Why rigid universal maintenance practices would not only set the elevator industry back but could also put the riding public at unnecessary risk

by Amy Blankenbiller

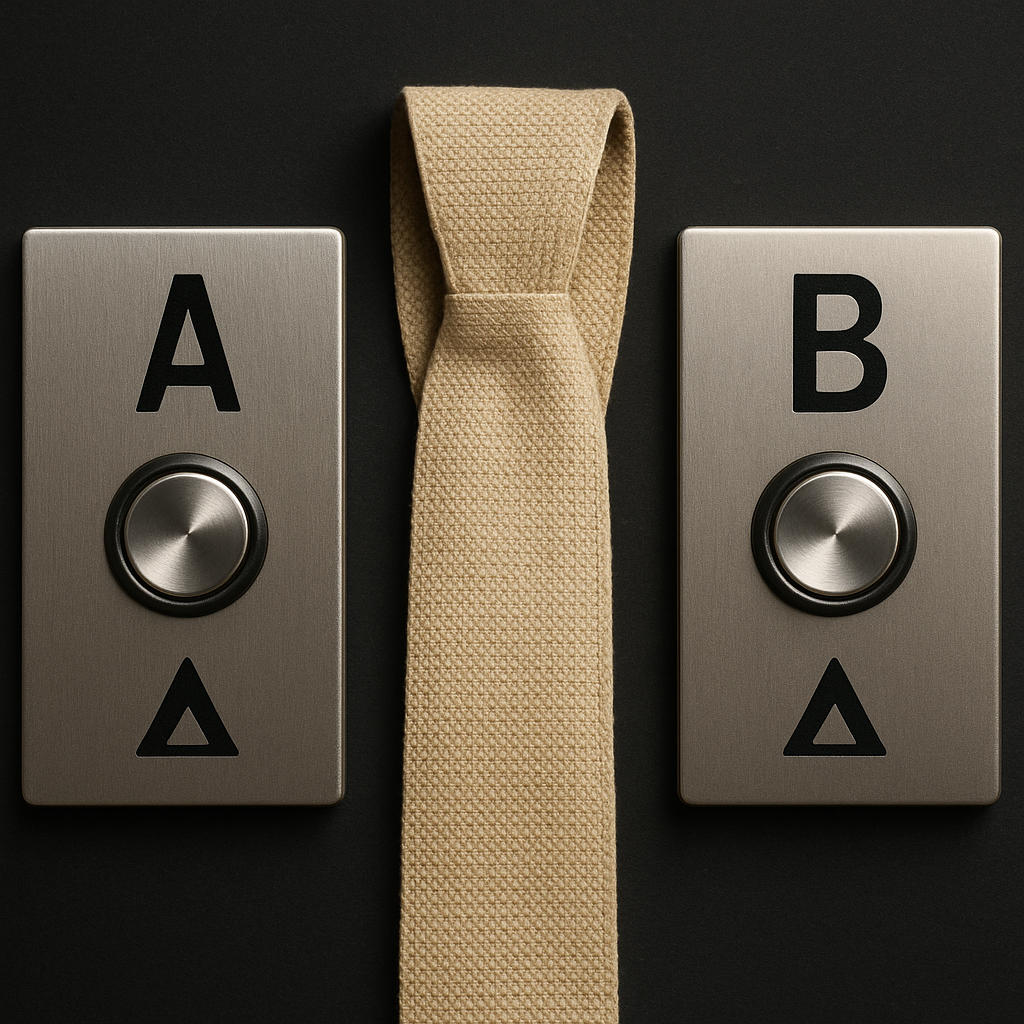

Have you ever found something in a catalogue labeled as “one size fits all” and against your better judgement, you order it only to find out that it is not even close to fitting when it arrives? That is because one cut of a garment cannot accommodate every size and type of body. I realize clothing and elevators are not comparable, but the analogy applies — there is no one size fits all when it comes to maintenance practices for elevator equipment.

Tech-Savvy

Today, we are living in the era of smart elevators where AI, machine learning and the Internet of Things (IoT) are helping to analyze data in real-time, predict maintenance needs, detect an issue before it occurs, adjust operation based on building traffic or even allow passengers to summon an elevator from a smartphone. Most of this technology was in its infancy 25 years ago and none of it existed 50 years ago. Not only has this revolutionized elevator movement, but elevator maintenance, as well. But what technological advancements are waiting in the wings to further enhance the safety and efficiency of an elevator system in the next 25 years?

Fifty years ago, elevators were far less sophisticated and technologically advanced. One example is the use of plugand- play circuit boards in elevators. Initially, point-to-point wiring was common, but printed circuit boards in plug-andplay designs became the standard due to their advantages in space, weight and durability. Surface mount technology enables even smaller plug-and-play circuit boards, streamlining installation, maintenance and troubleshooting. Another example would be elevator relay connections, which have evolved significantly since the days of manual elevators when operators were needed to guide the car and manually open and close doors. Manual elevators relied on levers and cranks for operation, but as elevators became more automated, components such as relay controllers helped control floor selection, door operation and car movement.

These technological advancements also helped contribute to the vertical construction boom. Hydraulic elevator systems were far more common 50 years ago than traction elevators, especially in low- to mid-rise buildings. But traction elevators got a huge lift in popularity in 2000 for a variety of reasons. They are faster and make high-rise building travel possible, allowing builders to create even more awe-inspiring skyscrapers. They are also more energy efficient, less space intensive and offer a smoother and more comfortable ride compared to hydraulic elevators.

While each elevator system serves the same purpose — to safely transport people from point A to point B — they are not the same elevator system and should not be treated in the same manner. Like equipment, maintenance practices must evolve and grow and cannot be approached with a one-size-fits-all approach, even if every elevator system ultimately serves the same purpose.

A Not So Simple Plan

Yes, there are general rules within a proactive maintenance plan that elevator technicians follow when maintaining or servicing an elevator. It starts with everyone (building owner, property manager, elevator service company) having the same three priorities for the elevator system: safety, reliability and longevity. Proactive maintenance steps that can help ensure all three priorities are met include monthly, quarterly or annual inspections by qualified service technicians.

Meanwhile, preventative maintenance best practices can include lubrication to ensure components are properly lubricated to reduce friction and wear; cleaning and disinfecting elevator buttons and frequently touched surfaces; and testing of various components such as motors, gears, cables, pulleys, guide rails and control panels. A regular test of all emergency systems should also be conducted, as well as spot checks between scheduled inspections to detect potential issues early.

But, not all elevator systems and buildings are equal. Each has its own unique footprint, and ASME A17.1/CSA B44 (A17) recognizes this fact. Rather than providing a one-size-fits-all approach, A17 Requirement 8.6.1.2.1(e) provides criteria for determining the appropriate maintenance interval, including the age, condition and wear on the equipment, design, usage, environmental conditions, technology and manufacturers’ recommendations based on any third-party certifications.

Put simply, different buildings have different usage patterns. A low-rise office building is going to have different needs than a mid-rise hospital, and the mid-rise hospital is going to have different needs than a high-rise residential building. The age of the elevator system, as well as the technology used, are also key factors as older elevators, and older technologies, typically require more maintenance. Would it make sense to develop the same maintenance plan for a traction elevator system installed last year in a mixed-use high-rise building as a hydraulic elevator system installed 25 years ago in a low-rise industrial building? Of course not.

Similarly, not all maintenance routes are the same. Routes are developed based on a number of factors — geographical density of units in an area, equipment mix, maintenance contract obligations, skill sets of mechanics, etc. There are other considerations to take into account, as well. For example, will the route mechanic be responsible for all maintenance and callbacks, or will there be a callback specialist handling callbacks and the route mechanic focuses on performing maintenance? There are many route optimization tools companies use to construct their routes based on these and other factors.

The elevator industry is constantly innovating and looking for ways to better support passengers, as well as those tasked with keeping those passengers safely moving. But to do that, there must be customized maintenance packages rather than one universal maintenance best practices approach. Code officials, lawmakers, building owners and managers are counting on the elevator industry to create maintenance best practices that can be tailored to meet the specific needs of their respective communities and properties. And in the case of elevators, there is no one-size-fits-all approach that will give them that peace of mind that they seek and deserve. To learn more, go to neii.org.

Get more of Elevator World. Sign up for our free e-newsletter.