Robots and Remote Elevator Operability

Nov 1, 2022

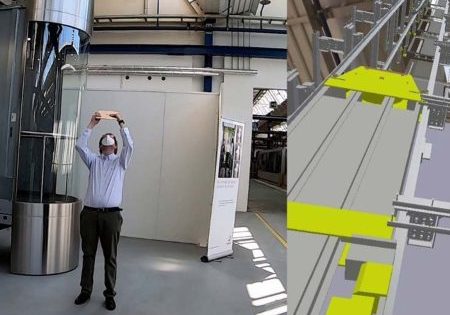

TKE provides digitally advanced elevators at Canada’s new Calgary Cancer Centre.

Advances in Application Programming Interfaces (APIs) paved the way for companies like TK Elevator (TKE) to offer robot-elevator APIs to their customers. These APIs allow robots to operate elevators via software that interfaces directly with the elevator controller. While TKE has integrated its elevators with various third-party systems for decades — including robots and autonomous vehicles — these integrations were custom-designed to be discretely wired into elevator control systems. They could be labor- and material-intensive, and prone to failure if not properly maintained. In 2018, the OEM released its inaugural, standard robot-elevator API, the result of a successful pilot program that involved hospitality robots at a San Francisco hotel in 2017. Now, the technology is being integrated into the new Calgary Cancer Centre (CCC) at Foothills Medical Centre, set to open in 2023 and operated by Canada’s Alberta Health Services (AHS) in the city of Calgary. TKE Head of Digital Services Jon Clarine says:

“The [San Francisco] deployment was very similar to that of the [CCC]. However, the robot use was different. At [CCC] they will be used for delivery and hospital operations. Once the robot system is programmed to communicate with our API, the implementation in the building is relatively simple: An ethernet connection is established between the robot server and the elevator controller, and the rest is software.”

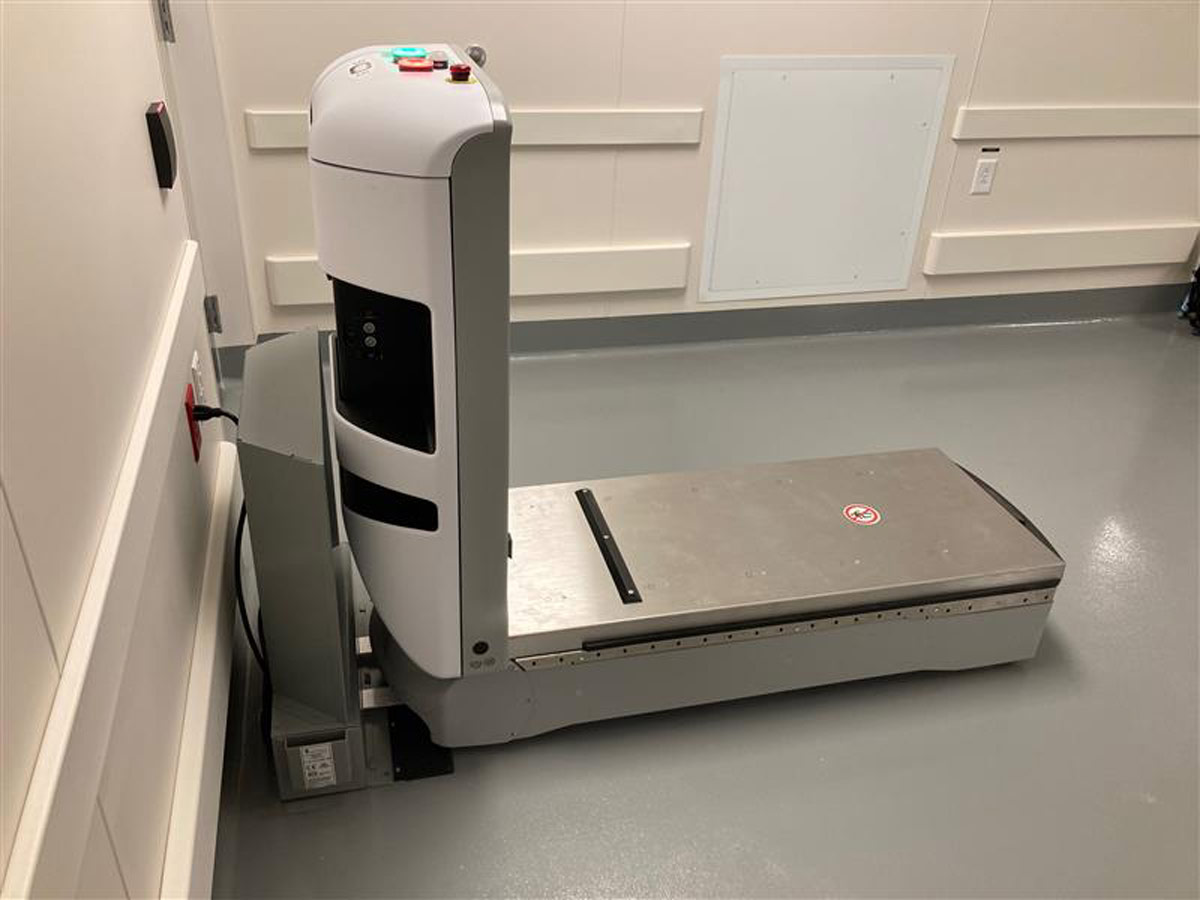

Through software, robots can ‘talk’ to elevators to place elevator calls and transit floors without the expense and complexity of discrete wiring or robotic arms, Clarine says. He observes that robots — often looking more like a piece of machinery than R2-D2 in a hospital or hotel setting — use elevators a bit differently than humans. Some move slower than humans or are programmed to wait until an elevator is unloaded prior to boarding the elevator car. For example, through the API, a robot can request the elevator to pause to hold doors open for extra time to unload — another special operation a human user doesn’t typically need. The robots at the CCC are being provided by Pittsburgh-based Aethon.

A Healthcare Milestone for Canada

TKE announced in September it had completed installation of approximately 30 digitally advanced elevators at the new CCC. When it was approved, the CAD1.41 billion (US$1 billion) facility became the largest healthcare infrastructure project in the province of Alberta. Upon completion by general contractor PCL Construction, it will be the largest standalone cancer center in Canada. TKE was awarded the vertical-transportation contract shortly after construction started in 2017, and Clarine tells ELEVATOR WORLD an API to enable robot-elevator interaction was part of the scope of work (SOW) from the beginning. An undetermined number of robots will be used to complete various tasks, primarily involving transporting medical supplies throughout the facility.

Through software, robots can ‘talk’ to elevators to place elevator calls and transit floors without the expense and complexity of discrete wiring or robotic arms.

The CCC’s 12 service elevators will feature TKE’s robot-elevator API, which promises to improve in-house logistics and increase productivity. The API will allow robots to call an elevator via Wi-Fi or 5G LTE, select a floor, then exit the elevator upon reaching its destination. TKE observes:

“Using Machine Vision, a robot can determine if an elevator has enough room or it’s too full to accommodate a robot. The interface also informs the elevator system when to open the doors and adjust door dwell times to ensure the smoothest journey possible for the robot. The robotics interface can also be used for purposes such as housekeeping and security.”

Clarine explains that Machine Vision, also known as computer vision, refers to the ability to process images or video by computer to gain understanding of the physical world. He elaborates:

“With that understanding, a computer can further process what it ‘sees’ to do cool stuff. For example, a robot may use its camera to identify obstacles in its path so it can navigate around them. TKE’s elevators can use computer vision to detect objects and even activities in elevators that are used to improve dispatching and safety.”

Beyond Elevators and Robots

Remote technology goes beyond elevators. TKE, he says, pioneered computer vision on escalators where it is used to detect unsafe activity such as someone leaning over the handrail or a child running in the opposite direction of travel. The system can then alert building security or slow the unit down to minimize injury risk.

Remote capability extends beyond robots at the CCC, as well. Three of its service elevators are designed to be remotely controlled when moving dangerous materials such as nitrogen, meaning employees are no longer exposed to such materials. TKE has also installed a remotely activated “code blue” function on a group of elevators that can be used to quickly transport patients upon arrival at the CCC. Although “code blue” elevators were part of the original SOW, remote capability came about after work began. Clarine says:

“It had to be custom-developed. The idea behind it was to have the ability to initiate code blue response from the main hospital. This expedites the mobility of the code blue response team, as the cars are ready and waiting, as opposed to arriving, a person turning a key switch to initiate [code blue status] and then waiting.”

TKE will also provide maintenance and support for the entire CCC elevator system, adding to the nearly 150 units it already supports at health facilities across Calgary.

TKE North America President and CEO Kevin Lavallee says the CCC is “what smart hospitals will look like in the future.” TKE Canada President and CEO Gary Medeiros adds the hospital is a place where “advanced research and innovation will thrive, embodying the future of cancer care and treatment.” He went on to say:

“Our modern elevator systems, blending remote and robot functionality, fit perfectly within this hub of medical innovation and will enhance the overall experience for staff and visitors.”

Get more of Elevator World. Sign up for our free e-newsletter.