Powerful, Refined and Smart

Apr 1, 2022

Bucher Hydraulics promotes becoming “smart and networked.”

Submitted by Bucher Hydraulics

Hydraulic drive technology in elevator construction is a small but excellent niche. It comes into play when large forces or architecturally sophisticated solutions are required. Bucher Hydraulics, based in Frutigen, Switzerland, is now taking a step forward, noting that elevator technology is becoming smart and networked.

A clear benefit of hydraulics: The forces can be transferred directly via the building foundation, whereas in the case of traction elevators, they usually make their way into the building structure via the shaft head. “Freight elevators with high loads are the domain of hydraulic elevators,” said Tony Aschwanden, head of Product & Application-Elevator at Bucher Hydraulics. “Equipped with one or more cylinders, they can lift loads of more than 40-mT over 25 m and higher.”

The company says these elevators can also look elegant: An area of application is architectural elevators featuring large areas of glass but with no sign of suspension ropes, which would have a negative visual impact and be distracting. A central cylinder, often a slim, shiny telescopic design below the car, appears delicate and aesthetic. Modern designs can even work without any lateral car guidance, such as round glass cars. This allows elevator doors to be installed in any direction. The hydraulics themselves also keep a low profile: The power unit and other equipment fit in a wall cabinet or in the shaft.

Frequency Inverter: No More Oil Than Necessary

There are about 5 million elevators in the European Union (EU). They use about 18 terawatts (trillion watts) h of electricity per year, or about 0.7% of the total electricity demand. That’s why within the foreseeable future, elevators are to become subject to the EU Ecodesign Directive. A pilot study has already been completed under the leadership of the Fraunhofer Institute for Systems and Innovation Research (ISI) of Karlsruhe, Germany. In terms of energy efficiency, however, hydraulic elevators have been heading in the right direction for quite a long time. In fact, looking at their whole service life, they are usually superior to traction elevators, according to a study by the Spanish technology center Instituto Tecnológico de Aragón (ITAINNOVA) of Zaragoza, Spain. The Swiss Federal Office of Energy, in its study, “Electricity Consumption and Savings Potentials in Elevators,” also attests that typical hydraulic elevators in apartment buildings have lower maintenance costs than traction elevators.

A major factor in saving energy: the use of frequency inverters. Without a frequency inverter, the pump’s drive motor runs at full speed right from the start. The travel curve — i.e., acceleration, full speed and deceleration — is controlled by a valve. The surplus oil is fed back to the tank in an energy wasteful manner, causing it to heat up unnecessarily. As a result, an oil cooler may even become necessary.

“With 30-40% energy savings, the extra cost of the frequency inverter pays for itself, especially in frequently used elevators.”— Tony Aschwanden, Bucher Hydraulics head of Product and Application-Elevator

Frequency inverters, on the other hand, control the motor from as low as zero speed. As a result, only as much oil is pumped as is needed for the ideal travel curves. “With 30-40% energy savings, the extra cost of the frequency inverter pays for itself, especially in frequently used elevators,” says Aschwanden.

But there’s more. One example: the use of supercapacitors, or supercaps for short. They can be charged and discharged much faster than rechargeable batteries. In addition, they withstand far more charging cycles. Among other applications, they have become known for storing electrical energy in the Kinetic Energy Recovery System (KERS), used in Formula 1 racing cars and for regenerative braking in buses and trains.

Bucher Hydraulics has adapted this technology for elevators. It can even be retrofitted to existing units through appropriate software modifications. The oil displaced from the cylinder by the car drives the pump. The pump turns backward and the motor generates electrical energy, which is temporarily stored in the supercaps via the frequency inverter. During the next up travel energy is available, reducing power consumption from the grid. Depending on the application, energy savings of 20-30% can be achieved this way. The system is particularly worthwhile in highly utilized industrial installations.

iValve: A New Era in Elevator Hydraulics

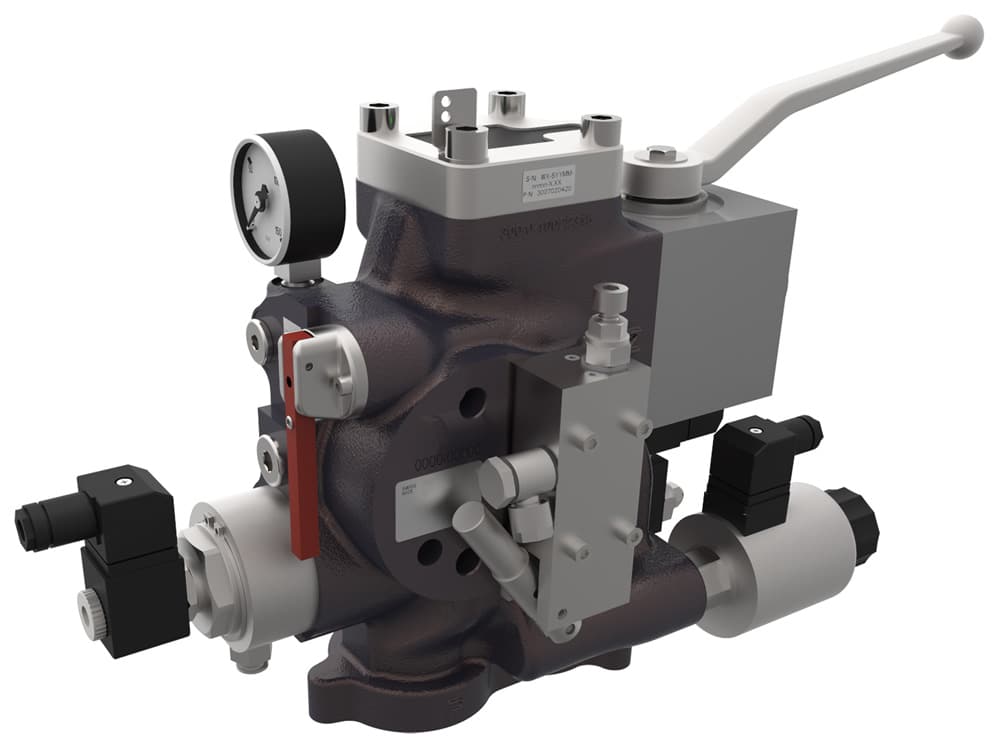

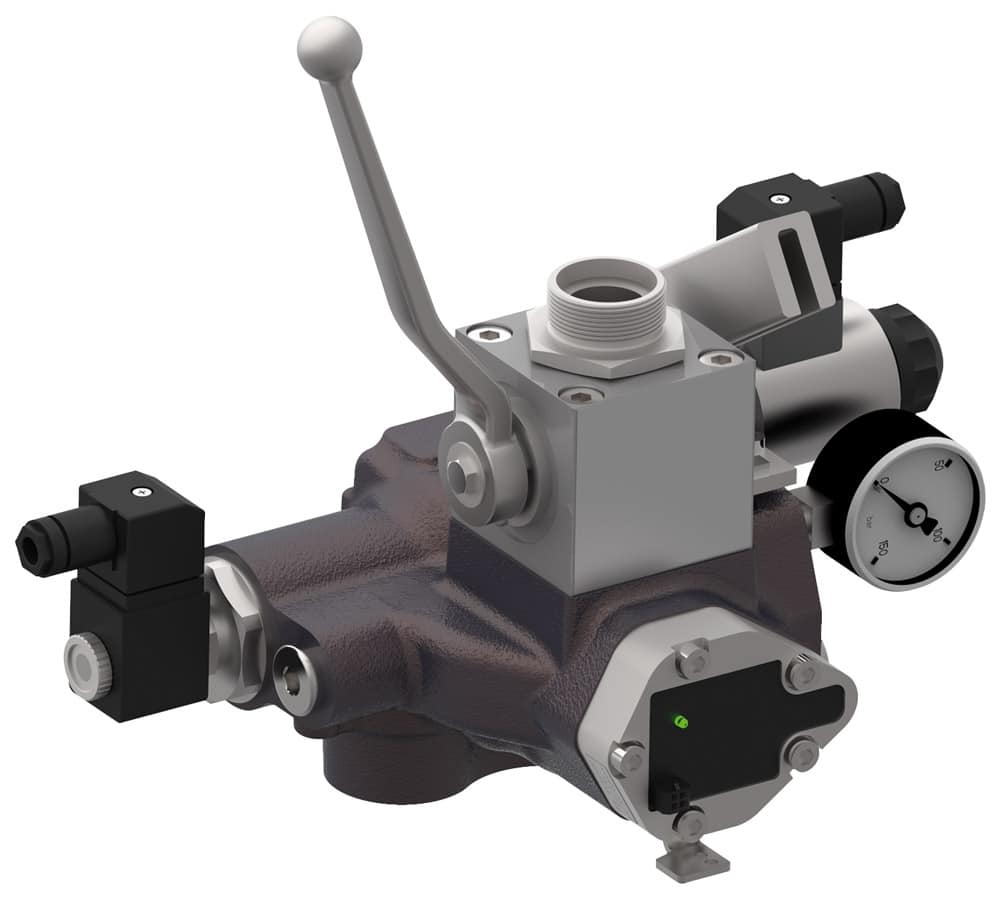

Bucher Hydraulics is a member of the VDMA BlueCompetence initiative and has committed itself under the motto “ECOdraulics.” Based on this, the company develops and manufactures products with a particular focus on energy savings, low emissions, long life, light weight and space savings. A prime example: the intelligent hydraulic iValve for the elevator industry, with flow rates of 250 and 500 l/min (66 and 132 U.S. gal./min).

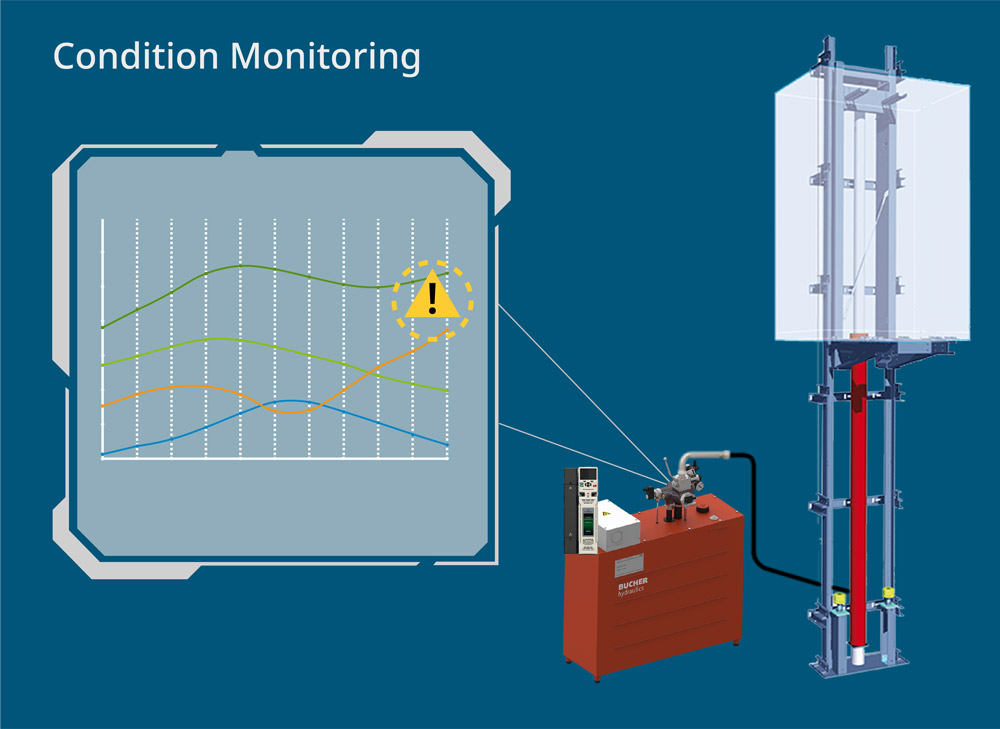

The iValve is a strategic optimization of the LRV (lift control valve) toward industry 4.0. It can be installed and put into operation significantly faster. Thanks to sensors and corresponding software, the valve is self-learning and self-optimizing. In addition, it has extensive networking capabilities. This makes the iValve a future-proof choice, as it can be substantially retrofitted thanks to its modular design.

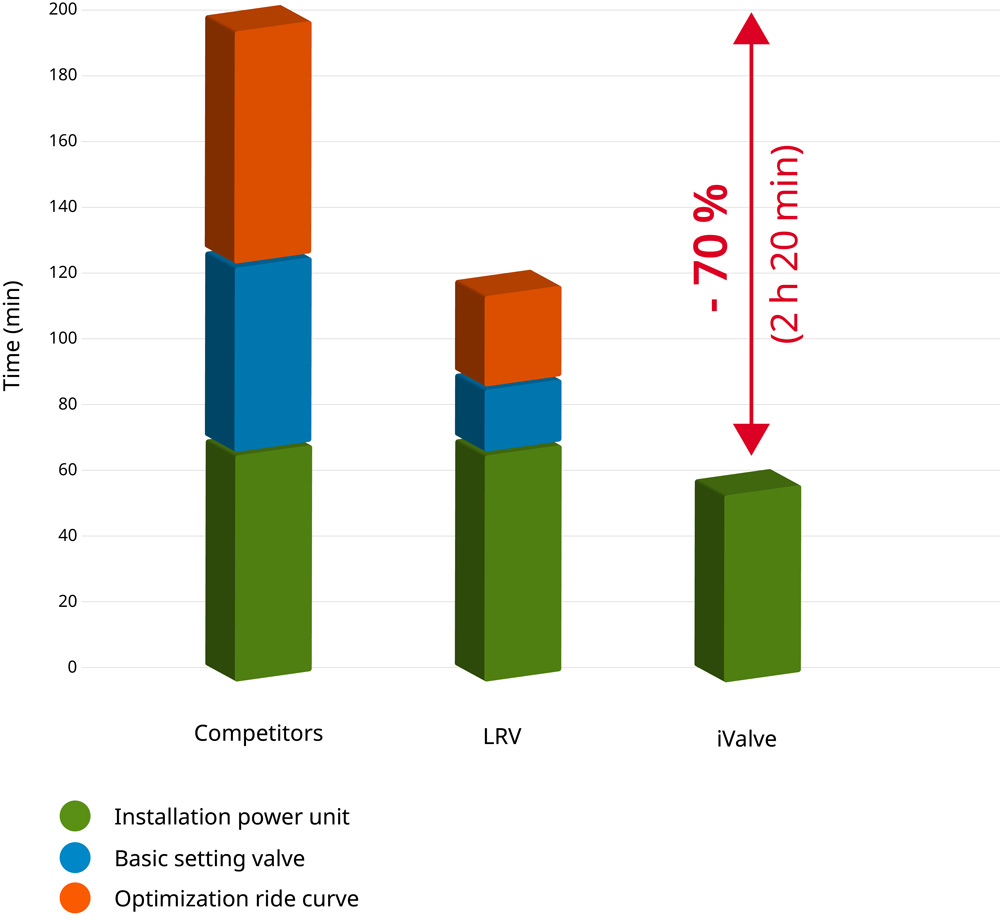

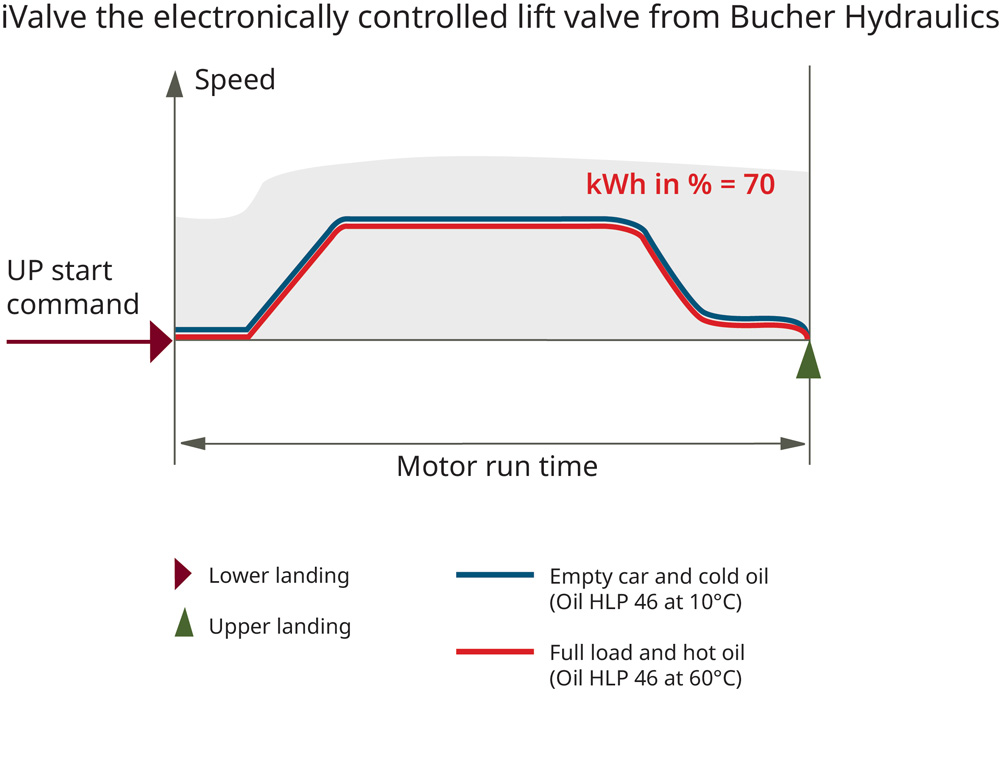

Installation time is reduced by up to 70%, compared to a mechanical hydraulic valve. It also saves up to 30% energy. A very precise closed-loop control circuit ensures first-class ride quality and excellent leveling accuracy in both directions, regardless of the temperature and viscosity of the oil. “Smart” is the optional predictive maintenance, which makes it possible to respond before any damage occurs.

iTeach Ensures Fast Commissioning

The installation and commissioning time for an iValve is only 60 min, as opposed to 120 min for an LRV series valve or 200 min for a conventional valve. The installation time is shortened because only two connecting lines between the electronics and the valve are used, instead of several cables to the pressure sensors.

The iValve is an electronically controlled lift-control valve for controlling hydraulic elevators.

The major part time savings, however, is due to the complete elimination of the basic valve settings and the optimization of the travel curve. This is done by the iValve itself using iTeach based on the shaft information supplied by the lift control system.

An initial travel curve after installation looks like this: start with long start-up phase and slow speed, full speed, deceleration, and again a long travel distance at slow speed until the valve stops. For a typical travel distance, this takes about 14.5 s between starting and stopping the car. The IValve optimizes itself during the first five travels via iTeach, and significantly reduces the total travel time to 8.5 s, which saves a lot of energy.

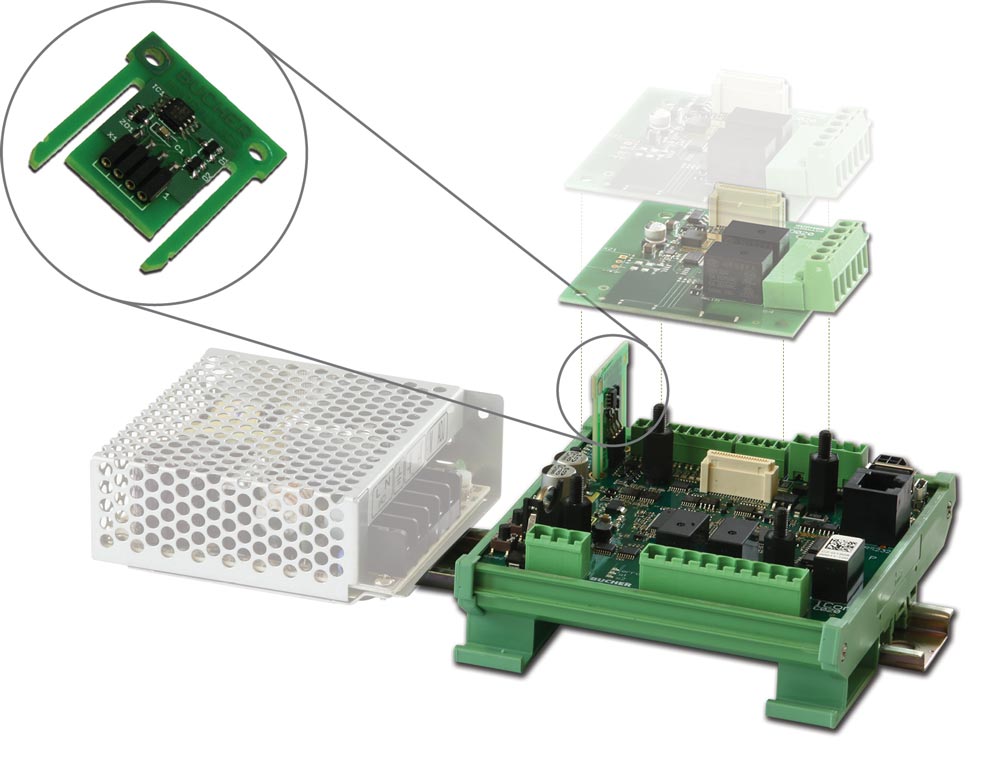

Networking Made Easy With CANopen-Lift

In combination with the iCon electronics, the iValve offers every option for modern networking. The bus system used is CANopen-Lift, an open-source quasi-standard in elevator engineering. This simplifies the wiring effort for the overall system and communication with the drive. Initial field-test systems with this CANopen connection are in operation in Germany, the Netherlands and Switzerland.

Thanks to the optional CANopen connection via a plug-in card on the iCon controller, no additional terminals are necessary. The parameters can be changed centrally via the lift control system. The iCon board is equipped with a fault memory, which can be read out for analysis on site, or remotely using smart devices. For the elevator manufacturer, this is the direct path to predictive maintenance: the iValve can pass on status information, data log files and warnings, which are sent to the lift control system. From there, they can be shared globally. This does not just apply to new systems: it can also be retrofitted to approximately 50,000 systems worldwide.

The Features at a Glance

iValve brings a number of features:

- Up to 70% installation time savings

- No parameterization or mechanical adjustments necessary

- iTeach algorithm that generates the shortest travel curve automatically

- Up to 30% energy savings

- Short travel times, regardless of loading and temperature

- In many cases, no oil cooling is necessary.

- First-class ride quality and highest level of safety

- Leveling accuracy of ±3 mm

- Self-monitoring function that guarantees fully integrated A3 conformity

- Pleasant acceleration and slowdown, direct approach into landing

- Intelligent implementation

- Two digital, freely programmable pressure switches

- Hand pump/emergency lowering

- Ball valve

- A3 safety valve

- Intelligent accessories

- Open-system controller “iCon-2”

- Memory card “ParamCard”

- Power supply (optional)

About Bucher Hydraulics

Bucher Hydraulics is an international leading provider of innovative drive and control technologies, from the initial project phase to the finished product, for mobile and industrial hydraulic applications. Production facilities and sales centers are located in Europe, India, China, Brazil and the U.S. Target industries are construction machines, materials handling and lifting technology, municipal equipment, renewable energy, agricultural technology, mechanical engineering and elevator technology.

Elevator builders worldwide — including not only global market leaders but also many medium-sized companies — use hydraulic elevator components from Bucher Hydraulics. The valves, power units and cylinders can be found in passenger and freight elevators in airports, train stations, shopping centers and commercial buildings. The elevators reach travel heights of 25 m (82 ft) and more. The payload ranges from 320 kg (705 lb) to more than 40-mT (U.S. 44.1-T; 39.4-T imperial long T). The components can also be used to modernize existing installations and offer architects a wide creative scope. Machine-room-less (MRL) hydraulic systems, for example, solve the problem of space and also meet the highest design requirements. The systems are characterized by low maintenance requirements and high energy efficiency. They are long-lasting and offer a very good cost-benefit ratio. Last, but not least, passengers appreciate the outstanding ride comfort.

Get more of Elevator World. Sign up for our free e-newsletter.