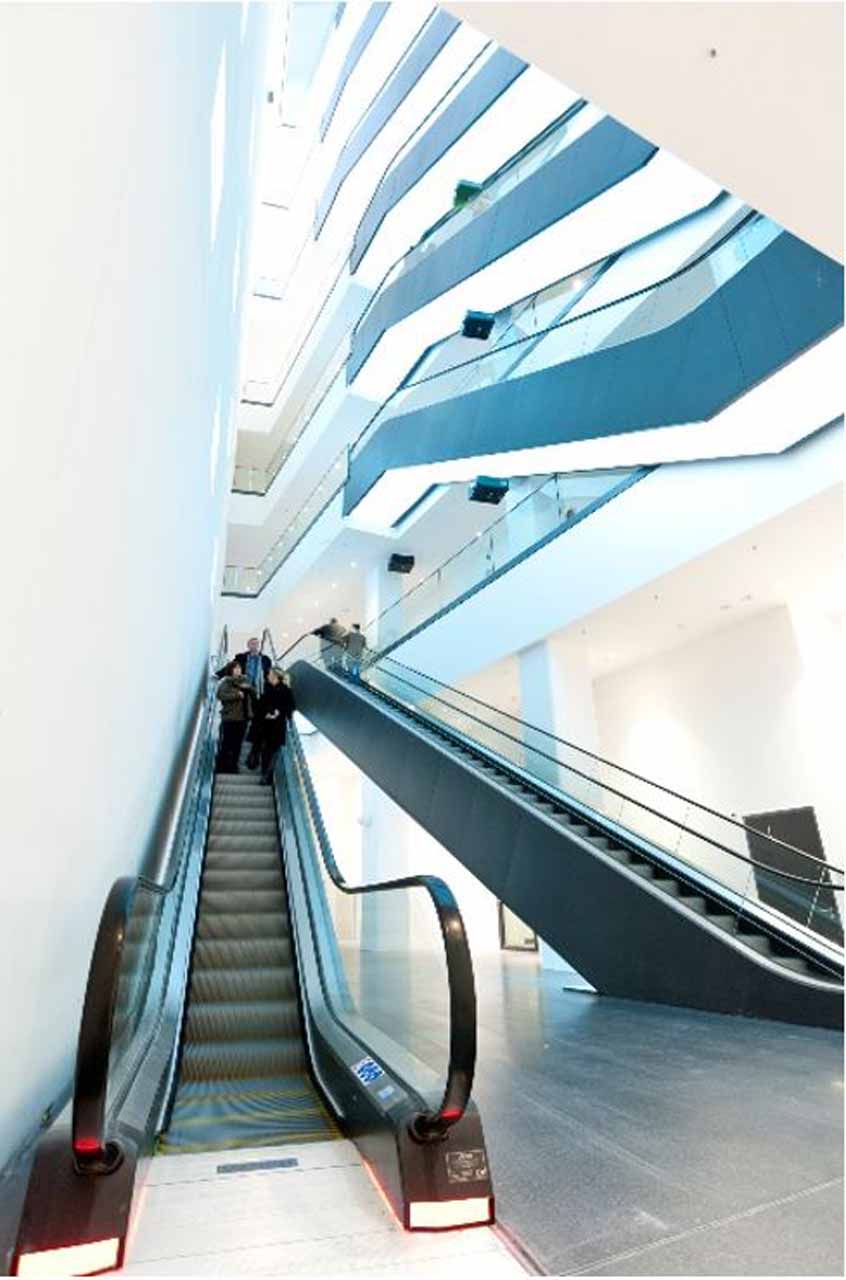

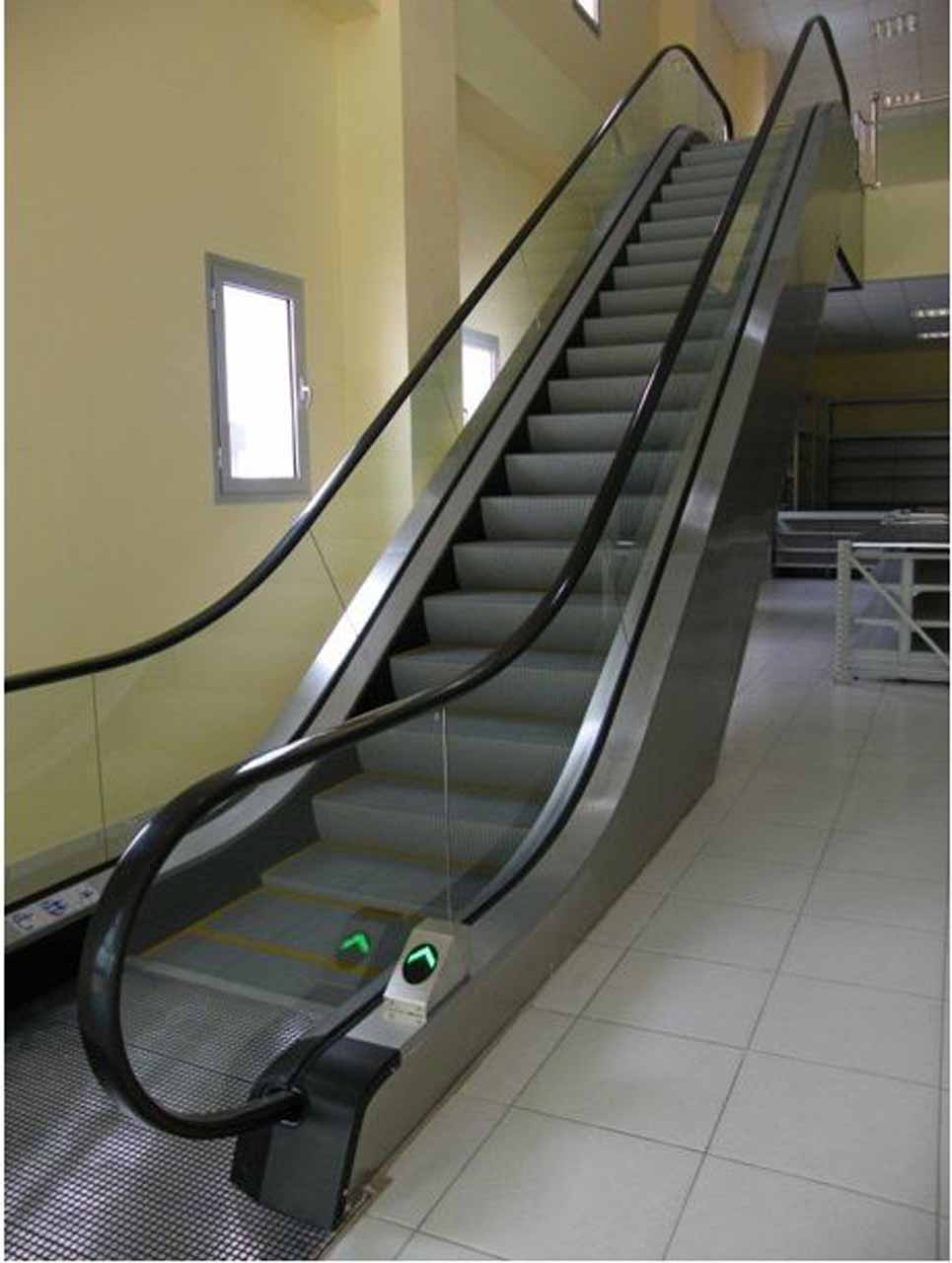

1.3. Modern Appearance

Escalators, a means of vertical transportation, have become more modern and practical by keeping up with the innovations of the age. They are sometimes used as an advertising tool.

1.4. Energy Saving

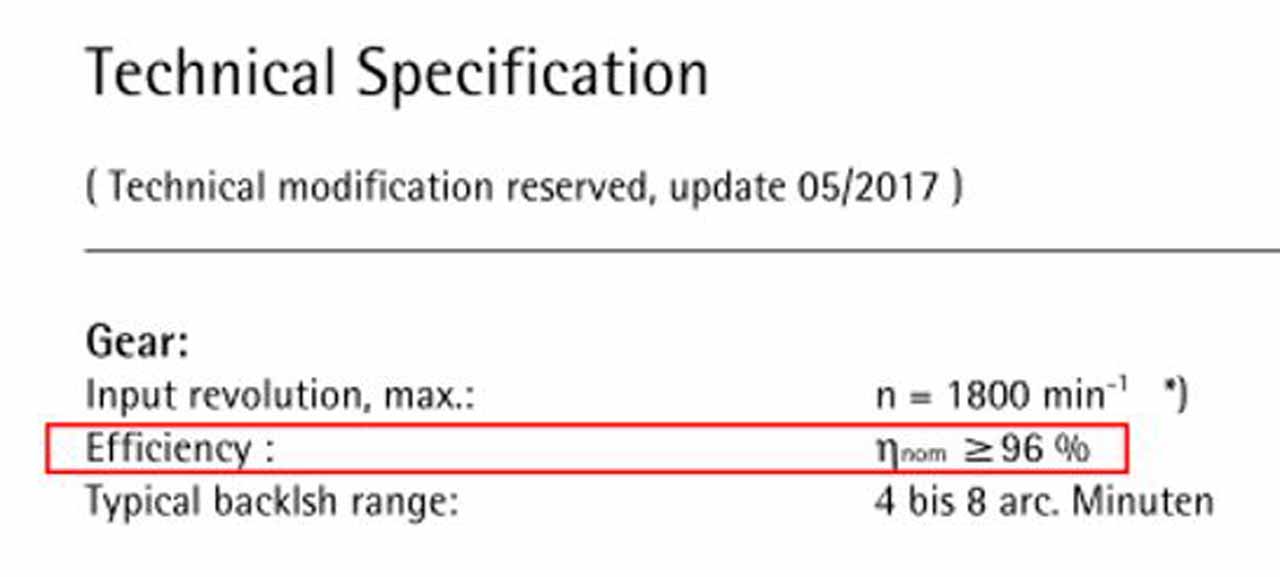

Considering how valuable and important energy is, escalators, which operate 24/7, are also included in this evaluation. The drive systems of escalators mostly work with asynchronous motors and gear reducers. Increasing the efficiency of these two components is the most important factor for energy savings in escalators. Today, with gear reducer efficiency reaching up to 96%, it is considered that gear loss can be minimized by using synchronous motors instead of asynchronous motors to increase motor efficiency.

Another element of energy saving is the lighting equipment used. Lighting and signaling energy savings of up to 80% can be achieved with LED technology.

Escalators can operate more efficiently with modifications made to the control systems. Various operating scenarios can be added such as operating the escalator up or down at certain times of the day or responding to a fire or earthquake. In an escalator operating 24/7, motion detection sensors can be used to stop the escalator when there are no passengers instead of continuous operation.

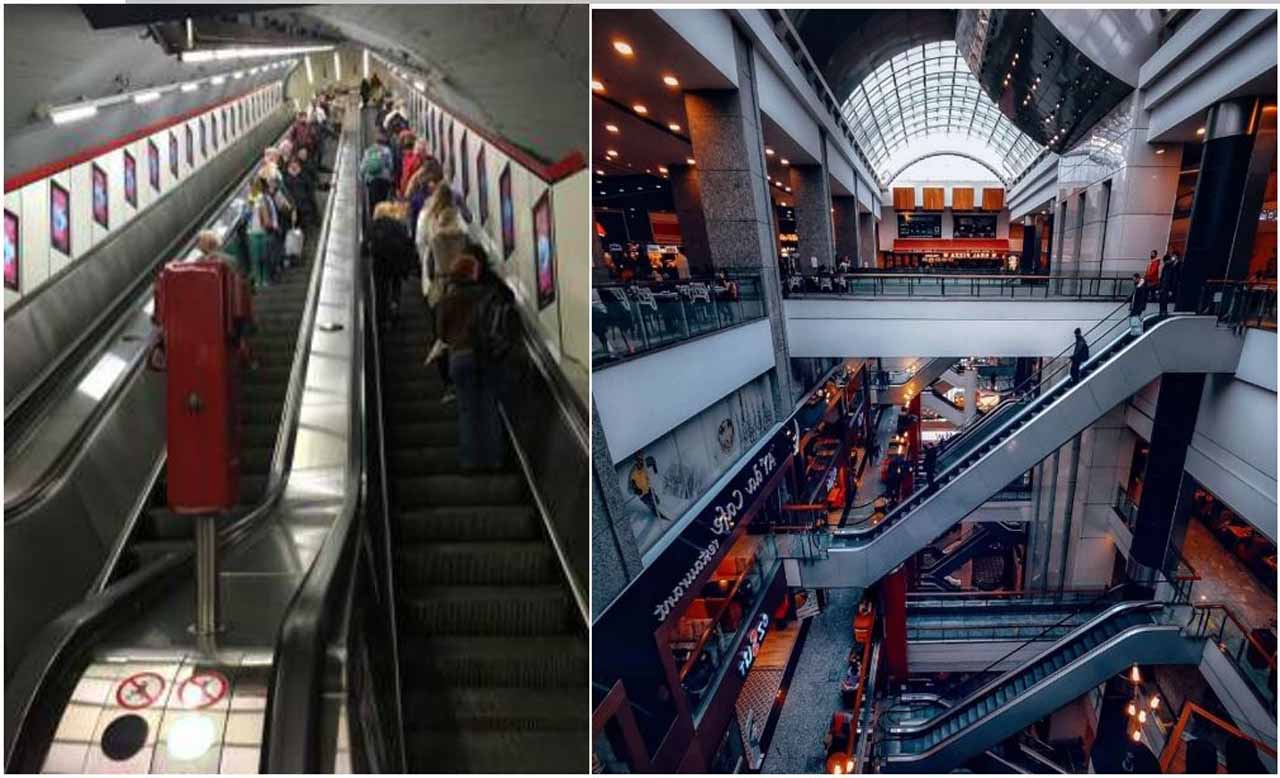

2. Reasons For On-Site Modernization

Why is on-site modernization more attractive, even if it is sometimes more expensive, than buying a new escalator?

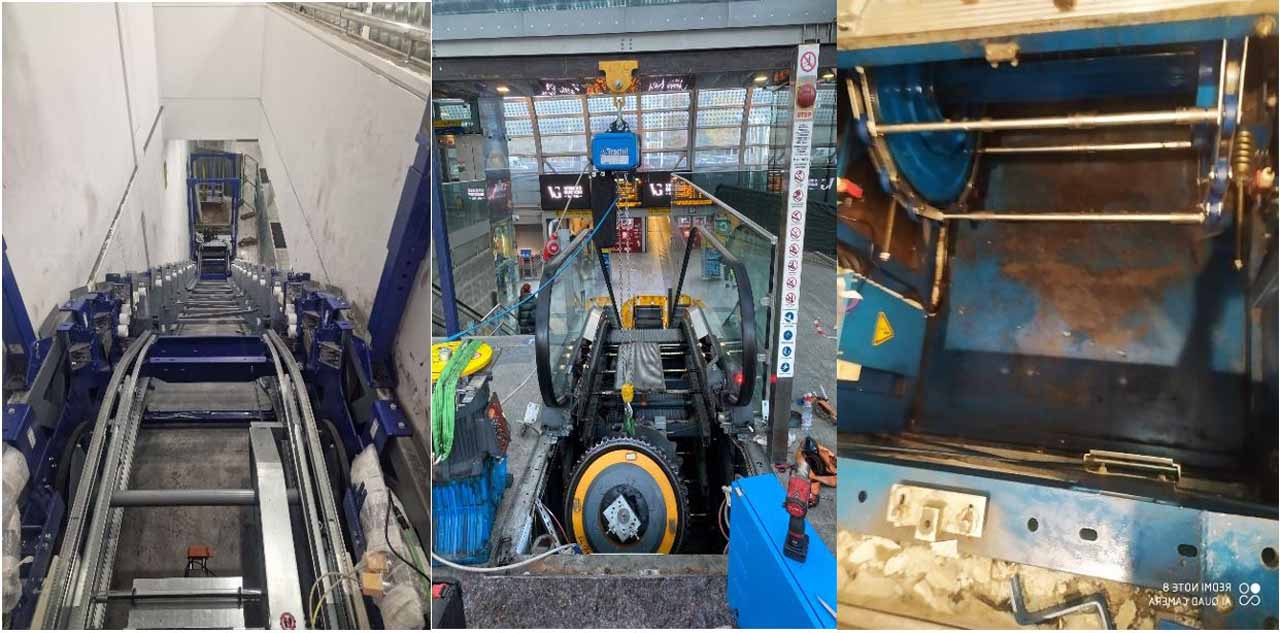

- In locations such as subway stations, shopping malls with narrow spaces, etc., it may sometimes be impossible to deliver and install a new escalator.

- It is a very difficult process to dismantle steel with asbestos, which was used as a good insulation material in the past and has become a carcinogenic substance over the years.

- Revisions are often economically compelling.

- Procurement processes are often shorter compared to a new escalator.

3. Stages Of Modernization

The stages of modernization are as follows.

- 1. Inspection

- a. Measurement

- b. Determining the preparations to be made before assembly

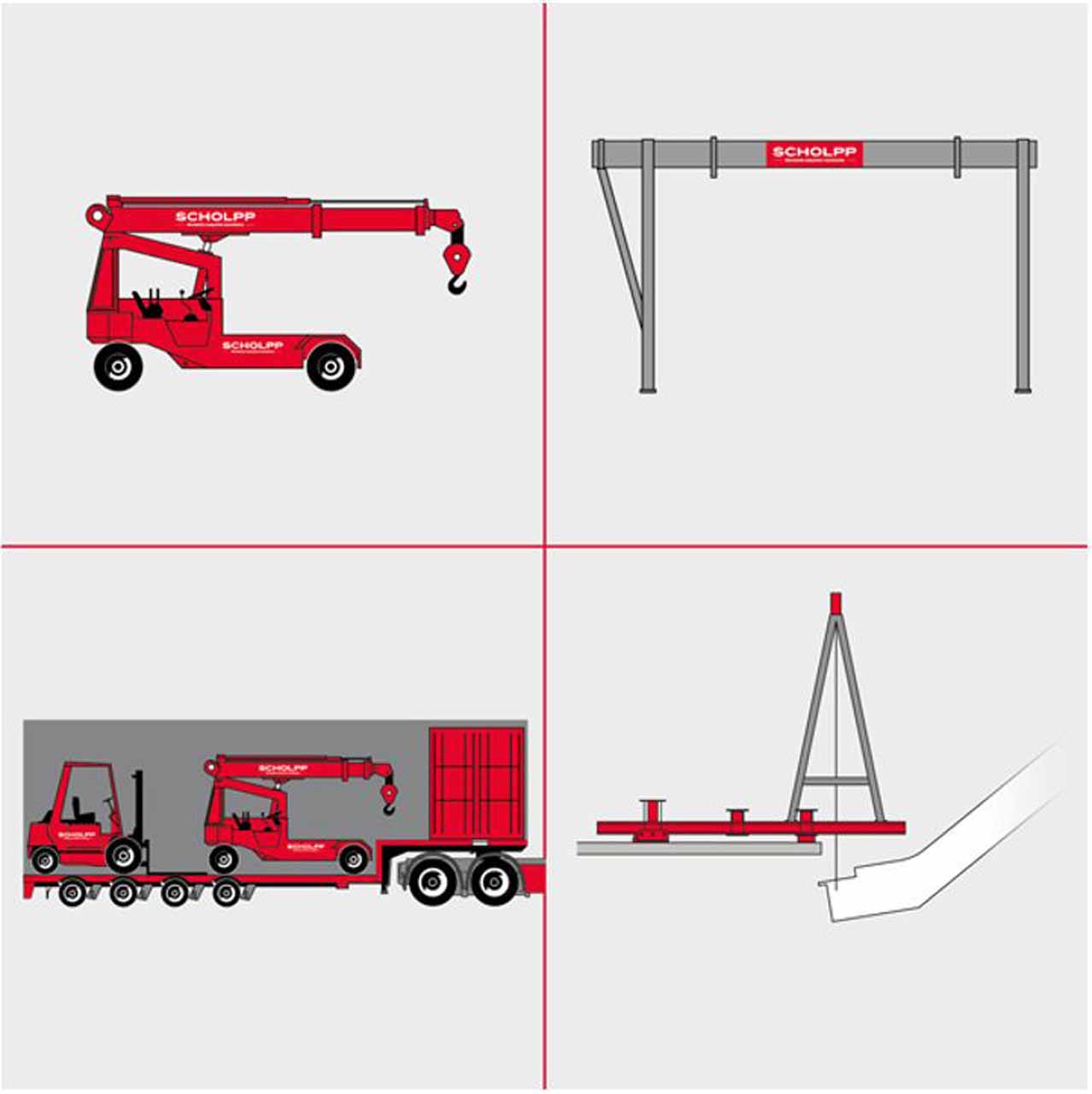

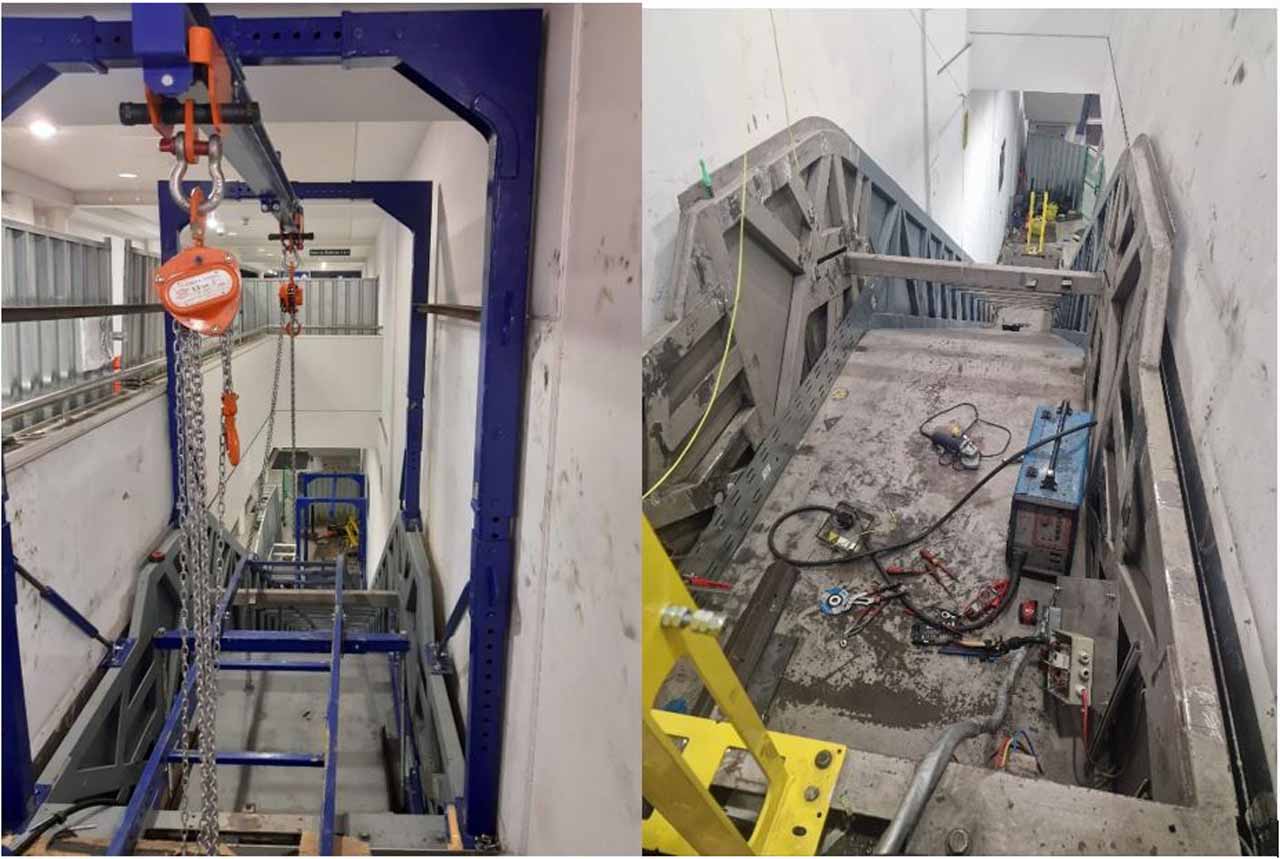

- c. Determining the necessary equipment during the disassembly and assembly period

- 2. Design

- 3. Disassembly-Assembly

3.1. Inspection

- a) First, the parts to be replaced/repaired are identified. Then, on-site measurements of the equipment to be replaced or repaired are collected and communicated to the design unit.

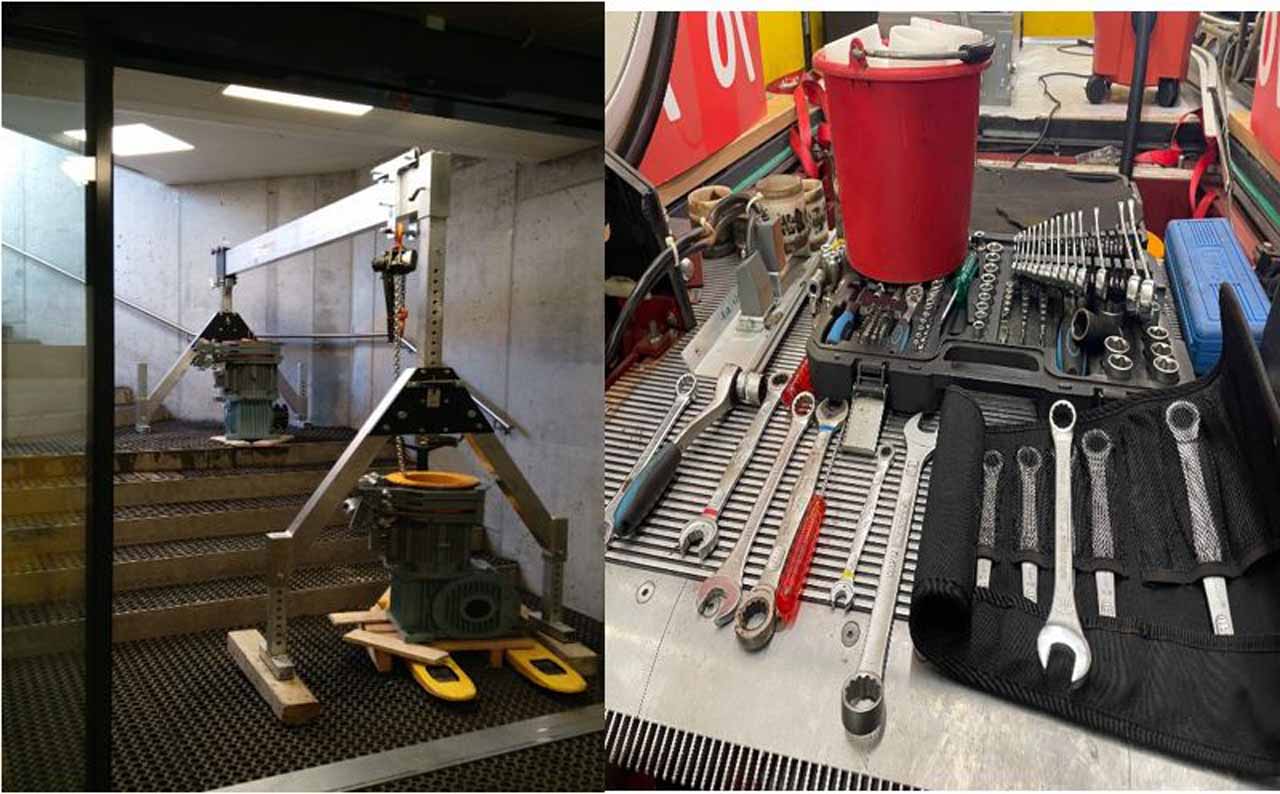

- b) In-building and equipment preparations are made for the delivery of the equipment to the site. c) The equipment to be used in the disassembly and assembly phase is determined (crane, crane suspension stands, pallet trucks, hand tools, etc.).

3.2. Design

The design unit designs and manufactures the necessary components depending on the parts to be replaced.

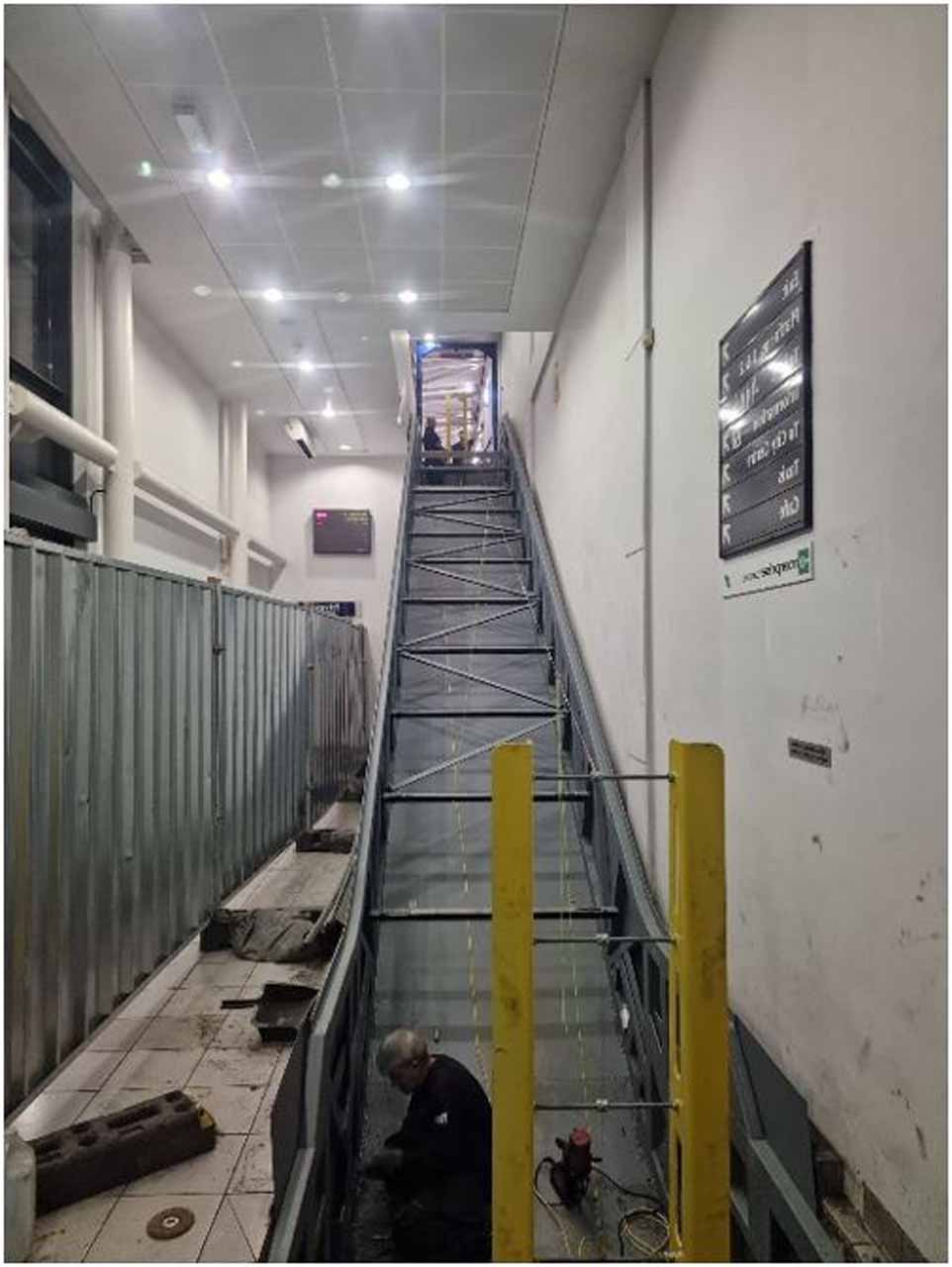

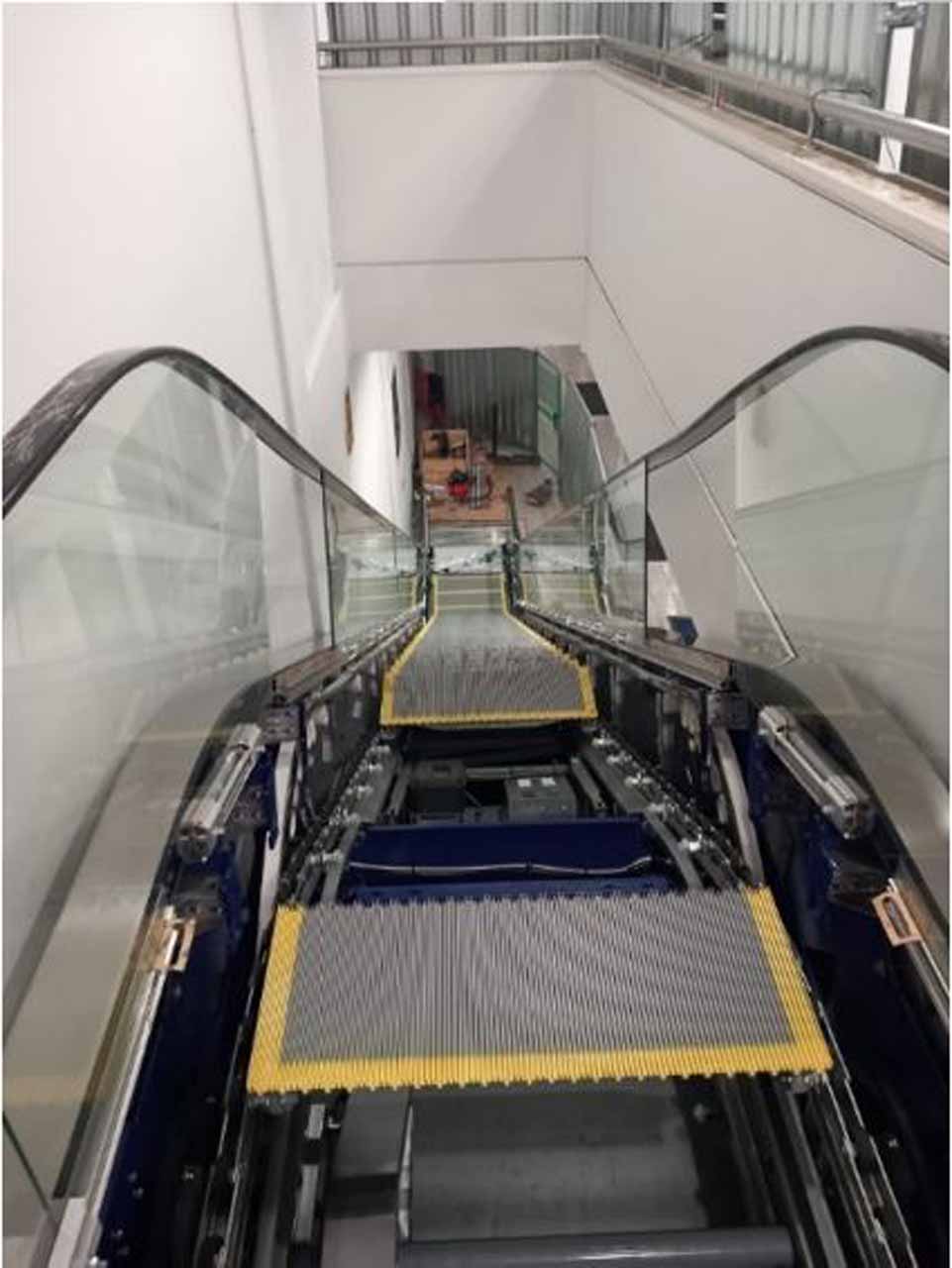

3.3. Disassembly – Assembly

All materials to be replaced are safely disassembled and removed from the site. Afterwards, all parts in the main steel body of the escalator below are serviced (cleaning, painting, etc.)

Then, the necessary preliminary preparation is made for the parts to be assembled. (The center of the escalator is determined with a line throw.)

Skirting brackets and glass brackets, if it has glass railings, are mounted on the escalator. The top and bottom station and the drive gear system are assembled. Steps, step-chain rails and rail brackets are assembled next. After that, the step chain is assembled.

Once these processes are completed, the plate of the new motor and the motor to be installed are assembled and the escalator is prepared for the first stroke with the mobile panel.

Control panel and safety sensors are installed.

The following components are then assembled respectively:

- Top and bottom comb plates

- Skirting boards

- Steps

- Glass and handrail railing

- Glasses

- Handrail

After all the assembly is completed, the escalator is ready for use. After this point, it is recommended to have the unit audited by an accredited independent organization.

Get more of Elevator World. Sign up for our free e-newsletter.