Polymer Matrix Composite Applications on the Elevators of the Future

Feb 1, 2023

by Emre Köroğlu and Ali Kiliç

This paper was presented at the 2022 International Elevator & Escalator Symposium in Barcelona, Spain.

Abstract

One of the most popular research areas globally is innovative construction materials. Several researchers are particularly concentrated on polymer matrix composites (PMC) because of their high performance and versatility, which can change the engineering approach to construction systems in the very near future. By considering the year 2030 — mentioned in the theme of this symposium — it is obvious that our forecast for the next-generation of elevators should be the near future. An estimated projection should be feasible for developing futuristic elevator designs that will be extremely different from the current ones in the next 10 years. Considering the recent pandemic from a pessimistic viewpoint, 10 years may not be enough for a radical change in elevator technology. But, in any case, it is a certain reality for today and it will be the same again in the future that every stakeholder of the elevator industry is trying to make their products more preferred by their customers as they try to reduce the cost of their products. According to this reality, it seems possible that new ideas to make the product more preferrable will turn into application within 10 years. Due to the gradual increase of PMC materials usage in many sectors of the industry, one of these ideas will be the use of PMC materials for elevator components to make the elevator lighter, stronger, more esthetic and more energy efficient. Therefore, in this article, the types of composite materials, suitable manufacturing methods with composite materials for elevator parts, advantages of composite materials for elevators and challenges of composite applications in compliance with elevator regulations will be discussed. In summary, this article provides satisfying information regarding elevator applications of PMC materials that are innovative alternatives for elevator components.

1. Introduction

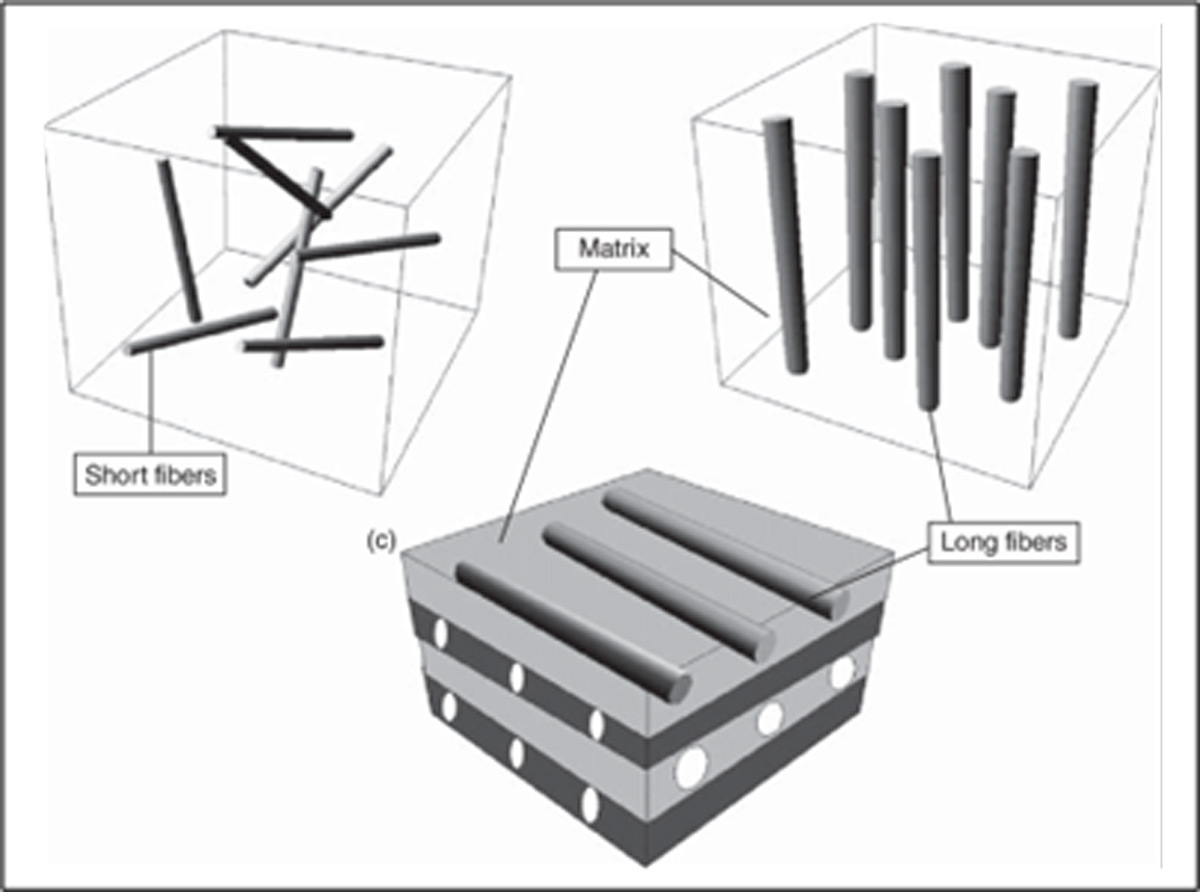

Composite structures are produced from two or more different materials without dissolving in each other. That provides a new combination on a macro/micro/nano scale so that they show superior properties. Components are called matrix and reinforcement material (fiber). The matrix holds the structure together, protects the reinforcement material and transmits the applied force to the reinforcement materials, while the reinforcement material (fiber) carries the load to which the structure will be exposed. Protecting the fibers from corrosive and oxidative effects, matrix material can be either polymer, metal or ceramic, depending on the area of use. Metal matrices that are resistant to abrasion, have high fracture toughness and compressive strength cannot form a good interface with each reinforcement component, which makes manufacturing difficult.[1,2] Ceramic matrices are resistant to extreme temperatures, light, erosion and abrasion.[2] Due to their hardness, they are extremely brittle and show low elongation at break. Therefore, 90% of the composite materials produced worldwide are polymer matrix.[1] Polymer matrices are divided into two as thermoset or thermoplastic, according to their reaction behavior to heat. Thermosets are preferred more than thermoplastics because they are easy to produce and are isotropic.[3] The most important feature of PMC materials is that they have a high specific strength value. Composite materials with polymer matrix, which have a specific elasticity value of five times higher than aluminum, are preferred over aluminum alloys in areas such as the automotive, aerospace and defense industries where both strength and lightness are required. PMC’s compatibility with many different reinforcement materials has also facilitated the manufacture of complex parts.[2] Reinforcing materials used with polymer matrices are generally glass, carbon or aramid fiber.[4]

There are various production methods compatible with thermoset and thermoplastic resin in PMC production. A very basic system is hand laying, which is based on dispersing the liquid resin with a roller between the reinforcing layers. As a second approach, the reinforcing element and matrix resin are sprayed over a surface together during spray laying. In the compression molding method, it is based on the formation of part geometry at elevated pressures as the mold is compressed by the fiber and the matrix placed in an open mold. Apart from these methods, vacuum infusion, pultrusion and filament winding methods are the other, most-preferred methods. In the vacuum infusion method, molten matrix is injected onto the reinforcement element placed in an evacuated mold and the resin is cured after the cavity is filled. In the pultrusion method, reinforcing fibers are firstly soaked into the resin bath, then it is shaped in the mold and the final form of the profile is formed at curing temperatures. In filament winding, unlike pultrusion, after the resin bath the excess resin on the reinforcement fibers are thrown away and the profile form is formed by winding the fibers on a mandrel in the drying device.

2. PMC Materials in Elevator Construction

Before finding an answer to this question, we need to look at the subject from a slightly broad perspective and understand why composite materials are an alternative to other structural materials. Actually, it’s not hard to understand. Because, considering their performance, it is clear why composite materials can be a serious alternative to many other materials. Polymer matrix composites (PMC) performing the same mechanical properties are 60% to 80% lighter than steel and 20% to 50% lighter than aluminum.[5,6] These properties alone have made composite materials a highly preferred alternative in many engineering applications. In addition, it is thought that composite materials provide advantages such as lightness, design flexibility and durability in the areas where they are used, which will facilitate the construction and increase the sustainability score of a building.[7]

Due to their superior mechanical properties, flexibility in design and high performance at a relatively low cost, composite materials are frequently used in various applications, especially transportation, construction, automotive and aerospace.[8] Their usage rate is increasing day by day, for instance a 5% increase in the annual growth of the use of composite materials was observed in the automotive industry since 2015.[5,9,10] The mass of composite material used in the Boeing B-787 Dreamliner aircraft is approximately 50% of the mass of the entire aircraft.[11] From an overall perspective, global composite market size has reached US$1188.4 billion by 2019[12], while worldwide demand for composite materials was approximately US$22.2 billion in 2015[5,9,10], … etc. supports this thesis.

In summary, the above technical and statistical data point to the fact that composite materials will be the material of the future. Therefore, the best answer to the question of why we should use PMCs in elevators will bring another question: Why not use them? Considering the goals to lighten the structural weight of elevators; aim to ensure energy efficiency by reducing the weight of moving components; durability of the critical structural components being more resistant to environmental conditions such as corrosion; manufacture flexible and aesthetic enough to enable different architectural designs to be realized and thus make a difference… and if we have to meet the mechanical strength criteria while doing all these, there is no alternative other than PMC material.

Although the requirements listed above seem arbitrary in today’s conditions, they will be faced by the elevator industry as a necessity in the near future. The increase in building heights and the diversification of building forms will necessitate the renewal of today’s functional elevator designs. In the transformation that will start with such requirements, the role of PMC materials in the elevator sector will be quite large.

3. Application of PMC Materials as Elevator Components

3.1. Current State of the Art

There are two known examples in the literature regarding the use of PMC materials in elevators. One of them is KONE UltraRope®, a carbon fiber reinforced elevator rope, and the other is the composite elevator car designed for the linear motor elevator system, MULTI developed by TK Elevator (TKE). The main motivation in both design ideas is the same: lightness.

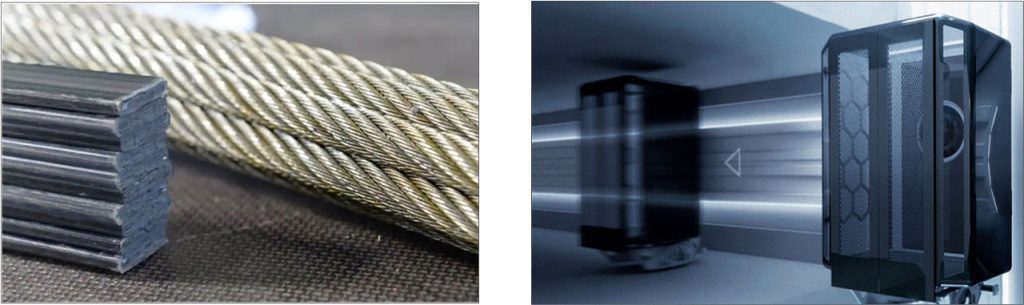

The carbon fiber reinforced plastic (CFRP) elevator rope KONE UltraRope produced by pultrusion method is a kind of PMC material. When we look at the resources on the subject, it is seen that four different epoxy resin formulations are examined and it is concluded that an acid anhydride-based epoxy is the optimal epoxy formulation for CFRP rope production.[13] With this product, KONE has succeeded in reducing the weight of the elevator rope itself by more than 50%. In a 500-m-tall building, using conventional elevator hoisting technology means moving masses weighing around 27,000 kg. It cuts the weight of moving masses inside the shaft for a 500-m-tall building to roughly 13,000 kg. Among the introductory information given by KONE about the product, it was emphasized that this lightening saves between 15% and 40% in terms of energy consumption and operating costs.[14]

In the MULTI system developed by TKE, we encounter an elevator system with a linear motor where ropes are not used. Here again, the situation that leads the designers to use PMC material is the weight reduction of the moving mass. For this, elevator cabin panels are designed using CFRP material, which is a kind of PMC. When the relevant sources are examined, it is seen that the total weight of the moving mass in the elevator model in which CFRP material is used has decreased by approximately 40% compared to the weight in the traditional elevator model. The same source says that the lightening is 80% when only the weights of the cabin walls are compared. In addition, it was reported that “the designed elevator model has been approved to meet the strength and stiffness criteria presented in the elevator inspection parameter”.[15]

3.2. Future of PMCs in Elevators

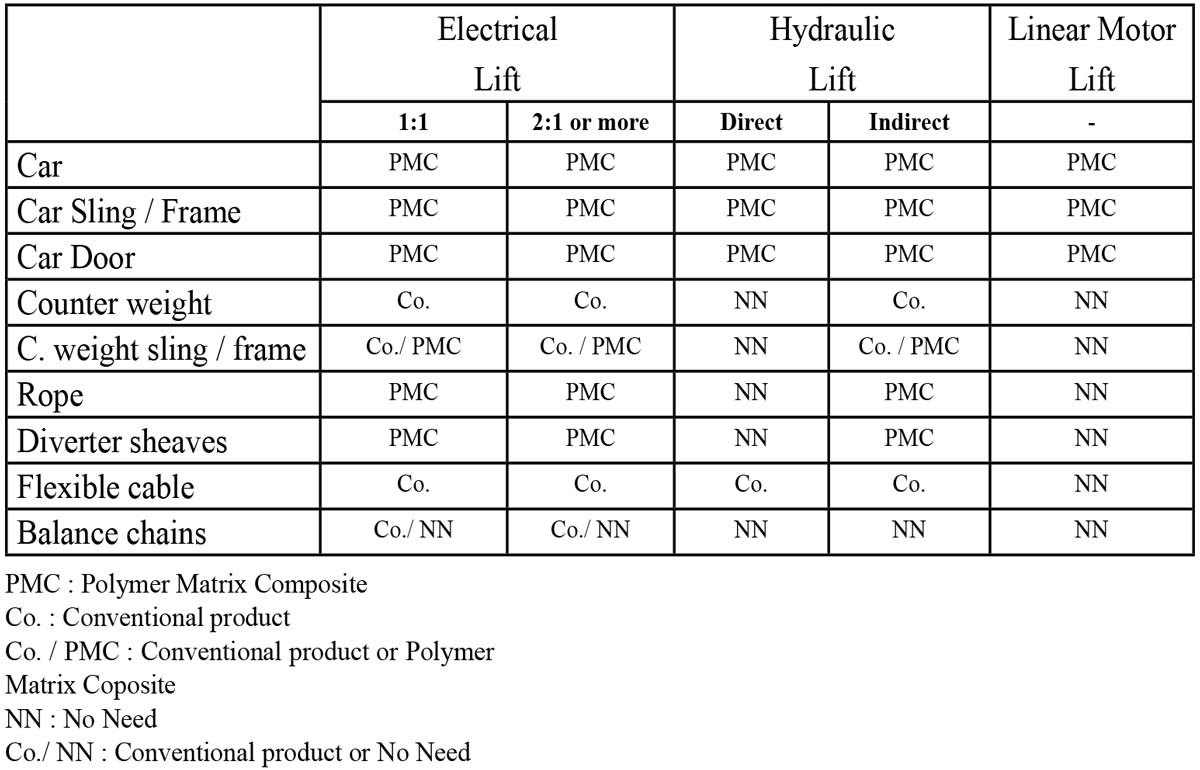

It can be easily predicted that there will be an absolute increase in the variety of elevator components using PMC in parallel with the widespread use of composite materials (especially PMCs) in almost every sector. While it is expected that elevators with linear motors (so-called ropeless elevators) will be used in the near future, it is obvious that traditional rope and hydraulic elevators will continue to be installed in new buildings. Regardless of the elevator system to be installed in buildings in the near future, the need to reduce the weight of the total moving mass will remain an engineering problem that enables innovative ideas to emerge in the sector. It is thought that the components on which this problem will focus and, therefore, the elevator components where PMCs can be used, will be the moving structures of the elevator such as the car, car frame, counterweight frame, car door, ropes, deflection pulleys and brake gear. Among these components, the car, car frame and car door are found in all systems, while the use of other components may vary according to the elevator system. This variability is summarized predictively in Table 1.

As can be seen from the table, almost every moving elevator component can be produced using PMC material, while it is foreseen that, as a result of the lightening that the use of PMC material will create in the system, the use of some components will no longer be necessary and PMC materials will not be preferred in others. For example, when PMC materials are used according to Table 1, the use of balance chain may not be necessary in a conventional electrical elevator system and the counterweight material and counterweight carcass may not be preferred to be produced using PMC materials, since their purpose is to create weight. In the example of a linear motor system, the car and the car frame can be designed as an integrated structure and the use of other components may not be necessary due to the structure of the elevator system.

Although the use of PMC in elevators is mostly focused on moving parts, the use of PMC in other elevator components — such as machine chassis, rails and rail connection consoles and even landing doors — can be considered in terms of static loads or environmental conditions such as corrosion.

3.3. Elevator Components Manufactured With PMCs

When we look at the manufacturing methods using thermoset PMCs, we come across five basic techniques that are widely used. These are hand layup, spray layup, resin transfer molding, pultrusion and prepreg techniques. If we accept these manufacturing methods as the state of the art, it is possible to produce all of the components specified in Table 1 with these known methods. Which production technique will be used can be found by determining three basic criteria related to the component to be produced. The first of these criteria is whether the component will be produced in parts or as a solid body, the second is the geometry of the component or parts of the component to be produced and the last is the mechanical performance expected from the component.

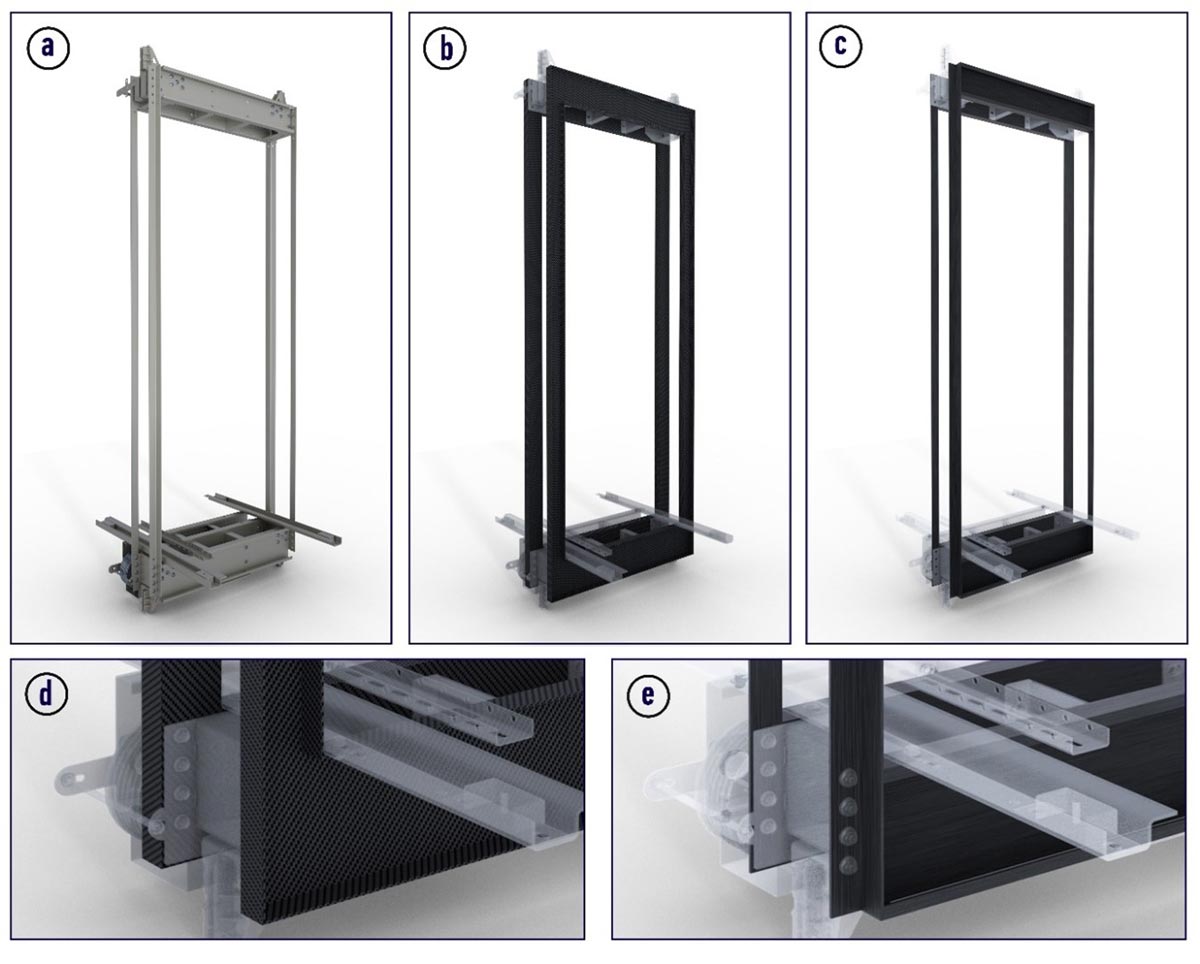

In order to manufacture components with composite materials, it would be appropriate to evaluate each part at the design stage by considering the production method and to design components according to the evaluation result. For example, considering manufacture of the car frame of a conventional electric elevator using PMC materials, the first decision we have to make here is whether to produce this structure as a whole (solid) or in parts. There is no absolute correct answer to this question. So the answer may vary depending on the design made with engineering approaches. By using PMC, this structure can be designed as a solid structure, or it can be thought of as a design similar to the one made of steel, that is, as parts to be added to each other later. In this case, if the carcass design is solid, the production method will be VARTM, in other cases the parts produced separately will be combined mechanically or chemically. The production method of each part that will form the carcass can be evaluated in a similar way. For this example, the geometry of all the parts shown in the Figure 3-c and Figure 3-e is suitable for the pultrusion method. It is also possible to combine parts produced by different methods with mechanical or chemical binders.

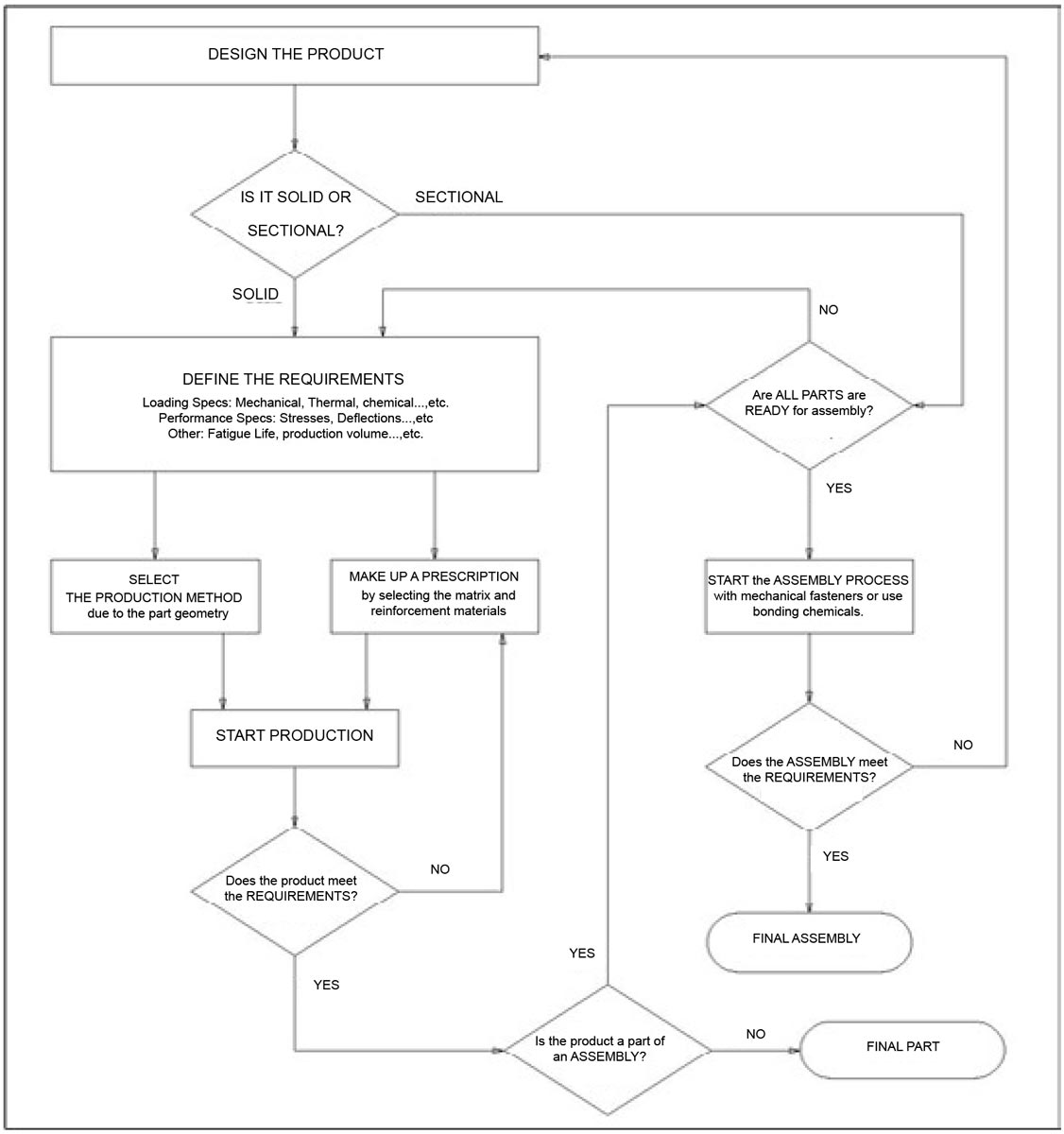

At the decision stage on the manufacturing method, reinforcement element and matrix material selections are made simultaneously according to the mechanical constraints. Carbon fiber or glass fiber can be preferred for reinforcement material, and epoxy or polyester resins with a mixture of various agents can be preferred as matrix. Although it is possible to decide material preferences after simulations, the selections made with experimental methods must be verified for the desired mechanical performance. For this reason, the prescriptions prepared to achieve the desired results are know-how. If the desired results are not achieved, it may be inevitable to turn back to the start and review the component design. In order to make this process more understandable, a flow chart has been shown in Figure 4.

3.4. Challenges of the Use of PMC Products in Elevators

PMC materials are superior structures that meet the mechanical performance expectations of the sectors in which they are used, and even show a better-than-expected performance in many applications. However, depending on the industry, the expected performance from PMC materials may not be just to meet the mechanical requirements. In addition to mechanical requirements, performance parameters determined by environmental conditions such as electrical conductivity, thermal conductivity, flammability, recyclability, etc., can also be decisive in the use of PMC materials. An example of such a situation is encountered in the elevator industry. The EN 81-20 standard refers to the EN 13501-1 standard and states that the supporting structure of the cabin defined in article 5.4.4 must be made of non-flammable materials. It has also been explained by the relevant CEN committee in the question-answer section that what should be understood from the supporting structure here is the cabin frame and supporting platform. This structure, which is one of the most suitable elevator components for the use of PMC material in the elevator system, both in terms of the load it is exposed to and, therefore, the required strength criteria, and in terms of constituting almost 30% of the total weight of the moving mass, must be manufactured from non-flammable materials according to the standard. It is obvious that the flammability classes defined according to the EN 13501-1 standard cannot be provided with an unmodified polymer. In other words, if the cabin carcass is to be produced with PMC material, the material design should be studied before the carcass design, and the know-how that will meet the non-flammability criterion should be obtained. According to the literature, it is already known that the non-flammability property of PMC materials can be improved with some chemical agents to be mixed with the resin or by coating the surface of a finished product. For example, it has been reported that results can be obtained with phosphate-based flame retardants with low toxicity, halogen-free, low smoke emissivity. However, the effects of such theoretical recipes on the mechanical properties of the material or the production process should be observed and optimized in practice.

In addition to the cost of PMC material development in accordance with current elevator standards, another challenge is to apply theoretically known production processes in practice. While the method of application of the technique related to manufacturing with PMC is clear in the literature, the parameters that affect the process during the application have not been mentioned much. For example, operational parameters of the pultrusion method such as optimum fiber number, fiber routing stages, line drawing speed, die temperature, cooling distance, etc., can only be determined according to the experimental study results. A standard value cannot be assumed for these and similar operational parameters. The main reason for this is the difference in the recipes that determine the PMC content. The fact that an ingredient is added or removed from the recipe or the proportional amount of an existing ingredient changes can directly affect operational parameters. Possible effects and optimization process according to the new situation is only possible with empirical methods. In addition, the confidentiality of the composite material industry and constraints on information sharing makes all these processes extra difficult.

Working with PMC materials in general is quite different from working with steel, both in terms of design and manufacturing. Steels have a homogeneous structure and are diversified according to their chemical content defined in the standards and, therefore, their mechanical properties. The general engineering approach in designs using steel is to make a dimensional part design synchronously with the selection of appropriate quality steel according to the strength requirement. If the results obtained in the design verification did not meet expectations, the results can be improved by choosing another steel of different quality or by revising the part dimensions. However, when working with composite materials, the process is slightly different from this conventional method. First of all, PMC materials may not be homogeneous like steel. In this case, the behavior of this non-homogeneous structure under load will pose a new engineering problem. However, while producing a solution to this problem, the current situation can also be turned into an advantage. For example, in areas where the load density is high on the PMC part, local strength can be increased by interfering with the number or orientation of the fibers. In summary, an engineering team with old fashioned steel-processing skills should learn how to analyze and find solutions to new situations that arise due to the nature of PMCs.

4. Conclusions

In conclusion, PMCs as the materials of the future, will be used in the elevators of the future and can be considered a realistic prediction rather than a utopian approach. In the event that this estimation is realized, the engineering approaches of the component and system manufacturers serving the elevator industry will differ. Developing new PMC materials, preparing a suitable recipe according to the needs, optimizing the production processes according to different recipes and designing the complete elevator system containing PMC components will be on the agenda of elevator and component manufacturers in the near future.

References

[1] Kaya A.İ., Kompozit Malzemeler ve Özellikleri, Putech & Composites, Temmuz Ağustos, 2016

[2] Özdemir B., Polimer Matrisli Kompozit Malzeme İmalatı İçin Vakum Destekli Mekanizmaların Geliştirilmesi Ve Performanslarının İncelenmesi, Master Thesis, 2020

[3] Itoh, M., Inoue, K., Hirayama, N., Sugimoto, M., Seguchi, T. (2002), “Fiber-Reinforced Plastics Using a New Heat-Resistant Silicon Based Polymer, Journal of Materials Science, 37 (17), 3795-3801.

[4] Advani S., Hsiao K., Manufacturing Techniques for Polymer Matrix Composites (PMCs), Woodhead Publishing 2012

[5] S. Mazumdar, “State of the Composites Industry,”, Basalt Today, edition 2016.

[6] Hull, D., and Clyne, T.W., “1996: An Introduction to Composite Materials,” Cambridge University Press, Cambridge, U.K.

[7] 2021 Yılı Küresel İnşaat Pazarı Görünümü, Composites TURKEY, sf 35

[8] Yakout M., Elbestawi M. A., “Additive Manufacturing of Composite Materials: An Overview 6th International Conference on Virtual Machining Process Technology (VMPT),” Montréal, May 29-June 2, 2017

[9] C. Campbell, Lightweight Materials: ASM International, 2012.

[10] M. Zhou, R. Fleury, and M. Kemp, “Optimization of Composite: Recent Advances and Application,” Altair Engineering, Inc., 2011.

[11] J. Merkisz, M. Bajerlein, “Composite Materials Used in the Aerospace Industry,” Logistyka, June, 2011, 2829-2837.

[12] Kocaoğlu İ.,Kompozit malzeme sektörü ve Türkiyenin durumu, İzmir Kalkınma Ajansı, March 24, 2021.

[13] Kwon, D. J., Kim, J. H., Park, S. M., Kwon, I. J., DeVries, K. L., & Park, J. M., “Damage Sensing, Mechanical and Interfacial Properties of Resins Suitable for New CFRP Rope for Elevator Applications, Composites Part B: Engineering,” doi:10.1016/j.compositesb.2018.08, 2016

[14] KONE The Secret is in the Rope, accessed September 21, 2021

[15] Bae, S. Y., Yoon, S. M., and Kim, Y. H. (2020). “A Study on the Lightweight Design of Lift Structure by Composite Materials, Modern Physics Letters B, 34(07n09), 2040032

Get more of Elevator World. Sign up for our free e-newsletter.