PU-Coated Ropes as Elevator Suspension Means

May 5, 2023

This Technology article looks at the European experience.

Introduction

Elevator suspension means have mostly remained unchanged for more than 165 years. In 1834, a steel wire rope was first conceived for a mining elevator in central Germany. Since then, the product has been subjected to technological evolution, but basically remained in the form of wire rope until the beginning of the 21st century.

Coated steel belts were introduced as a suspension means, and only a few years after, the so-called “small diameter” alternative appeared on the market. It completely changed the landscape of modern elevator design. Well, let’s not forget that just after the latter, polyurethane (PU)-coated ropes had started to appear, as well, joining together the benefit of the elastomeric-coated suspension means and small diameter ropes.

At this point, we must pose to ourselves a driving question: Why do we have to complicate our lives as elevator designers by introducing alternative suspension means into our projects? The objective of this short article is to properly address the answers to this question. Follow along as we delve deeper and explore this matter.

The European Experience

For this exercise, we are in European territory where the average elevator is suited for an application in a building defined as low rise, low speed (maximum 10-15 floors, with a speed of up to 1.6 m/s), and in which the space available holds historical significance.

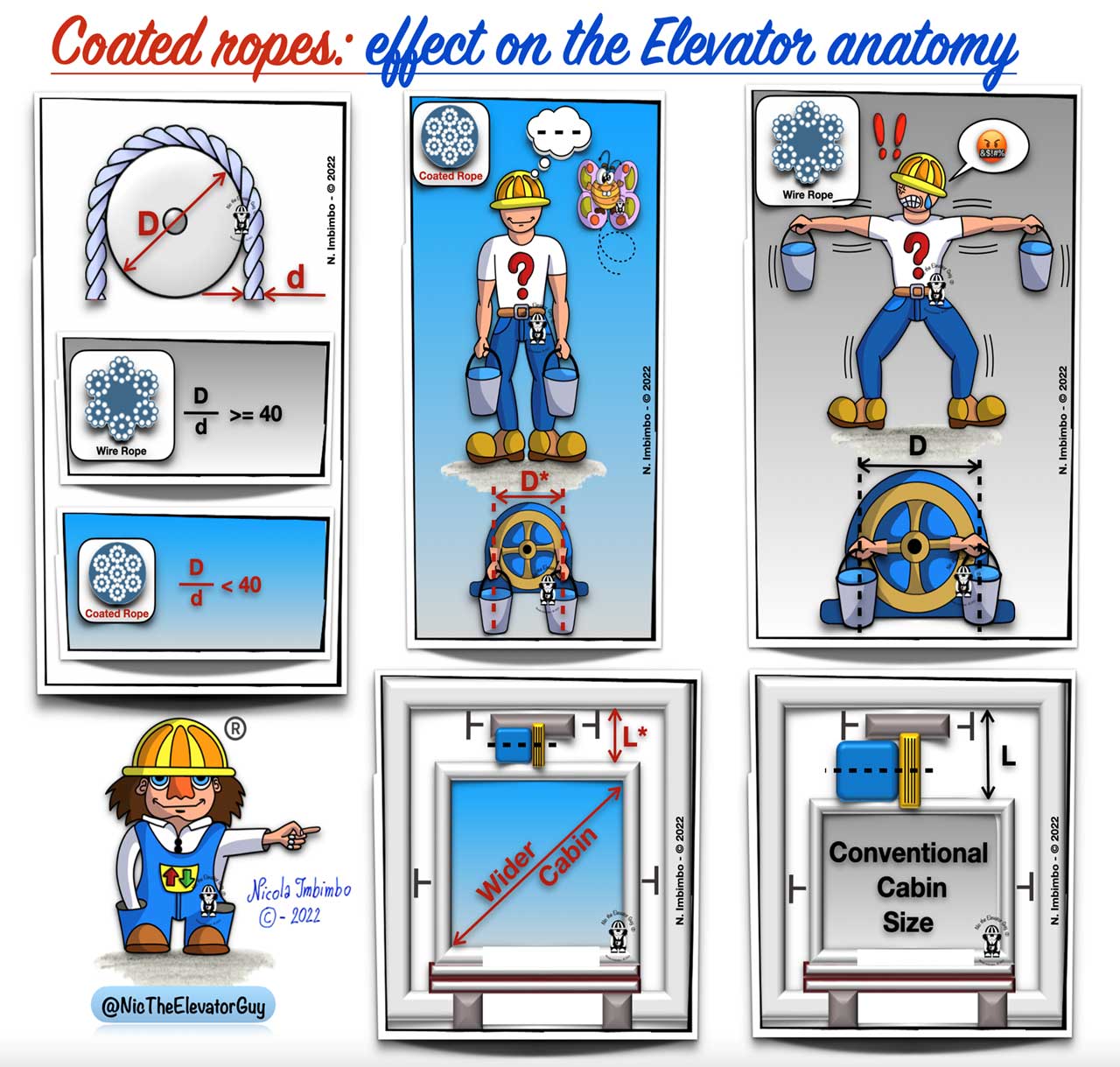

The average European elevator has a capacity of 630 kg (eight person payload), and based on the EN 81-20/50 technical rule, the minimum wire rope diameter shall be >= 8 mm with a minimum bending ratio over the sheaves of 40:1, bringing the traction sheave diameter to >= 320 mm.

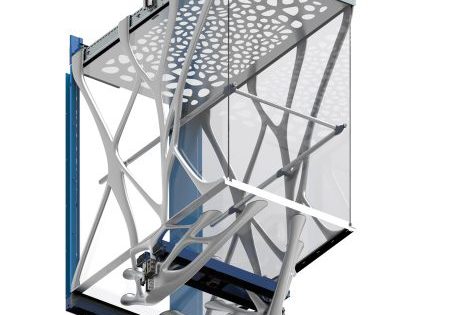

With these minimum values in mind, we proceed into the elevator design phase understanding that, with such narrow spaces available, the only way to increase cabin dimensions is to reduce the size of the motor, and to accomplish that, there is only one way: lean toward small-diameter suspension means (to be compliant with Lift Directive 2014/33/UE, small-diameter suspension means can only be applied on elevators if accompanied by an Examination Conformity Certificate issued by a Notified Body).

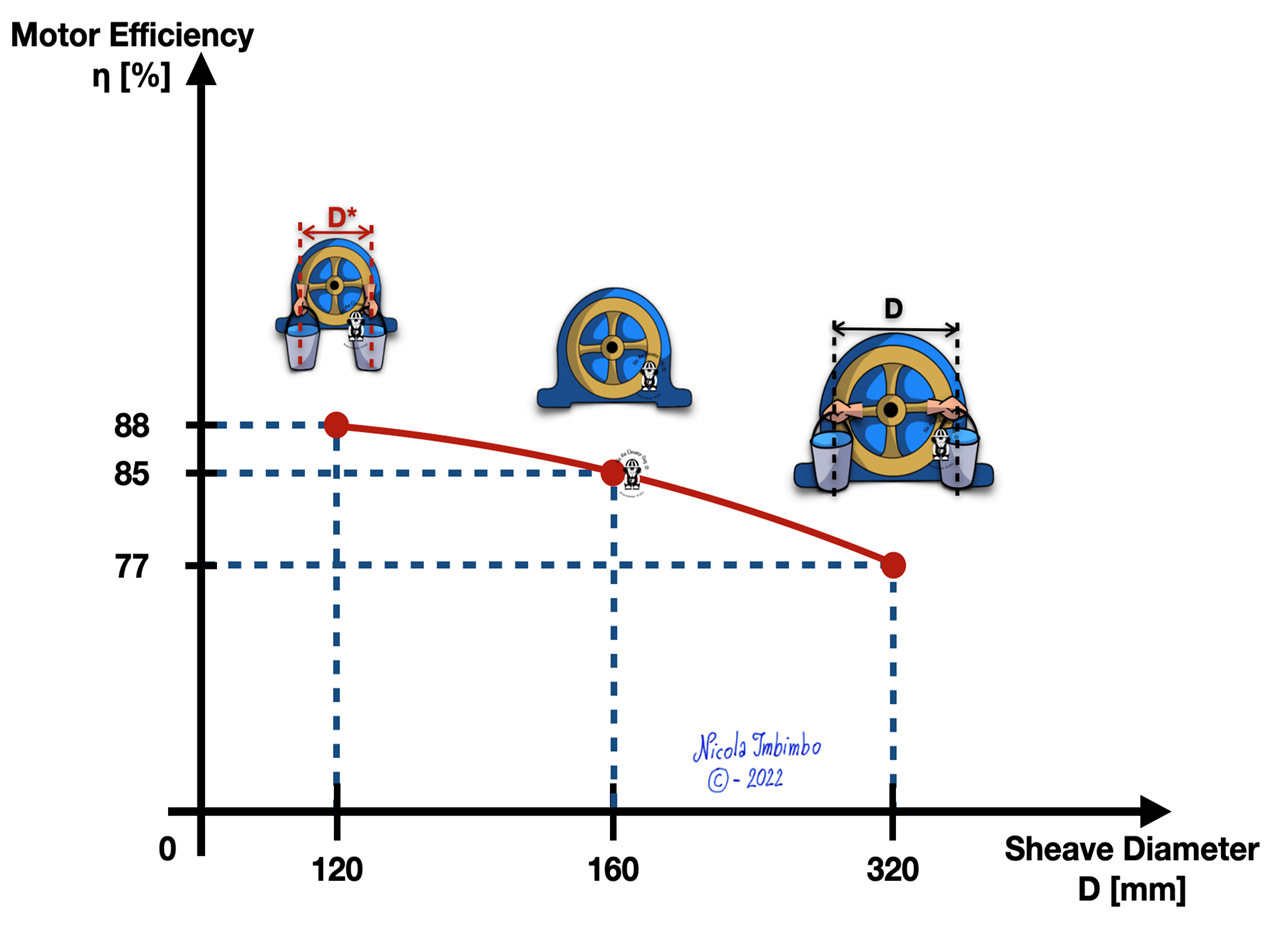

Understand motor torque, and consequently motor dimensions, are directly proportional to the traction sheave diameter. The larger the sheave, the higher the torque requested and the larger the motor size (motor size will be directly proportional to torque requirements). Inversely, the smaller the sheave, the lower the ampere requested by the motor, requiring a smaller inverter. It is comparable to the domino effect.

“The Bucket Challenge” exercise helps simulate this topic and the physical relationships discussed (Figure 1). Imagine holding two buckets full of water with your arms positioned flat at your sides; you’d be able to stand in this position for quite a long time. Now, raise your arms upward into a horizontal position. You won’t be able to stay in this position for too long. Correct, but why? Your shoulders have just experienced “torque,” and, similarly, this is experienced by the motor with the traction sheave diameter (Figure 1).

As shown, it is evident that small-diameter suspension means can accomplish this task. Not only is it a space-driven advantage, but cost-driven as well, considering that motors and inverters are among the most important cost-heavy items in low-rise, low-speed elevators.

In conclusion, at the same cabin travel speed, if the traction sheave diameter is reduced, the motor shall rotate at a higher speed (RPM). This will bring the motor itself to operate in a range in which energy efficiency is increased (Figure 2).

Example: A bank of elevators suited for a 10-15 floor building, in which you would nominally require four elevators (630 kg, eight person payload) to fulfill traffic handling during peak hours. All of this is based on a conventional elevator design with a rope d. 8 mm and a traction sheave diameter of 320 mm — minimum.

Switching to small-diameter suspension means and reducing the traction sheave diameter to 120 mm with the aid of PU-coated ropes in the same shaft dimension, you can theoretically install an elevator with a payload of at least 750 kg (10 person payload), leading you to install three elevators instead of four.

Not only would this configuration save the cost of an elevator installation, but it also benefits building designers and owners by providing additional apartment or office space.

It is worth noting that this is intended as a purely theoretical exercise, which does not consider many boundary conditions. It is an experiment that could give us guidance in understanding the philosophy of using coated suspension means and small diameter ropes.

Coated Vs. Uncoated

Why would it be necessary to move into elastomeric-coated wire ropes instead of conventional wire ropes?

If you are an elevator designer, you are most certainly familiar with the concept of minimum number of ropes required, the effect of specific pressure and how they affect wire rope service lifetime.

Consider when reducing the traction sheave diameter with small-diameter wire ropes (not coated) for suitable traction, V-hardened traction sheaves must be used. These grooves are quite aggressive toward reducing the wire ropes’ lifetime, and although not required by code, it is recommended to perform a specific pressure verification and adjust for reasonable service lifetime.

Remember, codes are safety rules, and do not describe lifetime requirements. Further considerations must always be made.

For comparison purposes, refer to the previous example of a 630 kg elevator (eight person payload) with a reeving arrangement 2:1, and a reduced dimension traction sheave (120 mm), in which we are going to apply two different suspension means: 1) d. 6.5 mm 8x19W+IWRC, and 2) d. 6.5 mm PU-coated ropes.

In the first case with V-hardened grooves, we would need to use eight to 10 ropes to gain a suitable lifetime. While in the second case, with PU-coated ropes and U-plain groove, the same elevator can use three to four ropes. The greatest difference between both scenarios is that the lifetime of the coated ropes will far exceed that of the ropes that are not coated.

By this comparison, it is quite clear the PU-coated ropes bring many design advantages. Lastly, the PU-coated ropes have no patent limitations and can be used in any elevator configuration.

Application Recommendations

Having clarified the advantages of PU-coated ropes, it is important to read and understand the user manual supplied by the manufacturer. This will provide all the design elements that should be considered during the development of the elevator project.

As for conventional steel wire ropes, the amount of historical data and reference material compiled for elevator applications exceeds 180 years, which is lacking for PU-coated ropes. Every combination of coated suspension means and traction sheave is to be tested to ensure verification of the actual f factor.

Please be aware of the difference between μ and f: μ is the friction coefficient between the materials, while f is the apparent friction factor obtained by laboratory experiment that takes into consideration the groove geometry, the surface finishing and any other element that will affect traction.

By this comparison, it is quite clear PU-coated ropes bring many design advantages. Lastly, PU-coated ropes have no patent limitations and can be used in any elevator configuration.

These initial values are obtained in a lab setting, then tested with the prototype elevator, as f factor results could vary depending on the configuration, shaft efficiency and materials used. For this reason, it is recommended that a prototype elevator is built to perform all the necessary experiments before introducing the final elevator into the market. Environmental conditions must be considered, as well. It is not the intent of this article to cover every aspect. Please refer to the manufacturer’s user manual for more detailed information.

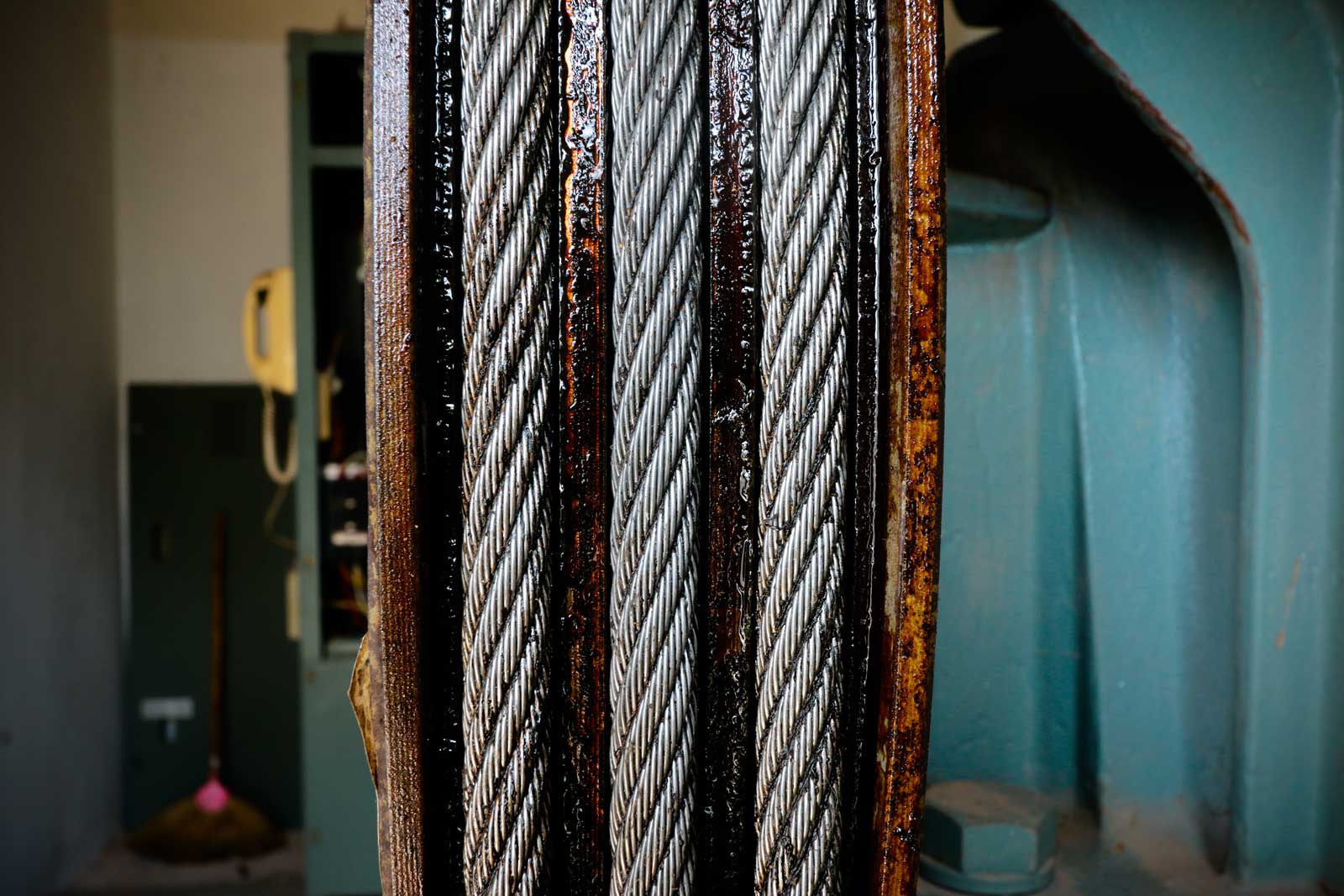

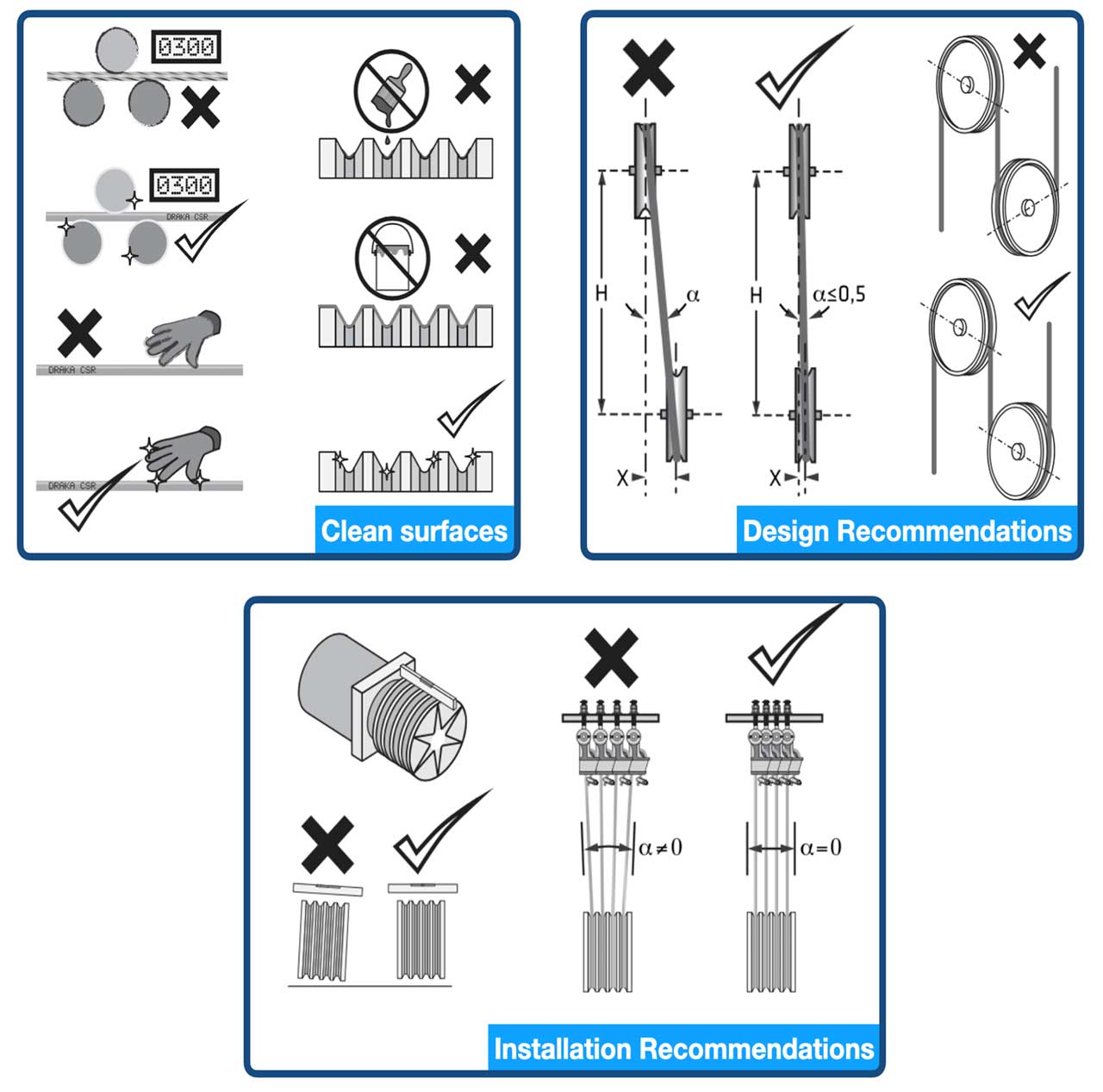

Please remember, PU-coated ropes require a different mindset compared to conventional wire ropes. To get the best benefit of their characteristics, you must manage them properly, starting with handling and care: PU materials are very sensitive to environmental conditions and to the cleanliness of contact points. Handle them with clean gloves, and do not make contact with any source of lubricant or grease. Once contaminated, it will be very difficult to clean properly. This will degrade the PU-coated rope and cause slippage (Figure 3).

PU-coated ropes need to remain clean, and if necessary, a periodic cleaning should be performed with a specific product recommended in the user manual of the manufacturer. Following the above recommendations will allow you to get the most from your PU-coated ropes.

Conclusion

The elevator industry is continuously evolving while integration of new sustainable materials brings cost and energy savings to new and exciting innovative solutions. In this respect, the benefit of the PU-coated ropes can support this trend, providing the ability to implement designs that were not previously possible.

As with all new technology, the different characteristics of PU-coated ropes should be taken into consideration during the project development and design stage. It is equally important to maintain strong communication and a good working relationship with suppliers, who will be able to provide guidance in the proper application of their product.

Get more of Elevator World. Sign up for our free e-newsletter.