Nowadays, cars ask their drivers to go for visits to the garage. The car tells you what it wants and even sometimes informs the garage. Some of us might need a pacemaker at some point, but the little electronic insert will not tell you if it detects an anomaly in your heartbeat. No, it will call your surgeon’s cell phone straightaway. Tomorrow, your kitchen “robots” and machines will do the same and will “intelligently” interact to explain their maintenance needs. Remote monitoring and even maintenance is penetrating every human activity.

And the elevator sector? Most majors have devised a remote-monitoring system (Otis Elite or thyssenkrupp MAX, for example), but they have jealously guarded it against competition. The software is proprietary and usually only applies to the (newest generation of) elevators of that particular brand. Typically, in the European market, a large company has some 20% of the elevators installed, and among these, only 5% are of the latest generation that can be equipped with the proprietary remote-monitoring system of the brand. That is very little. They offer the remote-monitoring system to their customers, but the price tag is, of course, higher than that for conventional maintenance contracts; so, the remote solution never really took off in the industrial sector, which is — let’s admit it — quite conservative.

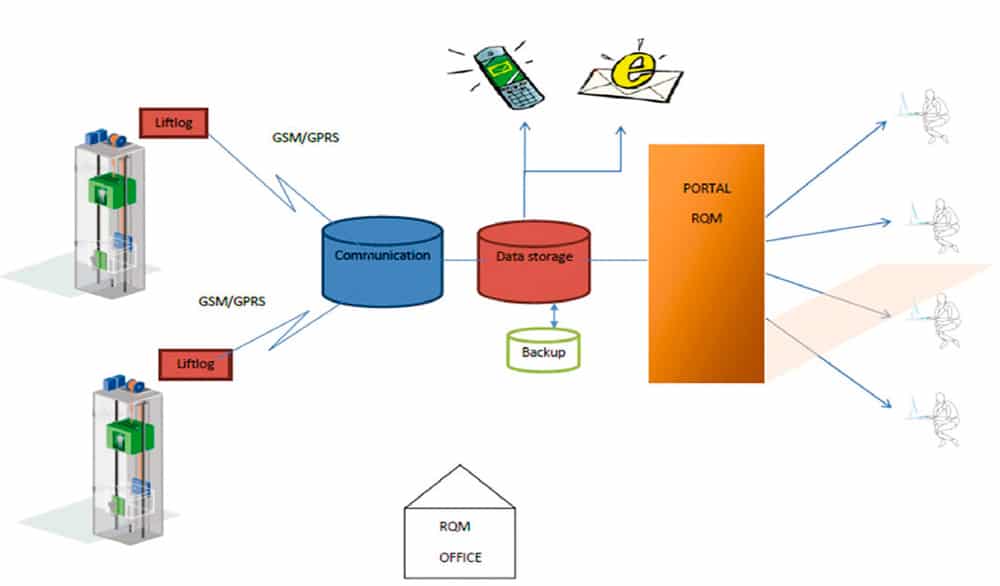

Not so anymore. A small Belgian startup, Remote Quality Monitoring (RQM), launched by elevator professional Lars Odlen, has developed an intelligent “box” called “LiftLog.” The product relays a series of electric indicators for an elevator to a server in the cloud and delivers data on the performance of that particular lift over time. The system is not intrusive and is approved by the TÜV SÜD. It is positioned in the shaft or the machine room in the vicinity of the controller.

Odlen, an engineer who spent most of his career at KONE and M2M Telematics, explained:

“It is amazing what rock-hard conclusions you can obtain with a few parameters taken on a functioning lift. No more discussions and bickering between owners and maintenance companies over breakdowns, especially intermittent failures and stoppages, or the time spent by the maintenance technicians on the elevator during their regular visits. The monitoring facilitates the analysis of the failures by the professionals. The idea is that — as for a plane — a lift may never fail. We measure effectively — to the minute — the quality of service for every elevator. . . .”

Peter Coopman, the former owner of Coopman Lifts NV, the Belgian elevator firm, sold his company to the Spanish firm Orona a few years ago and felt like investing in a clever and promising project in the elevator industry. For him, RQM has the right potential:

“. . . we collect data, freshened up every few minutes, which are invaluable for the large building owners, who often have hundreds of lifts under management in the buildings that they own and/or administrate. They are not elevator specialists. They have a lot of things to follow, from heating and air-conditioning to all the building services, and want their elevators to function without a hitch. They want to forget about them! The problem until now is that they have had all types and brands of elevators installed over the years. They want the same system to follow all elevators. That is the great advantage of RQM’s discreet little box, LiftLog, and the services it provides.”

RQM has already installed a few hundred LiftLogs in Belgian cities. Customers include major insurance companies, banks and large building-management firms. A few initial surprising conclusions have appeared after one year of functioning, such as:

- Only 5% of elevators have zero annual breakdowns. Twenty-two percent of elevators break down five to 10 times per year, and 25% break down 10-30 times annually.

- Twenty percent of maintenance visits take less than 20 min., and 56% take less than 1 hr.

- LiftLog has detected that on many banks of elevators with six or more units, one or two elevators are idle. The bigger the group, the less likely it is to detect an unused elevator as traffic is taken care of by remaining units in service.

- Elevators in Europe should conform to EN 81:28 (compulsory two-way communication system), but 6% have no working phone line, and 41% do not perform the mandatory test alarms. For all lifts (old and new), 40% have no functioning phone. The norm indicates the elevator must send a compulsory alarm signal every 72 hr. indicating the two-way communication system functions. The revised EN 81-28 is sharpening requirements on indications, battery supervision and lift identification. It gives guidelines on how Notified Bodies inspectors should test the emergency phones. In practice, the phones are not tested. It is a legal obligation, but, obviously, there is a lot to improve.

In social housing, LiftLog helps identify the reasons behind stoppages and their timing. Managers know that some 20% of their elevators are problem units, because of vandalism, use of the elevator shaft for illegal purposes (such as hiding drugs), etc. Owners and building managers can also be very precise in answering tenants who complain “of having been stuck in the elevator for 2 hr.” when, actually, they were trapped for only minutes.

Maintenance companies are, of course, a little suspicious about LiftLog, the little “spy.” The LiftLog can, for example, detect if the elevator technician has stayed for only 5 min. during a maintenance visit. But, several large maintenance operators are interested in the possibility of better controlling their business. Intermittent failures are a pain and can be very difficult to correct. LiftLog helps greatly, whether for doors or the elevator itself. Transparency is a good argument to persuade the building manager to sign a new contract.

Preventive maintenance and performance contracts are greatly helped by the indisputable data collected by LiftLog on any elevator. The product can introduce virtuous “performance contracts” to replace frequent “signature visits.” The customer is then sure of paying for the uptime (not visits) of an elevator.

A small enterprise such as RQM could play the role of the butterfly in chaos theory. The behavior of a dynamical system such as the functioning of the elevator market can be highly sensitive to initial conditions (the “butterfly effect”). The systematic collection of electronic data can yield outcomes that could change such a dynamical system and give a larger share of real decision-making to building owners and managers in the future.

LiftLog Report Content

Per Unit

- Number of trips per time unit (day, week)

- Timeline: trips per day (based on a week)

- Total number of trips/identical previous period

- Number of doors’ opening

- Out-of-order total time (month, quarter, year)

- Out-of-order number of incidents (month, quarter, year)

- Delay time of arriving technician/incident announcement

- Total time presence technician

- Maintenance-visit total time spent

- Number of maintenance visits/period

- Repair total time of presence

Per Bank of Lifts

- Average number of trips for the bank of lifts

- Discrepancies between lifts/parallel reports (traffic, incidents, visits, etc.)

- Identification of problem units (quadrant)

- Maintenance visit average time/lift

- Cascading or not between lifts in the bank and modification (quarter, year, etc.)

- Travel delay during peak hour if a lift(s) is (are) out of order

For All Lifts Followed by Remote Quality Monitoring (Can Be Different Buildings with Same Manager)

- Discrepancies between comparable lifts (including traffic, maintenance visits, callouts and repair visits)

- Comparison by categories (including load, speed and type)

Get more of Elevator World. Sign up for our free e-newsletter.