People Selling to People

Oct 6, 2022

Quad City Safety delivers by knowing its customers.

Mike Smeaton, Jr., and Dave White graduated within a few years of each other in the late 1990s from Murray State University in Kentucky. They were already familiar with the safety equipment business, particularly for the vertical-transportation (VT) industry, through working for Smeaton’s father’s business, Quad City Safety, Inc., named for the four cities in Iowa and Illinois that make up the Quad Cities. The business did a lot of work with Montgomery-KONE. Headquartered in Moline, Illinois (one of the Quad Cities), Montgomery Elevator was acquired by KONE in 1994. Originally based in Moline, Quad City Safety was purchased by Smeaton, Sr., in the 1980s. He moved it just across the border to Davenport, Iowa (another of the Quad Cities), to a 40,000-ft2 facility that was approximately twice the size of the original in 1997, which President and CEO Smeaton, Jr., and Chief Financial Officer (CFO) White say was instrumental in giving it the ability to grow.

The Safety Kit

KONE, says White, was one of the first VT OEMs to “really get into the idea of a safety kit,” which includes all safety items a VT technician needs, whether performing a new installation or modernization, in one package. White elaborates:

“Each company wants different items in it, but those kits are created so when our customers call us they can buy refills. We’re taking the pain out of the ordering process because we’ve got, say, 45 parts ready to go in a work bag that just shows up at their office. Companies will often send us components they want to add — like their updated handbook or safety manual — but the core components of the kit stay the same.”

After working for the previous iteration of Quad City Safety for a little over five years, Smeaton and White bought the business in 2004. That year, the pair say, they got the “brilliant idea” to attend the National Association of Elevator Contractors (NAEC) convention and expo in Baltimore. They knew what a cornerstone Montgomery-KONE had been for the business, and sought to capitalize on that. They now always make it a point to attend NAEC, and count numerous OEMs and independents among their loyal VT customers.

Regardless of company size and pocketbook, Quad City customers receive the same, high-quality service and pricing, Smeaton and White say. For a customer that’s spending US$20,000, or millions, the Quad City team will track down custom safety equipment that precisely fits their needs, Smeaton says. Further, he says, the concept of “kits” includes a couple of things that are “huge for the elevator industry.” Customers, Smeaton says, save time and money thanks to Quad City working with safety committees to get the right, approved products. “Otherwise, a technician in NYC would be running around town during work hours trying to find the right gloves.”

Brands include Gemtor, Inc., an ISO 9001-registered manufacturer of fall protection, confined space retrieval and rescue equipment based in New Jersey. Gemtor Vice President of Sales Larry Schertzer says Quad City does a “fantastic job for us in the industry,” providing “great knowledge and great customer service.” Like Quad City, Gemtor takes a “down-home” approach to business. Its owner Craig Neustater is accessible, and Smeaton and White like that. At Quad City’s request, Gemtor has authored several technical papers addressing particular dangerous applications or near misses. “They can evaluate a jobsite and even recommend a product, if needed,” Smeaton says. “It’s a pretty big deal in this industry to have people who are flexible and jumping on a particular situation to make sure it does not happen again.”

PPE

Personal protection equipment (PPE) products sold by Quad City Safety are all mandated by laws and standards (such as national or state OSHAs in the U.S. or Canada’s CSA Group standards organization). They are tested to the highest standards and ordered for specific characteristics. “For instance, we are hearing many in the industry say they need gloves with cut protection and touchscreen capability, so we went on the hunt to find those and are now supplying them,” Smeaton says. What a customer needs often depends on their geographical location. Smeaton observes:

“Each state has the ability to be part of federal OSHA or their state OSHA. California has a state-run OSHA that goes above and beyond. Then you have states like Oregon that are very centered around the timber industry, so they need more things related to that.”

Quad City’s top VT industry sellers are fall- and hand-protection (gloves) products. These, however, are only the tip of the iceberg in terms of what the company offers for VT safety. Additional products include lockout/tagout devices, eye and face protection and fall protection. The company has done business in all 50 states and “I forget how many foreign countries,” Smeaton says. “Basically, wherever you can input a credit card number and we can ship there, we can sell it to you.”

Beyond VT

In addition to VT, Quad City Safety serves customers in the solar and wind energy industries. The company also has a strong relationship with the American Foundry Society, and deals with all types of construction contractors. “We always try to learn what people are actually doing so we can share technologies and concepts that are working well in other verticals,” White says. “We share knowledge back and forth among all our customers.”

Smeaton and White pride themselves on truly knowing their products. Yes, they are salesmen, but “consultant salesmen,” they say. “We don’t just pull a part number and not know what it is,” White says. “We’re very intimate with the product — what its limitations are, how to use it and how to maintain it.” Smeaton says the office gets more product samples than he can count, and he reviews them — much like the guys who chomp down on the latest fast food chicken sandwich and talk about it — in detail on YouTube, pointing out the product’s plusses and minuses.

Pandemic Upends Operations

The pandemic, they say, truly upended operations. Smeaton says:

“It was kind of a debacle. The government mandated N95 masks as the preferred facemask. The construction industry accounts for about 80% of the consumption of respiratory protection, and basically, the government stepped in and told suppliers to sell to their non-traditional customers — i.e., the medical profession, which was given priority. So, lack of masks was an issue, and then we had supply chain issues. We dealt with it as best we could, but there was a lot of pivoting. For instance, we started importing disinfectant wipes from Israel. We actually had a period of time where we put our core business on hold and just tried to figure out what we could provide folks as it related to fighting the pandemic.”

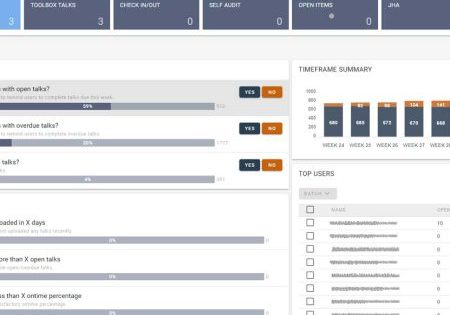

Other than lingering supply chain and pricing issues, business is, by and large, back to normal, Smeaton and White say. Quad City Safety just upgraded its ERP (enterprise resource planning) system to enable it to handle “high-end data-entry” tasks. “For instance, if somebody sends us a PDF, we’ve now got software that will put all that information into our system,” White says.

Since they purchased the company, employment has roughly doubled to 36. Smeaton and White need more employees, but finding them has been a challenge, to say the least. “We had three interviews scheduled for yesterday and nobody showed up; today, we had five scheduled and two showed up,” White says. “One looked like he was very down on his luck and the other was literally in, like, his jam-jams.” Neither interviewee was interested in becoming a true “consultant salesman.”

Onward and Upward

Quad City Safety is currently working on modernizing its salesforce. Outside sales, Smeaton and White observe, is not what it used to be. Today, it entails email, Zoom and the ability to move content around. Customers have access to materials and are more educated than ever before. “So, most of the time we’re working with customers to fine tune the safety ‘recipe’ they’re looking for,” Smeaton says. “They already have the basic idea.”

“We’re very intimate with the product — what its limitations are, how to use it

— Quad City Safety CFO Dave White

and how to maintain it.”

Smeaton and White believe their company is resistant to the “Amazon effect,” which sees people jumping online and ordering products for themselves. Why? Because their products are backed by the expertise of people who know them inside and out. How many times, they ask, has your author ordered something off Amazon and ended up throwing it away because it was either a) not what had been advertised or b) fell apart. Several times, at least. “We’re still people selling to people,” White says. “All of our customers have mine and Mike’s cell phone numbers. They call us all the time.”

Advice From a Pig: “Bacon” Is Born

In an industry lacking pizazz, safety can be boring. So Quad City Safety decided to inject a little fun into the equation via its safety mascot, “Bacon.” Conceived by White in 2017, Bacon is a cartoon pig that provides solid advice on topics ranging from self-retracting lifelines with leading-edge capability to first aid supplies for workers via colorful illustrations on the Quad City website. “A chicken — it gives an egg, but a pig goes all in and gives everything,” Smeaton says. “That was kind of the thought process.” Some of Quad City’s customers like Bacon, some don’t, Smeaton and White say. At first, Bacon was more popular with the younger generation, but now, the “older generation is buying into that kind of stuff,” Smeaton says. “It’s interesting to see how it’s all changing and that we were kind of ahead of the curve.”

Get more of Elevator World. Sign up for our free e-newsletter.