Review: Spiral Escalators Configuration Design

Oct 1, 2013

by H.Y. Tian and Li Yuxiang

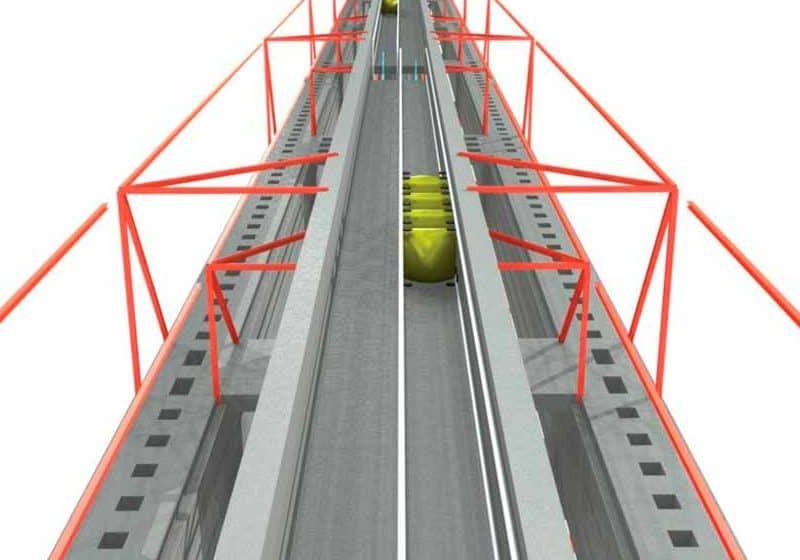

Escalators are a common form of public transportation, and as time goes by, their aesthetic demands increase with their popularization. As the basic function of an escalator is to transport passengers between different space levels, an alternative is the design of a spiral escalator with less room required and greater aesthetic appeal.

Depending on mathematical models, escalators can be categorized into linear and space-curve escalators. The linear escalator can be taken as a linear planar motion mechanism by projection through the side of the escalator. By comparison, the motion trajectory of the space-curve escalator is a continuous curve in the surface perpendicular to two-dimensional space. The space-curve escalator can also be deemed a linear escalator joined by movement perpendicular to the plane in which it lies. A spiral escalator is included in the category of space-curve escalators.

We can also classify escalators as uniform motion and uniform variable motion according to their dynamical and drive systems. The uniform variable-speed synthesis have speed- and orientation-variation modes. The orientation-variation mode brings many challenges to the technology of the chain-drive system in spiral escalators. The design program of spiral-escalator products is of fixed velocity, but existing patents on variable-speed escalators are of kinematotropic mechanisms, in which there is no gap between components in the chain-of-step sequence. The kinematotropic mechanisms could be key to designing spiral escalators.

We can utilize the reverse-cycle stage as another escalator in order to transport passengers to a lower level by making full use of the escalator’s conveying capacity, in which the un-utilized reverse cycle always hides beneath the series. In view of the physical contradictions between the spiral-escalator series and ring-sector components found in the design course, engineers hope changes in the movement form of chains around the sprocket wheel will comprehensively utilize the reverse-cycle stage. Some programs proposed models, such as a moving stairway and ascending and descending endless escalators. In view of the stability problem of an overpass bridge escalator, we cannot solve the cup-form step component challenge.

Milestones in the Development of Spiral Escalators

The design concept of spiral (“curved”) escalators was proposed by Jesse W. Reno and Charles Seeberger (ELEVATOR WORLD, April 2008). Reno produced the first laboratory equipment to create a spiral escalator for the London subway in 1906, but the device did not get public recognition, and the experiment failed. The 1911 blueprint completed by Seeberger has been the most relevant technology reference.

In 1985, Mitsubishi installed a spiral escalator (EW, February 1985); however, there are many defects and insufficiencies with this design, including excessive gaps between parts, slow speed, noise problems, complex manufacturing technology, complicated control, limited grade, one-fourth pitch of movement and a steering angle less than 180°. Still, Mitsubishi brought forward a huge development in this area.

More recently, Jack Levy, Emeritus Professor of Mechanical Engineering at City University London, invented the ‘Levytator’ (EW, August 2005). This design has no drive chains, so the steps have flexibility in the vertical axis, while being at different heights. Thus, the escalator can turn in any direction without restriction. Compared to the traditional chain structure, the Levytator’s advantages and disadvantages are clear. The loopback part of the Levytator ladder was used as the downstream, and its dual uses can consume less electricity, making maintenance easier. On the other hand, with the massive weight and width limitation of the step component, as well as the vibration and adaptability of the secondary drive made by the Levy ladder itself, it can only exist as a substitute to linear escalators.

Function and Concept Design

Most existing patented designs of spiral escalators and related programs are from the U.S., Japan and Europe. The majority chose to focus on mechanism design, not involving analysis of conceptual design or functionality. For what is the spiral escalator designed? This problem should be the first issue all designers address. Many designers of spiral escalators feel the aesthetic value is a fundamental objective compared to that of traditional escalators. There are three further advantages of spiral escalators – independent structure, infinite height and environmental friendliness.

The main function of a spiral escalator is to deliver passengers from a lower to an upper floor in a spiral track by way of a chain drive. As an auxiliary function, a step series moving along a curve or a line in level is needed for passengers to enter or leave the escalator safely. The step series also needs a closed ring reciprocating movement. But, requirements of the three parts make the design and production impossible.

In general, spiral escalators could be thought of as traditional escalators with vertical deflection added to their chain planes, and the mathematical model consists of right helicoids, rather than spiral lines. The parameter of right helicoids in construction engineering is one line and one helix. A radial line horizontally intersects, or a vertical plane slits a standard cylinder helix on the cylindrical surface. Thus, we can get a standard for conception, program or mechanism design.

Design of Spiral Escalators

There are two main ideas in spiral-escalator scheme design: to transform mature framework of existing escalators and make some level drop on the basis of the existing curved moving walk.

Spiral Escalator Design Based on Right Helicoid

The main issue of the scheme to transform a traditional escalator to a spiral escalator deals mostly with the kinematic model.

Issue One: Speed Coordination between the Horizontal and Spiral

According to the right-helicoid mathematic formula:

in which a stands for spiral lift rate, which refers to radius and lift angle determined by the group spirals on one right-helicoid surface.

in which H stands for lift rack range on a spiral surface, and a stands for lift angle to the horizon.

So, the spiral speed is:

If we still use two roller chains – one on the inside and the other on the outside in the radial direction – to synchronously guide step movement, the movement speed of both sides’ relationship should have the following conditions:

where the upper means the step series’ radial inside, and the lower means the steps series’ radial outside.

Results then become:

So, the projection of chain of radial inside and outside in horizontal should meet the movement proportion:

If we still use the chain drive system, under system-interface requirements of the escalator-step sequence movement, radial speed inside and outside must be proportionally driven. Based on the chain-drive primary mechanical theory, the speed’s value and ratio of both spiral-escalator drive chains at different locations on the radius must be constant, whether the right-helicoid stage, to promote the passenger or the ring circular stage’s right helicoid projecting on the horizon for passengers getting on or off the escalator. In view of this, the instantaneous centers of the right-helicoid stage and ring circular stage do not coincide. U.S. Patent Nos. 4895239, 4930622, 4893160, 4884673 and 5184710 prove this standpoint. In order to meet the above requirements, the center of the right-helicoid and ring circular stages do not coincide. We have to change the trajectory of the chain to meet the needs of different velocities. Therefore, there must be connections between the helicoid and ring circular stages. Mitsubishi’s design uses this stage making cascade level pedal rectangle so that the passenger can enjoy transportation in both the up and down directions.

If we do not choose the whole processing chain-drive mode as the spiral escalator’s drive, we will only need to keep the steps moving at the same speed, continuously, in a certain dimension in place. It is possible to coincide their movement at the ring circular stage with projection of the right-helicoid stage, such that the axes locations of both stages can be fixed; also, the movement model is simplified and the design program is complicated. For example, U.S. Patent Nos. 5158167, 4434884 and 5165513 have different approaches but equally satisfactory results with runway-type escalators.

Issue Two: Connection Problem of Two Right-Helicoid

Trajectories with Vertical Distance

The main parts of the escalator and loopback are connected by the reverse part, which provides tensioning support to the whole chain. According to the basic principle of a machine sprocket, the shafts must be parallel; therefore, traditional escalators’ power and drive system cohesion is not an issue. Spiral-escalator serials in the vertical plane bend horizontally; thus, two questions are raised. First, the radial velocity inside is less than the radial velocity outside, so the step series cannot reverse synchronously in this stage, and the right-helicoid central axis direction will change with the steps’ serials. Second, we can design an axle pin as a radical straight for chains with flexible settings, instead of the usual chain.

Therefore, the chains can close like a ring on the level plane in parallel with the chain links’ pin, as opposed to the plane vertical to the pin. Then, such range of spiral escalators diversion angle is limited naturally. A good example would be how Mitsubishi’s design cannot exceed a limit of 180°. One is to make the inside radial chain slightly higher than the outside radial chain, with a dip angle changing both sides of the radial angle at the same level height. The chain difference will be compensated in the reverse stage. (For example, U.S. Patent Nos. 5775477, 4809480, 5094335, 5020654 and 4662502.) The other project uses a chain as a drive system inside or outside and lets the other synchronize with special mechanisms. U.S. Patent Nos. 5158167 and 4434884 include illustrations with outside radial chains, and U.S. Patent No. 5165513 illustrates inside radial chains. Of course, we can easily see that the compromise approach has been contrary to the original design intention of the spiral escalator. (It is merely a ring model.) At the end of the last century, Orenstein & Koppel of Germany proposed a design to solve the problem of a single-chain flip. Practical applicability stopped this program from continuing development after the patent application was authorized.

Arbitrary-Curve Escalators

The predecessor of the spiral escalator is the circulating moving walk, as the moving walk followed the escalator. Circulating moving walks did not cause much of an impact relative to the advent of the idea of spiral escalators, because their function is very limited. The model and structure of circulating moving walks should be simple compared to a spiral escalator design. However, mechanical engineers turned to the circulating transmission device, thus creating curved moving walks.

The Levytator is based on U.S. Patent Nos. 3493097 and 3185108. However, due to the curve of the moving walk’s cascade in the horizontal variation, engineers ran into trouble by the cascade to the relevant technical requirements. A problem with the Levytator was a gap between the step by the dual drive. Levy said this can be ignored below the limited width.

For kinematics, this arbitrary-curve escalator set steps in the circulating transmission device, its level in height disparity completely decided by pathway. Although they can follow any design requirements, according to building-space requirements, escalators’ basic function is to provide vertical transportation. Arbitrary-curve escalators make no improvement in this aspect, so they are more decoration than project.

Conclusions

The core technical problem with spiral escalators is their uniform rotation based on right-helicoid, varying-velocity chain-drive style and track-varied chain drive. To design the spiral escalator, we have to solve the three core problems of velocity coordination of radial in and out in the right-helicoid and ring circular stages, space-chain power-drive transmission mechanism and spiral reverse. An innovative screw-transmission mechanism could solve all the problems above, and the spiral-chain architecture must be different from the traditional screw mechanism in its new perspective. Thus, the prospective of creating new power- and drive-system modes remains a mystery. This also explains why mature spiral-escalator designs have not appeared.

The new mechanism has no option but to come from innovation, and creation of the screw transmission is to inevitably result from the spiral space conception. There is no fault of concept of synthesis-uniform circular motion joined with a vertically proportional lift. Of course, we also can imitate Leonardo Da Vinci to deal with squaring the circle. To fix the parameter, Anaxagoras constructed a helix by rolling a piece of white paper on an oblique line. This tilted the space to make the line present a spiral, making a plane with a certain angle into the process such as the right helicoid, as shown in the formula. For the first and fifth octants, we roll space, making 3D cube space of the traditional escalator into a spiral of hollow cylinder space:

where r is the basic standard to roll up.

For right-helicoid and circular connection, we can use reconfigurable mechanisms to eliminate velocity contrast on circular motion between right-helicoid and circular velocity. By making the step series with the rigid structure reconfigurable mechanisms, we can design and manufacture a spiral escalator of right-helicoid trajectory.

Get more of Elevator World. Sign up for our free e-newsletter.