Richard Blaska Talks Industry Passion, the Founding of Smart Elevator Tech and Working to Make a Difference

Aug 1, 2013

Richard Blaska, principal of RCB Elevator Consulting, LLC and owner of Smart Elevator Tech, LLC, was born and raised on a beef and dairy farm in Sun Prairie, Wisconsin. “We had a large shop on our heavily mechanized farm, and we made or repaired all of our own equipment,” Blaska said. “In those days, you didn’t call someone when something broke; you fixed it yourself. I learned to weld at a young age and even made the hockey goals for my high school,” Blaska added. Blaska had a hands-on work approach from the get go and credits his father’s work mentality for influencing his career. “My father used to say, ‘If you are not afraid to work, you will always have a job.’ He could have never worked for anyone but himself, a trait I inherited but didn’t immediately [know I had],” Blaska explained.

Blaska attended the University of Wisconsin in Oshkosh, Wisconsin, where he studied political science and business. Two years into college, he decided to take a break and moved to San Diego. However, he returned to Wisconsin to complete his degree during the Rust Belt recession. He explained, “I thought I would have a better chance of getting a job in Southern California.” A friend landed Blaska an interview with Cubic Corp., which led to an interview with United States Elevator Corp. (USEC) in Spring Valley, California. “Les Haywood, vice president of Marketing for USEC, hired me into [the company’s] sales training program, which began with a stint in Bob Meyer’s estimating department,” Blaska said. Blaska realized the elevator industry was the right path for him when, during his first day on the job:

“Someone asked me who I was, and after I introduced myself, [he] said, ‘Well, you’re in the elevator business now, and you are never going to leave.’ It took years until I knew what he meant. This is an incredible industry.”

Blaska worked for USEC for six months and was promoted to assistant manager of Distributor Operations. Six months later, he was promoted to New Products Sales engineer and moved to San Francisco. “I became Modernization and Repair manager in 1987 and ran a backlog of code work, fire service, seismic upgrade and disability access,” he explained. About a year later, Blaska moved to Honolulu and worked as a branch manager, something he says was difficult. “I was fairly clueless about the culture. My California managerial experience consisted of hiring labor when you need it and laying off when you didn’t, which was not well received on the island,” Blaska explained. “We did manage to get the branch turned around financially within 15 months, before it was agreed that I should go.” Blaska was then sent to the Sacramento branch, where he worked in sales for the next couple of years.

In 1992, Blaska moved back to San Francisco and ran construction for several years, before going back into sales, where he became the top company grosser for three years. “USEC was then purchased by ThyssenKrupp Elevator. I left at the end of 1998 to start my own business. Initially starting RCB Consulting, I went to night school and received my Microsoft Certified System Engineer certificate,” Blaska said. He then explained how he thought he needed to leave the elevator business and decided to go into computer networking. “I enjoyed computers and maintained USEC’s San Francisco office network. For income, I contracted a few local elevator companies to draft their elevator shop drawings,” he explained.

During his time at USEC, Blaska worked with the engineering department on the company’s pre-engineered elevator product AutoCAD files, learning the CAD process. “It worked well. I trained others, resulting in better quality and more project-specific submittal packages,” Blaska said. By 1999, he was both an elevator draftsman for hire and a computer-network technician, installing and maintaining a few small office computer systems. Eventually, Blaska decided to drop the computer networking and focus exclusively on elevators. “The old guy I met on my first day at USEC was right,” Blaska said.

In 2002, RCB Consulting was founded to provide elevator and structural engineering services directly to major and independent elevator contractors. For structural projects, Blaska usually subcontracts Ronald Eddington, a senior engineer for Eddington Engineering, Inc. Blaska said:

“I enjoy working with Eddington. We put our minds together to solve structural design problems. We’ve gravitated to more technically complex projects. Through these projects, we’ve come up with unique solutions to vexing problems.”

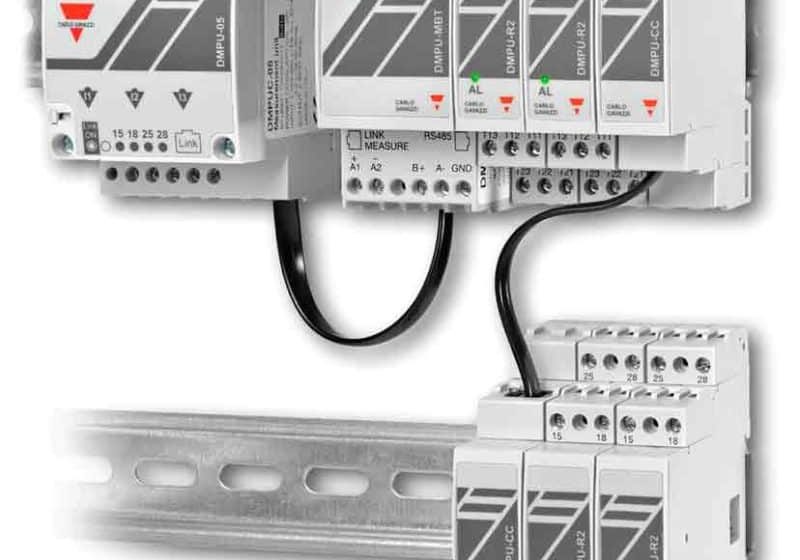

One of the projects RCB Consulting was chosen for was the modernization of elevators at the California Pacific Medical Center, which required meeting stringent Office of Statewide Health and Planning Development seismic standards. “Some of the car guide rails were only 1.25 in. from the asbestos-laden plaster walls, making the standard choices for seismic fishplates not an option,” Blaska explained. “Eddington and I designed the Low-Profile Fishplate™ (p.143), which is only 1 in. thick behind the guide rails yet has the same required strength as the rail,” Blaska said. Following that project, Blaska designed the Retracta Ladder® (ELEVATOR WORLD, April 2010) for a winding-drum-to-traction conversion at a hotel in San Diego, where there was only 5 in. of running clearance between the car and hoistway. “It occurred to me that these products might have a larger market, so I founded Smart Elevator Tech in January 2010,” Blaska said. Today, Smart Elevator Tech offers several other products, including the Rope Align Block™, Deflector Sheave Isolator™ (EW, January 2012), and, most recently, the Powered Retracta Ladder® (EW, February 2013). “We also provide custom, project-specific metal fabrication of components stemming from our elevator alteration engineering,” Blaska explained.

Blaska believes his best bit of luck was finding MetalworX in Waterloo, Wisconsin, which serves as Blaska’s product fabricator and distributor. He said:

“Larry Waldo owns and operates a 15,000-sq.-ft. computer numerically controlled milling and metal fabrication facility, and his son, Joel, provides SolidWorks fabrication design support. Their combination was the perfect fit for Smart Elevator Tech.”

When asked about work challenges, Blaska says there aren’t enough hours in the day. “For elevator engineering, I’ve had to become more selective about the jobs I take. I prefer the more technically complex alterations, where I feel I can add the most value,” he explained. Regarding professional strengths and what he finds most rewarding about his job, Blaska believes his passion for his work is above all. He added:

“I love working out a difficult layout or bracket design, which I tend to visualize in my mind before drawing it in CAD. For my products, my sales experience has been very helpful. And, as I’m the inventor of each product, no one can know the product better. Seeing my products being installed in such important places as the Statue of Liberty, the One World Trade Center and a historical Washington, D.C., building is very rewarding.”

When asked about the advice he would give someone considering a career in the elevator industry, Blaska says, “Make yourself as valuable as you can. If you are coming into the field, take courses that can enhance your skills, such as welding, electrical engineering, etc.” He also believes it is important to learn as much as possible about the technical aspects of elevators and escalators. “Learn the codes, figure out how the equipment works, attend the trade shows, and ask questions of the seniors around you,” Blaska added.

In his spare time, Blaska enjoys vacationing with his wife, Margaret, and daughter, Jacqueline. Blaska said:

“Last summer, we went to Peru. We recently purchased a weekend getaway in the wine country, which overlooks a vineyard and the distant Mount Sonoma. The neighboring rancher occasionally runs his bulls in a paddock along our fence, which brings back memories of my life on the farm.” When asked about retirement, Blaska insists working for himself is advantageous when it comes to planning time off: “In time, I will become more selective about the jobs I take on. I’ve still got a lot of years left in me, health permitting. I plan to go out with my boots on.”

Get more of Elevator World. Sign up for our free e-newsletter.