Optimizing Maintenance and Repair Cost Reduction

Nov 1, 2012

Adopting intelligent lift-system sensors with intelligent evaluation algorithms can facilitate permanent monitoring.

This paper was presented at  USA 2012, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

USA 2012, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

(website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Condition monitoring, predictive maintenance, preventive maintenance, wear detection

Abstract

A new sensor with intelligent evaluation algorithms will allow the wear and tear of essential lift system components to be permanently monitored. This will permit maintenance and repair work to be planned without the need to meet specific intervals and a high level of availability to be achieved with an optimum resource efficiency. The new assessment concept is devised to automatically create forecasts and trends on the basis of the data collected and present them to the user. For the first time it is possible to measure the wear of lift system components and issue appropriate servicing recommendations so that the material no longer needs to be replaced at specific servicing intervals and the use of resources can be adapted to the actual needs.

1. Introduction

Up to now condition monitoring has rarely been used to improve maintenance measures. If applied, it was limited to identify fault storages of lift control systems or occasionally of lift drive units. Each manufacturer applied different concepts on this issue.

If sensors are used to detect the level of lift system wear, it is done with mobile ones. With these sensors spot checks of the lift car’s acceleration behaviour, the noise level or the rope tension can be carried out and they will provide the respective, but -uncommented- measurement data.

First initial tests have been conducted with mobile sensors with the aim of converting the widespread interval-based maintenance of lift systems into a predictive or even proactive maintenance. The goal is to replace the old and limited procedures and to establish this new predictive maintenance service.

2. Initial Situation

2.1 Prevailing Maintenance Strategies for Lift Systems

The widespread lift system maintenance concept in use worldwide combines reactive, preventive and sometimes also condition-oriented maintenance measures in initial stages. Preventive maintenance of lift systems is carried out in regular intervals. Service technicians initiate measures either after a given period of time or after reaching a certain number of rides in order to retard further deterioration of the wear. Topping up gearbox oil, greasing the guide rails etc. are the measures taken to achieve this objective. The wear level of certain lift components such as guide shoes or brake linings are also checked at that point. The latter can be seen as a first attempt to achieve a predictive, condition-oriented maintenance. Based on the information gathered e.g. of the wear, it can be deduced which components need to be replaced at which point in time in order to prevent any kind of system failure or safety-critical conditions of the lift system.

2.2 Condition Monitoring in an Industrial Environment

Condition Monitoring is nowadays in nearly all industrial areas one of the key maintenance measures needed to efficiently operate and maintain technical plants. This approach is based on a regular and/or permanent capturing of the data of the machine’s state by measuring and analysing meaningful physical parameters. The technological developments achieved in the field of sensor technology, tribology and microprocessor technology provide such a quantity and quality of information applicable to the maintenance of production machinery never attained before. This leads to the effect that industrial environments cannot be imagined without Condition Monitoring any more. It has to be regarded as a conditio sine qua non for a condition-oriented and/or proactive maintenance.

2.3 Advantages of Condition Monitoring

The significance of Condition Monitoring depends highly on the kind of maintenance strategy: the more comprehensive the strategy and the requirements it has to meet, the more distinctive the importance of Condition Monitoring. Condition Monitoring can be of great help in a variety of ways supporting a maximum plant efficiency. Condition Monitoring will ensure

- safety improvement against failure. This is achieved through efficient prediction of defects with the result of their prevention.

- considerable reduction of downtimes. This is accomplished on the basis of an integrated planning of repair measures indicated by the Condition Monitoring.

- increase of components’ service life by preventing any conditions that shorten their life, and

- cost-reduction and nearly full use of the component’s wear potential.

The three stages of Condition Monitoring:

- Determination of the system’s condition. This means, the relevant machine parameters reflecting its current state have to be measured and documented.

- Comparison of the data concerning the condition. The current condition has to be contrasted with a specified reference value. If the complexity of the plant is extremely high, the data are determined empirically.

- Diagnosis. In this step a diagnosis is carried out based on the machine’s condition data in order to achieve results which will indicate possible faults as early as possible and will enable a determination of their cause.

3. Condition Monitoring In Lift Systems

If one try to transfer the above mentioned steps to lift systems, one soon find out that there are hardly any technical measuring systems offered on the lift market not even for the first of the Condition Monitoring steps, the determination of the condition. It is only for the intermittent monitoring of vibration and noise data that ride quality measuring systems conform to ISO 18738 such as the EVA system or the LiftPC system can be used. These systems provide data on the condition of the lift system to be recorded simultaneously while inspections are carried out. This enables a detection of long-term developments for use of further analysis, but short-term or transient events and processes cannot be detected. Furthermore, a combination with other data such as the load condition, temperature, etc. is also quite difficult.

Long-term trends as well as erratic or transient changes of condition can just be recorded and detected on the basis of a continuous monitoring of physical lift system parameters in real time. Subsequent comparisons of the condition and diagnosis algorithms will have a comprehensive data stock available. This will make it possible to generate accurate and reliable maintenance suggestions.

3.1 Pilot Project: Testing Condition Monitoring in Lift Systems

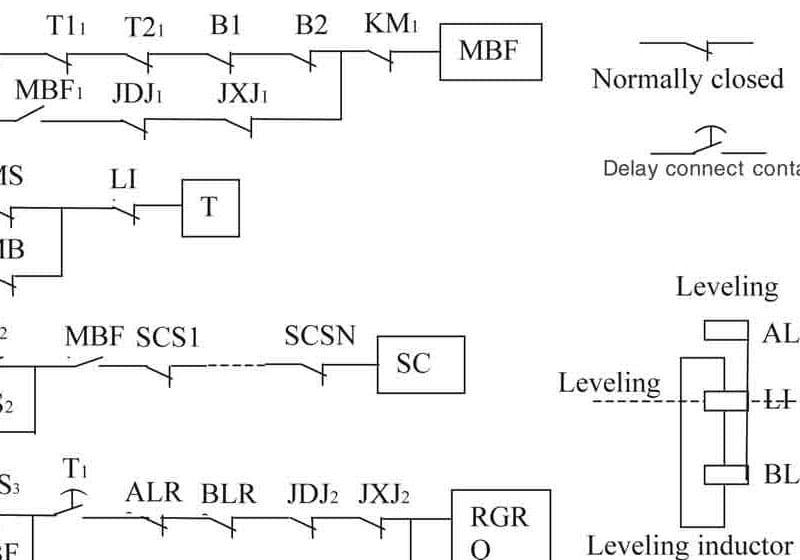

Company Henning installed prototypes of a lift condition monitoring system in eleven lift systems of the chemicals group BASF as early as 2004. Different types of sensors were installed to measure and monitor acceleration and vibration, as well as the traction sheave speed, the current hoisting height, the overall cab load and the individual rope tensions. The measurements were analysed by an industrial personal computer located directly at the lift system. The results of this analysis were transferred by remote data transmission to a data centre. The main component of the Condition Monitoring system is a vibration and acceleration sensor, which was placed directly on top of the car. Being in this position it recorded the actual ride movements of the cabin as well as the car guides, door movements and – indirectly via the ropes – even the behaviour of the drive unit.

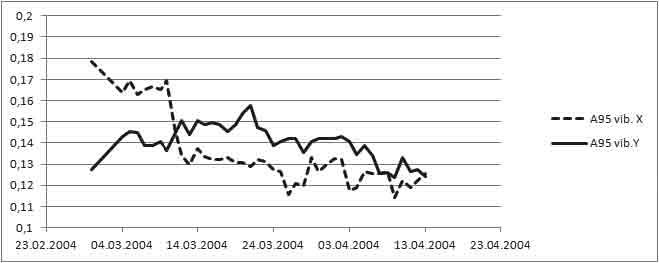

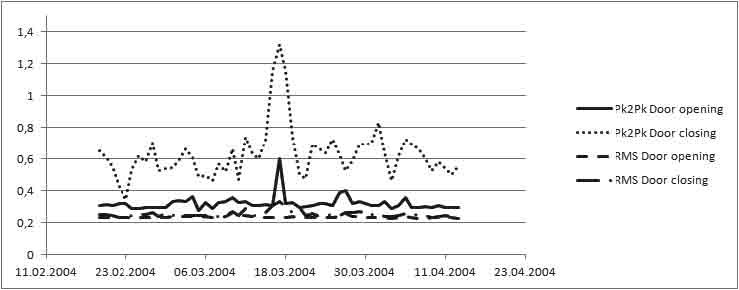

The recorded data of all sensors were converted to specific characteristic values for each ride and checked to verify if they exceeded any of the specified limits. Subsequently the characteristic values of each ride of one day were summarized to one statistic mean value. These mean values resulting from several hundred rides per day were used for actual trend monitoring purposes. The following two data examples e.g. show a trend over several days based again on thousands of rides.

At the beginning of the recording period shown in Fig. 1 the slide guides of the cab are already worn out. On March 11, 2004, the guides were replaced by new guide shoes. One clearly can see that the vibrations in direction X (vertical to the actual distance between guide rails) are reduced immediately. On the other hand, the vibration behaviour parallel to the actual distance between guide rails increases before again dropping to the original value after a period of some 25 days. The vibration course in direction Y can be explained by a non homogenous actual distance between guide rails over the entire hoisting height of the lift system: the new slide guides must be allowed to first “grind in” in this direction is space. The diagram shown allows to determine a limit for the vibration behaviour in direction X which the system is not allowed to exceed. In this particular case, a guide shoe maintenance suggestion is tripped, in case it does exceeded the specified limit.

The second example (Fig. 2) shows four characteristic vibration values for the door movements. The period between March 15 and 17 shows an irregular peak. The graph clearly indicates that the event is of a sporadic nature. The guides of the car door were contaminated by winter grit probably originating from the tyres of a fork lift truck. The automatic door monitoring system tripped an alarm in this case. Therefore, the fault could be eliminated within a very short period of time so that door rollers and guides did not suffer consequential damages.

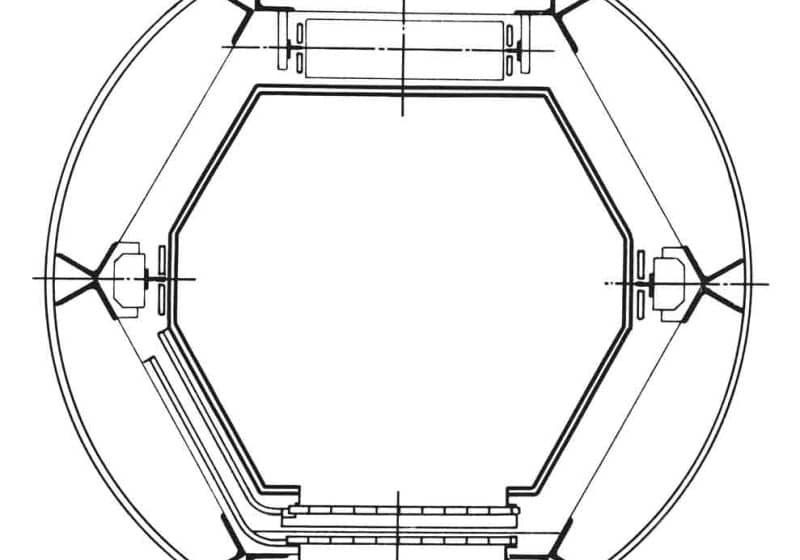

Besides vibration data, also the measurement of the individual rope tensions and of the loading condition has proven to be absolutely significant. The loading condition affects the vibration levels as a matter of course so that these can only be evaluated in combination with the actual load. Furthermore, the individual rope tensions in the rope set also have to be taken into account. A replacement of the motor torque by the motor speed generates a trend in the lift industry to use increasingly thinner ropes and higher suspension ratios. Research on ropes shows that the rope bending capacity is continuously reducing with the diameter (Scheunemann, 2007). A smaller traction sheave diameter to rope diameter ratio (D/d) additionally reduces the bending capacity. This is also applicable to multiple rope deviations. This immensely boosts the influence of only one badly adjusted rope of one rope set: the wear of the rope can for example reduce the life of the entire rope set by 60 % if one rope merely deviates by 15 % from the mean value of the single rope loads (Feyrer, 2000).

Based on the results of the pilot project and the exhaustive examination of measuring methods suitable for lift systems, company Henning have developed in the past few years a Condition Monitoring system for lifts. It will be completed at the end of 2012 and will then go through field testing in Germany. The specific characteristic of the WearWatcher is an intelligent vibration sensor which permanently monitors the wear of important lift system components. The sensor is fitted on top of the car and it detects the current ride condition so that door movements, ride starts, constant rides, etc. can be examined separately. The vibration sensor does this monitoring autonomously without being connected to the lift control system. In each of these ride conditions significant characteristic values are generated. The monitoring and analysis of all this data allows to detect long-term trends as well as erratic or transient changes in condition which can be fully documented. Vibrations are also transmitted to the sensor via the suspension gear which allows to indirectly record even motors and gearboxes. The sensor is able to distinguish between numerous wear aspects of critical components such as doors, drive units and guides. Furthermore, at the same time other sensors detect the load on each suspension rope. Therefore also the load in the car is identified.

A connection to higher-ranking building management systems can be done without any difficulty due to the system’s adequate interfaces. Significant changes in the transmitted characteristic values will then generate a warning well before the failure limit of a component is reached so that the required maintenance activity can be planned in advance and is no longer subject to fixed intervals.

4. Summary

Condition Monitoring is already widespread in many areas of industry but still rather neglected in the lift industry. Servicing strategies ending up in a condition-oriented and proactive maintenance are not necessary for all lift systems, but this kind of cost-intensive preventive maintenance strategy is the only promising alternative for lift systems which are part of a production process, which are used in public sectors to secure the mobility of people with physical impairments or which are indispensable for representation purposes. The only adequate countermeasure which will be able to compensate the partially massive cost reductions affecting lift components in the past few years can only be in form of a monitoring of safety-relevant and function-critical components. An efficient solution to the above mentioned problems is Automatic Condition Monitoring. It guarantees an optimum resource efficiency combined with a high plant availability.

REFERENCES

1.) Feyrer, Prof. Dr. K. (2000). Drahtseile: Bemessung, Betrieb, Sicherheit. 2nd ed. Springer Verlag, Berlin Heidelberg New York.

2.) Scheunemann, Dr. W. (2007). Randbedingungen für den Einsatz von Tragseilen unter 8 mm im Aufzug. Lecture at Schwelmer Symposium.

Get more of Elevator World. Sign up for our free e-newsletter.