thyssenkrupp’s MULTI is designed to meet the challenges of exploding urbanization.

This article was first presented at the 2018 International Elevator & Escalator Symposium in Istanbul. For more information on November 2019’s event in Las Vegas and toparticipate, visit www.elevatorsymposium.org.

MULTI harnesses the power of linear-motor technology to move multiple cars in a single shaft, both vertically and horizontally and without ropes. It is the world’s first elevator that can literally open up new directions in people transportation. MULTI has been designed to increase passenger shaft capacity by 50%. It does this by enabling multiple cabins to travel safely up one shaft and down another in a single continuous loop, much like a circular shuttle.

With half the world’s population already living in cities, this number will jump to nearly 70% by the middle of the century. In fact, every day, builders put up the equivalent of a one- million-person city. While cities are getting bigger, so are skyscrapers. The number of buildings over 200 m tall has tripled since 2000, and more than 180 buildings over 250 m are currently under construction. Buildings are becoming like vertical cities, and they need a flexible transportation system similar to a metro. Traditional elevators, with one single cabin in a shaft, cause restrictions in terms of mobility and space and limit the height of the building. Against this backdrop, it is clear that efficient mobility in buildings is no longer a luxury but an absolute necessity, making MULTI one of the most significant innovations in urban mobility — the beginning of a new era for the elevator industry.

Introduction

In 1950, rural populations accounted for 70% of the global population. By 2050, urban populations will account for nearly the same percentage. We are in the midst of the most- significant demographic shift in modern history.

The swiftest growth rates can be found in Africa, Asia, the Middle East and Central America, but Europe and North America are also strongly affected by the trend. Based on projections of average household sizes and increases in city populations, an estimated 250 million additional housing units will be required by 2030 across the 12 countries that account for 61% of the global population (excluding demands for refurbishment and replacement).

Outward expansion — so-called “urban sprawl” — is not the answer. By expanding cities on the horizontal plane, we destroy natural environments, increase the number of cars on the streets (increasing pollution and commuting times) and reduce quality of life. Many global cities, such as Hong Kong, face natural barriers that completely prevent urban sprawl.

Current urbanization trends require us to find solutions that allow us to live comfortably, while accommodating the increasing population density. This means that cities must use the space they have more effectively. The rising density of urban areas requires the development of more mid- to high-rise buildings, which allow for the most environmentally friendly and cost-effective usage of space. Tall buildings occupy less ground space, which is essential to securing green areas for the city and allowing for centralized and intelligent control of energy.

Skyscrapers can also become part of the solution. According to the Council on Tall Buildings and Urban Habitat (CTBUH), the number of buildings over 200 m has gone from about 260 in 2000 to more than 1,300 today,[1] and there are more than 180 buildings over 250 m in height currently under construction.[2] When it comes to the construction of supertall buildings (300 m and higher), the Middle East and Asia are clearly in the lead.

Tall buildings are becoming more like self-contained communities, providing office, residential and commercial space. Sometimes, they are even interconnected with one another. Just like any other place in a city, every location within a building needs to be well connected if it wants to attract commercial investors, tenants or even casual shoppers. To achieve this level of connectivity, building-transportation systems need flexibility similar to that of a metro.

Innovations Are Required

Taller buildings pose a challenge in terms of practicability: the higher floors become less attractive if they do not ensure quick connections to the street level. This can, in part, be overcome by bringing the amenities and shopping opportunities one finds at the street level to the upper reaches of the skyline.

Another attractive option is to introduce skybridges to buildings. Skybridges can provide for the social connectivity that is normally only possible at the street level, bringing shops, parks and cafés that are accessible to several buildings. With the proper elevator technology, skybridges could also allow passengers to travel from the upper floors of one building to another without having to go to the ground floor and walk.

Traditional elevators with a single cabin in a single vertical shaft restrict mobility and take up space. They also limit the height of a building, because they reach their limits at about 400-500 m.

Plus, it’s a waste of building space to use such a high shaft for a single elevator cabin. It’s like operating one train between two cities on one track, instead of using a flexible number of trains on parallel tracks. Traditional elevator technology also does not allow for horizontal transportation, which is necessary to link the elevator systems of two buildings via skybridges or underground tunnels.

Description of MULTI

With all this in mind, it is clear that efficient mobility in buildings is no longer a luxury, but an absolute necessity. MULTI is thyssenkrupp Elevator’s solution to meet that need and more. MULTI is a next-generation elevator system that can put as many cabins in one shaft as needed, but it doesn’t operate in a single shaft alone. MULTI cabins operate in a circuit, traveling up one shaft and down another. And, since there are no ropes, MULTI systems can even travel sideways to connect different buildings or adapt to buildings with innovative new geometries and formats.

By critically reexamining the most basic elements of the modern elevator, the company’s engineers decided it was time to get rid of the ropes, as they were the root cause of nearly every shortcoming in traditional elevators (Table 1).

How It Works

In most cases, MULTI follows the basic premise of a circular system, much like a paternoster. MULTI uses ropeless, linear-drive technology, which means that multiple cabins can be incorporated in a single loop. With a targeted speed of 5 mph, this system will enable near-constant access to an elevator cabin every 15-30 s. with a transfer stop every 50 m. Passengers will benefit from reduced waiting times, and the option of double entries on the ground floor improves ease of access in large buildings.

thyssenkrupp Elevator already increased passenger capacities in 2002 with the introduction of the TWIN elevator system, which offers two cabins per shaft and a 30% increase in transport capacity, as well as a 30% reduction in the elevator footprint. But now, after the company has removed the suspension cables and leveraged its expertise in magnetic levitation (maglev) technology, it has the ability to operate elevator systems like mass-transit systems and increase transport capacities by 50%, while also reducing the elevator footprint by 50%.

MULTI takes advantage of the linear-motor technology developed for the German maglev train Transrapid and applies it to elevator cabins. This enables the cabins to move in shafts in the same way trains move in rail systems, with various independent cabins per shaft that can move both vertically and horizontally. According to the company, safety is ensured by the multiple propulsion and braking systems in cabins and the proven safety control system developed for TWIN elevators, which prevents cabins from getting too close to one another.

The company further states that MULTI offers much higher capacities, as well as faster and more comfortable movement, when compared with high-speed elevators, which are limited by the effects of pressure on the human body, with many people experiencing discomfort at speeds higher than 10 mps.

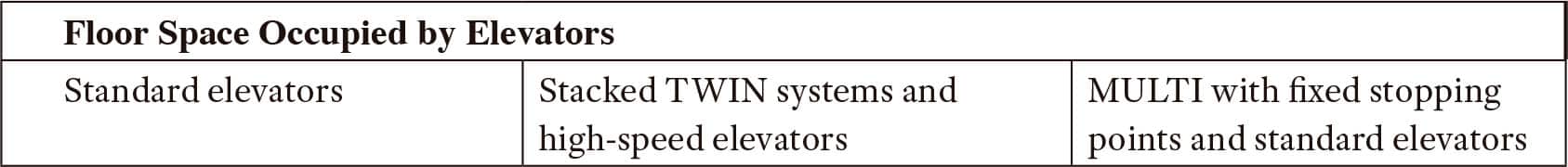

300 m or higher is the ideal building height for MULTI installations using the paternoster-style, dual-shaft circuit. Yet the system is not dependent on a building’s height. With no ropes, a multilevel brake system and wireless power transfer from shaft to cabin, adopters of MULTI will benefit from smaller shafts of 6 m2, compared with other technologies that typically occupy a space of 9 m2. This can mean significant cost savings for the developer, says thyssenkrupp Elevator. The overall increase in efficiency also translates into a reduced need for elevator shafts, thereby decreasing a building’s elevator footprint and providing further usable floor space and revenues to building owners (Figure 2).

While MULTI applies similar control systems and safety features as those used for TWIN, it includes new elements, such as lightweight carbon composite materials for cabins and doors, which weigh about 50 kg instead of the standard 300 kg in normal elevator cabins. This results in an overall weight reduction of 50%, compared to standard technologies. With the new linear drive, a single motor is sufficient to perform horizontal and vertical movements, while an exchanger lets cabins change direction and move from one shaft to another (Figure 3). By combining groundbreaking technologies with a simple operation concept and making it more convenient for passengers, MULTI has made the futuristic vision of multiple cabins per shaft into a reality.

Berlin 2020: First Commercial Use

The new MULTI system is not just an idea — it is currently being deployed in a new project in Berlin. This will be the world’s first commercial installation of a multidirectional elevator. The project, East Side Tower, is conceived to be an urban landmark for years to come. In addition to its pioneering use of the MULTI system, the 140 m office high rise is being designed by the award- winning architects of Bjarke Ingels Group (BIG). BIG is known for its unconventional, bold designs, as well as its dynamic incorporation of progressive and sustainable ideas. Examples include the playful LEGO® House in Billund, Denmark, a waste-to- energy plant in Copenhagen — which doubles as a ski-slope — and the angular VIA 57 West in New York City.

The East Side Tower site is being developed by OVG Real Estate, the largest real-estate developer in the Netherlands and a leading global proponent of smart, “green” buildings. OVG’s previous projects include The Edge in Amsterdam, which was awarded British rating agency Building Research Establishment Environmental Assessment Method’s top award for worldwide new office construction in 2016. The Edge also scored the highest sustainability score ever recorded: 98.4%.

By bringing together innovators like these, East Side Tower is clearly destined to become a lighthouse project for innovative environmental and utilization technologies — such as MULTI. The building is slated for completion in 2020.

New Possibilities for Future Cities

As outlined above, MULTI can be understood as a vertical mass-transit system, with parallel tracks and independent “trains” (cabins). That means that any two points on a vertical plane can be connected with one another, just like a metro.

Looking beyond applications to improve passenger throughput and elevator efficiency in singular tall buildings, MULTI’s mass- transit approach means that multiple buildings and structures can be connected across skybridges or via underground tunnels. This could be an attractive option for unprecedented accessibility and connectivity within low-rise building complexes or buildings with unique geometries, such as the Dubai Frame (U.A.E.), the Interlace (Singapore) or so-called “landscrapers,” buildings with very large footprints, their lengths comparable to skyscrapers’ heights.

Use Case: MULTI Underground

There are several ways MULTI could enhance the accessibility of underground stations and solve the limitations caused by our current dependence on escalators for reaching underground platforms. Today, people who travel on subways must often descend several levels, passing through long corridors and going down multiple escalators before they reach a train. If there is an elevator, it has limited handling capacity. Both options can be time consuming and stressful for commuters. This, however, can be changed. Because MULTI significantly increases handling capacity and reduces the waiting time for elevators, it would be possible for many more people to use lifts instead of escalators. Furthermore, due to the speed and handling capacity of MULTI, it would be possible to build deeper metro lines that could bypass the complex infrastructure underground. Seamless connections between buildings and metro lines would also be feasible (Figure 5).

Higher Levels of Connectivity: MULTI in Skybridges

Skybridges between buildings have existed for years, but they have recently moved beyond simple architectural novelties. Now, they’re widely seen as part of a new revolution in urban connectivity. That’s because new thinking and technologies dramatically expand the practical potential of skybridges, making them multifunctional architectural components that promise exciting design opportunities. Skybridges may soon become expected and indispensable features of any new building.

The benefits are obvious. Urban real estate is expensive. The empty spaces between buildings can be profitably used, providing additional amenities for residents and tenants. They offer a new plane for social interaction and communal spaces at the upper levels that are normally only possible at street level. In addition, skybridges offer better integration of electrical, water, heating, ventilation and air conditioning, and building management systems, and can provide failsafe system redundancies and alternate emergency escape routes.

Skybridges also offer benefits for mobility, saving time for people who need to move between two (or more) buildings (Figure 6). MULTI provides designers with their first major tool in using skybridges to seamlessly bridge the gap between buildings. Architects may even be encouraged to rethink the entire architecture of buildings. In the meantime, skybridges are bringing significant horizontal urban habitat in the sky within reach. Using skybridges, MULTI will provide the connection between buildings, street and sky — and between people.

IoT Powered: MULTI and Digitalization

Digitalization and the Internet of Things (IoT) are hot topics today, and MULTI is designed to use their every advantage. One example is MULTI’s digitalized interface Willow Twin, a state-of- the-art building-management system created by thyssenkrupp Elevator and Australian digital specialist Willow. The tool integrates hundreds of data sources to streamline building performance and efficiency in the areas of maintenance, resource utilization, energy efficiency and improved “user-experience” for building tenants and visitors. Naturally, that includes elevator operations.

Willow Twin collects and integrates hundreds of data streams from individual proprietary systems to provide a single view, creating actionable insight through a visually intuitive software platform accessible by all levels of asset management in real time. It also uses the data collected by MAX, the predictive-maintenance system that is already connecting and analyzing data from more than 120,000 elevators around the world to reduce elevator downtime by half.

- Figure 1

- Figure 2

References

[1] CTBUH/The Skyscraper Center (www.skyscrapercenter.com/compare- data/submit?type%5B%5D=building&status%5B%5D=COM&base_ height_range=4&base_company=All&base_min_year=1885&base_ max_year=9999&skip_comparison=on&output%5B%5D=list).

[2] CTBUH/The Skyscraper Center (www.skyscrapercenter.com/compare- data/submit?type%5B%5D=building&status%5B%5D=UC&base_ height_range=4&base_company=All&base_min_year=1885&base_ max_year=9999&skip_comparison=on&output%5B%5D=list).

Get more of Elevator World. Sign up for our free e-newsletter.